Professional Documents

Culture Documents

Kenco Chemical Injectors Minimize Corrosive Buildup

Uploaded by

miltoncOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kenco Chemical Injectors Minimize Corrosive Buildup

Uploaded by

miltoncCopyright:

Available Formats

KENCO CHEMICAL INJECTORS

INDUSTRIES SERVED

Natural Gas Transmission and Distribution

Oil and Gas Production and Rening

Petrochemical

Water Treatment

Fluid Processing

Pulp & Paper Processing

KENCO CHEMICAL INJECTORS

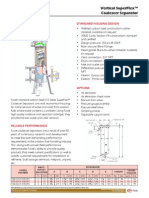

KENCO RETRACTABLE INJECTORS

APPLICATION

APPLICATION

Kenco chemical injectors are designed to inject and properly atomize

corrosive chemicals into the turbulent stream of a process system pipeline.

The Kenco chemical injector will minimize the possibility of corrosive

chemical build-up on the walls of the pipeline.

Kenco retractable injectors allow for injector insertion or removal without

interrupting the main process in the pipeline.

FEATURES

Unique aspirator tip design on injector disperses chemical evenly

into process stream and away from pipe walls

Check valve in injector eliminates backow

Injector is ideal for high pressure applications up to 6000 psig

Injector has been designed so that it can be mounted in any orientation

Standard lengths available in 3 and 5 sizes. Custom lengths up to 24

also available.

Injector available in 316 SS, Hast C-276, and CPVC

Standard Injector chemical feed port is 1/2 NPT

MINI-INJECTOR

Mini injector assembly atomizes chemical in smaller pipelines

up to 3 1/2 NPT

Injector chemical feed port is 1/8 or 1/4 NPT

SPECIFICATIONS

PRESSURE AND TEMPERATURE SPECIFICATIONS:

Injector Material Maximum Working Pressure Maximum Operating Temperature

316 SS

Hast C-276

CPVC

6000 psi

6000 psi

340 psi at 73F;

150 psi at 150F

KENCO Chemical Injectors have a

unique design that has been engineered

to minimize the possibility of corrosive

chemical build-up on the walls of the

pipeline.

800F

800F

200F

FEATURES

Unique aspirator tip design on injector disperses chemical evenly

into process stream and away from pipe walls

Ball valve assembly isolates pipeline from injector assembly when

injection is not required

Compression seal holds the assembly from back pressure

Safety chain prevents the injector assembly from being completely

withdrawn and protects against blowout

Standard ball valve assembly is brass. Also available in

316 SS, Alloy 20, and CPVC. Standard retractable injector

is CPVC. Also available in 316 SS, and Hast C-276.

Optional spring loaded check valve available in 316 SS, Hast

C-276, and CPVC. Check valve available with body bleed valve.

Standard process connection is 3/4 NPT

SPECIFICATIONS

PRESSURE AND TEMPERATURE SPECIFICATIONS:

Valve Material Maximum Working Pressure

Maximum Operating Temperature*

Brass

316 SS

Alloy 20

CPVC

500 psi

800 psi

1000 psi

235 psi at 73F

110 psi at 150F

up to 350F

up to 475F

up to 400F

200F

* Note: maximum operating temperature dependent on compression seal material

This photograph of a KENCO injector

illustrates the misting created by the

unique design.

STANDARD INJECTOR

INSERTION

LENGTH

"A"

"B"

3"

3 1/8"INJECTOR

5 5/8"

STANDARD

5"

5 1/8"

7 5/8"

INSERTION

custom

length

up to"A"

24" up to "B"

26 1/2"

LENGTH

3"

5"

custom length

3 1/8"

5 1/8"

up to 24"

5 5/8"

7 5/8"

up to 26 1/2"

v

REQUESTED BY:

COMPANY:

ADDRESS:

PHONE:

CITY:

FAX:

STATE:

ZIP:

EMAIL :

KINJ

Injector Style

KINJ = Standard Injector

Process Connections

50 = 1/2 NPT

75 = 3/4 NPT

Material of Construction

Process Connections

125 = 1/8 NPT

250 = 1/4 NPT

Material of Construction

Insertion Length (inches)

S6 = 316 Stainless Steel (Standard) L3 = 3 1/8 for 4 to 6 O.D. pipelines

HC = Hastelloy C 276 w/ceramic ball L5 = 5 1/8 for 8, 10 & 12 O.D. pipelines

CP = CPVC w/ceramic ball

* L(_) = custom length up to 24 (6-24)

*indicate desired length in box above

KINJM

Injector Style

KINJM = Mini Injector

KRINJ

S6 = 316 Stainless Steel (Standard)

HC = Hastelloy C 276 w/ceramic ball

75

Injector Style

KRINJ = Retractable Injector

Process Connections

75 = 3/4 NPT

Check Valve

N=None

CVB = Check Valve: w/Body Bleed

CVN = Check Valve; no/Body Bleed

Compression Seal Material

B=Buna-N (Standard)

V=Fluorocarbon

A= Aas

E=Ethylene Propylene

K=Kalrez

Material of Construction (Injector)

CP = CPVC (Standard)

S6 = 316 Stainless Steel

HC = Hastelloy C 276

Material of Construction (Valve)

B = Brass (Standard)

S6 = 316 Stainless Steel

A2O= Alloy 20

CP = CPVC

* Ball check spring material on all applicable

models is Inconel.

Other ball check spring materials available

(consult factory for options)

You might also like

- KENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesDocument2 pagesKENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesMEHDINo ratings yet

- Catalogo - Pluma de DosificaciónDocument2 pagesCatalogo - Pluma de DosificaciónsetsuNo ratings yet

- RHFS PG Page-KofloInjectionQuillDocument1 pageRHFS PG Page-KofloInjectionQuillHadi JuventinoNo ratings yet

- EIG Product Catalogue PLASTICSDocument40 pagesEIG Product Catalogue PLASTICSrodinooNo ratings yet

- CSD Data SheetDocument3 pagesCSD Data SheetDucVikingNo ratings yet

- Blakeborough DesuperheatersDocument12 pagesBlakeborough DesuperheatersthiruvilanNo ratings yet

- Pascal Pipe Fittings Complete Catalogue 1Document36 pagesPascal Pipe Fittings Complete Catalogue 1Serm Lim100% (1)

- Materials Specification Table of ContentsDocument40 pagesMaterials Specification Table of ContentsLuong Do Dat0% (1)

- 08 Push in Fittings For PneumaticDocument20 pages08 Push in Fittings For PneumaticNilesh MistryNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- Purging Brochure PDFDocument19 pagesPurging Brochure PDFjustinctlNo ratings yet

- Centrifugal Pump Skid: Pre-Engineered Water Treatment SolutionsDocument2 pagesCentrifugal Pump Skid: Pre-Engineered Water Treatment SolutionsAbhishek BaneNo ratings yet

- ValvesDocument8 pagesValvespravin_2011No ratings yet

- 2010 KMT Waterjet PSC Catalog - LDocument39 pages2010 KMT Waterjet PSC Catalog - LaeradriNo ratings yet

- Nozzle Check ValvesDocument12 pagesNozzle Check Valvesjshadwan100% (1)

- MK0002 Heat Exchanger Product Line Guide ENG Low ResDocument8 pagesMK0002 Heat Exchanger Product Line Guide ENG Low ResKzsr FrostNo ratings yet

- Air Valves-Complete (Dragged)Document2 pagesAir Valves-Complete (Dragged)ArmandoNo ratings yet

- Model"Dc": Dual Chamber Orifice FittingDocument13 pagesModel"Dc": Dual Chamber Orifice FittingFrankNo ratings yet

- CV For Pressure Up To 50bDocument4 pagesCV For Pressure Up To 50bmattuiffNo ratings yet

- Product BrochureDocument16 pagesProduct BrochureHans Hans SadzNo ratings yet

- TK ConnDocument6 pagesTK ConnPingu3No ratings yet

- 200 Series Check ValvesDocument2 pages200 Series Check ValvesMoanquileNo ratings yet

- Infinity CatalogDocument16 pagesInfinity CatalogSarah KuglinNo ratings yet

- PVC Irrigation Pipe GuideDocument6 pagesPVC Irrigation Pipe GuideNaeemSiddiquiNo ratings yet

- Superflex Coalescer SeparatorDocument2 pagesSuperflex Coalescer SeparatorNoe Ojeda AlvarezNo ratings yet

- Products Services CatalogueDocument79 pagesProducts Services CatalogueMayur PatelNo ratings yet

- Accessories: Components & SizesDocument1 pageAccessories: Components & SizesChevronelleNo ratings yet

- Swing Check ValveDocument6 pagesSwing Check ValveAsemota OghoghoNo ratings yet

- Desuperheater Equipment&SystemDocument12 pagesDesuperheater Equipment&Systemquoctrangbk02No ratings yet

- Duynamic GaugesDocument44 pagesDuynamic GaugesCentral HydraulicsNo ratings yet

- Delta Et Vacuum SystemDocument16 pagesDelta Et Vacuum SystemsanjeevnnNo ratings yet

- LoResCentron 2010Document145 pagesLoResCentron 2010Hendy96No ratings yet

- Injection and Sample Quills: Specifications & FeaturesDocument2 pagesInjection and Sample Quills: Specifications & FeaturesDonatas BertasiusNo ratings yet

- Awwa c900 y c905Document4 pagesAwwa c900 y c905Angel LopezNo ratings yet

- 63 Cosasco Two-Inch System Injection and Sampling AssembliesDocument4 pages63 Cosasco Two-Inch System Injection and Sampling Assembliesalamandy66100% (1)

- RV Valves Product Data SheetDocument16 pagesRV Valves Product Data SheetWaqar DarNo ratings yet

- Ae-Landing ValveDocument2 pagesAe-Landing ValveAlvi SarowarNo ratings yet

- Surface Mining Presentation: Victaulic's Grooved Piping SolutionsDocument66 pagesSurface Mining Presentation: Victaulic's Grooved Piping SolutionsXena Nurraini Anun CakranegaraNo ratings yet

- Coiled Tubing StringDocument10 pagesCoiled Tubing StringVirnando NainggolanNo ratings yet

- Tubería AWWA C900Document3 pagesTubería AWWA C900Julio CabreraNo ratings yet

- 316 Stainless Steel Tube Fitting SpecificationDocument3 pages316 Stainless Steel Tube Fitting SpecificationSam Chong Ks100% (1)

- Shur JointDocument132 pagesShur JointCleiton Rodrigues100% (1)

- Rectangular Duct & Fittings: Specifications ForDocument12 pagesRectangular Duct & Fittings: Specifications ForEric MagnayeNo ratings yet

- 63 Injection Sampling AssembliesDocument4 pages63 Injection Sampling AssembliesAbdul Hannan NazeerNo ratings yet

- AQUApipe Stainless Stee Pipe System Specifcation - 2020Document7 pagesAQUApipe Stainless Stee Pipe System Specifcation - 2020Josh WhiteNo ratings yet

- Mechanical Engineering Department Institut Sains & Teknologi Akprind Yogyakarta 2018Document36 pagesMechanical Engineering Department Institut Sains & Teknologi Akprind Yogyakarta 2018anonim 1178No ratings yet

- 2012 Transair 6 Inch BrochureDocument8 pages2012 Transair 6 Inch Brochurejaydee45No ratings yet

- Valves Product RangeDocument6 pagesValves Product RangesvvsreddyNo ratings yet

- SFS Products BrochureDocument14 pagesSFS Products BrochureJoshuaNo ratings yet

- 02 Precision Pipe FittingsDocument28 pages02 Precision Pipe FittingsNilesh MistryNo ratings yet

- Piping Design Enginerring & Construction: Atul PatelDocument19 pagesPiping Design Enginerring & Construction: Atul Patelसरदार अतुल भाई पटेलNo ratings yet

- Coiled Tubing For Downhole ProcessDocument10 pagesCoiled Tubing For Downhole ProcessCristian BarbuceanuNo ratings yet

- Eaton Vickers Cylinders Hydro TransDocument592 pagesEaton Vickers Cylinders Hydro TransCentral HydraulicsNo ratings yet

- Product Range: Gieminox-Tectubi Raccordi Welding Pipes DivisionDocument2 pagesProduct Range: Gieminox-Tectubi Raccordi Welding Pipes Divisionyrdna nawaiteosNo ratings yet

- Series: High Performance Flanged Full Port Ball ValveDocument8 pagesSeries: High Performance Flanged Full Port Ball Valvemanmohansingh1999No ratings yet

- Valves - AWWA Valves PDFDocument28 pagesValves - AWWA Valves PDFnilnilen2009No ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- CX500 Hoists PDFDocument2 pagesCX500 Hoists PDFmiltonc100% (1)

- Suspension Syst EDocument2 pagesSuspension Syst EmiltoncNo ratings yet

- Alpha: Operate in Your Work Environment The ALPHA IsDocument2 pagesAlpha: Operate in Your Work Environment The ALPHA IsshambhoiNo ratings yet

- Us 4819809Document5 pagesUs 4819809miltoncNo ratings yet

- Flex It Running GearDocument3 pagesFlex It Running GearmiltoncNo ratings yet

- TechData IM 7840EDocument4 pagesTechData IM 7840EmiltoncNo ratings yet

- Changes in The Directional Drilling and Surveying MarketsDocument12 pagesChanges in The Directional Drilling and Surveying MarketsfannyadilaNo ratings yet

- Dbi Sala Shock Absorbing Lanyards CatalogDocument13 pagesDbi Sala Shock Absorbing Lanyards CatalogmiltoncNo ratings yet

- Pa 361125Document8 pagesPa 361125miltoncNo ratings yet

- Sens It ProbeDocument2 pagesSens It ProbemiltoncNo ratings yet

- Instruction ManualDocument35 pagesInstruction ManualmiltoncNo ratings yet

- IM970REV38Document44 pagesIM970REV38miltoncNo ratings yet

- 155 255broDocument8 pages155 255bromiltoncNo ratings yet

- Automotive Cooling SystemDocument58 pagesAutomotive Cooling SystemMoniruzzaman ShuvoNo ratings yet

- Woodwork: Cambridge International Examinations General Certificate of Education Ordinary LevelDocument12 pagesWoodwork: Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Jun 09 Cooling Water Chemical Dosing SystemDocument6 pagesJun 09 Cooling Water Chemical Dosing SystemRKVSK1No ratings yet

- TG-500M CRANE SPECIFICATIONSDocument16 pagesTG-500M CRANE SPECIFICATIONSnamduong368No ratings yet

- Appendix A References: EM 1110-2-2000 1 Feb 94Document4 pagesAppendix A References: EM 1110-2-2000 1 Feb 94ماقوريNo ratings yet

- Masterseal ADocument6 pagesMasterseal Aapi-283891975No ratings yet

- Ryebrassware 0505Document40 pagesRyebrassware 0505api-36492444No ratings yet

- AlbanyDocument3 pagesAlbanyMohammad Sobhan RajabiNo ratings yet

- As 1038.15-1995 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Ash FusibilityDocument8 pagesAs 1038.15-1995 Coal and Coke - Analysis and Testing Higher Rank Coal Ash and Coke Ash - Ash FusibilitySAI Global - APACNo ratings yet

- Engineering Disasters - Alexander L. KiellandDocument8 pagesEngineering Disasters - Alexander L. KiellandAnonymous ka2kX4jNNo ratings yet

- Science ProbeDocument258 pagesScience ProbeoakesmNo ratings yet

- Rintal Misterstep BrochureDocument7 pagesRintal Misterstep Brochureharry irawanNo ratings yet

- Chap: Wood and Wood ProductsDocument2 pagesChap: Wood and Wood ProductsT N Roland BourgeNo ratings yet

- Structural Design For Embankment Dam BottomdischargeDocument8 pagesStructural Design For Embankment Dam BottomdischargeAnonymous 87xpkIJ6CFNo ratings yet

- EV Battery Disposal and EDocument3 pagesEV Battery Disposal and EAvnip Sharma100% (1)

- 09 28 13 Cement Board CeilingsDocument6 pages09 28 13 Cement Board CeilingsWagih NabihNo ratings yet

- Service Life of StructuresDocument44 pagesService Life of StructuresPablo Benitez100% (1)

- Foerster Circograph 2014 enDocument6 pagesFoerster Circograph 2014 enTiến NguyễnNo ratings yet

- Auto Tank Cleaning Machine DesignDocument9 pagesAuto Tank Cleaning Machine Designvidyadhar G100% (2)

- Duraband Information Vs 300XTDocument4 pagesDuraband Information Vs 300XTanhlhNo ratings yet

- Pulsed Laser Deposition (PLD)Document32 pagesPulsed Laser Deposition (PLD)Mohit YadavNo ratings yet

- 4 Case Adt Tran PDFDocument85 pages4 Case Adt Tran PDFRached Douahchua100% (3)

- 10 Steps To A Better Rheological Measurement PDFDocument44 pages10 Steps To A Better Rheological Measurement PDFHílary VpbNo ratings yet

- Comparison Table For Pipes and Fittings PDFDocument1 pageComparison Table For Pipes and Fittings PDFrcpretoriusNo ratings yet

- S154-1209 IomDocument66 pagesS154-1209 IomAlfredo GodinezNo ratings yet

- Properties Are Used To Identify Substances.: How Can Properties Help You Identify A Substance?Document5 pagesProperties Are Used To Identify Substances.: How Can Properties Help You Identify A Substance?Pothik OchenaNo ratings yet

- VINAIR Systems & ServicesDocument24 pagesVINAIR Systems & Servicessridevi anandhamNo ratings yet

- Sample SowDocument41 pagesSample Sowamir11601No ratings yet

- Abu Dhabi Oil Refining Doors and Windows SpecDocument16 pagesAbu Dhabi Oil Refining Doors and Windows SpecHalim KazdarNo ratings yet

- CBSE Sample Paper Class 8 Science SA1 Set 2: General InstructionsDocument4 pagesCBSE Sample Paper Class 8 Science SA1 Set 2: General InstructionsVijayalakshmi SenthilNo ratings yet