Professional Documents

Culture Documents

Welding Consumables For Cast Iron Materials

Uploaded by

skidanjeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Welding Consumables For Cast Iron Materials

Uploaded by

skidanjeCopyright:

Available Formats

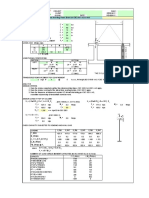

Welding consumables for

cast iron materials

Welding consumables for cast iron

Electrodes

UTP Product

Designation

Typical analysis

Coating type

DIN EN ISO 1071: E C NiCl 1

AWS A5.15: E Ni-CI DIN 8573: E Ni-BG 22

DIN EN ISO 1071: E C NiCl 1

AWS A5.15: E Ni-Cl DIN 8573: E Ni-BG 22

DIN EN ISO 1071: E C NiCl 1

AWS A5.15: E Ni-Cl DIN 8573: E Ni-BG 22

C 1,2 Fe 0,5 Ni rest

graphit-basic

C 0,9 Fe 1,5 Ni rest

graphit-basic

C 0,8 Mn 0,7 Fe 2,0 Cu 2,0

Ni rest

C 1,0 Fe 1,0 Ni rest

graphit-basic

8C

88 H

8 NC

DIN EN ISO 1071: E C NiCl 1

AWS A5.15: E Ni-Cl DIN 8573: E Ni-BG 12

83 FN

DIN EN ISO 1071: E C NiFe-1 1

AWS A5.15: E NiFe-Cl DIN 8573: E NiFe-1 BG 23

DIN EN ISO 1071: E C NiCl 1

AWS A5.15: E Ni-Cl DIN 8573: E Ni-BG 22

DIN EN ISO 1071: E C NiFe-1 1

AWS A5.15: E NiFe-Cl DIN 8573: E NiFe-1 BG 23

C 1,3 Ni 52,0 Fe rest

graphit-basic

C 1,1 Fe 8,0 Cu 0,5 Ni rest

graphit-basic

C 1,2 Ni 54,0 Fe rest

graphit-basic

DIN EN ISO 1071: E C NiFe-1 3

AWS A5.15: E NiFe-Cl DIN 8573: E NiFe-1 BG 12

DIN EN ISO 1071: E NiCu-2

AWS A5.15: ~E NiCu-B DIN 8573: E NiCu-BG 12

C 1,2 Fe 45,0 Ni rest

graphit-basic

C 0,8 Fe 1,0 Cu 30,0

Ni rest

graphit-basic

C 1,0 Si 0,5 Mn 0,5 Fe rest

graphit-basic

807

DIN EN ISO 1071: E Fe

AWS A5.15: ~E St DIN 8573: E Fe-1

DIN 8573: E Fe-2

C 0,05 Si 0,4 Mn 0,5 V 10,0

Fe rest

basic

5E

DIN 8573: E FeC-1-BG 40

C 3,2 Si 3,5 Mn 0,6 Fe rest

graphit-basic

5D

DIN 8573: E FeC-G-BG 40

AWS A5.15: E Cl-B

C 3,0 Si 3,0 Mn 0,4 Fe rest

graphit-basic

84 FN

85 FN

86 FN

8 Ko

81

graphit-basic

Wires for MIG/MAG welding

UTP Product Designation

Typical analysis

Yield strength, elongation,

hardness

A 8051 Ti

DIN 8573: MSG NiFe-2

C 0,1 Mn 3,5 Ni 55,0 Fe rest Ti traces

> 300 MPa, > 25 %, appr. 200 HB

A 8058

DIN 8573: MSG NiFe-1

C < 0,1 Si 0,1 Mn 1,0 Ni 60 Fe rest

> 450 MPa, > 25 %, appr. 130 HB

Rods for gas welding

UTP Product Designation

5

5M

Typical analysis

DIN EN ISO 1071: FeC-1

C 3,2 Si 3,5 Mn 0,6

AWS A5.15: R-Cl DIN 8573: G FeC-1-G0

Flux: UTP Flux 5 (powder)

flux-coated

Metal powders for spray-fuse welding (HA-Bond)

UTP Product EN 1274

Typical analysis

Grain size

m

Melt

intervall ( C)

HA-3

C 0,03 Fe 0,5 B 1,3 Si 2,3 Ni rest

- 106 + 20

1090 - 1120

C 0,04 Fe 0,5 Si 2,0 B 1,2 Cu 20,0 Ni rest

- 106 + 20

1005 - 1050

C 0,03 Fe 0,5 B 1,4 Si 2,4 Ni rest

- 53 + 20

1090 - 1120

2.2 - 106/20

HA-6315 G 2.1 - 106/20

HA-6320

2.2 - 53/20

Yield strength, hardness Current

polarity

appr. 220 MPa, appr. 180 HB

=/~

appr. 220 MPa, appr. 180 HB = / ~

appr. 250 MPa, appr. 180 HB = / ~

Applications

Pure nickel cold welding electrodes for welding of grey and malleable

cast iron, cast steel and for joining these base metals to steel, copper

and copper alloys, especially for repair and maintenance. Outstanding

welding properties, spatter free welding, free of undercutting. Slag is

easliy removable. Peen the weld metal carefully.

appr. 220 MPa, appr. 180 HB = / ~

Cast iron electrode with graphite lime-type non-conductive coating for

cold welding of all common cast iron sorts, esp. suited for plug welding

appr. 300 MPa, appr. 190 HB = + / ~

Ferro-nickel electrodes for joining and surfacing of grey and malleable

cast iron, nodular cast iron and for joining these materials to steel, copper and copper alloys. Universally suitable for repair-, production- and

construction welding by cold welding.

Outstanding welding properties, spatter free welding, free of

undercutting. Slag is easliy removable, high mechanical properties.

appr. 230 MPa, appr. 180 HB = / ~

appr. 320 MPa, appr.200 HB

=+/~

appr. 340 MPa, appr. 220 HB = / ~

appr. 200 MPa, appr. 160 HB = / ~

Nickel-copper electrode for production welds, if a similarity in colour to

the cast material is needed, by cold welding (bowhole welding).

appr. 350 HB

=/~

appr. 180 HB, appr. 230 HB

1 layer on GJL-250 (GG 25)

=+

Ferro-based electrodes for pickup layers on poorly weldable cast iron

and for wear resistant surfacings on grey and nodular cast iron by cold

welding.

appr. 200 HB

=/~

Structure matching cast iron electrode for hot welding of cast iron

appr. 220 HB

=/~

Structure matching cast iron electrode for hot welding of nodular cast

iron. Preheating min. 500 C, identical in colour and structure.

Shielding gases

EN 439

Argon,

M 12 (Ar + 2,5 % Co2)

Argon,

M 12 (Ar + 2,5 % Co2)

Applications

Ferro-nickel wires for surfacing and joining of grey, nodular and malleable cast iron and

for mixed joints with steel, copper and copper alloys. Suitable for repair-, production- and

construction welding by cold welding. Preferably by applying the pulsed current arc process.

Hardness

Flameadjustment

Applications

appr. 200 HB

neutral

Gas welding rods for structure matching hot welding of cast iron. The

weld deposit is of the same colour and structure.

Hardness

HV

Flameadjustment

Applications

205 - 260

neutral

170 - 240

neutral

Ni-base spray fuse metal powders for repairing deteriorted cast

iron parts and for surfacing worn out parts. Major application:

Glass mould repair.

190 - 260

neutral

UTP Schweimaterial GmbH

Elssser Strae 10

D - 79189 Bad Krozingen

Germany

Fon:

Fax:

E-mail:

Web:

+49 (0) 76 33 - 4 09 - 01 (24-h-Serviceline)

+49 (0) 76 33 - 4 09 - 2 22

info@utp.de

www.utp.de

Member of the BHLER-UDDEHOLM Group

UTP is a certificated company

TV-certification according to DIN EN ISO 9001

DIN EN ISO 14001

You might also like

- Reliable partner for welding cast iron materialsDocument8 pagesReliable partner for welding cast iron materialshrk100No ratings yet

- Nickel-base filler metals GTAW rodsDocument1 pageNickel-base filler metals GTAW rodsc131508No ratings yet

- Welding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationDocument6 pagesWelding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationTaufikWibowoNo ratings yet

- B Bã-Hler Nibas 70 20-Fd Fcaw 02Document1 pageB Bã-Hler Nibas 70 20-Fd Fcaw 02kamals55No ratings yet

- CI-500 Cast Iron Repair ElectrodeDocument1 pageCI-500 Cast Iron Repair ElectrodeLasandu WanniarachchiNo ratings yet

- SS - Filler Wire SelectionDocument26 pagesSS - Filler Wire SelectionBaraa AzebNo ratings yet

- UTP Brazing Filler MetalsDocument8 pagesUTP Brazing Filler MetalsIvan Dulic100% (1)

- Fontargen Sales ProgramDocument20 pagesFontargen Sales ProgramCarlos Nombela PalaciosNo ratings yet

- 57 - Datasheet enDocument1 page57 - Datasheet enFerhat KahveciNo ratings yet

- Chinese To DinDocument7 pagesChinese To Dindnageshm4n244No ratings yet

- Consumables For Duplex Stainless SteelDocument6 pagesConsumables For Duplex Stainless SteelMohamed FaragNo ratings yet

- EJ Handbook.A5Document261 pagesEJ Handbook.A5ElMacheteDelHuesoNo ratings yet

- Welding GuideDocument48 pagesWelding Guideedu_canete100% (2)

- Welding TrainingDocument87 pagesWelding Trainingeswar100% (1)

- 3 05 A Welding Specification of Carbon Steel Alloy SteelDocument40 pages3 05 A Welding Specification of Carbon Steel Alloy SteelvancongthanhNo ratings yet

- All Types of MaterialsDocument8 pagesAll Types of MaterialsAniket KabadeNo ratings yet

- Nickel-Iron For Cast Iron: Data SheetDocument3 pagesNickel-Iron For Cast Iron: Data SheetSandro ChiliquingaNo ratings yet

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- Fox - FFDocument1 pageFox - FFGustavo NietoNo ratings yet

- Evb 50P: Electrodes: Low Alloyed Steels - BasicDocument2 pagesEvb 50P: Electrodes: Low Alloyed Steels - BasicKočanLarisaNo ratings yet

- Inception Report Air SelangorDocument3 pagesInception Report Air SelangorNurul IzzatiNo ratings yet

- Copperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloysDocument1 pageCopperfil Cusi3: MIG-MAG Wires Nickel and Copper AlloyssatnamNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- Stainless Steel Welding by Weld RealityDocument50 pagesStainless Steel Welding by Weld RealitylightwinterdayNo ratings yet

- FSH TigDocument105 pagesFSH TigChee WeiNo ratings yet

- TL Welding ConsumablesDocument60 pagesTL Welding ConsumablesDuvall AnggraitaNo ratings yet

- UTP For OffshoreDocument16 pagesUTP For Offshorekamals55No ratings yet

- Catalogue MetalweldDocument17 pagesCatalogue MetalweldRadivojevic SasaNo ratings yet

- Welding Product Range SummaryDocument28 pagesWelding Product Range SummaryFilipe CoelhoNo ratings yet

- Eutectrode 6666: Manual Arc Welding ElectrodeDocument1 pageEutectrode 6666: Manual Arc Welding ElectrodemortezaheidarianNo ratings yet

- Chinese To DinDocument7 pagesChinese To DinDamla KaymakçıNo ratings yet

- MIP Bohler Welding Austria 62Document1 pageMIP Bohler Welding Austria 62Pradeepta MohantyNo ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- Avesta 2205 VDX Ac DCDocument1 pageAvesta 2205 VDX Ac DCpipedown456No ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Brazing & Soldering of Solar PanelsDocument9 pagesBrazing & Soldering of Solar Panelskamals55No ratings yet

- INOX B 19/9 Nb electrode for welding stainless steelsDocument1 pageINOX B 19/9 Nb electrode for welding stainless steelsIvan DulicNo ratings yet

- Esab 309cbDocument1 pageEsab 309cbGokul RajanNo ratings yet

- Ok Tigrod S2 Ok Tigrod S2 (SPL)Document1 pageOk Tigrod S2 Ok Tigrod S2 (SPL)Gokul RajanNo ratings yet

- 5 - Duplex Stainless Steels and Nickel AlloysDocument44 pages5 - Duplex Stainless Steels and Nickel AlloysdennykvgNo ratings yet

- Chapter 14 WeldingDocument22 pagesChapter 14 WeldingRiian ApriansyahNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Sava 150 BDocument1 pageSava 150 BHans DitrihNo ratings yet

- Barrettetig Catalogo Oerlikon 35035Document44 pagesBarrettetig Catalogo Oerlikon 35035mp303No ratings yet

- C12200 PD Copper - Austral Wright Metals - AustraliaDocument3 pagesC12200 PD Copper - Austral Wright Metals - Australiamohsen_267No ratings yet

- CERTILAS EN Edition2023 316Document1 pageCERTILAS EN Edition2023 316Alireza KhodabandehNo ratings yet

- FontargenDocument282 pagesFontargenMIHAINo ratings yet

- UTP Chemical GBDocument12 pagesUTP Chemical GBajaychackotecsoNo ratings yet

- HILCO Stick Electrodes at A GlanceDocument6 pagesHILCO Stick Electrodes at A Glanceziaee950No ratings yet

- Technical Data & Terms for Welding AlloysDocument32 pagesTechnical Data & Terms for Welding Alloysnarutothunderjet216No ratings yet

- Carbon Steel 01Document1 pageCarbon Steel 01amekkehNo ratings yet

- Böhler Ti 2 Ni T-FD: Seamless Cored WireDocument2 pagesBöhler Ti 2 Ni T-FD: Seamless Cored WireThanh TamNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- 1 4305a30365Document2 pages1 4305a30365skidanjeNo ratings yet

- En10083 1Document28 pagesEn10083 1skidanjeNo ratings yet

- Ruukki Hot Rolled Steels Welding General 2014.ashxDocument13 pagesRuukki Hot Rolled Steels Welding General 2014.ashxskidanjeNo ratings yet

- Replacement of en 473 by ISO 9712 TUV RheinlandDocument1 pageReplacement of en 473 by ISO 9712 TUV Rheinlandflore73No ratings yet

- Thu Jun 24 14:54:42 2004Document16 pagesThu Jun 24 14:54:42 2004skidanjeNo ratings yet

- Thu Jun 24 14:54:42 2004Document16 pagesThu Jun 24 14:54:42 2004skidanjeNo ratings yet

- LAB 7 MAE 4333 Daniel Perez & Trevor KaaseDocument4 pagesLAB 7 MAE 4333 Daniel Perez & Trevor Kaasedaniel perezNo ratings yet

- RESULT and DISCUSSIONDocument5 pagesRESULT and DISCUSSIONnisasoberiNo ratings yet

- Abstracts Book EWWM2014Document276 pagesAbstracts Book EWWM2014azilleNo ratings yet

- Basement Column Design Analysis and Capacity CheckDocument3 pagesBasement Column Design Analysis and Capacity CheckPhanithNo ratings yet

- Building BOQ FinalDocument42 pagesBuilding BOQ FinalRefisa JiruNo ratings yet

- Matachana - AP4 - Water Treatment System For Steriliser - User ManualDocument8 pagesMatachana - AP4 - Water Treatment System For Steriliser - User ManualWahidi AzaniNo ratings yet

- Specification and Schedule of Quantities BrickworkDocument11 pagesSpecification and Schedule of Quantities BrickworkSyed AbthahirNo ratings yet

- Use of Water Reducers To Impove Grindability and Performance of PC Clinker PDFDocument10 pagesUse of Water Reducers To Impove Grindability and Performance of PC Clinker PDFTran Huynh NamNo ratings yet

- Loctite 577™: Technical Data SheetDocument5 pagesLoctite 577™: Technical Data SheetAditya DarmawanNo ratings yet

- Reactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFDocument32 pagesReactive Wetting, Evolution of Interfacial and Bulk IMCs and Their Effect On Mechanical PDFeid elsayedNo ratings yet

- Performance Qualification of Autoclave Cum Bung ProcessorDocument17 pagesPerformance Qualification of Autoclave Cum Bung ProcessorĐức LinhNo ratings yet

- Strength-Durability Correlation of OsteosynthesisDocument17 pagesStrength-Durability Correlation of OsteosynthesisdeniNo ratings yet

- Prof. Dr. Zainul Huda: Resume ofDocument31 pagesProf. Dr. Zainul Huda: Resume ofMuhammed ThanzeelNo ratings yet

- Flexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MembersDocument10 pagesFlexural Behavior of Composite Reinforced Concrete Slurry-Infiltrated Mat Concrete (SIMCON) MemberspicottNo ratings yet

- Product Data Sheet: Sikacor® Eg-1Document4 pagesProduct Data Sheet: Sikacor® Eg-1Thompson LaiNo ratings yet

- Champion Lubricants Storage HandlingDocument6 pagesChampion Lubricants Storage HandlingIonut SomneaNo ratings yet

- Low-Bias Transport in Graphene:an IntroductionDocument57 pagesLow-Bias Transport in Graphene:an IntroductionLIAKMANNo ratings yet

- GFML Executive Report: Environmental Legislation ConsultationDocument9 pagesGFML Executive Report: Environmental Legislation ConsultationEdmund BrightNo ratings yet

- Asme BPVC - Ssc.i.ii.v.ix - Xiii-2023Document42 pagesAsme BPVC - Ssc.i.ii.v.ix - Xiii-2023mmendozagNo ratings yet

- Urban Ae Paper - 20669792 - 2023 - 07 - 28 - 16 - 48Document14 pagesUrban Ae Paper - 20669792 - 2023 - 07 - 28 - 16 - 48Rabi DasNo ratings yet

- Microstructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialDocument17 pagesMicrostructural and Mechanical Properties Analysis of Plasma ARC Welded 316L Austenitic Stainless Steel Joints Without Addition of Filler MaterialEditor IJTSRDNo ratings yet

- Resistência Da Cor Ao Calor Prensagem A Quente - AATCC 133-2010Document2 pagesResistência Da Cor Ao Calor Prensagem A Quente - AATCC 133-2010raissaNo ratings yet

- Principles of A Permanent-Magnet Axial-Field D.CDocument6 pagesPrinciples of A Permanent-Magnet Axial-Field D.CHoang Hoang LeNo ratings yet

- Mechanical Operations PPT 1Document49 pagesMechanical Operations PPT 1akshadnagdeote01No ratings yet

- Sikagrout 214-11 PdsDocument2 pagesSikagrout 214-11 PdscharlessimoNo ratings yet

- Global Packaging Report for Peruvian Table Grape ExportsDocument11 pagesGlobal Packaging Report for Peruvian Table Grape ExportsFelipe IllanesNo ratings yet

- Sample Questions - Chapter 2Document5 pagesSample Questions - Chapter 2Rasel IslamNo ratings yet

- E00159 EZ11 ManualDocument30 pagesE00159 EZ11 ManualRuddy MariusNo ratings yet

- Lava Plus High Translucency Zirconia BrochureDocument4 pagesLava Plus High Translucency Zirconia BrochureMario MlinarićNo ratings yet

- Conduits and FittingsDocument285 pagesConduits and FittingsNashwanNo ratings yet