Professional Documents

Culture Documents

RT Duroid 5870 5880 Data Sheet

Uploaded by

Kingslayer RennesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT Duroid 5870 5880 Data Sheet

Uploaded by

Kingslayer RennesCopyright:

Available Formats

Data Sheet

RT/duroid 5870 /5880

High Frequency Laminates

Features:

RT/duroid 5870 and 5880 glass microfiber reinforced PTFE

composites are designed for exacting stripline and microstrip

circuit applications.

Lowest electrical loss for reinforced

PTFE material

Low moisture absorption

Isotropic

Uniform electrical properties over

frequency

Excellent chemical resistance

Some Typical Applications:

Glass reinforcing microfibers are randomly oriented to

maximize benefits of fiber reinforcement in the directions

most valuable to circuit producers and in the final circuit

application.

The dielectric constant of RT/duroid 5870 and 5880 laminates

is uniform from panel to panel and is constant over a wide

frequency range.

Its low dissipation factor extends the usefulness of RT/duroid

5870 and 5880 laminates to Ku-band and above.

RT/duroid 5870 and 5880 laminates are easily cut, sheared

and machined to shape. They are resistant to all solvents

and reagents, hot or cold, normally used in etching printed

circuits or in plating edges and holes.

Normally supplied as a laminate with electrodeposited

copper of to 2 ounces/ ft.2 (8to 70m) or reverse treated

EDC on both sides, RT/duroid 5870 and 5880 composites can

also be clad with rolled copper foil for more critical electrical

applications. Cladding with aluminum, copper or brass plate

may also be specified.

When ordering RT/duroid 5870 and 5880 laminates, it is

important to specify dielectric thickness, tolerance, rolled,

electrodeposited or reverse treated copper foil, and weight

of copper foil required.

100 S. Roosevelt Avenue, Chandler, AZ 85226

Tel: 480-961-1382 Fax: 480-961-4533 www.rogerscorp.com

Page 1 of 2

Commercial Airline Broadband

Antennas

Microstrip and Stripline Circuits

Millimeter Wave Applications

Military Radar Systems

Missile Guidance Systems

Point to Point Digital Radio Antennas

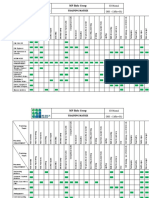

PROPERTY

TYPICAL VALUES

DIRECTION

UNITS[3]

CONDITION

TEST METHOD

2.20

2.20 0.02 spec.

Z

Z

N/A

C24/23/50

C24/23/50

1 MHz IPC-TM-650 2.5.5.3

10 GHz IPC-TM 2.5.5.5

2.33

2.20

N/A

8 GHz - 40 GHz

Differential Phase Length

Method

0.0005

0.0012

0.0004

0.0009

Z

Z

N/A

C24/23/50

C24/23/50

1 MHz IPC-TM-650, 2.5.5.3

10 GHz IPC-TM-2.5.5.5

RT/duroid 5870

RT/duroid 5880

Dielectric Constant, r

2.33

2.33 0.02 spec.

Dielectric Constant, r

Dissipation Factor, tan

[1]

Process

[4]

Design

Thermal Coefficient of r

-115

-125

ppm/C

-50 - 150C

IPC-TM-650, 2.5.5.5

Volume Resistivity

2 X 107

2 X 107

Mohm cm

C96/35/90

ASTM D257

Surface Resistivity

2 X 10

3 X 10

Mohm

C/96/35/90

ASTM D257

N/A

J/g/K

(cal/g/C)

N/A

Calculated

ASTM D638

ASTM D695

Specific Heat

Tensile Modulus

ultimate stress

ultimate strain

Compressive Modulus

ultimate stress

ultimate strain

0.96 (0.23)

0.96 (0.23)

Test at

23 C

Test at

100 C

Test at

23 C

Test at

100 C

N/A

1300 (189)

490 (71)

1070

(156)

450 (65)

1280 (185)

430 (63)

860 (125)

380 (55)

50 (7.3)

34 (4.8)

29 (4.2)

20 (2.9)

42 (6.1)

34 (4.8)

27 (3.9)

18 (2.6)

9.8

8.7

6.0

7.2

9.8

8.6

4.9

5.8

1210 (176)

680 (99)

710 (103)

500 (73)

1360 (198)

860 (125)

710 (103)

500 (73)

803 (120)

520 (76)

940 (136)

670 (97)

30 (4.4)

23 (3.4)

27 (3.9)

22 (3.2)

37 (5.3)

25 (3.7)

29 (5.3)

21 (3.1)

54 (7.8)

37 (5.3)

52 (7.5)

43 (6.3)

4.0

4.3

8.5

8.4

3.3

3.3

7.7

7.8

8.7

8.5

12.5

17.6

MPa

(kpsi)

MPa

(kpsi)

Moisture Absorption

0.02

0.02

N/A

.062 (1.6mm)

D48/50

ASTM D570

Thermal Conductivity

0.22

0.20

W/m/K

80C

ASTM C518

Coefficient of

Thermal Expansion

22

28

173

31

48

237

X

Y

Z

ppm/C

0-100C

IPC-TM-650, 2.4.41

Td

500

500

N/A

C TGA

N/A

ASTM D3850

Density

2.2

2.2

N/A

gm/cm

N/A

ASTM D792

1 oz (35mm)

EDC foil

27.2 (4.8)

31.2 (5.5)

N/A

pli (N/

mm)

Flammability

V-0

V-0

N/A

N/A

N/A

UL94

Lead-Free Process

Compatible

Yes

Yes

N/A

N/A

N/A

N/A

Copper Peel

after solder

float

IPC-TM-650 2.4.8

[1] Specification values are measured per IPC-TM-650, method 2.5.5.5 @ ~10GHz, 23C. Testing based on 1 oz. electrodeposited copper foil. er values and tolerance reported by

IPC-TM-650 method 2.5.5.5 are the basis for quality acceptance, but for some products these values may be incorrect for design purposes, especially microstrip designs. We

recommend that prototype boards for new designs be verified for desired electrical performance.

[2] Typical values should not be used for specification limits, except where noted.

[3] SI unit given first with other frequently used units in parentheses.

[4] The design Dk is an average number from several different tested lots of material and on the most common thickness/s. If more detailed information is required, please contact

Rogers Corporation. Refer to Rogers technical paper Dielectric Properties of High Frequency Materials available at http://www.rogerscorp.com.

STANDARD THICKNESS

0.005 (0.127mm),

0.010 (0.254mm),

0.015 (0.381mm),

0.020 (0.508mm),

0.031 (0.787mm)

0.062 (1.575mm)

0.125 (3.175mm)

STANDARD PANEL SIZE

18 X 12 (457 X 305mm)

18 X 24 (457 X 610mm)

18 X 36 (457 X 915mm)

18 X 48 (457 X 1.224m)

STANDARD COPPER CLADDING

oz. (9 m) electrodeposited copper foil depending on dielectric thickness

oz. (17m), 1 oz. (35m), 2 oz. (70m) electrodeposited reverse treated EDC and rolled

copper foil.

Thick metal cladding are also available. Contact customer service for available claddings

and panel sizes.

The information in this data sheet is intended to assist you in designing with Rogers circuit materials. It is not intended to and does not create any warranties express or

implied, including any warranty of merchantability or fitness for a particular purpose or that the results shown on this data sheet will be achieved by a user for a particular

purpose. The user should determine the suitability of Rogers circuit materials for each application.

These commodities, technology and software are exported from the United States in accordance with the Export Administration regulations. Diversion contrary to U.S. law prohibited.

RT/duroid, and the Rogers logo are licensed trademarks of Rogers Corporation.

2015 Rogers Corporation, Printed in U.S.A. All rights reserved. Revised 1109 041515 Publication #92-101

Page 2 of 2

You might also like

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous yz5MQGtNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetdrhammoudaNo ratings yet

- Rogers Corp Product Selector GuideDocument3 pagesRogers Corp Product Selector GuideGeorgios SarrisNo ratings yet

- RT Duroid 6006 6010 Laminate Data SheetDocument2 pagesRT Duroid 6006 6010 Laminate Data SheetSaravanakumar SermarajaNo ratings yet

- What Is Rogers RTDuroid 5880LZ MaterialDocument8 pagesWhat Is Rogers RTDuroid 5880LZ MaterialjackNo ratings yet

- RO3035 Laminate Data Sheet PDFDocument2 pagesRO3035 Laminate Data Sheet PDFrahul05singhaNo ratings yet

- RT Duroid 5870 5880 Data SheetDocument2 pagesRT Duroid 5870 5880 Data SheetAnonymous zBSE9MNo ratings yet

- RT-duroid 5870 - 5880 Data SheetDocument2 pagesRT-duroid 5870 - 5880 Data SheetDenis CarlosNo ratings yet

- RO4000 Laminates Data SheetDocument4 pagesRO4000 Laminates Data SheetJavier De La VegaNo ratings yet

- RO4835IND LoPro Laminate Data SheetDocument2 pagesRO4835IND LoPro Laminate Data SheetChar OuzoNo ratings yet

- RT Duroid 5870 5880 Data Sheet PDFDocument2 pagesRT Duroid 5870 5880 Data Sheet PDFNom MonNo ratings yet

- RT-duroid 6006-6010LM Laminate Data Sheet PDFDocument2 pagesRT-duroid 6006-6010LM Laminate Data Sheet PDFClaudia FonsecaNo ratings yet

- RO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Document4 pagesRO3000 Laminate Data Sheet - RO3003, RO3006, RO3010Juliano Rodrigues BrianezeNo ratings yet

- High Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFDocument12 pagesHigh Frequency Laminates - Product Selector Guide and Standard Thicknesses and Tolerances Low Resolution PDFrahul05singhaNo ratings yet

- Reliability and Key Properties of RT Duroid 6002Document4 pagesReliability and Key Properties of RT Duroid 6002xdsesNo ratings yet

- RO3000 Pour Rogers 3006 PDFDocument4 pagesRO3000 Pour Rogers 3006 PDFTeddy112No ratings yet

- RT Duroid 6002 Laminate Data SheetDocument2 pagesRT Duroid 6002 Laminate Data SheetPratikNo ratings yet

- Ferrite Chip Inductors - 0805AF (2012)Document2 pagesFerrite Chip Inductors - 0805AF (2012)TestronicpartsNo ratings yet

- ST Series Soft Termination MLCCsDocument10 pagesST Series Soft Termination MLCCsppanagos5664No ratings yet

- RO4500 Series Cost Performance Antenna Grade LaminatesDocument2 pagesRO4500 Series Cost Performance Antenna Grade LaminatesRodrigoFlorianNo ratings yet

- Taconic RF-35TC Technical Data SheetDocument4 pagesTaconic RF-35TC Technical Data SheetTato YudayanaNo ratings yet

- RO4000 High Frequency Laminate With TICER FoilDocument2 pagesRO4000 High Frequency Laminate With TICER FoilNur Afifah OmarNo ratings yet

- RO3000 Laminate Data Sheet RO3003 RO3006 RO3010 RO3035Document4 pagesRO3000 Laminate Data Sheet RO3003 RO3006 RO3010 RO3035Joe MullerNo ratings yet

- RO4725JXR & RO4730JXR Antenna Grade Laminates Data SheetDocument2 pagesRO4725JXR & RO4730JXR Antenna Grade Laminates Data SheetdrhammoudaNo ratings yet

- HTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HCV With Bracket (English)crplzNo ratings yet

- RO4500 Antenna Grade Laminates For High Volume ApplicationsDocument4 pagesRO4500 Antenna Grade Laminates For High Volume ApplicationsMeenakshi Sundaram KaruppiahNo ratings yet

- What Is Rogers RT Duroid 5870 Laminate For PCBDocument8 pagesWhat Is Rogers RT Duroid 5870 Laminate For PCBjackNo ratings yet

- RO4835 Laminate Data SheetDocument2 pagesRO4835 Laminate Data SheetChar OuzoNo ratings yet

- RT-duroid 6202 Laminate Data SheetDocument2 pagesRT-duroid 6202 Laminate Data SheetAditya Bonnerjee 21BEC0384No ratings yet

- Datasheets - High TG Material: General InformationDocument3 pagesDatasheets - High TG Material: General InformationAnonymous T9zQADFxZRNo ratings yet

- What Is Rogers RT Duroid 6002 For PCBDocument10 pagesWhat Is Rogers RT Duroid 6002 For PCBjackNo ratings yet

- Types of Ferrite Materials: Material 33Document4 pagesTypes of Ferrite Materials: Material 33lux302006No ratings yet

- 3M Scotch 50 51 Data SheetDocument4 pages3M Scotch 50 51 Data SheetPedro Francisco Hernandez MendozaNo ratings yet

- RF-35TC thermally conductive low loss laminateDocument4 pagesRF-35TC thermally conductive low loss laminateElectronic BoyNo ratings yet

- What Is Rogers Ro4003c MaterialDocument6 pagesWhat Is Rogers Ro4003c MaterialjackNo ratings yet

- E Rogers 4350b HF WWW - Multi Circuit Boards - EuDocument4 pagesE Rogers 4350b HF WWW - Multi Circuit Boards - EuSaad MohsinNo ratings yet

- RO4830 High Frequency Laminates Data SheetDocument4 pagesRO4830 High Frequency Laminates Data SheetSimbisaiNo ratings yet

- Ceramics ResonatorsDocument3 pagesCeramics Resonatorshakim-brestNo ratings yet

- RT/duroid 6006/6010LM High Frequency Laminates: FeaturesDocument2 pagesRT/duroid 6006/6010LM High Frequency Laminates: FeaturesyyryNo ratings yet

- R04350BDocument1 pageR04350BEduardo OlivaresNo ratings yet

- High Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionDocument12 pagesHigh Frequency Laminates Product Selector Guide and Standard Thicknesses and Tolerances Low ResolutionPriyanka ChoudharyNo ratings yet

- MPPTDraftDocument2 pagesMPPTDraftosadeamos8684No ratings yet

- GP-MR200 Stator Wire Details PDFDocument2 pagesGP-MR200 Stator Wire Details PDFButnaru JanNo ratings yet

- High Power Resistors: Type Bds 100 SeriesDocument2 pagesHigh Power Resistors: Type Bds 100 Seriesmanjubd1No ratings yet

- Where To Buy Rogers RT Duroid 5880 LaminateDocument5 pagesWhere To Buy Rogers RT Duroid 5880 LaminatejackNo ratings yet

- 3M Electrically Conductive Transfer TapesDocument6 pages3M Electrically Conductive Transfer TapesmazacotesNo ratings yet

- HTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HSV (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HSV (English)crplzNo ratings yet

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - BR (English)Document4 pagesHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - BR (English)crplzNo ratings yet

- HTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HMV (English)Document3 pagesHTR India - Products - Wire Wound Resistors - Ceramic Encased Resistor - HMV (English)crplzNo ratings yet

- RT-Duroid 5880 PropertiesDocument2 pagesRT-Duroid 5880 PropertiesJesus GarciaNo ratings yet

- Mgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedDocument2 pagesMgt-Xlpe Oscr LSZH Swa LSZH 2.5 RedJason Secret100% (1)

- HTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFP (English)Document4 pagesHTR India - Products - Wire Wound Resistors - Silicone Coated Resistors - HFP (English)crplzNo ratings yet

- HTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)Document3 pagesHTR India - Products - Current Sense Resistors - Ceramic Encased Resistor - RL (English)crplzNo ratings yet

- Full Intruction About Rogers Circuit Board MaterialDocument16 pagesFull Intruction About Rogers Circuit Board MaterialjackNo ratings yet

- D 025 Topflex Motor 109Document2 pagesD 025 Topflex Motor 109MarcosNo ratings yet

- 2 - 7714-U0gy8-HaDocument1 page2 - 7714-U0gy8-HaMohd Sami UddinNo ratings yet

- Specification: Specification of Electrical Double Layer CapacitorDocument16 pagesSpecification: Specification of Electrical Double Layer CapacitorselocaNo ratings yet

- Increased Safety Stator Winding Temperature Sensors: Specification and Order OptionsDocument2 pagesIncreased Safety Stator Winding Temperature Sensors: Specification and Order Optionsswapneel_kulkarniNo ratings yet

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- AWWA Bacterial Regrowth in Distr Sys PDFDocument368 pagesAWWA Bacterial Regrowth in Distr Sys PDFsaishankarlNo ratings yet

- 06 Scaffold Erection and Dismantling (JHA-JSA)Document4 pages06 Scaffold Erection and Dismantling (JHA-JSA)AmanNo ratings yet

- Chips Unlimited Blend LibraryDocument20 pagesChips Unlimited Blend Librarymizan sallehNo ratings yet

- Aqua Mon 4000 PH Red Ox AnalyserDocument4 pagesAqua Mon 4000 PH Red Ox Analyserarvindgupta_2005No ratings yet

- DCT PIR insulation technical data sheetDocument4 pagesDCT PIR insulation technical data sheetHenky MantophaniNo ratings yet

- Electric Charge: Conservation and Quantization Conductors, Insulators, and Induced ChargesDocument21 pagesElectric Charge: Conservation and Quantization Conductors, Insulators, and Induced ChargesAcadGucciManeNo ratings yet

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocument139 pagesSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)

- Reviewer On Nervous System Grade VIDocument4 pagesReviewer On Nervous System Grade VIKent Francis LayaguinNo ratings yet

- Co2 OrderDocument2 pagesCo2 OrderRamakant PatelNo ratings yet

- r48 2000e3 Rectifier User ManualDocument26 pagesr48 2000e3 Rectifier User Manualjose luis rivera sotoNo ratings yet

- Complete The Table With The Missing WordsDocument2 pagesComplete The Table With The Missing WordssoniaNo ratings yet

- MP Birla Group: Training MatrixDocument3 pagesMP Birla Group: Training MatrixAprilia kusumaNo ratings yet

- 02 - AFT - Know Your Pump & System Curves - Part 2ADocument8 pages02 - AFT - Know Your Pump & System Curves - Part 2AAlfonso José García LagunaNo ratings yet

- Self EducationDocument21 pagesSelf EducationSwami VedatitanandaNo ratings yet

- Rec2009 025 PDFDocument172 pagesRec2009 025 PDFEkaStaVTVNo ratings yet

- Router ScriptDocument10 pagesRouter ScriptfahadNo ratings yet

- 6013 GCS-CONTROLS enDocument5 pages6013 GCS-CONTROLS enMuhammad SyaqirinNo ratings yet

- IRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsDocument2 pagesIRELAND - Rivers, Lakes and Mountains: Look at The Maps and Answer These QuestionsHannaNo ratings yet

- SRWM M.PDocument34 pagesSRWM M.PAmare BayeNo ratings yet

- Why Britain Had Christianity EarlyDocument47 pagesWhy Britain Had Christianity EarlyChris WoodNo ratings yet

- Exercise 56 - Narration and SequenceDocument14 pagesExercise 56 - Narration and SequenceLéoKostasNo ratings yet

- #4 Types of Food, Ingredients and Procedures.Document7 pages#4 Types of Food, Ingredients and Procedures.Peter GonzálezNo ratings yet

- Final 401Document8 pagesFinal 401Hong Chul NamNo ratings yet

- W2AEW Videos (Apr 29, 2017) Topics Listed NumericallyDocument12 pagesW2AEW Videos (Apr 29, 2017) Topics Listed Numericallyamol1agarwalNo ratings yet

- Introduction To The Philosophy of Science First PartDocument138 pagesIntroduction To The Philosophy of Science First PartChandra Sekhar Sahu100% (1)

- Picard's Existence and Uniqueness TheoremDocument2 pagesPicard's Existence and Uniqueness Theoremmanjoy dasNo ratings yet

- Toxicology Compendium PDFDocument602 pagesToxicology Compendium PDFJUANNo ratings yet

- Soal Big A Tukpd 2011-2012 RevisiDocument5 pagesSoal Big A Tukpd 2011-2012 RevisiTriana WatiNo ratings yet

- Axminster CarpetDocument19 pagesAxminster Carpetrohit sinhaNo ratings yet