Professional Documents

Culture Documents

MS16995H Screw

Uploaded by

acparaujoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS16995H Screw

Uploaded by

acparaujoCopyright:

Available Formats

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

INCH-POUND

MS16995H

25 April 1997

SUPERSEDING

MS16995G

27 June 1995

MILITARY SPECIFICATION SHEET

SCREW, CAP, SOCKET HEAD- HEXAGON,

CORROSION RESISTANT STEEL, UNC-3A

This specification is approved for use by all Departments and

Agencies of the Department of Defense.

The requirements for acquiring the product described herein shall consist of this specification

sheet and the issue of the following specification listed in that issue of the Department of

Defense Index of Specifications and Standards (DODISS) specified in the solicitation: FF-S-86.

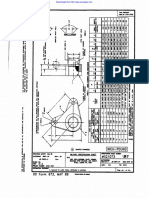

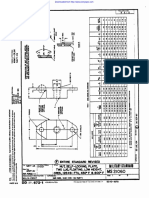

FIGURE 1. Dimensions and configurations.

AMSC N/A

1 of 9

DISTRIBUTION STATEMENT A. Approved for public release; distribution is unlimited.

FSC 5305

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

NOTES: TABLE I. DIMENSIONS AND DASH NUMBERS

Nominal Size

Threads Per Inch

#2 (.0860)

56 UNC-3A

.0860

.0822

#4 (.1120)

40 UNC-3A

.1120

.1075

#6 (.1380)

32 UNC-3A

.1380

.1329

D Body

Max

Min

A Head

Max

Min

.140

.134

.183

.176

.226

.218

H Head Height

Max

Min

.086

.083

.112

.108

.138

.134

S Head Side Height

Min

.077

.101

.124

J Socket Width

Across Flats

Max

Min

.0791

.0781

.0952

.0937

.1111

.1094

T Key Engagement

Min

.038

.051

.064

G Wall Thickness

Min

.029

.038

.047

K Chamfer or Radius

Max

.003

.005

.005

F Fillet Extension

Max

Min

.008

.004

.009

.005

.010

.006

.625

300

Grip

Length

Max

.7500

480

Grip

Length

Max

M Basic Thread Length 1_/ Ref

Min Tensile Strength Load Lbs

L Length

Tolerance

.188

.250

.375

.500

.625

+.000

-.030

Dash

No

Body

Length

Min

1

2

3

4

.750

1.000

1_/ See note 2.

Dash

No

Body

Length

Min

Dash

No

9

10

11

12

16

17

18

19

13

20

21

.7500

730

Grip

Body

Length Length

Max

Min

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

TABLE I. DIMENSIONS AND DASH NUMBERS - continued

Nominal Size

Threads Per Inch

D Body

A Head

#8 (.1640)

32 UNC-3A

.1640

.1585

Max

Min

#10 (.1900)

24 UNC-3A

.1900

.1840

1/4 (.250)

20 UNC-3A

.2500

.2435

Max

Min

.270

.262

.312

.303

.375

.365

H Head Height

Max

Min

.164

.159

.190

.185

.250

.244

S Head Side Height

Min

.148

.171

.225

J Socket Width

Across Flats

Max

Min

.1426

.1406

.1587

.1562

.1900

.1875

T Key Engagement

Min

.077

.090

.120

G Wall Thickness

Min

.056

. 065

.095

K Chamfer or Radius

Max

.005

.005

.008

F Fillet Extension

Max

Min

.012

.007

.014

.009

.014

.009

1_/ Ref

.875

. 875

1.000

M Basic Thread Length

Min Tensile Strength Load Lbs

L Length

Tolerance

.375

.500

.625

.750

.875

1.000

1.250

1.500

1.750

2.000

+.000

-.030

Dash

No

1,120

Grip

Length

Max

Body

Length

Min

Dash

No

25

26

27

28

29

35

36

37

38

39

30

40

41

42

+.000

-.040

1_/ See note 2.

1,400

Grip

Length

Max

Body

Length

Min

Dash

No

2,540

Grip

Length

Max

Body

Length

Min

47

48

49

50

51

.375

.375

.167

.167

52

53

54

55

56

.500

.500

1.000

.250

.250

.750

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

TABLE I. DIMENSIONS AND DASH NUMBERS - continued

Nominal Size

Threads Per Inch

D Body

A Head

5/16(.3125)

18 UNC-3A

.3125

.3053

Max

Min

3/8 (.375)

16 UNC-3A

.3750

.3678

1/2 (.500)

13 UNC-3A

.5000

.4919

Max

Min

.469

.457

.563

.550

.750

.735

H Head Height

Max

Min

.313

.306

.375

.368

.500

.492

S Head Side Height

Min

.281

.337

.450

Socket Width

Across Flats

Max

Min

.2530

.2500

.3160

.3125

.3790

.3750

T Key Engagement

Min

.151

.182

.245

G Wall Thickness

Min

.119

.143

.190

K Chamfer or Radius

Max

.008

.008

.010

F Fillet Extension

Max

Min

.017

.012

.020

.015

.026

.020

M Basic Thread Length 1_/

Ref

1.125

1.250

1.500

6,200

11,300

Min Tensile Strength Load Lbs

Tolerance

L Length

Size 5/16 (.3125)

and 3/8 (.375)

.375

.500

.625

.750

.875

1.000

1.250

1.500

1.750

2.000

+.000

-.030

+.000

-.040

4,190

Size

1/2 (.500)

+.000

-.030

+.000

-.060

2.250

2.500

2.750

3.000

Dash

No

Body

Length

Min

Dash

No

Grip

Length

Max

Body

Length

Min

Dash

No

61

62

63

64

65

77

78

79

80

92

93

66

67

68

69

70

81

82

83

84

85

.500

.500

.187

.187

94

95

96

97

98

86

87

1.000

1.000

.687

.687

71

72

+.000

-.060

Grip

Length

Max

.625

.347

1.125

1.125

.847

.847

+.000

-.080

1_/ See note 2

99

100

101

102

Grip

Length

Max

Body

Length

Min

.750

.750

.750

1.500

.365

.365

.365

1.115

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

TABLE I. DIMENSIONS AND DASH NUMBERS - continued

Nominal Size

Threads Per Inch

D Body

Max

Min

#5/8(.625)

11 UNC-3A

.6250

.6163

Max

Min

.936

.921

H Head Height

Max

Min

.625

.616

S Head Side Height

Min

.562

Socket Width

Across Flats

Max

Min

.5050

.5000

Key Engagement

Min

.307

G Wall Thickness

Min

.238

K Chamfer or Radius

Max

.010

Max

Min

.032

.024

A Head

Fillet Extension

M Basic Thread Length 1_/ Ref

Min Tensile Strength Load Lbs

Dash

No

L Length

Tolerance

1.000

1.250

1.500

1.750

2.000

+.000, -.030

2.250

2.500

2.750

3.000

+.000, -.060

+.000, -.080

1_/ See note 2.

1.750

18,100

Grip

Length

Max

Body

Length

Min

107

108

109

110

111

112

113

114

115

.750

.750

.750

.295

.295

.295

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

NOTES:

1. All dimensions are in inches.

2. The basic thread length M (Table I) is a referenced value controlled by the grip length and L

length as specified.

3. MS16995 supersedes MS35461 in part.

4. In the event of a conflict between the text of this document and the references cited herein, the text of this

document shall take precedence.

5. Unless otherwise specified, issues of referenced documents are those in effect at the time of solicitation.

6. MS16995 Socket Head Cap Screws manufactured prior to 25 April 1997 may be used until stock

is depleted.

REQUIREMENTS:

1. MATERIAL:

Austenitic Corrosion-Resistant Steel screws shall be manufactured from Type 304 (UNS S30400),

Type 304L (UNS S30403), Type 305 (UNS S30500), Type 316 (UNS S31600), Type 316L (UNS

S31603), Type 384 (UNS S38400), or Type XM-7(UNS S30430) in accordance with the chemical

compositions specified in ASTM F 593.

(See Material Identification Marking and Material Code).

2. FINISH:

Passivate in accordance with QQ-P-35 or

Black Oxide coating in accordance with MIL-C-13924, Class 4. (Except for Type 316 or Type

316L).

(See Finish Code).

3. MECHANICAL PROPERTIES:

The minimum tensile strength in load pounds, indicated for each size in Table I, is based on 80,000

PSI minimum tensile strength. Load pounds are calculated by the stress areas indicated in FEDSTD-H28/2. The yield strength, based on 0.2 percent offset, shall be 30,000 PSI minimum. The

minimum hardness shall be HRB 80.

4. MAGNETIC PERMEABILITY:

When specified, screws shall have a magnetic permeability of less than 2.0 (air = 1.0) for a field

strength H = 200 oersteds using a magnetic permeability indicator per ASTM A 342.

Note: Cold worked screws may not be capable of meeting permeability and strength requirements

simultaneously.

5. THREADS:

Screw threads shall be Unified external threads Class 3A UNC in accordance with FED-STD-H28/2.

Acceptability of screw threads shall be in accordance with FED-STD-H28/20, System 22.

Screws above the dashed lines shall have complete (full form) threads extended to within

two (2) threads of the head as measured with a thread ring gage.

6. HEAD STYLE:

Head of screw may be plain or knurled at manufacturers option.

7. MANUFACTURER IDENTIFICATION MARKING:

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

Screws nominal size #10 (.1900) and larger shall be permanently marked with the manufacturers

symbol. Marking size, type, and location of marks at manufacturers option. Screws shall not be

marked on bearing surfaces. Markings shall be raised or depressed on the screw head.

8. MATERIAL IDENTIFICATION MARKING:

Type 316 (UNS S31600) or 316L (UNS S31603) CRES screws nominal size #10 (.1900) and larger

shall be permanently marked 316. Markings shall be raised or depressed on the screw head at the

manufacturers option.

9. MATERIAL CODE:

For 300 Series CRES - No code after dash number indicates any 300 Series Austenitic Corrosion-Resistant

Steel listed in material requirement.

For Type 316 or 316L CRES - S316 after dash number indicates Austenitic Corrosion-Resistant

Steel

Type 316 or Type 316L.

10. FINISH CODE:

Passivate - No code letter after dash number, or after material code (if applicable), indicates

passivate.

Black Oxide - B after dash number indicates bl ack oxide coating (except for Type 316 or 316L

CRES).

11. PART NUMBER:

The part number shall consist of the basic MS number, followed by a dash number from Table I, a

material code (if applicable), and a finish code (if applicable).

EXAMPLES:

MS16995-1 indicates Screw, Cap, Socket Head, Hexagon, 300 Series

Corrosion-Resistant Steel; .0860-56 UNC-3A Nominal Thread

Size, .188 Length, Passivated

MS16995-1S316 indicates Screw, Cap, Socket Head, Hexagon, CorrosionResistant Steel Type 316 o r Type 316L; .0860-56 UNC-3A Nominal

Thread Size, .188 Length, Passivated

MS16995-1B indicates Screw, Cap, Socket Head, Hexagon, 300 Series

Corrosion-Resistant Steel; .0860-56 UNC-3A Nominal Thread

Size, .188 Length, Black Oxide Coating

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

The screws covered by dash numbers given in MS35461 that are replaced by applicable dash numbers in this

document are canceled after 5 April 62. Use the dash numbers given in the preceding sheets. The canceled

screws cannot always replace the new screws and should be used until existing stocks are depleted. Use only

the new screws for design and replacement. Replacement shall be in accordance with this table.

Interchangeability information regarding part numbers on superseded drawings are also contained in this

table.

TABLE II. INTERCHANGEABILITY TABLE

Part Numbers

Canceled

Superseding

MS35461

MS16995

Dash Number

Dash Number

1

25

2

26

3

27

4

28

5

29

Part Numbers

Canceled

Superseding

MS35461

MS16995

Dash Number

Dash Numbers

23

49

24

50

25

51

26

52

27

53

Part Numbers

Canceled

Superseding

MS35461

MS16995

Dash Number Dash Numbers

54

83

55

84

56

85

57

86

58

87

6

11

12

13

14

30

35

36

37

38

28

29

30

48

49

54

55

56

77

78

62

63

64

65

66

92

93

94

95

96

15

16

21

22

39

40

47

48

50

51

52

53

79

80

81

82

67

68

69

70

97

98

99

100

Screws covered by the following part numbers are inactive for new design and engineering. They shall be

used for maintenance of existing equipment to replace the 5/16 inch size screws used in counterbored holes or

other close applications.

Part Numbers

Inactive

MS35461

Dash Number

33

34

35

36

37

38

Downloaded from http://www.everyspec.com on 2012-09-12T13:38:01.

MS16995H

39

40

41

42

43

44

Custodians:

Army - AR

Navy - OS

Air Force - 82

Preparing activity:

DLA - IS

(Project 5305-2126)

Review activities:

Army - MI

Navy - MC, SH

Air Force - 11

NSA-NS

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- C955 09Document4 pagesC955 09jacr27No ratings yet

- ASTM A325 Structural BoltsDocument7 pagesASTM A325 Structural BoltsZulfikar N JoelNo ratings yet

- Tom Swift PaperDocument53 pagesTom Swift Paperimran_chaudhryNo ratings yet

- .250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeDocument3 pages.250 .031 R Collar, An876 (Proper Dash No.) Silver Solder To TubeAnonymous 1CBdStCXUNo ratings yet

- EN6114Document17 pagesEN6114Andrei Cozma67% (3)

- Din 938 - StudsDocument5 pagesDin 938 - StudsRicky WCKNo ratings yet

- Aa 036322 001Document1 pageAa 036322 001petronashscribdidNo ratings yet

- POWERMASTER Hydraulic-Bolt-Tensioners PDFDocument16 pagesPOWERMASTER Hydraulic-Bolt-Tensioners PDFPetar Jankovic100% (1)

- Ams S 13165Document26 pagesAms S 13165whalenon100% (2)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Instrucalc IIDocument27 pagesInstrucalc IINorberto Soto100% (1)

- Rivets AluminumDocument12 pagesRivets AluminumantblyNo ratings yet

- Schedule 40 PipeDocument2 pagesSchedule 40 Piperasnowmah2012No ratings yet

- Mil PRF 13789eDocument9 pagesMil PRF 13789eOm Parkash SharmaNo ratings yet

- MS27039FDocument6 pagesMS27039FbobbyfortunaNo ratings yet

- AN807 Rev7Document5 pagesAN807 Rev7MAI_QualityNo ratings yet

- LPS precision fastener manufacturerDocument16 pagesLPS precision fastener manufacturerHiren SonarNo ratings yet

- MIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsDocument11 pagesMIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsgamillosNo ratings yet

- Dalan0164380 Abs0112 4 18-11-14 enDocument7 pagesDalan0164380 Abs0112 4 18-11-14 enAndrei CozmaNo ratings yet

- Astm 416Document5 pagesAstm 416imzee25No ratings yet

- Aeroquip Wire Reinforced Synthetic Rubber Hose GuideDocument12 pagesAeroquip Wire Reinforced Synthetic Rubber Hose GuideMohamed ElmakkyNo ratings yet

- A 789 - A 789M - 02 Qtc4os0wmkeDocument4 pagesA 789 - A 789M - 02 Qtc4os0wmkeAhmad HajeerNo ratings yet

- Strainer Spec SheetDocument3 pagesStrainer Spec Sheetswaraj4uNo ratings yet

- 4 Snubber and Rigid StrutDocument8 pages4 Snubber and Rigid StrutkysucoNo ratings yet

- A 416 A416-M - 99Document5 pagesA 416 A416-M - 99Tan Tanju100% (1)

- Stud Bolt SpecificationDocument8 pagesStud Bolt SpecificationsantoshblonkarNo ratings yet

- UNBRAKO Metric Fasteners: StrengthDocument4 pagesUNBRAKO Metric Fasteners: StrengthMirza Zahid HussainNo ratings yet

- 20 TMSS 01 R0Document0 pages20 TMSS 01 R0renjithas2005No ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- ASTM A1063 / A1063M - 11aDocument4 pagesASTM A1063 / A1063M - 11avargas35No ratings yet

- Bolts, NutsDocument20 pagesBolts, Nutshlsimon100% (2)

- DTL 18182 FDocument10 pagesDTL 18182 FHutauruk Edward V RogateNo ratings yet

- Steel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed ConcreteDocument4 pagesSteel Strand, Seven-Wire, Uncoated, Compacted, Stress-Relieved For Prestressed ConcreteGustavo Suarez0% (1)

- Termination KitDocument18 pagesTermination KitJan Glen MenesesNo ratings yet

- Mil DTL 87161GDocument13 pagesMil DTL 87161Gugur kandemirNo ratings yet

- RTDDocument68 pagesRTDMaria DenetNo ratings yet

- Technical Specifications of Aluminium Rivets or Steel MandrelDocument3 pagesTechnical Specifications of Aluminium Rivets or Steel MandrelmutualscrewNo ratings yet

- Teddington Catalogue 2013Document76 pagesTeddington Catalogue 2013Joanna NewtonNo ratings yet

- Att 2 - EdsDocument30 pagesAtt 2 - Eds정동현No ratings yet

- Ductile Iron SpecificationsDocument12 pagesDuctile Iron SpecificationsDouglas BooyensNo ratings yet

- MS14182B - Parafuso Cabeça EstriadaDocument3 pagesMS14182B - Parafuso Cabeça EstriadaRenato WatanabeNo ratings yet

- Ham-Let Astava Line of ManifoldsDocument24 pagesHam-Let Astava Line of ManifoldsjcestupinanNo ratings yet

- Schedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Document2 pagesSchedule 40 Pipe, Galvanized: ASTM F1043 Group I-A, Federal Specification RR-F-191 Type 1, Grade A, AASHTO M-181 Grade 1Caolboy ButchNo ratings yet

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89No ratings yet

- IS-3757 HT BoltDocument6 pagesIS-3757 HT BoltRam Balak RoyNo ratings yet

- Bolts General1 PDFDocument2 pagesBolts General1 PDFFredNo ratings yet

- Flexible Conduit Systems EnDocument15 pagesFlexible Conduit Systems EnSam ANo ratings yet

- WTI UK Screw Thread Inserts and Kits CatalogueDocument16 pagesWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalNo ratings yet

- Mil DTL 32108Document16 pagesMil DTL 32108syrNo ratings yet

- A 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFDocument7 pagesA 313 - A 313M - 98 Qtmxmy9bmzezts1sruq - PDFTiến Lượng NguyễnNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Engineering & Construction Bulletin: Owned Special Provisions Sections 6.03 (Structural Steel) and M.06 (Metals)Document6 pagesEngineering & Construction Bulletin: Owned Special Provisions Sections 6.03 (Structural Steel) and M.06 (Metals)Hector CarreraNo ratings yet

- Catalogo Tecnico Stud WeldingDocument68 pagesCatalogo Tecnico Stud Weldingalexfc81No ratings yet

- Mil DTL 17849FDocument23 pagesMil DTL 17849FOm Parkash SharmaNo ratings yet

- Overview of the S-Series IPS SpecificationsFrom EverandOverview of the S-Series IPS SpecificationsNo ratings yet

- MS20257D HingeDocument2 pagesMS20257D HingeacparaujoNo ratings yet

- Strain Gage Rosette TheoryDocument7 pagesStrain Gage Rosette TheoryHasnain BukhariNo ratings yet

- MS35842E Hose ClampDocument2 pagesMS35842E Hose ClampacparaujoNo ratings yet

- MS21073G Nutplate CornerDocument2 pagesMS21073G Nutplate CorneracparaujoNo ratings yet

- IPC de Un Boeing 757Document22 pagesIPC de Un Boeing 757Armando VasquezNo ratings yet

- NAS1836 Light InsertDocument3 pagesNAS1836 Light InsertacparaujoNo ratings yet

- Mil F 25173a DzusDocument19 pagesMil F 25173a DzusacparaujoNo ratings yet

- NAS1921 Blind RivetDocument20 pagesNAS1921 Blind Rivetacparaujo100% (1)

- MS35842E Hose ClampDocument2 pagesMS35842E Hose ClampacparaujoNo ratings yet

- MS21060 Nutplate Low HeightDocument3 pagesMS21060 Nutplate Low HeightacparaujoNo ratings yet

- MS16998E Cap ScrewDocument5 pagesMS16998E Cap ScrewacparaujoNo ratings yet

- NAS517Document2 pagesNAS517naveensir100% (1)

- AN970 WasherDocument2 pagesAN970 WasheracparaujoNo ratings yet

- AN525 ScrewDocument1 pageAN525 ScrewacparaujoNo ratings yet

- MILITARY SPECIFICATION SHEETDocument5 pagesMILITARY SPECIFICATION SHEETacparaujoNo ratings yet

- MS16995H ScrewDocument9 pagesMS16995H ScrewacparaujoNo ratings yet

- HV-bolts For Wind Power (Based On DIN EN 14399-4) : Tabelle 5Document2 pagesHV-bolts For Wind Power (Based On DIN EN 14399-4) : Tabelle 5joehodohNo ratings yet

- Project Equipment Numbering ProcedureDocument48 pagesProject Equipment Numbering ProcedureBiginchNo ratings yet

- Dockweiler Bpe DirectDocument52 pagesDockweiler Bpe Directpradeep281001No ratings yet

- E2 Coupl Ident ChartDocument1 pageE2 Coupl Ident Chartaerohead34No ratings yet

- Chain Swivel Shackle Standards BS en 14606-2004 - (2017-03-20 - 11-58-13 Am) PDFDocument28 pagesChain Swivel Shackle Standards BS en 14606-2004 - (2017-03-20 - 11-58-13 Am) PDFNaw Az100% (1)

- Marine Anchor Design GuideDocument28 pagesMarine Anchor Design GuideKevin SaaVedra CastañedaNo ratings yet

- Connections in GeneralDocument10 pagesConnections in GeneralLes SzalaiNo ratings yet

- Jis G4051Document7 pagesJis G4051tnchsgNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet