Professional Documents

Culture Documents

Build the award-winning PAC-12 portable vertical antenna

Uploaded by

limazulusOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Build the award-winning PAC-12 portable vertical antenna

Uploaded by

limazulusCopyright:

Available Formats

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Build the PAC-12 Antenna

a multi-band portable vertical

designed by KA5DVS

Heres an award-winning, easy-to-homebrew, multi-band portable vertical antenna designed by

long-time antenna aficionado James Bennett, KA5DVS. Hes documented the design and

construction plans for a portable antenna that can be built with relatively ordinary components

obtained from the local hardware store, including replaceable loading coils. This is a very cool

antenna that's efficient and can easily be taken it along on quick trips to the field. Youll love it!

NOTES:

1. This article was originally published in issue #8 of QRP Homebrewer magazine, and

is posted here with the permission of author KA5DVS and the NJQRP Club.

2. See the Pacific Antenna website (www.pacificantenna.com) for production versions

of this great little antenna

3. The 72" telescoping antenna specified in this construction article is no longer

available from Radio Shack. A suitable replacement may be purchased from Pacific

Antenna ... see their ordering web page (http://www.pacificantenna.com

/Ordering.htm)

1 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Introduction

As someone who travels quite a bit on business, I am

always looking for ways to take along my ham radio

hobby. With the availability of a new class of small QRP

rigs such as the Elecraft K1 and K2, SGC 2020 and the

Yaesu FT-817, it has never been easier to take our hobby

on the road ( or bus or train or boat or plane).

When I rst started traveling with radio equipment, I

typically used a random wire and tuner to keep the total

antenna package small. However, with the wire,

launching weights and string as well as a tuner and SWR

bridge, the entire package gets somewhat bulky. Not to

mention the batteries, cables, key, microphone and other

radio accessories. Keeping the total weight of luggage to

a manageable level is a primary goal of mine. I have tried

a few designs based around the 72" telescoping whip

from radio shack coupled with an L- network tuner. While

these designs proved usable, I was not happy with the

conguration and portability of the design so I continued

to think about a way to make a better travel antenna.

Commercial antennas have come on the scene, these

include designs such as the Outbacker, SuperAntennas

MP1 and MP2, Maldol whips and a wide range of mobile

antennas that can be adapted to portable operation.

However, none of these quite t my needs for a

lightweight, packable antenna. Thus, I decided to try to

build my ideal travel antenna.

Building antennas is one of my favorite activities in

amateur radio. I often nd myself browsing for antenna

materials in the local Home Depot or other hardware

store. Over the years, like many of you, I have built many

dipoles, verticals and a few beams from a wide

assortment of wire, tubing nuts and bolts. On one such

trip, I ran across some 1/4 aluminum rod and threaded

couplings and started to think how I might use these

items in an antenna. That day, a pack of couplings and a

couple of sections of the rod followed me home. Using a

threading die, threads can be cut into the ends of the rod

to allow it to screw into the couplings. Soon, I had several

sections threaded. I ended up making each section 12"

long as that seemed a convenient length for antenna

sections. I already had several of the radio shack 72"

telescoping antennas that collapse down to almost 12" as

well as a good selection of PVC ttings and pipe used in

2 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

previous antenna projects. After a bit work, I had an

antenna that would break down into 12" or less sections

and when assembled would be approximately 8 in

length. I chose to move the loading coil away from the

base to improve the eciency. Two 12" sections of the

threaded aluminum rod were used to make the base

section. For the coil, I used 2 PVC caps and a section of

tubing along with 2 bolts, washers and nuts to produce a

coil assembly. Wire from one of my other favorite haunts

(Radio Shack) was used to wind the loading coil on the

PVC coil form. A PVC tting, a BNC connector and a

couple more bolts, nuts and washers and the antenna was

complete. I eventually named it the PAC-12 where PAC

stands for Portable Antenna Concept and the 12 comes

from the length when disassembled. It is also a bit of

word play on the PAC-10 conference.

The antenna has served well on many trips and has

continued to evolve, making it easier to construct and

assemble for use. On a whim, I entered it in the HFPack

antenna shootout held at the Pacicon conference in

October 2001. I was somewhat surprised to have the

antenna place rst in eciency as compared to a 1/4

wavelength wire vertical.

Also see Appendix C at the bottom of this page for many

examples of PAC-12 antennas as constructed by QRPers

in the NJQRP Club.

I hope many of you will build and use this antenna, please

drop me an email and let me know how it works for you.

James Bennett, KA5DVS/6

1196 Phillips Court

Santa Clara, CA 95051

email: ka5dvs@arrl.net .

PAC-12 Antenna, Tool and Parts List

Tools Needed:

Drill

Drill bits: 1/8, 9/32, 1/4, 5/16, 3/8"

1/4-20 Threading die

6-32 Tap and drill

3 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Hacksaw

Optional but recommended:

Drill Press

Bench Vice

Hardware:

1 Aluminum Rod, 1/4" x 48"

1 Flat aluminum stock, 1" x 1/8 or 1/16", approx 2" length

needed

1 PVC Riser 1/2 x 2"

PVC risers, 1/2"

40M: 8" (See Table 1 for riser lengths for other bands)

PVC threaded caps, 2 per coil needed.

Bolts 1/4-20 x 3/4", 3 plus 1 per each additional coil

Bolts 5/16" x 3/4" , 1 per coil

Coupler nuts 1/4-20, 1 package of 4

Coupler nuts 5/16, 1 package

Nuts 1/4-20, 4 plus 1 per each additional coil

Nuts 5/16, 1 per coil

Machine screw or thumbscrew 6-32 x 1/4". (for antenna

setscrew)

Star Washers 1/4" and 5/16"

Radio Shack:

72"

telescoping

antenna

(RS

270-1408B)

[See

http://www.pacificantenna.com/Ordering.htm to obtain an alternate antenna.]

22 AWG wire (black or red insulation) (RS 278-1215)

BNC panel mount

1/4 and 5/16"

assortment)

4 of 21

ring

terminals

for

22AWG

(RS

64-3120,

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

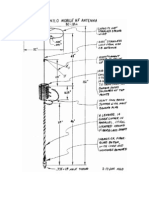

Whip Preparation

The whip section of the antenna is constructed from a Radio Shack

# 270-1408B, 72" telescoping whip antenna. This antenna has a

solid lug base with a single hole for mounting. While the antenna

can be mounted using a single screw through the base, I have found

that it is much more robust when supported inside a tting that

encircles the base of the antenna entirely. See Figure 1A. [NOTE:

The 72" telescoping antenna specified in this construction article is no longer available from

Radio Shack. A suitable replacement may be purchased from Pacific Antenna ... see their

ordering web page http://www.pacificantenna.com/Ordering.htm]

In order to attach the whip to the loading coils, an adapter is

prepared from a 5/16" coupling nut that is drilled using a 9/32" bit

for approximately 1/2 of its length. The depth is chosen to allow the

antenna to slip into the tting to just past the upper crimp line. At a

distance of 1/8" from the top, it is drilled and tapped for a 6/32"

screw that will serve to secure the whip. See Figure 1B.

The hex coupling nut is attached to the base of the whip taking care

to ensure that the setscrew applies pressure at or below the upper

crimp line. The section below the crimp lines is solid and clamping

here will avoid any chance of damaging the upper telescoping tubes

that form the whip. See Figure 1C.

Once assembled, the whip is ready to attach to the 5/16" thread end

of a loading coil.

Figure 1A:

Radio Shack 72" whip antenna

Figure 1B:

Modified hex rod coupling nut

Figure 1C:

Whip and modified coupling

assembly

Loading Coil Construction

The loading coils are prepared from 1/2" PVC risers that are drilled

5 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

as indicated below in Figure 2 using a 1/8" bit to create a point for

securing the end of the coils.

Figure 2: PVC riser, drilled

The coils are wound on the PVC risers with Radio Shack # 278-1215,

solid, insulated wire with the dimensions and turns indicated in the

table below. The number of turns is chosen for the low end of each

band and to move the resonant point higher in frequency, simply

shorten the telescoping whip. Depending on location and mounting,

you may nd that one or more turns may need be removed to bring

the low SWR point of the antenna to the proper frequency.

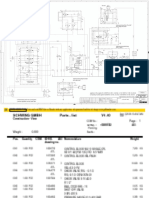

Frequency

(MHz)

Approximate

Coil Length

(inches)

PVC Length

(inches)

Hole Spacing

(inches)

Turns

3.560

18 *

220 *

7.0100

5.1

5.25

86

10.105

2.5

2.75

42

14.010

1.5

1.50

23

18.100

1.25

14

21.050

0.6

0.75

24.900

0.4

.50

28.050

0.2

.50

Table 1: Loading coil dimensions

* Note: 80m dimensions are approximate and

untested as-yet.

The end cap for each coil consists of a threaded PVC cap that is

drilled for the end bolts. Make sure to select PVC caps that are at

on top. Some manufacturers have the top of the screw on cap domed

and this will cause problems when assembling the coils. For each

coil, one cap has a 1/4 x 3/4" bolt, and a 5/16 x 3/4 bolt. The 1/4"

attaches to the antenna base sections, and the 5/16" connects to the

whip base. Each bolt is passed through the cap and a ring terminal,

star washer and nut are added. Tighten the nut to secure the ring

terminal and prevent the bolt turning in the cap.

6 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 3A: End cap with bolt

Figure 3B: End cap assembled

The caps are next screwed onto the PVC riser to create the complete

coil assembly. First, tighten the pvc caps onto the drilled riser.

Realize that it is normal for some threads to show when the caps are

in place. Adjust the position of the ends of the ring terminals to

align with the holes drilled into the PVC tube by loosening the end

bolts and aligning the ring terminals before re-tightening the nuts.

Figure 4: Completed coil form

To wind the coil, the wire is passed through one set of holes in the

PVC riser and soldered or crimped to the ring terminal under one

bolt. If you plan to solder the terminals, the plastic sleeves on the

crimp portion can be removed to expose the metal. Once the end of

wire is secured, begin winding around the PVC while keeping the

turns in close contact. An easy to do this is to rotate the coil form

7 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

with one hand while using the thumb of the other to feed the wire

onto the form. If you need to stop winding before completion,

electrical or masking tape can be used to secure the already wound

turns. Continue winding to the indicated number of turns while

keeping the windings close spaced and tight and secure the wire by

passing through the other set of holes and connecting to the ring

terminal on that end.

Figure 5: Completed coil

Figure 6: Photo of completed coil. (A pen is shown for size comparison.)

Base Sections

The antenna consists of a 24" base section plus the coil and 6 whip

to form an antenna of 8+ in length. The base section of the antenna

is constructed from 1/4" diameter aluminum rod. For maximum

portability when disassembled each section is 12" and has 1/4-20

threads on each end.

8 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

To prepare the base section cut the 48" rod into 4 equal pieces 12"

in length.

To make the threading easier, bevel the cut ends of the rod using a

sander or le. This will help with starting the threads straight on the

rod.

Be sure that the threading die is not tilted with respect to the rod

axis as the threading starts. While threading, turn slightly

backwards for every 1/4 to 1/2 turn forward to clear chips to clear

debris from the die teeth. Thread each piece for 1/4-20" threads for

approximately 3/8" distance from each end.

Figure 7A: 1/4" aluminum rod cut, beveled and threaded

Figure 7B: Completed threads

Test the threads by screwing into a 1/4-20 coupler nut to ensure that

they function smoothly.

9 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 7C: Rod and coupling

For additional guidance on creating the threaded end of the

aluminum rod, please refer to the Threading section at the end of

this article.

Feedpoint Insulator

Parts List

1/2" x 2" PVC Riser (1)

1/4-20 x 3/4 bolts (2)

1/4-20 x 1.5" bolt (1)

1/4" star washers (5)

1 x 1.5 x 1/8" aluminum (1, cut from a strip of at stock)

1/4" ring terminals (2)

BNC connector (1)

Construction

10 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

The base/center insulator is constructed from a 2" PVC riser with a

1/4" hole drilled through the center as shown in Figure 8.

Figure 8: PVC riser drilled for 1/4" bolt

In addition, a 1/4" hole should be drilled in each of the two PVC

screw caps. The hole is centered in the at end of each cap

To assemble the caps, a star washer is placed on a 1/4"-20 x 3/4" bolt

before it is passed through each from the inside. A ring terminal,

star washer and nut are added to the bolt on the outside and the nut

tightened to secure the connection. See Figure 9.

Feedpoint Insulator

Figure 10A: Feedpoint insulator components

The bracket is formed from 1" x 1.5" x 1/8" at aluminum stock that

is drilled for a bolt on one end and the BNC on the other. The plate

dimensions are 1 x 1.5" with a 1/4" hole centered at 1/4" from one

end. At 1/2" from the opposite end, a 3/8" hole is drilled for the BNC

connector. It is recommended to sand or le the aluminum to

remove burrs and sharp edges.

11 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 10B: BNC Mounting Plate

The BNC connector is installed in the plate using the supplied

hardware.

Next, a 1/4-20 x 1.5" bolt is passed through the PVC riser and the

1/4" hole in the at aluminum and secured by a nut and a star

washer. Approximately 1/4" of the bolt will be exposed and is used

for attaching radials or for supporting the antenna if used as a

dipole.

Each cap is screwed onto the PVC riser and tightened. Once

assembly is complete, short wires are soldered from the BNC

terminals and connected to the ring terminals on each of the caps.

Stranded wire is recommended as it will tolerate exing.

12 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 11: Completed feedpoint insulator

Radials

Radials are a crucial part of the antenna system for any vertical. For

radial wires placed on the ground, the actual length is not critical. A

convenient length such as 15 is a good compromise between length

and portability.

For the PAC12, I recommend use of at least 4 radials of 15 ft each.

They can be prepared from any exible wire (stranded, speaker, zip

cord etc). In this case, I used 15-conductor gray ribbon cable to

produce the radials. It works well and is relatively low weight. The

ribbon is separated into 5 sections of 3 conductors each. On each

section, the insulation is carefully removed from approximately 1/2

inch of the ribbon and the 3 stranded wires twisted together. The

sections may then be twisted together in pairs or left separate and

tinned with solder. Once complete, the ends are trimmed and

crimped or preferably soldered into a 1/4" ring terminal to allow

easy connection to the antenna feed point or base. The point where

the wire enters the ring terminal, heat shrink tubing or electrical

tape can be used to provide strain relief, as the ribbon cable wires

are somewhat fragile. Alternatively, the radials may be connected

using alligator clips rather than ring terminals.

In use, the radials are deployed on the ground in as straight lines as

possible in a bicycle wheel spoke pattern around the antenna base.

They are connected to the coax shield side of the feed point on the

shield side of the insulator or at the center bolt. Addition of a wing

nut to this bolt makes it easy to connect ring terminals.

APPENDIX B:

Guidelines for Threading Aluminum Rod

Threading tools are available at most hardware and tool stores.

Assembly of the Pac12 vertical/dipole requires a 6-32 tap (for cutting

inside threads) and a 1/4-20 threading die for preparation of the

aluminum rod sections. You can purchase either separate tools or

buy a tap and die set that contains a range of sizes. If you purchase

the tools separately, you will need the tap, handle and a #36 drill.

For the die, you will need to but a 1/4-20 die, and a handle.

13 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 12A: Die and handle

Figure 12B: Die in handle

On examination, you will note that the threading die has cutting

heads in the form of threads around the interior. The cutters are

also tapered so that one side has a larger opening.

When threading, the blank rod is started into the larger opening

side. This allows the cutting heat to engage the rod a bit before the

threading begins. Thus, the length of threads at any point will be a

bit less than the thickness of the threading die.

When cutting threads, it is important to work slowly. Using tapping

uid or light oil will help with the process. Turning the tool forward

and then a bit backward on each 1/4 turn or so will help to keep the

cutters free of debris and produce a cleaner thread. When threading

rod, it is important to secure it in a vise or pliers to prevent

slippage. Wooden blocks or other protective material may be used to

prevent the vice jaws from marring the surface of the aluminum rod.

14 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Figure 13: Cutting the threads

The threads should be uniform and clean. You may nd that the end

of the rod will need to be led to remove burrs after threading.

Once the threads are complete, test by screwing into one of the

1/4-20 rod coupling nuts. It should thread smoothly onto the rod if

not, check for burrs, damage or debris that may prevent engagement

of the threads. Both ends of the two 12" rods are threaded. If you are

also preparing a ground spike, thread only one end and le or sand

the other to a point to allow it to be inserted into the soil.

APPENDIX C:

PAC-12 Construction Examples

PAC-12 parts and coil collection of Dave Maliniak, AD2A

15 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

AD2A checking out a PAC-12 feedpoint insulator made by K2MGM

16 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

PAC-12 in a stand, by Ed Roswell K2MGM

K2MGM carrying case for PAC-12

17 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

20m beam made with PAC-12 antennas (by KA5DVS)

James Bennett, KA5DVS speaking to NJQRP Club, describing his modified PAC-12 with Slinky as

loading coil

18 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Here's the PAC-12 Slinky all set up

19 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

Joe Everhart, N2CX totes his PAC-12 in this nice hard-body plastic case

PAC-12 at Pacificon 2001

20 of 21

06/09/2015 11:10 PM

PAC-12 Antenna by KA5DVS

http://www.njqrp.org/pac-12/

PAC-12 Slinky Dipole

Last Modied: May 29, 2006

21 of 21

06/09/2015 11:10 PM

You might also like

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDocument349 pagesBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Designing and Constructing A Magnetic Loop Antenna: Presentation To The Richmond Amateur Radio ClubDocument52 pagesDesigning and Constructing A Magnetic Loop Antenna: Presentation To The Richmond Amateur Radio ClubDarko EpliNo ratings yet

- Pacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsDocument6 pagesPacific Antenna 20 and 40M Lightweight Dipole Kit: Diagram Showing Configuration and Approximate LengthsedosviracNo ratings yet

- Lathe Project - Cannon Barrel (TMJ 209)Document7 pagesLathe Project - Cannon Barrel (TMJ 209)sanu7blyNo ratings yet

- Yaesu Vx-3r Service ManualDocument44 pagesYaesu Vx-3r Service ManuallimazulusNo ratings yet

- Yaesu Vx-3r Service ManualDocument44 pagesYaesu Vx-3r Service ManuallimazulusNo ratings yet

- Biquad Antenna ConstructionDocument7 pagesBiquad Antenna ConstructionLlodiam OrtizNo ratings yet

- 80 15m Safari Inverted Vee Antenna g3rwf Iss 1 31Document5 pages80 15m Safari Inverted Vee Antenna g3rwf Iss 1 31Muharry HabibNo ratings yet

- End Fed 40meter Half Wave AntennaDocument4 pagesEnd Fed 40meter Half Wave AntennaDefaultAnomoly100% (1)

- FT MeterDocument5 pagesFT MeterlimazulusNo ratings yet

- FT MeterDocument5 pagesFT MeterlimazulusNo ratings yet

- 2 Meter Sling Shot AntennaDocument7 pages2 Meter Sling Shot AntennaNiko DiamesisNo ratings yet

- NVIS 2040-80 20antennaDocument7 pagesNVIS 2040-80 20antennaChris VinceNo ratings yet

- FT857 897 - CF1005 FixDocument4 pagesFT857 897 - CF1005 FixlimazulusNo ratings yet

- Limited-Space 160m Half SloperDocument4 pagesLimited-Space 160m Half Sloper1c1b964d100% (1)

- GPS Helix Antenna Construction GuideDocument6 pagesGPS Helix Antenna Construction GuideGuadalajara Jalisco100% (1)

- Build A 9dB, 70cm Collinear AntennaDocument3 pagesBuild A 9dB, 70cm Collinear Antennadr3x100% (1)

- A Horizontally Polarized Omni-Directional AntennaDocument2 pagesA Horizontally Polarized Omni-Directional AntennaHam Radio HSMM100% (1)

- Basic Fishing GearDocument41 pagesBasic Fishing GearFayaz Mohamed Khalfan100% (3)

- Build the Award-Winning PAC-12 Multi-Band Portable Vertical AntennaDocument12 pagesBuild the Award-Winning PAC-12 Multi-Band Portable Vertical AntennaJose Antonio BustosNo ratings yet

- Making Your Own Discone AntennaDocument172 pagesMaking Your Own Discone AntennaTayyab Hassan100% (3)

- 2 Meter Backpack Quad AntennaDocument27 pages2 Meter Backpack Quad Antennaadel agustiNo ratings yet

- How Make Wifi Feed HornDocument5 pagesHow Make Wifi Feed HornRajesh Punia100% (2)

- Antenna HandoutDocument8 pagesAntenna HandoutPhil BoxxNo ratings yet

- FT-897 Problems and FixesDocument2 pagesFT-897 Problems and FixeslimazulusNo ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- DIY Fractal HDTV AntennaDocument33 pagesDIY Fractal HDTV AntennaLeonel RodriguezNo ratings yet

- End Fed 6 - 40 Meter Multiband HF AntennaDocument6 pagesEnd Fed 6 - 40 Meter Multiband HF AntennalimazulusNo ratings yet

- End Fed 6 - 40 Meter Multiband HF AntennaDocument6 pagesEnd Fed 6 - 40 Meter Multiband HF AntennalimazulusNo ratings yet

- Samsung PartsDocument352 pagesSamsung PartsYustinus Ericko75% (4)

- Build a High-Gain Slim Jim Antenna for Ham Radio Bands Under 40 CharactersDocument9 pagesBuild a High-Gain Slim Jim Antenna for Ham Radio Bands Under 40 CharactersAmanda HardyNo ratings yet

- More Radio AntennaeDocument5 pagesMore Radio Antennaenw2sNo ratings yet

- Plumbing Materials and Fixtures ReportingDocument125 pagesPlumbing Materials and Fixtures ReportingChristine De JesusNo ratings yet

- Stacked 2m Array Dipole PDFDocument6 pagesStacked 2m Array Dipole PDFWillowNo ratings yet

- 6 Valve Regenerative Receiver With Automatic Regeneration ControlDocument8 pages6 Valve Regenerative Receiver With Automatic Regeneration ControlTEDY-RNo ratings yet

- HINO FM 1000 HR Service SheetDocument7 pagesHINO FM 1000 HR Service SheetYudi AriantoNo ratings yet

- Build The PAC 12Document19 pagesBuild The PAC 12ANdreaNo ratings yet

- A Q&D Multiband AntennaDocument2 pagesA Q&D Multiband AntennaDomingo ArroyoNo ratings yet

- Autocostruzione NVIS Antenna PDFDocument7 pagesAutocostruzione NVIS Antenna PDFjohnnibigNo ratings yet

- Inexpensive 17-Meter VerticalDocument10 pagesInexpensive 17-Meter VerticalSwlVUNo ratings yet

- A $20 HF Mobile Antenna: A Few Hours of Fun With PVC and Wire and You've Got Yourself A Respectable Road Radiator!Document4 pagesA $20 HF Mobile Antenna: A Few Hours of Fun With PVC and Wire and You've Got Yourself A Respectable Road Radiator!Marckos FrancoNo ratings yet

- Ilovepdf MergedDocument5 pagesIlovepdf Mergedvelin panchevNo ratings yet

- Features, Electrical Design, and Efficiency of The Rubber Duck AntennaDocument11 pagesFeatures, Electrical Design, and Efficiency of The Rubber Duck AntennajackNo ratings yet

- Long Range TX Antenna InstallDocument19 pagesLong Range TX Antenna InstallRyan KeyNo ratings yet

- CollantDocument2 pagesCollantpogee752No ratings yet

- Easy HT Improvements: by N6JSX 09/2013Document3 pagesEasy HT Improvements: by N6JSX 09/2013jujachaves silvaNo ratings yet

- Home 2.4ghzDocument12 pagesHome 2.4ghzjovicaradNo ratings yet

- Carc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableDocument9 pagesCarc Buildathon Project: A Tuneable Magnetic Loop Antenna For 7Mhz Made From Coaxial CableLuca Di ColaNo ratings yet

- Super Simple Ipod FM Transmitter - MakeDocument14 pagesSuper Simple Ipod FM Transmitter - MakeAisha RobinsonNo ratings yet

- Av 12avqDocument20 pagesAv 12avqalienagaNo ratings yet

- V-2R VHF Collinear Vertical Antenna ManualDocument7 pagesV-2R VHF Collinear Vertical Antenna ManualIrwan Wiradinata SondaNo ratings yet

- KK5JY Small Transmitting Loop ProjectDocument17 pagesKK5JY Small Transmitting Loop ProjecttlebrykNo ratings yet

- 70cm Collinear AntennaDocument3 pages70cm Collinear AntennaRds Comunicaciones EirlNo ratings yet

- Build a 9dB 70cm Collinear Antenna from CoaxDocument3 pagesBuild a 9dB 70cm Collinear Antenna from CoaxMio ClimberNo ratings yet

- Cha Counterpoise 15.0Document7 pagesCha Counterpoise 15.0Jernej BattistaNo ratings yet

- 2 Meter Phased Vert AntDocument6 pages2 Meter Phased Vert AntBenny SNo ratings yet

- Build Double Bazooka PDFDocument11 pagesBuild Double Bazooka PDFAtin surelawatinNo ratings yet

- Antenna Semi Vertical 7 BandasDocument6 pagesAntenna Semi Vertical 7 BandasTeodoro LeónNo ratings yet

- VHF Collinear Vertical Antenna ManualDocument8 pagesVHF Collinear Vertical Antenna ManualToto W. JuniartoNo ratings yet

- Endfed6 40Document8 pagesEndfed6 40Leopoldo AlvarezNo ratings yet

- Handmade Slim Jim Antenna's by N9TAXDocument8 pagesHandmade Slim Jim Antenna's by N9TAXshubhamformeNo ratings yet

- Mini LoopDocument5 pagesMini LooptiozecaNo ratings yet

- Antena Movil HFDocument10 pagesAntena Movil HF10sd156100% (1)

- FM TheoryDocument8 pagesFM TheoryMainak BandyopadhyayNo ratings yet

- Printed Antennas for Wireless CommunicationsFrom EverandPrinted Antennas for Wireless CommunicationsRod WaterhouseNo ratings yet

- Microstrip and Printed Antennas: New Trends, Techniques and ApplicationsFrom EverandMicrostrip and Printed Antennas: New Trends, Techniques and ApplicationsDebatosh GuhaRating: 4 out of 5 stars4/5 (1)

- OpenTrackerUSB ManualDocument43 pagesOpenTrackerUSB ManuallimazulusNo ratings yet

- FT1DR/DE Software Update InformationDocument2 pagesFT1DR/DE Software Update InformationlimazulusNo ratings yet

- Ft1dr Aprs EngDocument68 pagesFt1dr Aprs EnglimazulusNo ratings yet

- 9V Charger RevBDocument2 pages9V Charger RevBlimazulusNo ratings yet

- Aprs Event Tracker SetupDocument6 pagesAprs Event Tracker SetuplimazulusNo ratings yet

- Hitachi MicrocontrollersDocument5 pagesHitachi Microcontrollerslimazulus100% (1)

- FT 897 Static ProtectionDocument1 pageFT 897 Static ProtectionlimazulusNo ratings yet

- Ft1d Ams Sheet Eng Eh044m569Document1 pageFt1d Ams Sheet Eng Eh044m569limazulusNo ratings yet

- Aprs Event Tracker SetupDocument6 pagesAprs Event Tracker SetuplimazulusNo ratings yet

- SCU-18 Driver Installation ManualDocument14 pagesSCU-18 Driver Installation ManuallimazulusNo ratings yet

- Vertex VX 2000 BrochureDocument2 pagesVertex VX 2000 BrochurelimazulusNo ratings yet

- Ft1d Standby Beep Eng Eh044m554Document1 pageFt1d Standby Beep Eng Eh044m554limazulusNo ratings yet

- Catalogue Transformers - AQ MagnitDocument16 pagesCatalogue Transformers - AQ MagnitlimazulusNo ratings yet

- Yaesu Ft-817nd Service Manual EngDocument111 pagesYaesu Ft-817nd Service Manual EnglimazulusNo ratings yet

- FT817 DIY Data Modes Interface v2.0Document7 pagesFT817 DIY Data Modes Interface v2.0limazulusNo ratings yet

- APRS Equipment OptionsDocument5 pagesAPRS Equipment OptionslimazulusNo ratings yet

- Adtrx1v1 3 - Yu1lmDocument16 pagesAdtrx1v1 3 - Yu1lmlimazulusNo ratings yet

- IARU R1 VHF UHF Microwave BandplanDocument26 pagesIARU R1 VHF UHF Microwave BandplanlimazulusNo ratings yet

- Essential Fishing Knots PDFDocument4 pagesEssential Fishing Knots PDFDaniel Nicolas BriccolaNo ratings yet

- 2SC2625Document4 pages2SC2625limazulusNo ratings yet

- Ua 7805Document20 pagesUa 7805buayamyNo ratings yet

- CRT 48-35L PS EuDocument35 pagesCRT 48-35L PS Eujose alvaradoNo ratings yet

- VSA-E03: Audio/Video Multichannel AmplifierDocument48 pagesVSA-E03: Audio/Video Multichannel AmplifierChristian MulatilloNo ratings yet

- 72-10 YaDocument72 pages72-10 YaBEST STREET WORKOUT LCNo ratings yet

- BP2800Document4 pagesBP2800Praveen KumarNo ratings yet

- BIG ToolingDocument324 pagesBIG Toolingtrevorwoest0% (1)

- Elna 2300 Parts List GeneralDocument19 pagesElna 2300 Parts List GeneralRepuestos PartsNo ratings yet

- JVC RX - 6000VDocument39 pagesJVC RX - 6000VturucNo ratings yet

- Numeros de Parte FrecuentesDocument5 pagesNumeros de Parte FrecuentesJOSUÉ CABRERANo ratings yet

- PC SP 8300DN PartsIndexDocument20 pagesPC SP 8300DN PartsIndexJorgeNo ratings yet

- RXA800 Firmware Update Ver 2.05Document5 pagesRXA800 Firmware Update Ver 2.05croft59No ratings yet

- Electrical Layout-Sports FacilityDocument2 pagesElectrical Layout-Sports FacilityPatty GorospeNo ratings yet

- Positive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessDocument2 pagesPositive Displacement Air Blowers - Sizes 1 & 2: Based On SuccessRobert R. TiinNo ratings yet

- EME Unit 5 Lathe and Drilling Machines by Kalyan ChakravarthyDocument51 pagesEME Unit 5 Lathe and Drilling Machines by Kalyan ChakravarthyRavichandran GNo ratings yet

- Efficient Hydraulic Lift System Parts BreakdownDocument29 pagesEfficient Hydraulic Lift System Parts BreakdownTuan VuNo ratings yet

- Seiko PW. LPW Operator's GuideDocument4 pagesSeiko PW. LPW Operator's GuideantnioNo ratings yet

- Manual Samsung t24c550ndDocument46 pagesManual Samsung t24c550ndBillysx CastillenseNo ratings yet

- Final Work of English: Semester: Iv Technical: EnglishDocument22 pagesFinal Work of English: Semester: Iv Technical: EnglishAlexander Giron VillenaNo ratings yet

- Screws and Bits CatalogueDocument30 pagesScrews and Bits Cataloguegfhjhj gfsdasaNo ratings yet

- Hillsdale Elec Term 2020 Full CatalogDocument44 pagesHillsdale Elec Term 2020 Full CatalogBillNo ratings yet

- Kaizen Super - ManualDocument59 pagesKaizen Super - Manualvser19100% (1)

- EIM 10 Quarter 4 - Module 6 Nstalling Wiring Devices For Floor and Ground Fault Current Interrupting OutletDocument6 pagesEIM 10 Quarter 4 - Module 6 Nstalling Wiring Devices For Floor and Ground Fault Current Interrupting OutletEDU CHIONGNo ratings yet

- Planetary Gearbox For Servo Motor 2014Document40 pagesPlanetary Gearbox For Servo Motor 2014Blaze123xNo ratings yet

- TECNO CAMON 30 Series Specs Via Revu PhilippinesDocument2 pagesTECNO CAMON 30 Series Specs Via Revu PhilippinesAlora Uy GuerreroNo ratings yet

- Paasche CompressorDocument2 pagesPaasche CompressorKevin McGrathNo ratings yet