Professional Documents

Culture Documents

BD9848

Uploaded by

Henry CastandCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BD9848

Uploaded by

Henry CastandCopyright:

Available Formats

1/4

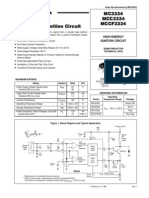

STRUCTURE

PRODUCTSERIES

Silicon Monolithic Integrated Circuit

2-ch Switching Regulator Controller

TYPE

BD9848FV

High Input-voltage ( Vcc=35V)

MOSFET-driver circuit built-indual circuit for step-down output

Built-in circuits for error amplifier reference voltage (1.0 V1%)

5 consecutive over current pulse detection circuit built in.

Soft-start timing adjustable

Master/Slave function

Absolute maximum ratingsTa=25

FEATURES

Item

Symbol

Limits

Unit

Power Supply Voltage

Vcc

36

Power dissipation

Pd

8121

mW

Output pin voltage

VOUT

Vcc-7VVcc

C5V pin voltage

VC5V

Vcc-7VVcc

Operating temperature

Topr

-40+105

Storage temperature

Tstg

-55+150

Tjmax

150

Maximum Junction temperature

*1 Should be deleted by 6.5mW/ at Ta=25 or more. When mounted on a glass epoxy PCB of 70.0mm70.0 mm1.6 mm

Recommended operating range (Ta=25)

Item

Symbol

Min.

Typ.

Vcc

3.6

VOUT

C5V

Power Supply Voltage

Output pin voltage

Max.

Unit

6.0

35

Vcc

Error amplifier input voltage

INV

VREF-0.9

Timing capacitor

CCT

47

3000

pF

100

1500

fosc

0

VCC

VSTB

STB input voltage

0

VREF+0.3

DT

DT input voltage

Vcc-0.2

Vcc+0.2

VOCP

OCP+/- input voltage

CTexternal oscillation waveform

1.9

2.3<VREF

VctH

input voltage range

1.4

1.6<VREF

VctL

Electrical characteristics (Unless otherwise specified, Ta=25VCC=6V)

Oscillation frequency

Item

Symbol

Limits

Unit

kHz

V

V

V

V

V

Conditions

Min.

Typ.

Max.

VREF

2.475

2.500

2.525

Line reg.

10

mV

Vcc=3.6V35V

Load regulation

Load reg.

10

mV

IO=0.1mA2mA

Output max. current

IOMAX

13

mA

VREF=(typ.)0.95

VREF output block

VREF output voltage

Line regulation

REV. C

IO=0.1mA

2/4

Electrical characteristics (Unless otherwise specified, Ta=25VCC=6V)

Item

Symbol

Min.

limits

Typ.

Max.

Unit

Conditions

Triangular wave oscillator block

Oscillation frequency

fOSC

95

106

117

kHz

Frequency variation

fDV

SS pin source current

ISSSO

1.4

2.6

SS=0.5V

SS pin sink current

ISSSI

12

mA

SS=0.5V

Dead time adjustable circuit block

IDT

DT pin input bias current

IDTSI

DT pin sink current

0.1

DT=1.75V

3.3

mA

DT=1.75V, (OCP+)-(OCP-)=0.5V

CCP=1800pF

Vcc=3.6V35V

Soft-start block

UVLO block

Threshold voltage

VUTH

3.0

3.2

3.4

Hysterisis

VUHYS

0.15

0.25

Vcc when rise time

Error Amp block

Non-Inverting

input

reference

Reference voltage variation

INV input bias current

VINV

0.99

1.01

dVinv

mV

INV=FB

Vcc=3.6V35V

IIB

INV=1V

AV

70

85

dB

Output FB voltage (Hi)

VFBH

2.30

VREF

Output FB voltage (Low)

VFBL

0.6

1.3

Output sink current

IFBSI

0.5

1.5

mA

FB=1.25V , INV=1.5V

Output source current

IFBSO

50

105

FB=1.25V , INV=0V

Vt0

1.4

1.5

1.6

On duty 0%

Vt100

1.9

2.1

On duty 100%

Output ON resistance H

RONH

10

RONH=( VCC -OUT)/ Iout, Iout=0.1A

Output ON resistance L

RONL

3.3

10

RONL=(OUT-C5V)/ Iout, Iout=0.1A

C5V clamp voltage

VCLMP

4.5

5.5

VCLMP= VCC-C5V , VCC 7V

0.04

0.05

0.06

Voltage between (OCP+)-(OCP-)

Open loop gain

PWM comparator

Input threshold voltage

fosc=100kHz

Output block

Over current protection circuit (OCP) block

OCP threshold voltage

VOCPTH

IOCP-

0.1

10

OCP+= VCC, OCP-= VCC-0.05V

Delay time for OCP

tdocpth

200

400

nS

OCP-= VCCVCC-0.2V

Min. hold time for OCP

tdocpre

0.8

1.6

mS

OCP-= VCC-0.2VVCC

Threshold voltage for each CH stop

VDTthL

1.1

1.25

1.4

Stand-by mode setting voltage range

VSTBL

0.5

Slave mode setting voltage range

VSTBM

2.4

2.5

2.6

Active(Master) mode setting voltage range

VSTBH

VCC

ISTB

70

100

OCP-input bias current

Stand-by switch block

STB current

DT Pin H/L

STB=6V

Total device

Stand-by current

ICCS

STB=0V

Average current consumption

ICCA

1.5

mA

INV=0V, FB=H, DT=1.75V

Not designed for radiation resistance.

REV. C

3/4

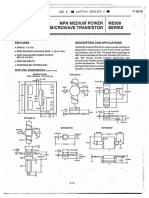

Outline figure

PIN No./ name / function

Pin

No

.

Pin name

type

Lot NO.

SSOP-B20 (Unit : mm)

Block Diagram

CT

External Capacitor pin for timing change

DT2

Dead time setting (CH2)

SS2

Soft-start time setting (CH2)

INV2

Error Amp inverting input (CH2)

FB2

Error Amp output (CH2)

GND

GROUND

OCP2

OCP2

C5V

10

OUT2

CH2 Output

11

OUT1

CH1 Output

BD9848

1 pin Mark

Pin function

Over current error amp inverting input (CH2)

Over current error amp input (CH2)

Vcc

13

OCP1

Power supply input

14

OCP1

15

STB

Over current error amp input (CH1)

Over current error amp inverting input (CH1)

16

FB1

Error Amp output (CH1)

17

INV1

Error Amp inverting input (CH1)

18

SS1

Soft-start time setting (CH1)

19

DT1

Dead time setting (CH1)

20

VREF

STB

Refer p.4 Operation note(9)

OCP1+ OCP1-

VCC

VREF

VCC

STB

OCP1

VREF

5pulse

OCP

C5V

REG

(VCC-5V)

50mV10mV

C5V

C5V

DT1

DT1OFF

FB1

1V10mV

SS1OFF

DT1Low

1.25V

VREF

2A

SS1

DT

+

VCC

+

+ PWM

-

+

+ ERR

-

LS

DRV

OUT1

C5V

INV1

PROTECTION LOGIC

DT1Low

OSC

SS1OFF

200A

+

200A

OCP1

1.5V

TSD

DT1OFF

Hold time

(1.6msec)

2.0V

TSD

UVLO

TSD

VCC

Hold time

(0.2msec)

VREF

2V

1.5V

OCP2

DT2OFF

Hold time

(1.6msec)

CT

C5V

3.2V

2.2V

UVLO

SS2OFF

DT2Low

VCC

VREF

2A

SS2

SS2OFF

+ PWM

+

LS

DT2

VCC

DT2OFF

DT

+

OCP2

DT2Low

5pulse

OUT2

DRV

1V10mV

FB2

UVLO

3V

INV2

+ ERR

+

50mV10mV

C5V

OCP

+

C5V

1.25V

Operation Notes

OCP2+ OCP2-

REV. C

Reference voltage2.5Voutput

VCC

REG

(2.5V)

Stand-by mode control

VREF

Output L voltageVcc-5V

12

VCC

GND

4/4

1) Absolute maximum ratings

Use of the IC in excess of absolute maximum ratings such as the applied voltage or operating temperature range may result in IC

deterioration or damage. Assumptions should not be made regarding the state of the IC (short mode or open mode) when such damage

is suffered. A physical safety measure such as a fuse should be implemented when use of the IC in a special mode where the absolute

maximum ratings may be exceeded is anticipated.

2) GND potential

Ensure a minimum GND pin potential in all operating conditions. In addition, ensure that no pins other than the GND pin carry a voltage

lower than or equal to the GND pin, including during actual transient phenomena.

3) Thermal design

Use a thermal design that allows for a sufficient margin in light of the power dissipation (Pd) in actual operating conditions.

4) Inter-pin shorts and mounting errors

Use caution when orienting and positioning the IC for mounting on printed circuit boards. Improper mounting may result in damage to the

IC. Shorts between output pins or between output pins and the power supply and GND pin caused by the presence of a foreign object

may result in damage to the IC.

5) Operation in a strong electromagnetic field

Use caution when using the IC in the presence of a strong electromagnetic field as doing so may cause the IC to malfunction.

6) Thermal shutdown circuit (TSD circuit)

This IC incorporates a built-in thermal shutdown circuit (TSD circuit). The TSD circuit is designed only to shut the IC off to prevent

runaway thermal operation. Do not continue to use the IC after operating this circuit or use the IC in an environment where the operation

of the thermal shutdown circuit is assumed.

7) Testing on application boards

When testing the IC on an application board, connecting a capacitor to a pin with low impedance subjects the IC to stress. Always

discharge capacitors after each process or step. Ground the IC during assembly steps as an antistatic measure, and use similar caution

when transporting or storing the IC. Always turn the IC's power supply off before connecting it to or removing it from a jig or fixture during

the inspection process.

8) Common impedance

Power supply and ground wiring should reflect consideration of the need to lower common impedance and minimize ripple as much as

possible (by making wiring as short and thick as possible or rejecting ripple by incorporating inductance and capacitance).

9) Over Current Protection

The OCP circuit is designed to be very sensitive circuit for protection of an application device. Therefore, it may detect ringing noises

besides the true current signal. This depends on an application circuit and a layout pattern. In this case, the OCP current value is lower

than the designed value. For the measure of this, please use CR filter on OCP input referring the circuit of the technical note.

10) General

Please refer the technical note on designing.

11) IC pin input

This monolithic IC contains P+ isolation and PCB layers between adjacent elements in order to keep them isolated.

P/N junctions are formed at the intersection of these P layers with the N layers of other elements to create a variety of parasitic

elements.

For example, when a resistor and transistor are connected to pins as shown in Fig. 10,

The P/N junction functions as a parasitic diode when GND > (Pin A) for the resistor or GND > (Pin B) for the transistor

(NPN).

Similarly, when GND > (Pin B) for the transistor (NPN), the parasitic diode described above combines with the N layer of

other adjacent elements to operate as a parasitic NPN transistor.

The formation of parasitic elements as a result of the relationships of the potentials of different pins is an inevitable result of the IC's

architecture. The operation of parasitic elements can cause interference with circuit operation as well as IC malfunction and damage.

For these reasons, it is necessary to use caution so that the IC is not used in a way that will trigger the operation of parasitic elements,

such as by the application of voltages lower than the GND (PCB) voltage to input and output pins.

Resistance

Transistor (NPN)

(PinA)

P substrate

Parasitic diode

(PinA)

(PinB)

Parasitic diode

(PinB)

P substrate

Parasitic elements

Other adiacent components

REV. C

Parasitic diode

Notice

Notes

No copying or reproduction of this document, in part or in whole, is permitted without the

consent of ROHM Co.,Ltd.

The content specified herein is subject to change for improvement without notice.

The content specified herein is for the purpose of introducing ROHM's products (hereinafter

"Products"). If you wish to use any such Product, please be sure to refer to the specifications,

which can be obtained from ROHM upon request.

Examples of application circuits, circuit constants and any other information contained herein

illustrate the standard usage and operations of the Products. The peripheral conditions must

be taken into account when designing circuits for mass production.

Great care was taken in ensuring the accuracy of the information specified in this document.

However, should you incur any damage arising from any inaccuracy or misprint of such

information, ROHM shall bear no responsibility for such damage.

The technical information specified herein is intended only to show the typical functions of and

examples of application circuits for the Products. ROHM does not grant you, explicitly or

implicitly, any license to use or exercise intellectual property or other rights held by ROHM and

other parties. ROHM shall bear no responsibility whatsoever for any dispute arising from the

use of such technical information.

The Products specified in this document are intended to be used with general-use electronic

equipment or devices (such as audio visual equipment, office-automation equipment, communication devices, electronic appliances and amusement devices).

The Products specified in this document are not designed to be radiation tolerant.

While ROHM always makes efforts to enhance the quality and reliability of its Products, a

Product may fail or malfunction for a variety of reasons.

Please be sure to implement in your equipment using the Products safety measures to guard

against the possibility of physical injury, fire or any other damage caused in the event of the

failure of any Product, such as derating, redundancy, fire control and fail-safe designs. ROHM

shall bear no responsibility whatsoever for your use of any Product outside of the prescribed

scope or not in accordance with the instruction manual.

The Products are not designed or manufactured to be used with any equipment, device or

system which requires an extremely high level of reliability the failure or malfunction of which

may result in a direct threat to human life or create a risk of human injury (such as a medical

instrument, transportation equipment, aerospace machinery, nuclear-reactor controller,

fuel-controller or other safety device). ROHM shall bear no responsibility in any way for use of

any of the Products for the above special purposes. If a Product is intended to be used for any

such special purpose, please contact a ROHM sales representative before purchasing.

If you intend to export or ship overseas any Product or technology specified herein that may

be controlled under the Foreign Exchange and the Foreign Trade Law, you will be required to

obtain a license or permit under the Law.

Thank you for your accessing to ROHM product informations.

More detail product informations and catalogs are available, please contact us.

ROHM Customer Support System

http://www.rohm.com/contact/

www.rohm.com

2009 ROHM Co., Ltd. All rights reserved.

R0039A

You might also like

- Epicor Table ERPDocument39 pagesEpicor Table ERPdeibyr6360No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- GD&T WikipediaDocument4 pagesGD&T WikipediaJayesh PatilNo ratings yet

- Ospf Network Analyzing Using OmnetDocument97 pagesOspf Network Analyzing Using OmnetIlaria Curcuglioniti100% (1)

- PD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Document5 pagesPD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Osama YaseenNo ratings yet

- 5.8W Car Audio Power Amplifier ICDocument10 pages5.8W Car Audio Power Amplifier ICHendraNo ratings yet

- La4628 PDFDocument8 pagesLa4628 PDFRICHIHOTS2No ratings yet

- Dual Output Voltage Regulator With Power Saving: BA44W12SATDocument10 pagesDual Output Voltage Regulator With Power Saving: BA44W12SATBeatris Medellin MendozaNo ratings yet

- L6565Document18 pagesL6565Sergio Daniel BarretoNo ratings yet

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersDocument9 pages20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66No ratings yet

- 300mA LDO REGULATOR RP114x SERIES DATA SHEETDocument28 pages300mA LDO REGULATOR RP114x SERIES DATA SHEETSol De GabrielNo ratings yet

- MITSUBISHI SERVO MOTOR DRIVER IC M51660LDocument5 pagesMITSUBISHI SERVO MOTOR DRIVER IC M51660LSergio SanchezNo ratings yet

- LA4628Document9 pagesLA4628jgpbNo ratings yet

- LA4555 Monolithic Linear ICDocument11 pagesLA4555 Monolithic Linear ICMiloud ChouguiNo ratings yet

- Quad Low Side Driver: DescriptionDocument17 pagesQuad Low Side Driver: DescriptionDan EsentherNo ratings yet

- Trickle-Charge IC For Two-Cell, Lithium-Ion BatteriesDocument8 pagesTrickle-Charge IC For Two-Cell, Lithium-Ion BatteriesDary CalaçaNo ratings yet

- BA5417Document11 pagesBA5417AntorimaNo ratings yet

- Datasheet MC3334Document6 pagesDatasheet MC3334odipasNo ratings yet

- BD9893FDocument5 pagesBD9893FAriel NavarreteNo ratings yet

- 2.7GHz Frequency Synthesizer IC GuideDocument15 pages2.7GHz Frequency Synthesizer IC GuideVanderlei MarcariniNo ratings yet

- Single Synchronous Buck PWM DC-DC ControllerDocument16 pagesSingle Synchronous Buck PWM DC-DC Controllerbachet56No ratings yet

- 500 Ma Output LDO Regulator With Voltage Detector: DatasheetDocument24 pages500 Ma Output LDO Regulator With Voltage Detector: Datasheetsamsularief03No ratings yet

- Go-iris-A6159 Fuente TV Samsung LCD 32"Document7 pagesGo-iris-A6159 Fuente TV Samsung LCD 32"Daniel GómezNo ratings yet

- Integrated Circuit Systems, IncDocument11 pagesIntegrated Circuit Systems, Incroger marqNo ratings yet

- AM5888SDocument10 pagesAM5888SproctepNo ratings yet

- Ncl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsDocument10 pagesNcl30160 1.0A Constant-Current Buck Regulator For Driving High Power LedsKhúc Hành QuânNo ratings yet

- Synchronous Rectification DC/DC Converter IC For Charging Li-Ion BatteryDocument56 pagesSynchronous Rectification DC/DC Converter IC For Charging Li-Ion BatterydigenioNo ratings yet

- TB2904HQDocument16 pagesTB2904HQllesli17No ratings yet

- Rp103X Series: Low Noise 150ma Ldo RegulatorDocument29 pagesRp103X Series: Low Noise 150ma Ldo RegulatorSol De GabrielNo ratings yet

- LD7552 DS 00Document10 pagesLD7552 DS 00BRIGHT_SPARKNo ratings yet

- Sua909 PDFDocument61 pagesSua909 PDFgabrielvadNo ratings yet

- Distributed byDocument42 pagesDistributed bydennyjoelNo ratings yet

- General Description: DMB TechnologyDocument11 pagesGeneral Description: DMB Technologyjsalinas78No ratings yet

- Data SheetDocument9 pagesData Sheetmauri_melcerNo ratings yet

- TA8248K Audio Power Amplifier ICDocument12 pagesTA8248K Audio Power Amplifier ICsontuyet82100% (1)

- Air Acond Ps21246 OnduladorDocument10 pagesAir Acond Ps21246 OnduladorJ CorreoNo ratings yet

- UDN2916Document10 pagesUDN2916ejoaomelchiorsNo ratings yet

- IC-ON-LINE - CN dm0365r 44840Document20 pagesIC-ON-LINE - CN dm0365r 44840MoscandoNo ratings yet

- La 42205Document7 pagesLa 42205ban4444No ratings yet

- 74HC4852 (Driver Injector)Document16 pages74HC4852 (Driver Injector)el_george0079491No ratings yet

- TDA7396Document12 pagesTDA7396Caravela CienxcuatroNo ratings yet

- Transition-Mode PFC Controller: 1 FeaturesDocument17 pagesTransition-Mode PFC Controller: 1 Featuresadriancho66No ratings yet

- PS21245 eDocument9 pagesPS21245 eTol SirtNo ratings yet

- MB39A132Document60 pagesMB39A132Krum BumbarovNo ratings yet

- Thb7128 InstructionsDocument9 pagesThb7128 InstructionsanhxcoNo ratings yet

- CCFL Inverter IC OZ960Document12 pagesCCFL Inverter IC OZ960davesworkshopNo ratings yet

- mPC8112TB - Data SheetDocument20 pagesmPC8112TB - Data SheetbigirimwNo ratings yet

- BD9275FDocument5 pagesBD9275Fproctep100% (1)

- Transistor TDSDocument5 pagesTransistor TDSdhoundiyal11No ratings yet

- Cold Cathode Fluorescent Lamp Driver General Description FeaturesDocument6 pagesCold Cathode Fluorescent Lamp Driver General Description FeaturesluisfeipezzNo ratings yet

- 7214Document12 pages7214Dan EsentherNo ratings yet

- Elemento de Flujo TVTHILL1Document50 pagesElemento de Flujo TVTHILL1Rafael Martin Anaya FigueroaNo ratings yet

- Subscriber Line Interface Circuit: DescriptionDocument22 pagesSubscriber Line Interface Circuit: DescriptionLam Nguyen DuyNo ratings yet

- Spreadsheet for MC33063 step-up converter designDocument9 pagesSpreadsheet for MC33063 step-up converter designAlonso CoradoNo ratings yet

- NCP 3063Document20 pagesNCP 3063Roozbeh BahmanyarNo ratings yet

- Reversible Motor Driver IC GuideDocument8 pagesReversible Motor Driver IC Guideeldel81No ratings yet

- Uc3842b 3843BDocument10 pagesUc3842b 3843Bbob75No ratings yet

- Intelligent CCFL Inverter Controller: FeaturesDocument12 pagesIntelligent CCFL Inverter Controller: FeaturesMirosław DżumakNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Aplicaciones de La Derivada-Matematica Dic-2008Document2 pagesAplicaciones de La Derivada-Matematica Dic-2008Circulo De Estudios CoredNo ratings yet

- En Web QIG SecurViewProDocument8 pagesEn Web QIG SecurViewProHenry CastandNo ratings yet

- Inductometro DigitalDocument9 pagesInductometro DigitalHenry CastandNo ratings yet

- ASIO4ALL v2 Instruction ManualDocument11 pagesASIO4ALL v2 Instruction ManualDanny_Grafix_1728No ratings yet

- Silicon Transistor ArrayDocument6 pagesSilicon Transistor ArrayHenry CastandNo ratings yet

- BTA08-600B: Haopin Microelectronics Co.,LtdDocument5 pagesBTA08-600B: Haopin Microelectronics Co.,LtdHenry CastandNo ratings yet

- Process Control Fundamentals 2Document73 pagesProcess Control Fundamentals 2Otuekong Ukpong100% (2)

- Using The Parallel Port in LabVIEWDocument6 pagesUsing The Parallel Port in LabVIEWAlberto EnriqueNo ratings yet

- Instrumentation Training Tutorial Part1Document6 pagesInstrumentation Training Tutorial Part1Gary8100% (1)

- Pi Face HTTP InterfaceDocument2 pagesPi Face HTTP InterfaceHenry CastandNo ratings yet

- Datasheet l298bDocument14 pagesDatasheet l298bgioganNo ratings yet

- Ir 2113Document18 pagesIr 2113rohitsingh2909No ratings yet

- QSGDocument7 pagesQSGHenry CastandNo ratings yet

- Motorola An 780ADocument6 pagesMotorola An 780ArobinsonsNo ratings yet

- SecurView Release NoteDocument1 pageSecurView Release NoteHenry CastandNo ratings yet

- NE56800 To NE56887Document9 pagesNE56800 To NE56887Henry CastandNo ratings yet

- Nud3105 DDocument10 pagesNud3105 DHenry CastandNo ratings yet

- TV-IP110 CamaraDocument12 pagesTV-IP110 CamaraHenry CastandNo ratings yet

- 1N4728 To 1N4764DDocument3 pages1N4728 To 1N4764DHenry CastandNo ratings yet

- General Description: Quad Bilateral SwitchDocument23 pagesGeneral Description: Quad Bilateral Switchtotal4321No ratings yet

- Introduccion A La Mecatronica y Los Sistemas de MeDocument1 pageIntroduccion A La Mecatronica y Los Sistemas de MeHenry CastandNo ratings yet

- Datasheet PDFDocument10 pagesDatasheet PDFVenkatesh VakamulluNo ratings yet

- IRFZ24NDocument8 pagesIRFZ24NarcatusNo ratings yet

- Max7219 Max7221Document17 pagesMax7219 Max7221Miguel Nallar SaucedoNo ratings yet

- CCD Signal Processors With Integrated Timing Driver: AD9848/AD9849Document36 pagesCCD Signal Processors With Integrated Timing Driver: AD9848/AD9849Henry CastandNo ratings yet

- ICM7218CDocument11 pagesICM7218CHenry CastandNo ratings yet

- Arduino InductanceDocument4 pagesArduino InductanceHenry CastandNo ratings yet

- LM386 Low Voltage Audio Power AmplifierDocument10 pagesLM386 Low Voltage Audio Power Amplifierapple.scotch.fool3550No ratings yet

- Series As HC-49/S: FeaturesDocument2 pagesSeries As HC-49/S: FeaturesCristian CaballeroNo ratings yet

- BAV99LT1 Dual Series Switching Diode: Maximum RatingsDocument4 pagesBAV99LT1 Dual Series Switching Diode: Maximum Ratingsaniruddhaphatak93No ratings yet

- As 111423 KVS11 Um 911GB GB WW 2050-1Document600 pagesAs 111423 KVS11 Um 911GB GB WW 2050-1Joko SusenoNo ratings yet

- Sony Hvr-V1j U N e P C Ver1.3Document504 pagesSony Hvr-V1j U N e P C Ver1.3DanNo ratings yet

- Getting Started With The: USB Oscilloscope, Function Generator, Logic Analyzer and Spectrum AnalyzerDocument6 pagesGetting Started With The: USB Oscilloscope, Function Generator, Logic Analyzer and Spectrum AnalyzerStephen MalinakNo ratings yet

- Install Ansible On Mac OSXDocument5 pagesInstall Ansible On Mac OSXNagendraNo ratings yet

- Simulating Crop Impact of Climate Change Using DSSATDocument34 pagesSimulating Crop Impact of Climate Change Using DSSATroberta_silva_2100% (1)

- Switch Enterasys Cli - GuideDocument720 pagesSwitch Enterasys Cli - GuideRaul Iglesias Gomez100% (2)

- Cisco Collaboration Roadmap For Partners August 2023Document247 pagesCisco Collaboration Roadmap For Partners August 2023Cristian Campos AguadoNo ratings yet

- Nutanix - Hardware Admin Ref AOS v511Document89 pagesNutanix - Hardware Admin Ref AOS v511lutung kasarungNo ratings yet

- Wii Okami ManualDocument25 pagesWii Okami Manualbeatrizascensao.workNo ratings yet

- Easy C Programming Problems & Solution For BeginnersDocument10 pagesEasy C Programming Problems & Solution For BeginnershsleonisNo ratings yet

- DocumentDocument96 pagesDocumentKatie Hui TongNo ratings yet

- List Operations in JavaDocument4 pagesList Operations in Javamadhu jhaNo ratings yet

- What is JavaScript? A Beginner's GuideDocument67 pagesWhat is JavaScript? A Beginner's GuideTech ChannelNo ratings yet

- Summative Assessment 1 To Upload 26 08 2023Document20 pagesSummative Assessment 1 To Upload 26 08 2023Diane WoolfordNo ratings yet

- I. Electronic Commerce Act of 2000 (R.A. 8792)Document3 pagesI. Electronic Commerce Act of 2000 (R.A. 8792)Lorelie SantosNo ratings yet

- BIOS Configuration Utility User GuideDocument19 pagesBIOS Configuration Utility User GuidecornolioNo ratings yet

- Survey MSTDocument29 pagesSurvey MSTAnonymous a3K3WgNo ratings yet

- 1Document977 pages1api-19641877100% (6)

- Petta Lab Raith EBL Guide for GaAs DevicesDocument13 pagesPetta Lab Raith EBL Guide for GaAs DevicesSudipta DuttaNo ratings yet

- B.Arch-2016 Nit TrichyDocument60 pagesB.Arch-2016 Nit TrichyGokunathhariNo ratings yet

- Data Mining MCQ FINALDocument32 pagesData Mining MCQ FINALAmit Kumar SahuNo ratings yet

- Monte Carlo Simulations ExplainedDocument10 pagesMonte Carlo Simulations ExplainedAbhishek SinghNo ratings yet

- Ecological Bin Packing SolutionDocument2 pagesEcological Bin Packing SolutionHello misterNo ratings yet

- Ergonomic Analysis of Motor VehiclesDocument14 pagesErgonomic Analysis of Motor VehiclesdeyeNo ratings yet

- WDV Dep MethodDocument24 pagesWDV Dep Methodsudershan9No ratings yet

- Cardiac Science AED Manager User Guide EnglishDocument21 pagesCardiac Science AED Manager User Guide EnglishEnerspect Medical SolutionsNo ratings yet

- M817 13 4-GO-LW A4 E ScreenDocument19 pagesM817 13 4-GO-LW A4 E ScreenRikyNo ratings yet