Professional Documents

Culture Documents

ESDEP Lecture 10 on Composite Construction

Uploaded by

iSoK11Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ESDEP Lecture 10 on Composite Construction

Uploaded by

iSoK11Copyright:

Available Formats

18-5-2015

ESDEP Lecture 10

COMPOSITE CONSTRUCTION

http://www.fgg.uni-lj.si/kmk/esdep/master/wg10/toc.htm

10.1

Composite Construction General; excluding sections: 3.3, 3.5 and 5

10.2

The Behaviour of Beams; excluding section 4

10.3

Single Span Beams

10.5.1 Design for Serviceability I; excluding section 3

10.6.1 Shear Connection I

10.6.2 Shear Connection II

10.7

Composite Slabs

10.8.1 Columns I

10.8.2 Columns II; excluding section 8

10.1 Composite Construction General

Eurocode 4: Design of Composite Steel and Concrete Structures:

EN 1994-1-1: Part 1.1: General rules and rules for buildings

18-5-2015

18-5-2015

18-5-2015

18-5-2015

18-5-2015

18-5-2015

CONCLUDING SUMMARY

Composite construction, particularly that using profiled steel sheeting, allows

rapid construction.

The weight of steelwork required in composite construction is significantly less

than if the materials were used independently.

There is no need for expensive formwork because the steel beam is able to sustain

the self weight of steel and concrete. Timber formwork can be replaced by precast

concrete elements or profiled steel sheeting.

The aforementioned advantages present a very strong argument for the use of

composite beams in buildings. They are more significant, however, for medium to

long spans than for short spans.

The main disadvantage of composite construction is the need to provide

connectors at the steel-concrete interface.

Another minor drawback is that it is somewhat more complicated than other

methods to design and construct.

18-5-2015

10.2 The Behaviour of Beams

18-5-2015

18-5-2015

Dead load on composite beam

Dead load on steel beam

10

18-5-2015

CONCLUDING SUMMARY

Composite beams, subject to sagging moments, fail by yielding of the steel

section, crushing of the concrete slab or shear of the connectors.

Unpropped composite beams need the steel section to be strong and stiff enough

to carry the weight of wet concrete.

Partially connected composite beams may be used to ensure economy of shear

connection.

10.3 Single Span Beams

11

18-5-2015

12

18-5-2015

Beam spacing

Eurocode 4

beff = L/4

13

18-5-2015

Resistance of concrete flange :

Rc = beff hc 0.85 fck /c

Resistance of steel flange :

Rf = b tf fy /a

Resistance of shear connection :

Rq = N Q

Resistance of steel beam :

Rs = A fy / a

Resistance of clear web depth :

Rv = d tw fy / a

Resistance of overall web depth :

Rw = Rs - 2 Rf

14

18-5-2015

Rconcrete > Rsteel beam

x = (Afy /a) / (beff kfck /c) = (Rs/Rc ).hc

Mpl.Rd = Rc.z = Rc (h/2 + hp + hc - Rs.hc/2Rc)

Rsteel beam > Rconcrete > Rweb

Mpl.Rd = Rs.h/2 + Rc (hc/2 + hp) - (Rs - Rc)2.tf / 4Rf

15

18-5-2015

Rs > Rc < Rweb

Mpl.Rd = Rc.(h + 2 hp + hc)/2 + Mpl.a.Rd - (Rc2/Rv)(d/4)

d = clear height of web between fillets

Rv = dtwfy

Mpl,V-red.Rd = {1 - (1 - do/d).A/(2A - Av)}.Mpl.Rd

Av = shear area of steel section = 1.04htw

16

18-5-2015

CONCLUDING SUMMARY

Plastic analysis of the cross-section is used to determine the positive bending

moment resistance of composite beams.

Eurocode 4 gives simple formulae for the effective width of concrete slab acting

compositely with the steel; this "concrete flange" must be detailed to avoid

longitudinal shear and splitting.

Design of composite beams involves ensuring that the forces and moments due to

factored loads are less than the corresponding design resistance.

Various expressions for the design of the positive moment of resistance can be

derived; these depend on the position of the neutral axis.

Eurocode 4 gives simplified rules governing the design of the shear resistance of

simply supported composite beams, with full shear connection.

Where high shear and moment are coincident part of the steel web is reserved to

carry shear, resulting in a decrease in moment resistance.

17

18-5-2015

10.5.1 Design for Serviceability - I

n = Es/Ec

NAc

ac

NAcomposite

aa

NAsteel beam

I = Ia + (Ac/n) . (hc2/12) + (Ac/n) . ac2 + As . (ac + as)2

fsteel = Mz/I

fconcrete = Mz/nI

18

18-5-2015

19

18-5-2015

Owing to a variety of factors, the deflections of composite elements deviate from

the values which would be predicted by a simple elastic model.

These factors include:

the continuous variation in member stiffness arising from cracking and from

variations in the areas of reinforcing steel.

the effects of tension stiffening in the cracked regions of reinforced concrete.

the variation with time of Young's Modulus for concrete.

shrinkage and creep of the concrete.

yielding of the steel member, as may happen at supports in continuous beams.

slip at the steel-concrete interface.

shear lag.

temperature.

The time-dependence of certain of these factors means that the actual sequence of

loading will have a bearing on the final deflections, and may invalidate simple

calculation procedures based on the superposition of effects. Additionally, material

properties (Young's Modulus, creep factor, etc.) which are used in analysis will

depend on factors such as the actual concrete mix used, and on temperature and

humidity levels during the early life of the structure.

20

18-5-2015

CONCLUDING SUMMARY

The serviceability limit state must be checked when designing simply supported

and continuous composite beams.

The main points to consider are:

The main design criteria are, deflection, control of crack width and limitation of

stresses.

For elastic calculations in positive moment regions, an uncracked section, with or

without reinforcement, can be assumed.

In negative moment regions, cracked sections must be assumed.

The influence of shrinkage, creep and temperature must be included.

10.6.1 Shear Connection - I

21

18-5-2015

Increased connector force near

plastic hinge at beam center

22

18-5-2015

23

18-5-2015

The design shear resistance of a stud is given by the smaller of:

stud shear resistance:

PRd = 0.8 fu (d2/4) / v

where the shear resistance of the connector is related to the tensile strength of the steel fu,

using a factor of 0.8

concrete resistance:

PRd = 0.29 d2 (fckEcm)1/2 / v

where d is the diameter of the shank of the stud,

fu is the specified ultimate tensile strength of the stud material ( 500N/mm2),

fck is the characteristic cylinder strength of concrete,

Ecm is the mean value of the secant modulus of concrete,

= 0.2 [(h/d) + 1] if 3 h/d 4 where h is the overall height of the stud and for

h/d > 4 = 1.0.

The partial safety factor v is normally taken as 1.25.

including strain hardening

24

18-5-2015

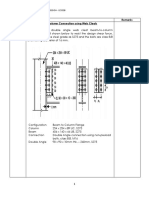

hp

bo

Reduction in shear resistance of studs

Ribs transverse to beam

kt = 0.7(bo/hp)(h/hp-1) / Nr1/2

kt 1.0 for Nr = 1 and kt 0.8 for Nr = 2

Ribs parallel to beam

kt = 0.6(bo/hp)(h/hp-1) 1.0

25

18-5-2015

CONCLUDING SUMMARY

The shear connectors between the slab and steel section in a composite beam are

required to resist shear, bending and tensile forces.

The stiffness, resistance and amount of confining concrete around each connector

affects the performance of the connection.

Welded shear studs are the most common form of connector.

Connector resistances may be determined using empirical formulae or "push-out"

tests.

The design resistance of a connector is normally assumed to be 0.8 times the

ultimate resistance.

Studs may normally be uniformly spaced along the beam.

Slabs formed with profiled steel sheeting may be used with composite beams as

long as the concrete in the troughs is ignored when calculating section properties.

10.6.2 Shear Connection - II

26

18-5-2015

"critical cross-section" is the cross-section of maximum bending moment.

"critical length" is the length between two adjacent critical cross-sections: AB and BC

The longitudinal shear force Vlf is equal to the lesser plastic axial resistance of either the

steel member or the concrete slab in the critical cross-section concerned

Vlf = lesser value of (Aa fy/a or 0.85Ac fck/c)

The required number of connectors to obtain full shear connection for the critical length is

Nf = Vlf / PRd

If the number N of shear connectors within the critical length is less than Nf: N < Nf

then the critical length is in partial shear connection and its degree of connection is

defined by the ratio N/Nf.

Fu(r) = NPRd = V

Obtain location of plastic neutral axis from equilibrium, i.e. Fcompression = Ftension

27

18-5-2015

The position of neutral axis ya and the ultimate moment Mu(r) are:

For ya t1 (neutral axis in top steel flange)

ya = [As(fy/a) Fu(r)] / [2b1(fy/a)]

Mu(r) = Fu(r)(hc + da- yc/2) + 2b1ya(fy/a)(da - ya/2)

For t1 ya da (neutral axis in steel web)

ya = {(Aa + 2t1tw - 2b1t1)(fy/a) - Fu(r)} / [2tw(fy/a)]

Mu(r) = Fu(r)(hc+ da- yc/2) + 2b1t1(fy/a)(da- t1/2) + tw(ya- t1)(fy/a)(2da- ya- t1)

Mu(r) = Muapl + (N/Nf)(Mu - Muapl)

28

18-5-2015

For steel sections with equal flanges:

(N/Nf)B = 0.4 where L 5 m

(N/Nf)B = 0.25 + 0.03L 1

where L > 5 m

For steel sections having a bottom flange with an area not exceeding 3 times the area

of the upper flange:

(N/Nf)B = 0.4 + 0.03L 1

In the case of slabs cast on profiled steel sheeting it is reasonable to consider an

increase in the ductility of the connectors and, therefore:

0.4 (N/Nf)B = 0.04L 1

for steel sections with equal or unequal flanges.

29

18-5-2015

Influence of partial connections on beam deflections

For propped beams:

= f + 0.5 (1 - N/Nf) (a - f)

For unpropped beams:

= f + 0.3 (1 - N/Nf) (a - f)

CONCLUDING SUMMARY

Partial shear connection is an important option for the economic use of composite

beams in buildings.

When non-ductile shear connectors are used, the simplest design method uses

elastic beam theory to calculate the longitudinal shear force per unit length.

When ductile shear connectors are used, the design method is based on plastic

resistance of cross-sections using the stress block method.

Attention is drawn to the requirement for a minimum degree of connection

depending on the beam span.

30

18-5-2015

10.7 Composite Slabs

provides a working platform for construction

acts as formwork for the concrete slab

constitutes bottom reinforcement for the slab

Steel grade 280 : fyb = 280 N/mm2

Steel grade 350 : fyb = 350 N/mm2

31

18-5-2015

Bond by friction:

(a) and (b).

Embossments: (c).

End anchorages:

(d), (e) and (f)

For the situation where the profiled sheeting acts as formwork, the following

loads should be considered:

self-weight of the profiled sheeting

weight of the wet concrete

construction loads

temporary storage load

The construction loads represent the weight of the operatives, any loads due to

placing the concrete, and also take into account any impact or vibration likely to

occur during execution.

Eurocode 4: use 1.5kN/m2 distributed on an area 3m x 3m and 0.75kN/m2 on the

remaining formwork surface.

For the situation where the steel and the concrete act compositely, the loads acting

on the slab should comply with Eurocode 1:

self-weight of the slab (profiled sheeting and concrete)

weight of floor finishes

imposed loads

32

18-5-2015

a) Analysis for the ultimate limit states

In most cases analysis of composite

slabs, continuous over several spans, is

performed according to the elastic

method, for a slab of unit width (1m),

comparable to a beam of constant inertia.

The assumed inertia is that of the

uncracked section.

It is possible to take concrete cracking into

account in several ways:

Arbitrarily reduce the moment at the

supports and increase the span moments

Neglect reinforcement over the supports

and consider the slab as a series of simply

supported beams

Consider that the slab is a beam with

variable inertia, depending on the

reinforcement. The assumed inertia is that of

the cracked section.

Critical sections which to be verified:

Section I :

ultimate moment of resistance failure for positive bending.

Section II :

ultimate moment of resistance failure for negative bending.

Section III-IV : ultimate resistance to vertical shear failure.

Section V :

ultimate resistance to longitudinal shear failure.

33

18-5-2015

ds

The ultimate moment of resistance of a section, Mpc, may be determined by assuming

a plastic distribution of stresses. The position of the plastic neutral axis is

x = [Aap.fyap/ap] / [b.0.85fck/c]

The neutral axis is in the concrete zone if

Aapfyap/ap 0.85bfck/c

Then

Mp,Rd = Aap.fyap[ds - x/2]/ap

ep

Neglecting the concrete in the troughs

Mp,Rd = Ncz + Mpa,r

z = ht - hc/2 - ep + (ep - e)Nc/[Aap.fyap/ap]

Nc = hc0.85fck/c

Mpa,r = 1.25Mpa [1 - Nc/(Aap.fyap/ap)] Mpa

34

18-5-2015

Nc = bcx 0.85fck/c = As.fys/s= Nt

x = [As.fys/s][bc0.85fck/c]

z = ds - x/2

Mp,Rd = As.fysz / s

Shear and Punching shear

Vv,Rd = bods c

dp

dp

c = Rd k1 k2

k1 = 1.6 - ds 1.0 (ds in m)

k2 = 1.2 + 40 o

o = As/bo ds < 0.02

As is the area of reinforcement in tension.

In positive bending regions, As is to be

replaced by Aap.

Rd basic shear strength: 0.30N/mm2

The punching shear resistance of a composite slab at a concentrated load is

Vp,Rd = Cp hc c

35

18-5-2015

36

18-5-2015

V,Rd = bds[(mAsp/bs) + k] / vs

ds or dp = distance from outermost concrete fiber to N.A. of steel

s the shear span

vs partial safety factor for longitudinal shear only

37

18-5-2015

b) Analysis for the serviceability limit states

An analysis of the composite slab, for calculating deflection, may be made with

the following assumptions:

The slab is comparable to a continuous beam of constant inertia, equal in value to

the average inertia of the cracked and uncracked section.

Long-term loading effects on the concrete are taken into account using a variation

in the modular ratio Ea/Ec. For simplification, Eurocode 4 recommends an

average value of Ea/Ec for both long and short term effects.

The deflection of a composite slab is calculated using elastic theory.

a) Cracked section

Ivc = [bx3/3n] + Aap(ds - x)2 + Iap

where x is the position of the elastic neutral axis:

x = [nAap/b]{[1 + (2bds/nAap)] - 1}

Iap is the unreduced second moment of area of the sheet

b) Uncracked section

The second moment of area Ibu of the uncracked section can be obtained from:

Ibu =

bc is the total average rib width over a slab width of 1 m.

xu is the position of the elastic neutral axis:

xu =

38

18-5-2015

CONCLUDING SUMMARY

The design of a composite slab must consider the performance of the profiled

steel sheeting, when it acts as shuttering for the wet concrete during execution,

as well as the composite performance of the steel and hardened concrete under

the imposed floor loading.

In the execution stage, the profiled steel sheeting acts as a thin-walled member.

Its design must take into account the possibility of local buckling.

The design of the composite slab must consider the resistance to positive and

negative moments and also to vertical and longitudinal shear.

The resistance to longitudinal shear at the steel/concrete interface is largely

derived from embossments in the steel sheet or from connectors placed at the

ends of the spans. Empirical methods are used to ensure adequate shear

resistance.

10.8.1 Columns I

39

18-5-2015

The plastic resistance of the cross-section of a composite column is given by the

sum of its component resistances:

Npl.Rd = Aa fyd + Ac fcd + As fsd

is 1.0 for concrete filled cross-sections and 0.85 in all other cases

40

18-5-2015

The relative slenderness, , for the determination of the load-bearing resistance

of a column under axial load is given by:

Npl.R is the cross-section resistance a = c = s = 1.0

Ncr is the elastic buckling load of the column

Ncr = (EI)e2/e2

(EI)e is the effective bending stiffness.

e is the buckling length of the column.

The effective bending stiffness is determined by adding up the individual

components:

(EI)e = EaIa + 0.8 EcdIc + EsIs

0.8 EcdIc is the effective bending stiffness of the concrete part and Ecd = Ecm / c

Ecm is the secant modulus of the concrete and c can be reduced to 1.35

When assessing the importance of creep and shrinkage using Table below

= Aafyd / NplRd

This represents the contribution of the structural steel to the normal force resistance.

Braced and

non-sway systems

For slenderness

Unbraced and

sway systems

Concrete encased sections

0.8

0.5

Concrete filled sections

0.8 / (1-)

0.5 / (1-)

less than values given in Table, creep and shrinkage can be ignored

The influence of creep and shrinkage can be taken into account by modification of

the modulus of elasticity of the concrete

Ec = Ecd

NSd is the design normal force.

NG.Sd is the permanently acting part of it

41

18-5-2015

For each of the principal bending axes of the column it must be shown that:

NSd Npl.Rd

Npl.Rd is the cross-section resistance for axial load

is the reduction factor from the appropriate buckling curve

curve a for concrete filled hollow steel sections

curve b for partially and completely concrete encased I-sections with bending

about the strong axis of the steel cross-section

curve c for partially and completely concrete encased I-sections with bending

about the weak axis of the steel cross-section

42

18-5-2015

CONCLUDING SUMMARY

Composite columns can be either partly or totally encased open sections, or

alternatively, they may be concrete filled tubes.

Eurocode 4 [1] gives limiting ratios for exposed steel parts of composite

columns, to ensure that local buckling does not occur. For fully encased

sections local buckling is not a problem.

Eurocode 4 gives simplified rules (European Buckling Curves, etc.), for

calculating the resistance of a composite column to axial load.

10.8.2. Columns II

Mmax

Mmin

Bending moment diagram

r = Mmin / Mmax

-1.0 r 1.0

Design bending moment

MSd = Mmax / (1 NSd/Ncr)

= 0.66 + 0.44 r 0.44

43

18-5-2015

Design procedure

for compression and

uniaxial bending

M-N Interaction curve

Strength only

represents maximum buckling load on column, i.e. no bending

k = moment due to imperfection decreases linearly to zero for n = 0.25(1 - r)

For design d = NSd / Npl.Rd , represents the remaining moment resistance

MSd 0.9 Mpl.Rd

44

18-5-2015

At D: Mmax.Rd = Wpa fyd + 0.5 Wpc fcd + Wps fsd

For the example of the concrete

filled rectangular hollow section:

hn =

b

Nc.Rd = fcd.2hn.b - fcd.hn.2t + 2fyd.2hn.2t

Mn.Rd = Wpanfyd + 0.5 Wpcnfcd + (Wpsnfsd)

Wpan, Wpcn and Wpsn plastic moments of

resistance of the areas in the region of 2hn

Now Nc,Rd/2

At B the moment resistance

Mpl.Rd = Mmax.Rd - Mn.Rd

45

18-5-2015

Mz.Sd/(z Mplz.Rd) 0.9

My.Sd/(y Mply.Rd) 0.9

My.Sd/(yMply.Rd) + Mz.Sd/(zMplz.Rd) 1.0

CONCLUDING SUMMARY

The influence of second order effects must be taken into account for slender

columns under significant axial load.

Combined bending and axial load can be checked using interaction diagrams

which also form the basis of the approach adopted in Annex D of Eurocode 4 .

Shear forces are taken into account by reducing the effective area resisting

bending; the cross-section interaction curve can then be determined using the

reduced section.

46

You might also like

- Lecture of FootingDocument195 pagesLecture of FootingMonirul IslamNo ratings yet

- Typical Anchor BoltsDocument33 pagesTypical Anchor BoltslucianduNo ratings yet

- Design-of-Steel-Structures Notes PDFDocument48 pagesDesign-of-Steel-Structures Notes PDFSatish Manal100% (2)

- Steel Design EC3Document45 pagesSteel Design EC3Tiago CunhaNo ratings yet

- Crane beam design analysis and section selectionDocument9 pagesCrane beam design analysis and section selectionLesego MatojaneNo ratings yet

- Steel Design ConceptDocument48 pagesSteel Design Conceptzin nyo thetNo ratings yet

- Vertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 TrangDocument7 pagesVertical Weld Design Bolt Design'!A1 Deflection!A1 Material Data'!a1 Index!a1 TrangSơn Nguyễn-LêNo ratings yet

- Beam To Beam ConnectionsDocument9 pagesBeam To Beam ConnectionskarthiksampNo ratings yet

- Composite Construction Design (ULS Only)Document93 pagesComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)

- Measure RPA ROI with KPIsDocument4 pagesMeasure RPA ROI with KPIsAdnan FarooqNo ratings yet

- Design Provisions of BS 5950 Part 1Document21 pagesDesign Provisions of BS 5950 Part 1ISMAEL SHAIK86% (7)

- Corbel CalculationDocument1 pageCorbel CalculationQuangKhảiNo ratings yet

- BS 5950-1 2000 Volume 2 Worked Example, Part 10 - Pinned ColuDocument5 pagesBS 5950-1 2000 Volume 2 Worked Example, Part 10 - Pinned ColuThando TshababaNo ratings yet

- Limit State DesignDocument12 pagesLimit State DesignEzhil KumarNo ratings yet

- Loads:: Donnees de Calcul ChargesDocument6 pagesLoads:: Donnees de Calcul ChargesAdekimi EmmanuelNo ratings yet

- Fractal ForestsDocument50 pagesFractal ForestsWell Fournier0% (1)

- Cracks in Immature ConcreteDocument2 pagesCracks in Immature ConcreterasikamalNo ratings yet

- Pile CapDocument8 pagesPile CapMdShahbazAhmedNo ratings yet

- Strengthening Design of Concrete Beams by Adition of Steel PlatesDocument10 pagesStrengthening Design of Concrete Beams by Adition of Steel PlatesgparratNo ratings yet

- PCA Concrete Floor Slab OpeningsDocument4 pagesPCA Concrete Floor Slab OpeningsRavindra MRNo ratings yet

- Steel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7Document29 pagesSteel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7iSoK11No ratings yet

- Steel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7Document29 pagesSteel Structures 3 - Composite Structures - Lecture Notes Chapter 10.7iSoK11No ratings yet

- SX019a-Example Column Base Connection Under Axial Compression PDFDocument5 pagesSX019a-Example Column Base Connection Under Axial Compression PDFdvelchev100% (1)

- Bracing Design To Eurocode 3Document13 pagesBracing Design To Eurocode 3B.A H100% (1)

- Beam-Column Using Double Angle CleatDocument7 pagesBeam-Column Using Double Angle CleatNur Syahira100% (1)

- Composite BeamDocument7 pagesComposite Beamsaif.mullaNo ratings yet

- Corner Cast in Place AnchorDocument7 pagesCorner Cast in Place Anchorwaweng22No ratings yet

- ESDEP Lecture 10 on Composite ConstructionDocument46 pagesESDEP Lecture 10 on Composite ConstructioniSoK11No ratings yet

- Structural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Document39 pagesStructural Design 50M SST - Medium Duty - Zone Ii, Exposure C Rev. No. 00 F0736Henj MirasolNo ratings yet

- Drop Panel CalculationDocument2 pagesDrop Panel Calculationsandiok86No ratings yet

- Stakeholder RegisterDocument7 pagesStakeholder Registerrouzbehk6515No ratings yet

- Design of Metal Anchors in Concrete According to ACI318-08Document4 pagesDesign of Metal Anchors in Concrete According to ACI318-08tamerragaaNo ratings yet

- Worked Example 1 - Composite Beam - Normal DesignDocument26 pagesWorked Example 1 - Composite Beam - Normal DesignTudor Tudor100% (1)

- Engg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefDocument3 pagesEngg/10/s4 Reinforced Concrete Design To Bs 8110: Contract RefGodfrey James MachotaNo ratings yet

- Corbel BS8110Document3 pagesCorbel BS8110Nugraha BintangNo ratings yet

- Structural Steel Design Project: Calculation SheetDocument18 pagesStructural Steel Design Project: Calculation Sheetrameshbabu_1979No ratings yet

- Weldgrp - Weld Group Analysis ProgramDocument16 pagesWeldgrp - Weld Group Analysis ProgramemoriderNo ratings yet

- Evo Design - Structural Design: Calculation SheetDocument7 pagesEvo Design - Structural Design: Calculation SheetAnand.5No ratings yet

- Implementing Product ManagementDocument156 pagesImplementing Product ManagementJyoti MohantyNo ratings yet

- Splice 03Document15 pagesSplice 03LexNo ratings yet

- Ec9 Ex61 Shear No StiffenersDocument3 pagesEc9 Ex61 Shear No StiffenersimotalpNo ratings yet

- Steel Joints According To Eurocode 3Document21 pagesSteel Joints According To Eurocode 3alfonxxlNo ratings yet

- Column Pad DesignDocument1 pageColumn Pad DesignMunene NdumiaNo ratings yet

- Robot Analysis of Beam-Column ConnectionsDocument5 pagesRobot Analysis of Beam-Column ConnectionsValentinoNo ratings yet

- Ec4 Composite StructuresDocument52 pagesEc4 Composite StructuresV B Shiva PrasadNo ratings yet

- TRITECH DESIGN OF CORBEL AND BEARING PLATEDocument2 pagesTRITECH DESIGN OF CORBEL AND BEARING PLATEsuman_civilNo ratings yet

- Readme v4B PDFDocument4 pagesReadme v4B PDFlucianduNo ratings yet

- EN1994 4 HanswilleDocument73 pagesEN1994 4 Hanswilleoluomo1No ratings yet

- Composite Steel DesignDocument33 pagesComposite Steel DesignALABIADESINA100% (1)

- Composite Steel DesignDocument33 pagesComposite Steel DesignscegtsNo ratings yet

- Design of Haunched Composite Connections For Long-Span Beam ConstructionDocument10 pagesDesign of Haunched Composite Connections For Long-Span Beam ConstructioncasanovavnNo ratings yet

- Design of Unbraced Multi-Storey Steel FramesDocument7 pagesDesign of Unbraced Multi-Storey Steel FramestaosyeNo ratings yet

- Design and analysis of composite concrete-steel deck systemsDocument16 pagesDesign and analysis of composite concrete-steel deck systemsAhmad FitrahNo ratings yet

- Design of CorbelDocument32 pagesDesign of CorbelSathish Kumar Civil100% (1)

- L08 - Web CrushingDocument20 pagesL08 - Web CrushingTszwun CheungNo ratings yet

- Design of Column BasesDocument9 pagesDesign of Column Basesdarshanakp100% (1)

- INFASO 9.4 Example FinalDocument28 pagesINFASO 9.4 Example Finalpperic13No ratings yet

- Crack Width Calculation For Rectangular RC BeamDocument1 pageCrack Width Calculation For Rectangular RC BeamRomyMohanNo ratings yet

- DOS Web Cleat ConnectionDocument31 pagesDOS Web Cleat ConnectionArfat PatelNo ratings yet

- Design of TrussDocument29 pagesDesign of Trussfrancis100% (1)

- Crack Width ConcreteDocument1 pageCrack Width ConcreteRuemu Godwin InikoriNo ratings yet

- CompositeDocument11 pagesCompositeluuvandong48xf396100% (1)

- Structural Design Brief - Rev 0Document6 pagesStructural Design Brief - Rev 0Umesh ChamaraNo ratings yet

- Design For ShearDocument17 pagesDesign For ShearGreg SchulteNo ratings yet

- Concrete strength propertiesDocument16 pagesConcrete strength propertiesMaharAl-hasanNo ratings yet

- 02 MainDocument329 pages02 MainiSoK11No ratings yet

- Scheen 0874245Document137 pagesScheen 0874245iSoK11No ratings yet

- Wind 2Document1 pageWind 2iSoK11No ratings yet

- GlossaryDocument78 pagesGlossaryiSoK11No ratings yet

- Plastic Analysis 0910Document116 pagesPlastic Analysis 0910Marcin GatalskiNo ratings yet

- Steel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2Document22 pagesSteel Strucsdftures 3 - Composite Structures - Lecture Notes Chapter 10.2iSoK11No ratings yet

- Examples HT2011Document77 pagesExamples HT2011Awv_No ratings yet

- Examples HT2011Document77 pagesExamples HT2011Awv_No ratings yet

- Linea de CedenciaDocument175 pagesLinea de CedenciaKatherine Prado100% (1)

- Steel Structures 3 - Stability of Arches and Research - Lecture Notes - 5Document10 pagesSteel Structures 3 - Stability of Arches and Research - Lecture Notes - 5iSoK11No ratings yet

- Linea de CedenciaDocument175 pagesLinea de CedenciaKatherine Prado100% (1)

- Technical KnowledgeDocument4 pagesTechnical KnowledgeiSoK11No ratings yet

- C 6 Slings SafetyDocument29 pagesC 6 Slings SafetyAshraf BeramNo ratings yet

- Iso 9712 2012 PDFDocument19 pagesIso 9712 2012 PDFBala KrishnanNo ratings yet

- Module 4 NotesDocument20 pagesModule 4 NotesvijaykumaryadavNo ratings yet

- MTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsDocument4 pagesMTBF and MTTR For Metal-Enclosed Capacitor Banks and Harmonic Filter SystemsbansalrNo ratings yet

- 2004 Level 3 Questions: Newham Bulk LEADocument18 pages2004 Level 3 Questions: Newham Bulk LEAPatience NgundeNo ratings yet

- Training Program for Newly Recruited AEEsDocument7 pagesTraining Program for Newly Recruited AEEsakstrmec23No ratings yet

- MY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Document4 pagesMY LIFE VISION, MISSION AND CORE VALUES BMEC 2W 2122Nikolai Avery NorthNo ratings yet

- Katalog - Bengkel Print Indonesia PDFDocument32 pagesKatalog - Bengkel Print Indonesia PDFJoko WaringinNo ratings yet

- 5100 Series Gas Analyzer: Product Data SheetDocument2 pages5100 Series Gas Analyzer: Product Data SheetSai KamalaNo ratings yet

- Academic SummaryDocument4 pagesAcademic SummaryJacqui PendergastNo ratings yet

- Vspa 50Document5 pagesVspa 50elfo111No ratings yet

- X English QPDocument29 pagesX English QPbadasserytechNo ratings yet

- Analytical ExpositionDocument7 pagesAnalytical ExpositionEman FakotNo ratings yet

- Physics: PAPER 3 Practical Test InstructionsDocument8 pagesPhysics: PAPER 3 Practical Test Instructionsmstudy123456No ratings yet

- Latex WikibookDocument313 pagesLatex Wikibookraul_apNo ratings yet

- American Statistical AssociationDocument7 pagesAmerican Statistical Associationmantu6kumar-17No ratings yet

- Quenching & TemperingDocument4 pagesQuenching & Temperingkgkganesh8116No ratings yet

- C6713 Lab ManualDocument51 pagesC6713 Lab Manualsmganorkar100% (1)

- ARHITECTURA Si FOCULDocument282 pagesARHITECTURA Si FOCULTheodor DinuNo ratings yet

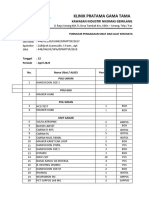

- Pengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuDocument8 pagesPengadaan Obat Dan Alkes TGL 22 April 2021 Klinik PembantuIsma Prasetya WardaniNo ratings yet

- Final AnswersDocument4 pagesFinal AnswersAnshul SinghNo ratings yet

- Waffle Slab - WikipediaDocument15 pagesWaffle Slab - WikipediaBryan PongaoNo ratings yet

- AN-029Wired Locker Access Control ENDocument13 pagesAN-029Wired Locker Access Control ENpetar petrovicNo ratings yet

- PronunciationDocument5 pagesPronunciationHưng NguyễnNo ratings yet

- Holt MCD Earth Science Chapter 30Document34 pagesHolt MCD Earth Science Chapter 30ADEDAMOPE ODUESONo ratings yet