Professional Documents

Culture Documents

Selo 1

Uploaded by

kjfenOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Selo 1

Uploaded by

kjfenCopyright:

Available Formats

Faizan

faizaneca@gmail.com

CONTENTS

1. BRIEF DESCRIPTION OF NTPC

2. GENERAL DESCRIPTION OF COMBINE CYCLE

3. SAILENT FEATURES OF ANTA STATION

4. GAS TURBINE

5. WASTE HEAT RECOVERY BOILER

6. STEAM TURBINE

7. COOLING TOWER

8.POWER PLANT CHEMISTRY

9.TRANSFORMER

10.SWITCHYARD

11.CONTROL & MONITERING MECHANISM

Faizan

faizaneca@gmail.com

BRIEF NTPC- AN INTEGRATED POWER MAJOR

A journey towards excellence established in 7nov.1975, NTPC limited, a

premier sector enterprise, is Indias largest power utility with an installed capacity

of 27,904MW through 26 power stations including stations operated under joint

exploration, power distribution trading and also plans to enter into nuclear power

development. NTPC plans to become a 50, 000 MW Company by 2012 and

75,000MW plus company by 2017. The company contributed 29.25% of the total

electricity generated in the country during 2006-07 with 20.71% share of the total

installed capacity of the nation including capacity and generation of joint venture

companies.

COMBINED CYCLE TECHNOLOGY

The year was 1985, government of India decided to effectively use the sweetened

natural gas, which was to be made available by GAIL through cross-country

HBJ gas pipe line NTPC was entrusted with a responsibility to set up gas based

power project in Gujarat, Rajasthan and utter Pradesh, NTPC submitted the

feasibility reports for 3 gas based projects at anta (Rajasthan), Auraiya (U.P.) and

kawas (Gujarat).

The feasibility report of anta was approved by government of India in

October, 1986. The land was simultaneously acquired, bhoomi poojan of the land

to star the work performed on 16.01.1987 by the then CMD shri M.L. shishoo, and

the charging of construction power was inaugurated

MILE STONE

Govt. approval of feasibility report

20.10.86

Bhoomi poojan

16.01.87

Award of main plant turnkey contract

24.08.87

Synchronization of GT-1

20.01.89

Synchronization of GT-2

04.03.89

Synchronization of GT-3

04.05.89

Synchronization of ST

09.03.90

Location

: anta in Baran district of Rajasthan

Total land

: 390.75 acres.

Fuel

: natural gas naphtha

Water source

; KOTA RIGHT MAIN CANAL

NET plant output

: 419.33MW

Faizan

faizaneca@gmail.com

GENERAL

DESCRIPTION OF

COMBINED CYCLE

The 419.33MW anta combined cycle power plant consists of three gas

turbines generator sets of 89.20MW each and one steam turbine generator set of

153.20 MW.the gas turbine are equipped with a dual fuel burner for gaseous fuel

(natural) and liquid fuel (naphtha).the station can be operated in the open cycle

mode via their exhaust gas bypass stacks or as modules together with their waste

heat recovery boilers and STG in the combined cycle mode.

The WHRB `S is designed as dual pressure boilers with high

pressure (HP) and low pressure (LP) sections and condensate preheating at the tail

end. The condensate pumped from the condenser hot well is degasified in the

deairator at constant pressure and stored in the feed water tank. From feed water

tank, the boiler feed water is extracted by mean of separate boiler feed water

pumps for the HP and LP system serving the 3 WHRB`S in common HP and LP

main steam lines the turbojet is composed of a single flow HP turbine and one

double flow LP turbine. The Generator is directly coupled to the shaft of LP

cylinder. The exhaust steam of the STG is condensed in a surface condenser cooled

by fresh water of the right main Kota canal in the once through cycle. During the

shut down of canal, the condenser is cooled via a wet cooling tower in the closed

cycle alternatively.

For start up and shut down as well as trip of STG one common

HP and LP steam bypass station for all 3 modules are provided leading the steam

directly into the condenser. Additional steam charged air presenters are installed in

front of the GT-compressor inlet to preheat the intake air for the gas turbine,

improving the heat rate during part load operation.

Faizan

faizaneca@gmail.com

SALIENT FEATURES OF ANTA

1. GAS TURBINE

REACTION TURBINE

2. GT COMPRESSOR

3. COMBUSTION CHAMBER

4. AIR INTAKE FILTER

5. BYPASS STACK

6. WASTE HEAT RECOVERY

BOILER

7. STEAM TURBINE

8. CONDENSOR

9. GENERATOR

10. BLACK START FACILITY

11. COOLING SYSTEM FOR

CONDENSER

12. PT.PLANT

13. DM.WATER PLANT

14. NET PLANT OUT

15. FUEL

16. WATER SOURCE

17. RESERVIOUR

18. TOTAL LAND

19. Plant output

: 89.20MW, TYPE 13D-2, ABB MAKE, 5th STAGE

: 18th STAGE AXU\IAL FLOW, RECTION

BLADING

: SINGLE SILO TYPE, DUAL FUEL FIRED

BURNER

: SELF CLEANING, SYNTHATIC PAPER,

TOTAL 945 FILTERS IN THREE TIERS.

: VERTICAL 25M.HIGH.

: DUAL PRESSURE, DOUBLEDRUM, UNFIRED,

FORCED CIRCULATION.

PRESSURE

FLOW

TEMP

: HP 62.70BAR

163 T/Hr

4850C

: LP 5.5 BAR

39.1T/Hr

2070C

153.20MW, TANDEM COMPOUNDED,

DOUBLE EXHAUST, CONDENSING TYPE,

SINGLE FLOW HYORRIZONTAL 25 STAGE

HP TURBINES.

: DOUBLE PASS SURFACE CONDENSORWITH

STAINLESS STEEL TUBES, COOLING

13988M3.

: 3 PHASES, TWO POLE, AIR COOLED

OUT PUT

VOLTAGE SPEED

GTG. 135MVA

10.5 KV

3000 RPM

STG. 191MVA

15.75 KV 3000 RPM

: 2.4MW DIESEL GENNERATOR SET, V-6.6KV

: 3*50% COOLING WATER PP AND

2*50% COOLING TOWER PP, CAPACITY15000M3

EACH, 11 NOS ARIFLOCCUATORS, CAP.110M3/HR

:2NOS ARIFLOCCULATORS, CAP.110M3/HR

: TWO STREAM OF 35 M3/HR EACH

: 419.33MW,

: NATURAL GAS (MAIN FUEL), THROUGH

HBJ PIPE LINE, NAPHTHA, (ALTERNATER)

FUEL BY ROAD TANKER

: KOTA RIGHT MAIN CANAL

: 10 MILLION M3, FOR 1 MONTH

: 390.75 ACRES

: 419.33MW

Faizan

faizaneca@gmail.com

GAS TURBINE

General description

A gas turbine plant in its most simple form consists of following main part:1. Air intake system

2. Compressor

3. Combustion chamber

4. Turbine

5. Generator

6. Main bearing thrust bearing

7. Hydraulic oil lubrication oil

8. Oil pump:-main oil pump, auxiliary oil pump, hydraulic oil pump, recirculation

oil pump,Dc emergency oil pump, jack oil pump, barring oil pump (ac/dc supply)

9. Naphtha fuel pump.

10. Bleed valves 4nos.

1. Air intake system

The air flow radial inward through the filter elements then upward to clean air

duct. The air inlet connection has horizontal air inlet and situated axially in front of

the compressor. Three are three horizontal floors in filter house each floors carry

315 filters. (Total filters are made of synthetic and cellulose fibers, using resin

impregnated.

2. Compressor

It is 18 stages with additional inlet guide blade, axial flow, reaction

compressor. The blade of the 18 rotor and 19 fixed rows are made of high tensile

ferric chrome steel.

The compressor casing is horizontally split at axis, and is made of spherical

graphite cast iron. This material possesses high tensile strength and good

expansion quality. Upper and lower halves of the compressor casing are provided

with robust flanges and are held together by expansion studs with socket head. The

compressor casing has three circular ducts at 4TH, 7TH, 10TH row of fixed blades.

These ducts are closed to the out side by four bleed valves. Bleed valves are kept

open unto 2700rpm, so that certain amount of compressor air can be blown off.

These bleed valves reduces the external power input required running compressor

during start up.

Faizan

faizaneca@gmail.com

COMBUSTION CHAMBER

In combustion chamber, the air compressed and supplied by compressor is

brought to the required process temp. By combustion of liquid/gas fuel. The single

combustion chamber is fitted with only one duel fired burner and mounted

vertically on the compressor/turbine assembly.

The combustion chamber is all welded steel plate fabricated. The main parts

are jacket with cover, lower upper combustion chamber bodies, finned segment

body, burner and inner casing.

Combustion chamber jacket, which houses the components, is made of heat

resistant, low alloy ferrite steel. Finned segment body encloses the hottest zone of

the combustion chamber.

The air from the compressor enter the combustion chamber from below and

flow upward through the annular space between combustion chamber jacket and

inner section of the lower combustion chamber body. Approximately 30% air flow

enter the combustion chamber through eight mixing nozzles provided at the lower

body as secondary and approximately30% air flow enter the combustion chamber

through upper body via finned segment row (there are 5row,the remaining40%flow

as primary air for combustion, into the swirl insert and enter the combustion space

with turbulence. After the fuel has ignited these gases are thoroughly mixed with

secondary air from mixing nozzles and brought to the permissible turbine inlet

temp.

The inner casing guides the hot gases coming from combustion chamber to

the turbine balding. It is thin welled construction made of heat resistant chromenickel austenitic alloy.

Faizan

faizaneca@gmail.com

Turbine

Turbine is five stage reaction turbines. Due to high temp. Of incoming

gases, the first and second row of rotor and fixed blading are air cooled with air

from compressor discharge. The cooling air is fed to the frist&second row of fixed

blades through holes drilled in the blade carrier and to the frist&second row of

rotor blades through hole drilled in shaft. Cooling air passes along several holes

made in blades and finally blowing out through numbers of slits in the trailing

/leading edge of the blade. This method of cooling ensures that blades are

thoroughly cooled, there by avoiding cracks induced by thermal stresses. These

cooled blades are fixed rotor blades of other rows are made of cast in nickel based

alloy. The fourth and fifth row of rotor blades fifth row of fixed blades are drop

forged. Turbine outer casing is split into two halves like compressor casing. The

turbine and compressor casing are bolted together at radial flange with expansion

bolts, turbine casing is made of heat resisting ferrite steel in order to with stand

thermal stresses. The blade carrier for turbine fixed blades is made of ferrite steel

alloy casting and axially like turbine/compressor.

27C

0.9745BAR

60%RH

370Kg/S

Ai r intake

BURN

ER

CCH

92MW

GEN.

18STAGE

E

COMP.

5STAGE

TURB.

505oc

EXHAUST

PR.0.980

Schematic diagram of ABB 13D2 gas turbine is shown in fig. the special feature of

ABB 13D2 gas turbine is:

Faizan

faizaneca@gmail.com

FEATURES OF ABB 13D2 TYPE GAS TURBINE

1. A single shaft of welded construction.

2. Axial compressor of 18 stages with bleed valves after 3rd, 6th, 9th

stages for protection against surging and also to reduce power required for startup.

3. A single combustion chamber with a single burner. The combustion

chamber is mounted vertically on the turbine outer casing. The large size of the

combustion chamber provides easy access to inspection of its internals as well as

approach to the turbine inner casing and first stage blades of turbine.

4. The burner is of dual fuel design and either gas, naphtha (or any

liquid fuel) or both can be fired.

5. Five stage axial turbine with axial exhaust for easy connection to a waste heat

boiler. First two stages of turbine blades are coated.

6. First 5 stage of compressor blades are coated to protect against

corrosion due to humidity.

7. First 2 stages of turbine blades are coated against high temperature

corrosion.

ORTHER CHARACTERISTICS OF GAS TURBINE:

1. The gas flow ducts must offer minimum hydraulic resistance.

2. The axial flow at exit from last stage of a gas turbine constitutes

150-200

mm/s and the kinetic energy of the gases attain 10% of the total useful energy. To

minimize losses an exhaust diffuser is provided.

3. If the ratio of mid diameter of stage to blade height is less than or equalto12

to14 twisted blades are decided.

4. There is no extraction like in steam turbines hence the flow path is simpler.

5. Liquid fuel usually contain impurities like VA, NA, S, etc. these

substances

destroy corrosion protective film on heat resistant steels.

Faizan

faizaneca@gmail.com

6. Along with use of high temp and heat resistant metals, various design techniques

are employed to reduce temperature levels and

remove heat from the hottest

elements in gas turbines. As much as 15% of compressor discharge air is used for

cooling of blades, rotors and blade carrier etc.

7. First rows of blades are made hollow or have longitudinal bore holes for

cooling. Non cooled blades are made solid and often have a

thinned portion at

the tip to minimize risk of damage on contact with the turbine casing.

8. Gas turbine rotors are usually disc type with intense cooling arrangement.

9.turbine blade carrier is horizontal split and is of strong and stiff design in order to

minimize radial blade clearances. Hence casing is made of symmetrical cross

section and with uniform wall thickness in order that temperature deformations

due to frequent and sharp changes in turbine operation could not distort the

cylindrical shape from inside. To lower casing wall temperature heat shields and

cooling is provided.

10. There is no governing stage in gas turbine. Partial admission is not permissible

and load control is only through control of TIT.

ADVANTAGES OF GAS TURBINE OVER STEAM TURBINE:

1. Gas turbine is more compact. There is no boiler or condenser.

Auxiliaries are very few.

2. They can be started and loaded very quickly (within 20 minute

form cold start to full load)

3. Gas turbines are simpler in maintenance and designs.

4. Gas turbine plants involve less metal and material.

5. They are lower in cost for installation capacity.

6. Gas turbines dont require enormous quantities of cooling water as in steam

turbines.

Faizan

faizaneca@gmail.com

DISADVANTAGES:

1. Gas turbines have lower specific power.

2. They have lower efficiency.

3. Gas turbines have shorter service life.

4. They are very sensitive to fuel quality.

3

T

2

4

1

ENTROPY KJ/KG K

BROYTON CYCLE

1-2

ISENTROPIC COMPRESSION

2-3

CONSTANT PRESSURE HEAT

ADDITION

3-4

ISENTROPIC EXPANSION

4-1

HEAT REJECTION

1-2, 2-3, 3-4, 4-1, REPRESENTS THE IDEAL CYCLE

Faizan

faizaneca@gmail.com

Generator

Generator is three phases, two pole air cooled machine. The generator and

turbine are placed on common and plain concrete foundation, with same center line

level for the turbine and generator rotor.

The mechanical energy generated by turbine is converted to electrical energy

by the generator and appear in the stator winding in the form of current and

voltage. The balances the torque of the gas turbine.

It lead the magnetic flux, and carries the field winding, the generator is self

excited. The power required for the excitation is taken from the generator term

finals and fed to the field winding through the excitation transformer and the

thruster- controlled rectifier units.

GAS TURBINE GENERATOR (MKA)

1. GENERATOR TYPE

:

2. No. of phases

:

3. No. of poles

:

4. Stator winding

:

5. Insulation class

:

6. Nominal apparent power

:

7. Nominal voltage

:

8. Nominal current

:

9. Reactances

A. direct axis synchronous reactance ad

B. direct axis transient reactance x`d

C. direct axis sub transient reactance

D. negative sequence reactance x2

E. zero sequence reactance x0

F. short circuit ratio kc

10. Full load efficiency

11. Stator winding resistance at 20oc

12. Rotor winding resistance at 20oc

13. Stator winding capacitance ph.to core

14. Weight, generator assembled

15. Rotor weight

wy 18 L-095LL

3

2

star

f

135MVA

10.5kv

7423a

:

:

:

:

:

:

:

:

;

:

:

:

191%

14.4%

10.2%

12.8%

5.8%

0.58%

98.38%

0.000607 ohm

0.2177 ohm

0.52 micro F

162 MT

31 MT

Faizan

faizaneca@gmail.com

Fuel system

GAS:

Gas comes from GRS at around 18 bars; manual isolation valve is to

be opened by operator. Motorized stop relief valve will be opened by GT program

when required. When this valve is depressurized. When valve opens, the relief port

is closed.

In the gas control block there is an emergency stop valve (ESV). This opens

with the help of power oil pressure against spring force. Whenever, turbine trip the

oil is drained (depressurized) and spray force closes the valve cutting off gas

supply to combustion chamber.

After the ESV is the gas CV. The opening of this valve controls the amount

of fuel going to the combustion chamber.

NAPHTHA:

Naphtha comes from naphtha station via the forwarding pumps at around

15bar. Manual isolation valve outside GT hall is to be opened by the operator

manual isolation valves before main fuel oil pump and also to be opened.

Motorized valve will be opened by GT program when FG liquid fuel is selected.

NAPHTHA then passes through duplex filter to the main fuel oil pump, which

raises the press to aproox.80 bar. There is release valve which opens when firing

speed is reached (600rpm).

There is an emergency stop valve similar to one in the gas scheme. Finally

there is the control valve directly coupled with the NAPHTHA nozzle. A minimum

opening of the nozzle is already pre-set. Once stable flame is formed, the nozzle

opening increases with the control valve opening.

Faizan

faizaneca@gmail.com

LUBRICATING OIL/ POWER:

The turbo generator set has four bearing which are continuously supplied

with lubricating oil form MOT which is located between the compressor&

generator. There are two bearings on either side of generator and one bearing at

turbine end one bearing at compressor end.

An auxiliary lube pump (AC motor driven) supplies lube oil during the start

up and during rotor turning operation. Incase of AC supply failure DC lube oil

pump will start automatically.

There are two high pressure AC motor driven jacking oil pumps there

function is lift the turbine/generator slightly, during startup, so that starting force is

reduced.

A vent fan mounted on the MOT keeps it under vacuum and removes the

fumes/vapors to atmosphere.

Barring gear pump-AC motor driven pump rotates the shaft in term intently

during rotor- turning operation to prevent sagging of rotor. In case of.

An auxiliary power oil pump (AC motor) driven) provides hydraulic oil for

operation of hydraulically operated valves A motor driven circulation pump keeps

oil in circulation through power oil system when the GT is under shut-down, to

avoid ingress of air.

During normal operation all the above pumps remain off. The lube and

power oil are provided by a shaft driven main oil pumps located inside the Gearbox on top of the MOT.

Lube oil is cooled in coolers outside GT hall. These are air cooled radiator

type coolers. Lube oil passes through tubes and air passes over these tubes induced

by 3 fans.

After cooler, the oil is passed through duplex type filters and goes to

bearings.

Faizan

faizaneca@gmail.com

AIR INTAKE SYSTEM

Air enters the suction of compressor after passing through fine filters. There

are 945 filters arranged in three levels. These are self cleaning type filters.

Compressed air from the instrument air compressors passes through diaphragm

valves and into the blowpipes. A pressure pulse is given to the filter elements in

the reverse direction (inside to outside) this impulse of air flow cleans the filters.

Make

:

FARR

Material of filter media

:

resin impregnated media

Consisting of synthetic and

cellulose fibers

Total number of filter cartridges

:

945

Initiation of pulse cleaning

:

6.4 m bar

Stop of pulse cleaning cycle

:

4.6 m bar

Compressed air for pulse clean

:

7 bar

Time interval between two pulses

:

30 sec.

Time of a pulse

:

0.1sec.

GENERATOR COOLING WATER SYSTEM

The generator is air cooled. The air in turn is cooled by air water coolers

inside the generator housing. This water is cooled in radiator type coolers outside

the GT hall the generator CW system is in closed cycle.

There are two pumps (one stand by)

Water to air cooler for GT generator

Type

Heat capacity

Medium

Temp. Inlet

Temp. Outlet

Medium flow rate

:EKV 84/18-5/2

:12KW

;water

: 67.8o c

; 59.5o c

: 34.5 kg/sec.

Faizan

faizaneca@gmail.com

GAS TURBINE PLANT OPERATION

The compressor sucks in air from the atmosphere through the filters

called air intake filters. The compresses air at approx. 9to11 bar passes into the

combustion chamber where it is used as primary air for combustion and secondary

air for cooling of very hot parts.

The gas turbine generates the necessary power to drive the

axial-flow compressor and the generator. The turbine and compressor are in

common casing.

Start-up of the GT is drives with the help of starting

equipment which runs the generator as a motor with speed increasing from 0to

600rpm. At this speed a pilot flame is ignited in the combustion chamber, fuel

(gas/naphtha) enters and combustion takes place.

The speed increases further both with the help of

generator motoring and the combustion of fuel up to about 2000 rpm. At this speed

starting equipment is switched off and only the generator is made ready for

synchronization with the grid. After synchronizations, the turbine load increases up

to base load with more and more fuel entering the combustion chamber.

The hot gases after combustion enter the gas

turbine at about 1000 c (at base load). The higher pressure and temperature gas

pass through the turbine rotating it and generator, this produces the electrical

power.

0

The exhaust gas coming out of the GT is at about

500 c.thiscan be utilized to produce steam in WHRB.

0

Faizan

faizaneca@gmail.com

SYSTEM DESCRIPTION OF WHRB:

Wagner-biro supplied boilers for anta combined cycle power plant known as

waste heat recovery boilers (WHRB), which are of non fired, dual pressure, forced

circulation type. The boiler has two different water/steam cycles known as high

pressure system and low pressure system. Each system has its own boiler drum and

circulating pumps, and are feed byHP&LP feed water pumps from a common feed

water tank. The pressure and temperature of high pressure super heated steam is 64

bar and 490 c and that of LP 6 bar and206 c

The HP&LP steam from the three boiler from four common headers HP live

steam line, HP bypass line, LP live steam line and LP bypass line, the bypass line

dump steam in the condenser through the HP and LP bypass system.

The HP steam drives the HP steam turbine through stop valves and control

valves. The LP steam after passing through stop valves and control valves mixes

with the HP turbine exhaust and drivers the gas turbine. This dual system of

operating utilizes the waste heavy from the gas turbine with maximum efficiency.

From LP turbine steam enters the condenser where it get condensed to water with

the help of cooling water .condenser is shell and tube, water flow through the tubes

and steam flow out side. The condensate get collected in hot well, from hot well it

enters the feed water tank through condensate extraction pump (3*50%) via

condenser with the of (2*50%) vacuum pump.

Each of the WHRB is feed with waste heat flue gas from the

respective gas turbine (GT). The gas turbines are fired either with gas or naphtha.

The flue gas temp.at boiler inlet is about 500c depending on GT load and outside

temp. Conditions. The flue gas temp. At boiler outlet is about 110c-140c to avoid

cold end corrosion.

During WHRB operation the flue gas is led through a horizontal duct

with integrated silencer to diverter flap of the WHRB. There are two positions of

diverter flap one open to the boiler and another is open to bypass stack.

Faizan

faizaneca@gmail.com

The energy from waste heat flue gas is transferred to water/steam by

means of heating surfaces of super heaters, evaporators, economizers and

condensate preheater.

The heating surface of each boiler is about 96000sq.m. The heating

surfaces in staggered arrangement are manufactured as finned tubes arranged

horizontally and installed in vertical duct supported by tube plates.

The steam-water system consists of a high (HP) and low (LP) pressure

system and in addition there is a condenser preheated in order to obtain a higher

efficiency.

COMPONENTS OF WHRB

LP-BOILER PART:

ECONOMISER:

The LP feed water, which flows from the 3X50% LP feed water

pumps through the common feed water line to the # WHRBS in parallel, enters a

WHRB at economizer gate valve. This gate valve is equipped with a parallel

bypass valve, which is used for first filling of WHRB and for pressure

equalization.

In the economizer the feed water is heated up by the flue gas.

After the economizer the feed water enters the LP boiler drum through feed

regulating station (FRS), where the feed water control valve ensures the correct

supply of feed water to the boiler.

Anther part of feed water after economizer is branched to the

feed water tank, where it used for deairating purposes.

Faizan

faizaneca@gmail.com

LP-BOILER DRUM-EVAPORATOR:

The feed water in the LP- boiler drum is pumped through the evaporator by

means of 2x100% LP circulation pumps. In the evaporator the water is partially

steamed by the flue gas passing at the outside of the evaporator tubes. The steam

and water mixture again enters the drum, where steam is separated and this steam

flows to the LP super heaters and the water is circulated again. Low level and high

level protections are provided for the protection of one vent valve is mounted on

the drum which opens automatically during start and closes when the pressure in

the drum rises above 1bar.2 nos. of safety valve with silencers are also mounted

against the over pressure protection. The circulation pumps ensure the correct

water flow through the evaporator for which the differential pressure between

discharge and suction side of the pump is supervised by means of pressure

differential switch. When the pressure drops the stand by pump will starts

immediately.

LP-SUPER HEATER:

The steam leaving at the top of the LP-drum flows through the flue gas

heated super heater, where it reaches the end temp. Of about 206 c.

The outlet header is equipped with motorized drain valve which is

automatically operated during start-up and this valve closes automatically after

pressurization. At the outlet pipe a safely valve protects the super heater against

over pressure.

HP-BOILER PART:

The principal design of the HP- boiler part is the same as for the LP- part.

The basic difference is of operating pressure.

Faizan

faizaneca@gmail.com

ECONOMISER:

The HP fed water, which flows from the 3x50% HP feed water pumps through the

common the feed water line to the HP parts of 3 WHRB in parallel, enters a

WHRB at the gate valve of economizer. This gate valve is equipped with a parallel

bypass valve as in LP-economizer.The HP economizer coils are in two parts one

part is just below the LP economizer and other part is below LP super heater and

both the coils are connected in series. After the economizer the feed water enters

the HP boiler drum through high pressure feed regulating station (FRS), where the

feed water control valve ensures the correct supply of feed water to the boiler.

The HP/LP economizers are provided with safety valves against the

protection of over pressure.

HP-BOILER DRUM, EVAPORATOR:

The feed water in the HP- boiler drum is pumped through the evaporator by

means of 2x100% HP circulation pumps in the evaporator water is partially

steamed as in LP part, this partially steamed water enters in HP drum where steam

is separated, and water is circulated again. Theses steam is super heated in HP

super heater.

The HP circulation pumps ensure the correct water flow through evaporator

for which differential pressure switches are provided.

One vent valve and two nos. of safety valves with silencers are also mounted on

the HP drum just like the LP drum.

HP-SUPER HEATER:

The HP super heater consists of two parts with a spray attemperator between

them. This configuration allows the temp. Control of the super heated steam. The

spray water which is the cooling medium is branched from the feed water line at

the HP economizer inlet via a control valve to the attemperator if the temp. Of

super heater increases beyond the predetermined temp.

Then spray water control valve opens automatically and keeps down the

super heater temp at about 498 c. the outlet heater is equipped with mortised drain

valves. A safety valve is also given against the over pressure protection.

Faizan

faizaneca@gmail.com

CONDENSATE PREHEATER:

The main condensate is pumped by 3x50% condensate extraction pumps

(CEP) to the feed water tank. Before entering the feed water tank the condensate is

passed through the condensate preheaters which are situated at the tail end of the

WHRB and heated by the flue gas to achieve the highest cycle efficiency.

By means of the 3-way control valve the preheaters can be partially or

totally bypassed.

At certain load conditions and also depending on ambient temperatures, it is

necessary to increase the condensate temp. Before entering temperatures, it is

necessary to increase the condensate temp. Before entering the preheater. This is

to avoid drop of the flue gas temperature below the sulphuric dew point, which

would cause corrosion at the preheaters. For this purpose 2x100% condensate

circulation pumps are installed. These pumps take automatic start when the

condensate temperature falls below a certain limit.

Blow down tank:

One blow down tank is provided for each WHRB to collect drains e.g. CBD,

IBD and drum over flow water from hp and LP system of the WHRB. The water

level in this tank is maintained through an over flow pipe, which leads the water to

hot drain collecting system. The steam flows via a silencer to the atmosphere.

Faizan

faizaneca@gmail.com

STEAM TURBINE

GENERAL DESCRIPTION

The steam turbine consists of two turbine sections, a single flow high

pressure turbine and double flow low pressure turbine arranged in same center line.

The shaft turning gear and the shaft turning gear is engaged and disengaged

automatically when turbine is turbine is started and shut down.

HP live steam is taken from the boiler HP system through the main

steam pipe to the combined main stop and control valves. From there it flow

through four opening in the outer casing into the interior of the HP turbine and

enters the reaction blading through exhaust connection at the top of the HP casing.

The cross over pipe between HP and LP turbines brings the steam to the reaction

blading in the LP turbine, where it expends down to condenser pressure.

The LP steam is taken from LP boiler system through the LP steam

main line to the combined stop and control valves. From there LP steam enters the

cross over piping, where it mixes with the HP exhaust before entering the reaction

blading of the LP turbine. In LP turbine expansion take place and finally steam get

condensed in the condenser.

The turbo generator set has four bearing which are continuously

supplied with lubricating oil from MOT like gas turbine. There are two bearings on

either side of generator and one bearing at HP turbine end one bearing in between

HP and LP turbine.

Faizan

faizaneca@gmail.com

HP FEED PUMPS SPECIFICATION

Medium

Feed water

Type

Five Stage Centrifugal Pump

Flow

307.3 m3/h

Temperature

111 C

Inlet Pressure

3 bar

Outlet Pressure

97.3 bar

Head

1010 m

Pump Power

Input

1019 kw

Rated Driver

Output

1250 kw

Pump Speed

2980

Current

127.6 Amp

VOltage

6600 V

Pressure Drop in

99.5 mwc

feed water piping

Faizan

faizaneca@gmail.com

LP FEED PUMPS SPECIFICATION

Medium

Feed Water

Flow

162.8 m3/h

Temperature

111 C

Inlet Pressure

2.85 bar

Outlet Pressure

16.2 bar

Diff. Pressure

13.8 bar

Head

143 m

Pump Power Input

91.5 kw

Rated Driver Out Put

119 kw

Pump Speed

2980 RPM

Current

185 Amp

Voltage

415 V

Pressure Drop in feed water piping

48.6 mwc

Faizan

faizaneca@gmail.com

COOLING TOWER

Cooling tower A tower- or building-like device in which atmospheric air (the heat

receiver) circulates in direct or indirect contact with warmer water (the heat source)

and the water is thereby cooled (see illustration). A cooling tower may serve as the

heat sink in a conventional thermodynamic process , such as refrigeration or steam

power generation, or it may be used in any process in which water is used as the

vehicle for heat removal, and when it is convenient or desirable to make final heat

rejection to atmospheric air. Water, acting as the heat-transfer fluid, gives up heat

to atmospheric air, and thus cooled, is recirculated through the system, affording

economical operation of the process. Two basic types of cooling towers are

commonly used. One transfers the heat from warmer water to cooler air mainly

by an evaporation heat-transfer process and is known as the evaporative or wet

cooling tower. Evaporative cooling towers are classified according to the means

employed for producing air circulation through them: atmospheric, natural draft,

and mechanical draft. The other transfers the heat from warmer water to cooler

air by a sensible heat-transfer process and is known as the non evaporative or dry

cooling tower. Non-evaporative cooling towers are classified as air-cooled

condensers and as air-cooled heat exchangers, and are further classified by the

means used for producing air circulation through them. These two basic types are

sometimes combined, with the two cooling processes generally used in parallel or

separately, and are then known as wet-dry cooling towers.

Evaluation of cooling tower performance is based on cooling of a specified

quantity of water through a given range and to a specified temperature approach to

the wet-bulb or dry-bulb temperature for which the tower is designed. Because

exact design conditions are rarely experienced in operation, estimated performance

curves are frequently prepared for a specific installation, and provide a means for

comparing the measured performance with design conditions.

Faizan

faizaneca@gmail.com

Faizan

faizaneca@gmail.com

POWER PLANT CHEMISTRY

WATER MANAGEMENT IN ANTA GAS POWER PROJECT

WATER UTILISATION PATTERN

AREA

APP. CONSUMP.

PER MONTH

PURPOSE

INDUSTRIAL

COOLING

WATER

450000 M3

Main condenser cooling

water & air conditioning

system, boiler feed water

DOMESTIC

PURPOSE

32000 M3

Potable water to main

plant & residential colony

PROCESS

CONTROL

7000 M3

PT & DM Plant effluent

treatment

WATER REQUIREMENTS IN POWER

PLANTS

CONDENSOR COOLING

AUXILLARY COOLING

FIRE FIGHTING

WATER TREATMENT PLANT

CLARIFIED WATER

DRINKING WATER

DM WATER FOR STEAM GENERATION

You might also like

- Anta Gas Power Plant ReportDocument45 pagesAnta Gas Power Plant ReportKrishna Sharma100% (1)

- NTPC Combined Cycle Power Plant ReportDocument45 pagesNTPC Combined Cycle Power Plant ReportPriya GuptaNo ratings yet

- Gas Turbine - Traning Report Bhel - 14 PageDocument14 pagesGas Turbine - Traning Report Bhel - 14 PageVivek PatelNo ratings yet

- Project Report On Gas Plant at NTPC DadriDocument16 pagesProject Report On Gas Plant at NTPC DadriSunil MåüřÿäNo ratings yet

- Gas TurbineDocument57 pagesGas TurbineMajid Sattar100% (1)

- IPGCL Gas Turbine Training ReportDocument42 pagesIPGCL Gas Turbine Training ReportkamleshNo ratings yet

- Gas Turbine Power PlantDocument15 pagesGas Turbine Power Plantrahul100% (1)

- Gas Turbine Power Plant PresentationDocument126 pagesGas Turbine Power Plant Presentationjehadyam100% (1)

- Brayton CycleDocument15 pagesBrayton CycleWahyudin BetaNo ratings yet

- External Reciprocating Steam EngineDocument8 pagesExternal Reciprocating Steam EngineabdiNo ratings yet

- 2 Report On Pem Nit ManipurDocument60 pages2 Report On Pem Nit ManipurArnob PhukanNo ratings yet

- NTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshDocument27 pagesNTPC Ltd. - Simhadri Super Thermal Power Station, Visakhapatnam, Andhra PradeshNiharika KolliNo ratings yet

- Thermal Power PlantDocument9 pagesThermal Power Plantmuneeb rafiqNo ratings yet

- Book 9HA CCPP Operations Training at AEPLDocument174 pagesBook 9HA CCPP Operations Training at AEPLFazalur Rehman Babar100% (2)

- Gas Turbine Start UpDocument131 pagesGas Turbine Start UpBaharudin Bin Kamarul Baharin100% (3)

- GT Frame 9 ManualDocument98 pagesGT Frame 9 ManualSANJAY100% (2)

- Internship Report of M AZHAR IQBALDocument11 pagesInternship Report of M AZHAR IQBALAzhar Iqbal Jutt100% (1)

- Brayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsDocument15 pagesBrayton Cycle: The Ideal Cycle For Gas-Turbine Engines in Relation To Power PlantsmechturboNo ratings yet

- Open Cycle Powe PlantDocument31 pagesOpen Cycle Powe PlantherdanandiNo ratings yet

- PASGT-Propulsion Ancillary Systems and Gas Turbine STCW ’78 as amended 2010 Table A-III/1 & Table A-III/2Document100 pagesPASGT-Propulsion Ancillary Systems and Gas Turbine STCW ’78 as amended 2010 Table A-III/1 & Table A-III/2Kyle100% (1)

- MitsubishiDocument10 pagesMitsubishiPrabhat Kisku100% (1)

- GT22 Operation ManualDocument72 pagesGT22 Operation ManualSyed Asim Ur RahmanNo ratings yet

- REPORT ElectricalDocument46 pagesREPORT ElectricalSonu Lovesforu100% (1)

- Report on Gas Power Plant and Coal Plant ComparisonDocument70 pagesReport on Gas Power Plant and Coal Plant ComparisonHardeep PenugondaNo ratings yet

- IRE - 21 TURBOFAN ENGINE DESIGN - Group - 2Document52 pagesIRE - 21 TURBOFAN ENGINE DESIGN - Group - 2Mr. Jaykumar JoshiNo ratings yet

- Gas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine EngineDocument22 pagesGas Turbine Power Plant: Fig.1-2: Components of A Basic Gas Turbine Engineام البنين الرياني100% (1)

- E3sconf Hsted2020 01033Document5 pagesE3sconf Hsted2020 01033jonyg01No ratings yet

- Gas Turbine MaintenanceDocument146 pagesGas Turbine MaintenanceMamoun1969100% (8)

- SIEMENS The H Class To Korea BrochureDocument8 pagesSIEMENS The H Class To Korea Brochurelink2u_007No ratings yet

- Presentation On Gas Power PlantDocument82 pagesPresentation On Gas Power Plantakshay gupta100% (2)

- Gas Turbine Performance Based On Inlet ADocument82 pagesGas Turbine Performance Based On Inlet Afateh1982No ratings yet

- Rayalaseema Thermal Power Plant ReportDocument24 pagesRayalaseema Thermal Power Plant ReportHarish Reddy50% (2)

- Classification of Gas Turbine Power PlantDocument7 pagesClassification of Gas Turbine Power PlantPK100% (1)

- Chapter Five Gas Turbine Power PlantDocument23 pagesChapter Five Gas Turbine Power PlantBese Mat100% (1)

- FR3 - Gas Turbine Combined Cycle Power SystemDocument69 pagesFR3 - Gas Turbine Combined Cycle Power Systemarindam misra8No ratings yet

- Mr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantDocument11 pagesMr. Hassan Alam: Heat Recovery Boiler of SNPC Power PlantYashal Syed, AhmedNo ratings yet

- TanmayDocument39 pagesTanmayDisha JainNo ratings yet

- Anta Gas Power Plant ReportDocument47 pagesAnta Gas Power Plant ReportChetan YogiNo ratings yet

- Gas TurbineDocument53 pagesGas TurbinedipakbagNo ratings yet

- Generation of Electric PowerDocument108 pagesGeneration of Electric Powermausam sharmaNo ratings yet

- The Tata Iron & Steel Company Ltd. Jamshedpur: Positional TrainingDocument23 pagesThe Tata Iron & Steel Company Ltd. Jamshedpur: Positional TrainingMahesh YadavNo ratings yet

- The Method of Operation of A Liquid-Propellant Rocket Motor and Liquid Rocket EngineDocument8 pagesThe Method of Operation of A Liquid-Propellant Rocket Motor and Liquid Rocket EngineĐinh Quốc Trí100% (1)

- pp1 Lab 10Document4 pagespp1 Lab 10Mian KaleemNo ratings yet

- How Does A Gas Turbine Power Plant Work?: 1. CompressorDocument8 pagesHow Does A Gas Turbine Power Plant Work?: 1. CompressorSuresh Ram R100% (1)

- Automotive Turbocharged Gas Turbine.Document48 pagesAutomotive Turbocharged Gas Turbine.Santanu ChakrabortyNo ratings yet

- Sala FormatDocument82 pagesSala FormatLemuel ReñaNo ratings yet

- SWITCHYARD, NTPC SIPAT Training ReportDocument35 pagesSWITCHYARD, NTPC SIPAT Training ReportSuresh Sunny80% (5)

- Combined Cycle Power Plant Technical DesignDocument84 pagesCombined Cycle Power Plant Technical DesignJohn Louie Pimentel0% (1)

- GPFDocument200 pagesGPFspvengiNo ratings yet

- TurbineDocument9 pagesTurbineKabir Bashir ShariffNo ratings yet

- Project Report On Thermal PlantDocument58 pagesProject Report On Thermal Plantmenyu198964% (11)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- 7SA522 CatalogueDocument53 pages7SA522 CataloguePhilip D'cruzNo ratings yet

- Water Treatments: Steam Water Cycle TreatmentDocument2 pagesWater Treatments: Steam Water Cycle TreatmentkjfenNo ratings yet

- Temperature Monitoring: FaizanDocument5 pagesTemperature Monitoring: FaizankjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

- REG670Document88 pagesREG670Rafael Hoffmann PaludoNo ratings yet

- 7 Ways Signal Noise Can Impact Your Electrical EquipmentDocument5 pages7 Ways Signal Noise Can Impact Your Electrical EquipmentkjfenNo ratings yet

- 555 Timer Tutorial - How to Build CircuitsDocument1 page555 Timer Tutorial - How to Build CircuitskjfenNo ratings yet

- Sub 131Document10 pagesSub 131kjfenNo ratings yet

- Load Forecasting and Standardized Load CurvesDocument10 pagesLoad Forecasting and Standardized Load CurveskjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

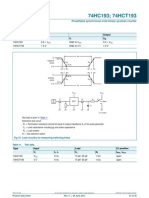

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC193 74HCT193: 17. Contact InformationDocument2 pages74HC193 74HCT193: 17. Contact InformationkjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

- 74HC193 74HCT193: 9. Static CharacteristicsDocument2 pages74HC193 74HCT193: 9. Static CharacteristicskjfenNo ratings yet

- Timer Tutorials 555Document1 pageTimer Tutorials 555kjfenNo ratings yet

- 74HC193 74HCT193: 14. AbbreviationsDocument2 pages74HC193 74HCT193: 14. AbbreviationskjfenNo ratings yet

- 74HC193 74HCT193: 10. Dynamic CharacteristicsDocument2 pages74HC193 74HCT193: 10. Dynamic CharacteristicskjfenNo ratings yet

- 74HC193 74HCT193: 13. Package OutlineDocument2 pages74HC193 74HCT193: 13. Package OutlinekjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC HCT193Document2 pages74HC HCT193kjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- 74HC193 74HCT193: 10. Dynamic CharacteristicsDocument2 pages74HC193 74HCT193: 10. Dynamic CharacteristicskjfenNo ratings yet

- 74HC193 74HCT193: 5. Pinning InformationDocument2 pages74HC193 74HCT193: 5. Pinning InformationkjfenNo ratings yet

- 74HC193 74HCT193: NXP SemiconductorsDocument2 pages74HC193 74HCT193: NXP SemiconductorskjfenNo ratings yet

- Financial Management Toolkit For Recipients of Eu Funds For External ActionsDocument12 pagesFinancial Management Toolkit For Recipients of Eu Funds For External ActionsGeorge BekatorosNo ratings yet

- Innovative Uses of Housing Lifting Techniques-JIARMDocument16 pagesInnovative Uses of Housing Lifting Techniques-JIARMPOOJA VNo ratings yet

- Business Process Reengineering and Performance Improvement in The BankDocument12 pagesBusiness Process Reengineering and Performance Improvement in The BankYakut Rumani SultanNo ratings yet

- Aartv Industrial Training ReportDocument48 pagesAartv Industrial Training ReportRupal NaharNo ratings yet

- ABE College Manila. 2578 Legarda Avenue Sampaloc, ManilaDocument11 pagesABE College Manila. 2578 Legarda Avenue Sampaloc, ManilaRonalie SustuedoNo ratings yet

- Haulmax HaulTruck 11.21.13 FINALDocument2 pagesHaulmax HaulTruck 11.21.13 FINALjogremaurNo ratings yet

- Royal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationDocument24 pagesRoyal Harare Golf Club: An Oasis of Excellence in The Midst of Political and Economic DevastationCompleatGolferNo ratings yet

- Container Stowage Plans ExplainedDocument24 pagesContainer Stowage Plans ExplainedMohd akifNo ratings yet

- Long Vowel SoundsDocument15 pagesLong Vowel SoundsRoselle Jane PasquinNo ratings yet

- Financial AccountingDocument10 pagesFinancial AccountingNumber ButNo ratings yet

- Factors Supporting ICT Use in ClassroomsDocument24 pagesFactors Supporting ICT Use in ClassroomsSeshaadhrisTailoringNo ratings yet

- Practical Approach To Practice 5SDocument4 pagesPractical Approach To Practice 5SNikola DjorovicNo ratings yet

- Jmeter Performance Testing Your Webapp 1203622239433273 3Document12 pagesJmeter Performance Testing Your Webapp 1203622239433273 3pallavi91No ratings yet

- Time Division Muliple AccessDocument4 pagesTime Division Muliple AccessAbhishek RanaNo ratings yet

- Condrada v. PeopleDocument2 pagesCondrada v. PeopleGennard Michael Angelo AngelesNo ratings yet

- Company Profile 2016 PDFDocument81 pagesCompany Profile 2016 PDFabioduncityNo ratings yet

- Create Config Files Python ConfigParserDocument8 pagesCreate Config Files Python ConfigParserJames NgugiNo ratings yet

- Portarlington Parish NewsletterDocument2 pagesPortarlington Parish NewsletterJohn HayesNo ratings yet

- List of Non-Scheduled Urban Co-Operative Banks: Sr. No. Bank Name RO Name Head Office Address PincodeDocument65 pagesList of Non-Scheduled Urban Co-Operative Banks: Sr. No. Bank Name RO Name Head Office Address PincodemanojNo ratings yet

- A Review of Bharat Nirman ProgrammeDocument3 pagesA Review of Bharat Nirman Programmevivek559No ratings yet

- KRAFT SOFTWARE SOLUTIONS Awards CriteriaDocument2 pagesKRAFT SOFTWARE SOLUTIONS Awards CriteriaAbdul SyedNo ratings yet

- Phyton para Sujetar HerramientasDocument21 pagesPhyton para Sujetar HerramientasAlex D H RuizNo ratings yet

- What Is International Business?: Educator Resource PPT To AccompanyDocument41 pagesWhat Is International Business?: Educator Resource PPT To AccompanyArif Raza100% (1)

- Politics FinalDocument29 pagesPolitics Finalmaychelle mae camanzoNo ratings yet

- Why Delegate Authority and Empower EmployeesDocument5 pagesWhy Delegate Authority and Empower EmployeesHarold MaribojocNo ratings yet

- Sample MCQ - Facility Location and LayoutDocument3 pagesSample MCQ - Facility Location and LayoutJITENDRA SINGHNo ratings yet

- Defining Yourself As A LeaderDocument1 pageDefining Yourself As A Leaderrosli2503No ratings yet

- Software Process & Quality Management: Six SigmaDocument26 pagesSoftware Process & Quality Management: Six SigmaPhu Phan ThanhNo ratings yet

- Pearce v. FBI Agent Doe 5th Circuit Unpublished DecisionDocument6 pagesPearce v. FBI Agent Doe 5th Circuit Unpublished DecisionWashington Free BeaconNo ratings yet

- Estimate For New College BuildingDocument8 pagesEstimate For New College BuildingslummdogNo ratings yet