Professional Documents

Culture Documents

Comparison of The Effect of Sectional Border Molding Using Different Molding and Final Impression Materials On The Retention of Maxillary Complete Denture Bases

Uploaded by

IOSRjournalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Comparison of The Effect of Sectional Border Molding Using Different Molding and Final Impression Materials On The Retention of Maxillary Complete Denture Bases

Uploaded by

IOSRjournalCopyright:

Available Formats

IOSR Journal of Dental and Medical Sciences (IOSR-JDMS)

e-ISSN: 2279-0853, p-ISSN: 2279-0861.Volume 14, Issue 7 Ver. V (July. 2015), PP 35-40

www.iosrjournals.org

Comparison of the effect of sectional border molding using

different molding and final impression materials on the retention

of maxillary complete denture bases

Prof. Dr. Hikmat J. Al-Judy

B.D.S., M.Sc., Ph.D in Prosthodontic, College of Dentistry/ Baghdad University/ Baghdad, Iraq.

Abstract:

Background: Restoration of dentition lead to an improvement in the oral health related quality of life.

Complete dentures are used to restore this oral cavity disability to an acceptable condition.

Aim of the study: was to compare the retention of complete denture bases made by sectional border molding

using the low fusing compound and putty type condensation silicone for border molding material and metallic

oxide and light body condensation silicone as a final impression materials.

Materials and Method: Fifteen completely maxillary edentulous patients were selected. Eight close fitted

custom trays were constructed for each patient; the first two trays were fully border molded using green stick

compound. The third and fourth trays were fully border molded using the putty type silicone. The fifth and sixth

trays, the labial flanges were molded using green stick compound while the buccal and posterior palatal seal

area were molded using the putty type silicone. The seventh and eighth the labial flanges were molded using

putty type silicone compound while the buccal and posterior palatal seal area were molded using the green

stick. In each group, the final impressions were made using metallic oxide in the first tray and light body silicon

in the second try. After pouring of impressions and producing master casts, fabrication of heat cured denture

bases were made on each cast. The retention forces were examined and compared using strain measuring

device.

Results: there was a statistically highly significant difference in retention forces between denture bases

obtained from full and posterior putty silicone border molding combined with the light body silicone and

metallic oxide final impression materials compared to denture bases obtained from other tracing procedure,

materials and final impression materials, Significance was set at P 0.05.

Conclusion: Denture bases produced by full putty silicone and posterior putty silicone tracing material and

light body silicone final impression materials showed the highest mean values of retention forces.

Key words: Border molding, retention, maxillay complete denture.

I.

Introduction

One of the important parts of dental education and practice is the complete denture prosthodontic (1),

since the teeth loss leads to disability & impairment, and teeth restoration lead to improvement in the life quality

throughout the oral health improvement (2). The acceptable function of a complete denture on great extent

depends on impression technique which includes the maximum coverage of denture supporting areas and

making a combination of managing movable soft tissues along with different kinds of impression materials and

techniques for accurate reproduction of oral foundation (2, 3) .

The finished and polished denture base borders should simulate the final impression denture borders,

and one of the important factors in complete denture retention is the border seal, which is the biological factor

that involves contact of the denture borders with the surrounding oral soft tissues (4). Border molding considered

to be as an important step in the in complete denture fabrication, since the retention of complete dentures depend

on several factors, as the biological, physical and mechanical, these factors could be achieved by mean of an

accurate border molding followed by an accurate final impression (5).

The border molding technique is the shaping of the border areas of a custom impression tray by manual

or functional manipulation of the tissue adjacent to the borders in order to duplicate the size and contour of the

vestibule resulting in maintains of the peripheral seal during function (5, 6). Metallic oxide (zinc oxide eugenol)

final impression material following border molding with low fusing compound was the most commonly used

final impression in complete denture because its fast setting, capable of details reproduction, easily handled with

no significant dimensional changes subsequent to hardening, although some limitation is being present as heat

irritation to the oral tissues and presence of undercut areas make the introduction of another material as

polyvinalsiloxaine to be use in undercut areas as the putty silicone material since it had the ability to be correctly

accommodated in the peripheral sulcus for proper retention of the dentures resulting in comfort of the patient (7).

DOI: 10.9790/0853-14753540

www.iosrjournals.org

35 | Page

Comparison of the effect of sectional border molding using

The raised purpose of this study was to compare the retention of complete denture bases made by

sectional border molding using the low fusing compound and putty type condensation silicone for border

molding material and metallic oxide and light body condensation silicone as a final impression materials.

II.

Materials And Methods

Fifteen completely maxillary edentulous patients (ten male patients and five female patients) were

selected from the prosthodontic clinic of college of dentistry / Baghdad University, with age ranging from 50-60

years.

The patients were selected according to the inclusion criteria like well formed maxillary edentulous

arch, well rounded, adequate width and height of the residual ridges, no severe undercuts or bony exostosis, firm

mucosa of moderate thickness all over the denture bearing area and with no signs of inflammation, hyperplasia

or ulceration were selected to contribute in the present study.

All patients were informed about the study through patient information sheet and informed consent was

sought.

The principles of sterilization were followed during all steps of study. Preliminary impression were

made for each patient using irreversible hydrocolloid impression material (alginate, hydrogum, Zhermack, Italy)

and poured in dental stone (elite stone, Zhermack, Italy) to produce a study model. Eight custom trays of self

curing acrylic resin were constructed on each cast for each patient. The custom trays were fully checked in the

mouth to ascertain that the borders were to be approximately 2mm short of the vestibular reflections.

First group:

For the first tray, border molding was done section wise using low fusing tracing compound

(Hoffmanns, Germany) were applied to the tuberosity region of the tray, glazed over flame and tampered in hot

water, then inserted inside the patients mouth with protrusion and lateral movements were done by the patient

till the tracing compound were showed a mat rolled edge, as shown in (Figure 1A).

The posterior palatal seal was functionally performed by application of green stick compound at the

posterior border of tray from one hamular notch to other hamular, and the patient was asked to swallow. For

buccal and labial tracing, the same procedure were followed by adding the soft glazed tracing compound then

tempered and inserted inside the patient mouth and functional movements were done by moving the cheeks and

lips upward, forward and downward. After accomplishing of tracing procedure and checking the final tracing,

dryness was done to the tray and patient mouth and metallic oxide final impression paste (SS white, England)

were mixed and applied over the whole tray which was inserted inside the patient mouth, gentle pressure with

correct centralization and good support were applied with proper border molding till the material was set, the

impression was removed from the patient mouth, inspected. This impression was the control to be compared

with other impressions, as shown in (Figure 1B).

Figure (1): A. Custom tray molded with green stick, B. Metallic oxide final impression wash.

DOI: 10.9790/0853-14753540

www.iosrjournals.org

36 | Page

Comparison of the effect of sectional border molding using

Second group:

Full putty polyvinalsiloxaine border molding -an adhesive for silicone (Promedica,Germany)

impressions was applied on the outside borders of the tray . One scoop of putty type rubber base (Zhermack,

Italy) was mixed thoroughly by hand with catalyst for 30-45 seconds then rolled and applied to all the borders of

the tray crossing the posterior palatal seal area, then inserted inside the patient mouth with correct centralization

and border molding movements were done as in the first group. Then the tray was removed after silicone

material setting and examined for accurate details for border limiting structures, as shown in (Figure 2A).

Final impression was made using metallic oxide as in the first group. The same procedure and material

of border molding was done and final impression was made using the light body silicone, as shown in (Figure

2B and C

Figure (2): A. Custom tray molded with putty silicon, B. Metallic oxide final impression wash, and C. Light

body silicon final impression wash.

Third group:

The custom tray was border molded sectionally; the labial flanges were molded using the green stick

compound follow the same procedure as in first group, while the buccal flanges and posterior palatal seal area

were border molded using putty polyvinalsiloxaine impression material following the same procedure in second

group. The finished border molding was checked and final impression was made using metallic oxide

impression paste, as shown in (Figure 3). The same procedure and material for border molding was used and

final impression was made using light body silicone.

Figure (3): Custom tray molded labially with green stick while buccally and palataly molded with putty silicon.

Fourth group:

The labial flanges were molded using the putty type polyvinalsiloxaine impression material with the

buccal and posterior palatal seal area were molded using the low fusing compound, following the same

procedure in the first and second groups (Figure 4). The finished border molding was checked and final

impression was made using the metallic oxide impression paste. The same procedure and material for border

molding was used and final impression was made using light body silicone.

All impression trays were beaded and boxed, then pouring the impression in dental stone to produce the

master casts.

DOI: 10.9790/0853-14753540

www.iosrjournals.org

37 | Page

Comparison of the effect of sectional border molding using

Figure (4): Custom tray molded labially with putty silicon while buccally and palataly molded with green stick.

Denture Base Preparations

Each patient received eight heat cured acrylic resin denture bases which was of thickness 2mm, that

had been constructed on the master casts for each patient. All mixing and curing was done according to

manufacturer recommendation. After flasking, the cured denture bases were finished and polished. For

measurement of retention, a wire loop of 0.9mm in diameter was constructed to be attached to the center of the

polished palatal surface by using autopolymerized acrylic resin, this wire loop would be used for hook

attachment of the force meter, the hook used being light in weight and its easily sterilized using 70% solution of

isopropyl alcohol.

A vertical downward force was applied to dislodge each denture base as the patient was set in an

upright position with the occlusal plane is being parallel to the floor, and the patients head was held firmly on

the head rest. The force values at which the denture bases were dislodged completely from the palate was

displayed on a strain measuring device represented by (mv) and by referring to the calibrated data, the force

values in grams could be calculated. The results were collected and statistically analyzed to evaluate the

difference in retention of the denture bases.

III. Results

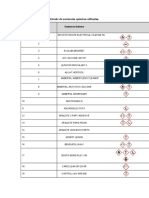

The statistical analysis of the data obtained indicated that the higher mean of retention forces were

found in the denture bases were fabricated by using the full putty silicone border molding accombined with

light body silicone final impression, then follow by the denture bases were fabricated from anterior green stick

tracing and posterior putty silicone border molding with light body silicone and metallic oxide final impression

material (Table 1), while the least retention forces of denture bases was indicated in the denture bases were

fabricated from full green stick tracing and metallic oxide impression materials and in posterior tracing using

green stick material a combined to metallic oxide and light body silicone final impression material. (Table 1),

(Figure 5).

The analysis of variance (ANOVA) test showed that there was a statistically highly significant

difference in retention force between denture bases obtained from full and posterior putty silicone border

molding combined with the light body silicone and metallic oxide final impression materials compared to

denture bases obtained from other tracing procedure, materials and final impression materials as shown in

(Table 2, 3). For the comparison between group, (Table 4), a highly significant differences between the denture

bases obtained by light body silicone final impression material as compared to denture bases obtained by

metallic oxide final impression material when the same tracing procedure and material were used.

Table (1): Descriptive statistics for retention force values in gm of all groups

Groups

1

2

3

4

5

6

7

N

15

15

15

15

15

15

15

Mean

1303.32

2908.39

3406.55

2895.06

3002.94

1330.30

1341.93

S.D.

9.57

7.89

6.78

8.29

7.36

2.05

0.14

S.E.

2.47

2.04

1.75

2.14

1.90

0.53

0.04

Min.

1288.90

2900.20

3400.60

2876.10

2992.90

1329.10

1341.70

Max.

1317.90

2924.30

3420.10

2908.90

3017.00

1337.20

1342.10

Table (2): ANOVA test for retention forces between and within groups

ANOVA

Between Groups

Within Groups

Total

Sum of Squares

79399480.12

4576.89

79404057.02

d.f.

6

98

104

Mean Square

13233246.69

46.70

F-test

p-value

283349.09

0.000

(HS)

Significant (S): P 0.05

Highly Significant (HS): P0.001

DOI: 10.9790/0853-14753540

www.iosrjournals.org

38 | Page

Comparison of the effect of sectional border molding using

Table (3): LSD test for retention forces between and within groups.

Groups

2

3

4

1

5

6

7

3

4

2

5

6

7

4

5

3

6

7

5

4

6

7

6

5

7

6

7

Mean Difference

-1605.07

-2103.23

-1591.74

-1699.62

-26.98

-38.61

-498.16

13.33

-94.55

1578.09

1566.47

511.49

403.61

2076.25

2064.63

-107.88

1564.76

1553.13

1672.64

1661.01

-11.63

p-value

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

0.000 (HS)

S.E. = 2.50

Table (4): Comparison of the retention forces of complete denture bases between groups

Groups

2 vs. 3

4 vs. 5

6 vs. 7

Mean Difference

-498.16

-107.88

-11.63

t-test

-185.48

-37.69

-21.86

d.f.

28

28

28

p-value

0.000 (HS)

0.000 (HS)

0.000 (HS)

Figure (5): The retention forces mean of maxillary complete denture bases (gm) produced by different sectional

border molding and different final impression materials.

IV. Discussion

One of the main goals of successful complete denture treatment is the construction of a retentive

denture, since the irretentive dentures disturb all other goals as mastication, speech and in turn affected patients

psychology (7). One of the greatest important factors to obtain such required retention is the peripheral seal, and

to gain this peripheral seal, border molding must be done (8).

This study deals with four different sectioning of border molding using two different materials and two

final impression materials to compare the maxillary denture base retention obtained from these border molding

and final impression materials. In the present study, patients with well formed residual ridges were selected

without undercuts to eliminate the effect of mechanical factors on dentures retention which is an important

variable during the research. The age of the patient participated in the study were selected with the age ranged

from 50-60 years, since patients over 60 were excluded as they are more susceptible to trauma of oral mucosa,

increased mitosis with slow turnover of tissue, and overall increase in the elastic fiber number.

The higher retention forces were detected in the denture bases produced by putty silicone full tracing

a combined by light body silicone final impression material as it was compared with other tracing procedure and

DOI: 10.9790/0853-14753540

www.iosrjournals.org

39 | Page

Comparison of the effect of sectional border molding using

materials, these results could be explained on the bases, that the putty silicone tracing characterized by an

excellent manipulative consistencies dimensional stability and being molding by fingers prior to be inserted

intra orally with an adequate working times(9), these properties of putty silicone tracing material resulted in

uniform border thickness and smooth continuity, with elasticity of putty silicone which help in accurate

adaptation of the tissue borders with simultaneous muscle movement resulted in a uniform recording of the

periphery (3) on both sides resulting in all around peripheral seal, in addition, as the light body silicone final

impression is being polymerized against the putty type silicone full tracing, so this exhibit good dimensional

stability as a result of greater bone strength between the putty tracing and light body silicone final impression

material (8), all these facts explain the higher retention forces and its statistically highly significant difference as

compared to retention forces of denture bases produced by full green stick tracing and metallic oxide final

impression, this may be clarified by the facts that during softening procedure, green stick by dry heat flame, this

may have resulting in flow and texture properties of green stick material, since the flow will be retained for a

short period of time, as its in contact with hot water & oral tissues, the green stick cool and flow ceased this may

be resulted in an inaccurate impression and if tissues are contacted before tray is properly seated for border

molding procedure (6). in addition, the newly added materials to a tray border with section being previously

molded this contact of fresh green stick material to already set one may compromise the bonding between fresh

and set green stick materials, which might be resulted in error in continuity, and the high heat required for

softening of the green stick, as it being in tissue contact, this may result in a alteration of muscle tonicity as

reflex to heat application and resulting in compromised border molding, and this may be associated with

multiple insertion during molding procedure which may alter the orientation of the tray and may incorporating

an error (3) that is why the denture bases resulting from full green stick and full metallic oxide is with least

retention forces compared to the other tracing procedures, and also explain why the retention forces is decrease

with use of green stick tracing for posterior palatal seal area in sectional tracing procedure, when the anterior

flanges were traced with putty silicone but the retention values is improved with use of light body silicone as

final impression material because of good flow property all over the peripheral surfaces, these finding are in line

with the findings of Rizk (7) and Yarapatineni et al. (3) while in using the putty type silicone as a tracing

materials for the posterior palatal seal areas resulting in a higher retention values than the use of green stick

tracing material, this may be attributed is the better adaptability of the putty silicone and better peripheral seals

were achieved due to the more accurate recording of the seal areas, this may associated with good flow of light

body silicone final impression all over the peripheral surfaces of the denture bearing area and the chemical

bond between the light body silicone final impression and putty silicone tracing, also the retention forces in

denture bases with use of metallic oxide as a final impression is less than is with use of light body silicone,

because of lacks bonding to both green stick and putty silicone tracing material.

IV. Conclusion

Within the limitation of this study, can conclude:

1. Denture bases produced by full putty silicone and posterior putty silicone tracing material and light body

silicone final impression materials showed the highest mean values of retention forces.

2. The denture bases produced by full green final impression material showed the lowest mean values of

retention forces

3. All the retention forces of all denture bases showed an acceptable retention forces on clinical examination.

References

[1].

[2].

[3].

[4].

[5].

[6].

[7].

[8].

[9].

Jayaprakash MB., Sahu K, Khan M, Khoriya S, Jadhav S, Rendre B, Lukaram A. Management of flabby ridge cases: A chanllenge

in clinical practice. Int. adv health sci 2014; 1(5): 32-7.

Tasleem R, Bin Saeed MH, Javed MU. Comparison of complete denture fabricated by two different border molding materials,

interms of patients satisfaction. J Ayub Med Coll Abbottabad 2013; 26(3-4): 78-80

Yarapatineni R, Vilekar A, Kumar JP, Kumar GA, Aravind P, Kumar PA. Comparative evaluation of border molding, using two

different techniques in maxillary edentulous arches-An in vivo study. Int oral heath 2013; 5(6): 82-7.

Patel JR, Sethuraman R, Chaudhari J. Comparative evaluation of border morphology produced by three different border molding

materials. Int. Journal of Contemporary Dentistry 2010; 1(3).

Olivieri A, Zuccari AG, Olivieri D. A technique for border molding with light polymerized resin. J Prosthet Dent 2003; 90: 101.

Smith DE, Toolson LB, Bolender CL, Lord JL. One step border molding of complete denture impression using polyether

impression material. J Prothet Dent. 1974; 41: 347-51.

Rizk FN. Effect of different border molding materials on complete denture retention. C.D.J 2008; 24; 3: 415-20.

Nawar NH. Eid HI, Sabet ME. A study on the effect of border molding on retentive efficiency of maxillary complete denture.

C.D.J. 2005; 21:135-40.

Felton DA, Cooper LF, Scurria MS. Predictable impression procedure for complete dentures. J Prosthet Dent. 1996; 40: 39-51.

DOI: 10.9790/0853-14753540

www.iosrjournals.org

40 | Page

You might also like

- Direct Bonding: in Orthodontic Treatment and Retention A Post-Treatment EvaluationDocument11 pagesDirect Bonding: in Orthodontic Treatment and Retention A Post-Treatment EvaluationDolores PerezNo ratings yet

- 13vol10issue7pp63 6720220719045919Document5 pages13vol10issue7pp63 6720220719045919Joshni LoitongbamNo ratings yet

- Ika Prof TriDocument4 pagesIka Prof TriHarry FaisalNo ratings yet

- Accuracy of Working Casts and Dies Produced by Fast-Setting Polyvinyl Siloxane ImpressionsDocument9 pagesAccuracy of Working Casts and Dies Produced by Fast-Setting Polyvinyl Siloxane ImpressionsDedi Rafael ChristiantoNo ratings yet

- Oral Sub-Mucous FibrosisDocument2 pagesOral Sub-Mucous FibrosisShreyans DamadeNo ratings yet

- 7 SEC Etching Time, IN PRIMARY TEETH - 2012Document9 pages7 SEC Etching Time, IN PRIMARY TEETH - 2012DrSugandh MittalNo ratings yet

- Repairability of Dental Siloranes in Vitro:, Barbara Görmann, Silke Jacker-Guhr, Werner GeurtsenDocument6 pagesRepairability of Dental Siloranes in Vitro:, Barbara Görmann, Silke Jacker-Guhr, Werner GeurtsensamanimahsaNo ratings yet

- Full Mouth Implant Rehabilitation Using Fixed Detachable Bio HPP Frameworks in The Presence of One Piece Implants A Clinical ReportDocument10 pagesFull Mouth Implant Rehabilitation Using Fixed Detachable Bio HPP Frameworks in The Presence of One Piece Implants A Clinical ReportAthenaeum Scientific PublishersNo ratings yet

- Thermoplastic Distal Extension Removable Partial Dentures Versus Vitallium OnesDocument4 pagesThermoplastic Distal Extension Removable Partial Dentures Versus Vitallium OnesDeasireeNo ratings yet

- Applied Sciences: Graphene-Chitosan Hybrid Dental Implants With Enhanced Antibacterial and Cell-Proliferation PropertiesDocument10 pagesApplied Sciences: Graphene-Chitosan Hybrid Dental Implants With Enhanced Antibacterial and Cell-Proliferation PropertiesPhoebe DavidNo ratings yet

- All-Ceramic Inlay-Retained Fixed Partial Dentures Preliminary Results From A Clinical StudyDocument5 pagesAll-Ceramic Inlay-Retained Fixed Partial Dentures Preliminary Results From A Clinical StudyBogdan Moruz SiniavschiNo ratings yet

- Case Report: Restoration of Endodontically Treated Molars Using All Ceramic EndocrownsDocument6 pagesCase Report: Restoration of Endodontically Treated Molars Using All Ceramic EndocrownsTaufiqurrahman Abdul DjabbarNo ratings yet

- Aesthetic Layering TechniqueDocument0 pagesAesthetic Layering Techniqueatul_singh2001No ratings yet

- Article About Lab Preparation of Implants For HistoDocument1 pageArticle About Lab Preparation of Implants For HistodrjonduNo ratings yet

- Composite Resin Fillings and Inlays. An 11-Year Evaluation: OriginalarticleDocument10 pagesComposite Resin Fillings and Inlays. An 11-Year Evaluation: OriginalarticleMira AnggrianiNo ratings yet

- A Simplified Method For The Fabrication of Obturator:a Case ReportDocument4 pagesA Simplified Method For The Fabrication of Obturator:a Case ReportinventionjournalsNo ratings yet

- 2 60 1613455536 1ijdrdjun20211Document8 pages2 60 1613455536 1ijdrdjun20211TJPRC PublicationsNo ratings yet

- Caculo Et Al-2013-Journal of Prosthodontics PDFDocument6 pagesCaculo Et Al-2013-Journal of Prosthodontics PDFArchitNo ratings yet

- Longterm Survey All Ceramic Inlays Onlays Quintessnce 2020Document11 pagesLongterm Survey All Ceramic Inlays Onlays Quintessnce 2020Raghu PratapNo ratings yet

- Ferrari Et Al 2017 JDentDocument29 pagesFerrari Et Al 2017 JDentAli Al-QaysiNo ratings yet

- Impression Materials in Fixed Prosthodontics - in Uence of Choice On Clinical ProcedureDocument8 pagesImpression Materials in Fixed Prosthodontics - in Uence of Choice On Clinical Procedurebigblue1907No ratings yet

- Clinical performance of indirect composite onlays and overlaysDocument23 pagesClinical performance of indirect composite onlays and overlaysAya Ibrahim YassinNo ratings yet

- Material Options For Class II Composite Restorations - Varied Clinical Parameters Require Different TechniquesDocument6 pagesMaterial Options For Class II Composite Restorations - Varied Clinical Parameters Require Different TechniquesMohammed NabeelNo ratings yet

- Windowimpressiontechnique 2018Document5 pagesWindowimpressiontechnique 2018Winda KhosasiNo ratings yet

- Twelve Years Results of A Direct Bonded Partial Prosthesis in A Patient With Advanced PeriodontitisDocument5 pagesTwelve Years Results of A Direct Bonded Partial Prosthesis in A Patient With Advanced PeriodontitisCarlos MuniveNo ratings yet

- Resin Bonded Fiber JurnalDocument9 pagesResin Bonded Fiber JurnalIna Permata DewiNo ratings yet

- Prosthetic Rehabilitation of A Maxillectomy Patient With A Titanium Closed Hollow Bulb Obturator Using Lost Wax Bolus Technique - A Case ReportDocument8 pagesProsthetic Rehabilitation of A Maxillectomy Patient With A Titanium Closed Hollow Bulb Obturator Using Lost Wax Bolus Technique - A Case ReportIJAR JOURNALNo ratings yet

- Grandini Poste AnatomicoDocument5 pagesGrandini Poste AnatomicoMariana Moraga RoblesNo ratings yet

- A Histopathologic Study On Pulp Response To Glass Ionomer Cements in Human TeethDocument8 pagesA Histopathologic Study On Pulp Response To Glass Ionomer Cements in Human Teethnahm17No ratings yet

- In Vitro Analysis of Quality of Dental Adhesive BondDocument4 pagesIn Vitro Analysis of Quality of Dental Adhesive BondDumitritaNo ratings yet

- Journal Homepage: - : IntroductionDocument8 pagesJournal Homepage: - : IntroductionIJAR JOURNALNo ratings yet

- Minimally Invasive Technique For The Treatment of A Wedge Defect in Hard TissuesDocument3 pagesMinimally Invasive Technique For The Treatment of A Wedge Defect in Hard TissuesAcademic JournalNo ratings yet

- The Influence of Impression Techniques of Distal Extension Removable Partial Dentures On The Periodontium of The Abutment TeethDocument4 pagesThe Influence of Impression Techniques of Distal Extension Removable Partial Dentures On The Periodontium of The Abutment TeethIKong IntasuwanNo ratings yet

- 0 TermosensDocument7 pages0 TermosensKadek AgusNo ratings yet

- Osseointegration of Rough Acid-Etched Implants: One-Year Follow-Up of Placement of 100 Minimatic ImplantsDocument14 pagesOsseointegration of Rough Acid-Etched Implants: One-Year Follow-Up of Placement of 100 Minimatic ImplantsMedstudNo ratings yet

- Rathmann 2017Document25 pagesRathmann 2017Alejandra LorancaNo ratings yet

- Telescopic Overdenture: Perio Prostho Concern For Advanced PeriodontitisDocument4 pagesTelescopic Overdenture: Perio Prostho Concern For Advanced PeriodontitisrekabiNo ratings yet

- Microleakage of Restorative Materials: An in Vitro Study: M P., D S., S ADocument4 pagesMicroleakage of Restorative Materials: An in Vitro Study: M P., D S., S Apreethi.badamNo ratings yet

- A New Bioactive Cement For Direct Pulp Capping: ClinicalDocument6 pagesA New Bioactive Cement For Direct Pulp Capping: ClinicalWulan Ambar WatyNo ratings yet

- Aesthetic Rehabilitation With Ultra-Thin Ceramic Veneers - Case ReportDocument4 pagesAesthetic Rehabilitation With Ultra-Thin Ceramic Veneers - Case ReportIJAERS JOURNALNo ratings yet

- Ijp 18 5 Grandini 7Document6 pagesIjp 18 5 Grandini 7kochikaghochiNo ratings yet

- V9n3a17 PDFDocument6 pagesV9n3a17 PDFRossye MpfNo ratings yet

- Rehabilitaton of Nose Using Silicone Based Maxillofacial ProsthesisDocument3 pagesRehabilitaton of Nose Using Silicone Based Maxillofacial ProsthesisOboroc IrinaNo ratings yet

- Comparative Evaluation of Microleakage in Class II Cavities Restored With Ceram X and Filtek P-90: An in Vitro StudyDocument6 pagesComparative Evaluation of Microleakage in Class II Cavities Restored With Ceram X and Filtek P-90: An in Vitro StudyRedhabAbbassNo ratings yet

- Nonvital Root Canal TreatmentDocument6 pagesNonvital Root Canal TreatmentAnother GNo ratings yet

- A Comparative Study of Impression Procedures For Distal Extension Removable Partial DenturesDocument6 pagesA Comparative Study of Impression Procedures For Distal Extension Removable Partial Denturesmilirose845153No ratings yet

- Efficacy of Airpolishing Devices Without Removal of Implantsupported Fullarch ProsthesesDocument11 pagesEfficacy of Airpolishing Devices Without Removal of Implantsupported Fullarch ProsthesesDiego Saavedra MoralesNo ratings yet

- The Use of Computer-Aided Manufacturing During The Treatment of The Edentulous Mandible in An Oral Radiation Therapy Patient: Clinical ReportDocument4 pagesThe Use of Computer-Aided Manufacturing During The Treatment of The Edentulous Mandible in An Oral Radiation Therapy Patient: Clinical Reportdent in dentistNo ratings yet

- Resinas Estécticas Inyectables-2216679Document9 pagesResinas Estécticas Inyectables-2216679Roberto PucNo ratings yet

- The Influence of Different Composite Placement Techniques On Microleakage in Preparations With High C-FactorDocument5 pagesThe Influence of Different Composite Placement Techniques On Microleakage in Preparations With High C-FactordaconetubeNo ratings yet

- MTA vs Calcium Hydroxide in Dentine Bridge FormationDocument7 pagesMTA vs Calcium Hydroxide in Dentine Bridge FormationCHOUCHOU12485No ratings yet

- TSWJ2023 9920850Document9 pagesTSWJ2023 9920850birkekocaunsalNo ratings yet

- N Vitro Wear of Resin-Based Materials-: Simultaneous Corrosive and Abrasive WearDocument7 pagesN Vitro Wear of Resin-Based Materials-: Simultaneous Corrosive and Abrasive Wearu1azadNo ratings yet

- Effect of Different Denture Base Materials and ChaDocument6 pagesEffect of Different Denture Base Materials and ChadentureNo ratings yet

- Effect of Different CAD-CAM Materials On The Marginal and Internal Adaptation of Endocrown Restorations: An in Vitro StudyDocument7 pagesEffect of Different CAD-CAM Materials On The Marginal and Internal Adaptation of Endocrown Restorations: An in Vitro StudyNetra TaleleNo ratings yet

- Naumovski2017 PDFDocument8 pagesNaumovski2017 PDFCristobalVeraNo ratings yet

- EuropeanDocument162 pagesEuropeanagusaranpNo ratings yet

- Accuracy of Polyether and Addition Silicone After Long-Term Immersion DisinfectionDocument5 pagesAccuracy of Polyether and Addition Silicone After Long-Term Immersion DisinfectionEmaFYNo ratings yet

- Effect of Hyaluronic Acid On The Osseointegration of Dental ImplantsDocument5 pagesEffect of Hyaluronic Acid On The Osseointegration of Dental Implantsjaviers45No ratings yet

- Treatment Planning Single Maxillary Anterior Implants for DentistsFrom EverandTreatment Planning Single Maxillary Anterior Implants for DentistsNo ratings yet

- Socio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanDocument7 pagesSocio-Ethical Impact of Turkish Dramas On Educated Females of Gujranwala-PakistanInternational Organization of Scientific Research (IOSR)No ratings yet

- "I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweDocument5 pages"I Am Not Gay Says A Gay Christian." A Qualitative Study On Beliefs and Prejudices of Christians Towards Homosexuality in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Assessment of The Implementation of Federal Character in Nigeria.Document5 pagesAssessment of The Implementation of Federal Character in Nigeria.International Organization of Scientific Research (IOSR)No ratings yet

- An Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyDocument14 pagesAn Evaluation of Lowell's Poem "The Quaker Graveyard in Nantucket" As A Pastoral ElegyInternational Organization of Scientific Research (IOSR)No ratings yet

- A Review of Rural Local Government System in Zimbabwe From 1980 To 2014Document15 pagesA Review of Rural Local Government System in Zimbabwe From 1980 To 2014International Organization of Scientific Research (IOSR)No ratings yet

- Relationship Between Social Support and Self-Esteem of Adolescent GirlsDocument5 pagesRelationship Between Social Support and Self-Esteem of Adolescent GirlsInternational Organization of Scientific Research (IOSR)No ratings yet

- A Proposed Framework On Working With Parents of Children With Special Needs in SingaporeDocument7 pagesA Proposed Framework On Working With Parents of Children With Special Needs in SingaporeInternational Organization of Scientific Research (IOSR)No ratings yet

- Attitude and Perceptions of University Students in Zimbabwe Towards HomosexualityDocument5 pagesAttitude and Perceptions of University Students in Zimbabwe Towards HomosexualityInternational Organization of Scientific Research (IOSR)No ratings yet

- The Role of Extrovert and Introvert Personality in Second Language AcquisitionDocument6 pagesThe Role of Extrovert and Introvert Personality in Second Language AcquisitionInternational Organization of Scientific Research (IOSR)No ratings yet

- The Impact of Technologies On Society: A ReviewDocument5 pagesThe Impact of Technologies On Society: A ReviewInternational Organization of Scientific Research (IOSR)100% (1)

- Comparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesDocument7 pagesComparative Visual Analysis of Symbolic and Illegible Indus Valley Script With Other LanguagesInternational Organization of Scientific Research (IOSR)No ratings yet

- Investigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehDocument4 pagesInvestigation of Unbelief and Faith in The Islam According To The Statement, Mr. Ahmed MoftizadehInternational Organization of Scientific Research (IOSR)No ratings yet

- Importance of Mass Media in Communicating Health Messages: An AnalysisDocument6 pagesImportance of Mass Media in Communicating Health Messages: An AnalysisInternational Organization of Scientific Research (IOSR)No ratings yet

- Edward Albee and His Mother Characters: An Analysis of Selected PlaysDocument5 pagesEdward Albee and His Mother Characters: An Analysis of Selected PlaysInternational Organization of Scientific Research (IOSR)No ratings yet

- Human Rights and Dalits: Different Strands in The DiscourseDocument5 pagesHuman Rights and Dalits: Different Strands in The DiscourseInternational Organization of Scientific Research (IOSR)No ratings yet

- The Lute Against Doping in SportDocument5 pagesThe Lute Against Doping in SportInternational Organization of Scientific Research (IOSR)No ratings yet

- Beowulf: A Folktale and History of Anglo-Saxon Life and CivilizationDocument3 pagesBeowulf: A Folktale and History of Anglo-Saxon Life and CivilizationInternational Organization of Scientific Research (IOSR)No ratings yet

- Topic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshDocument7 pagesTopic: Using Wiki To Improve Students' Academic Writing in English Collaboratively: A Case Study On Undergraduate Students in BangladeshInternational Organization of Scientific Research (IOSR)No ratings yet

- Role of Madarsa Education in Empowerment of Muslims in IndiaDocument6 pagesRole of Madarsa Education in Empowerment of Muslims in IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- Classical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahDocument9 pagesClassical Malay's Anthropomorphemic Metaphors in Essay of Hikajat AbdullahInternational Organization of Scientific Research (IOSR)No ratings yet

- An Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsDocument6 pagesAn Exploration On The Relationship Among Learners' Autonomy, Language Learning Strategies and Big-Five Personality TraitsInternational Organization of Scientific Research (IOSR)No ratings yet

- Transforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweDocument9 pagesTransforming People's Livelihoods Through Land Reform in A1 Resettlement Areas in Goromonzi District in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Kinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationDocument6 pagesKinesics, Haptics and Proxemics: Aspects of Non - Verbal CommunicationInternational Organization of Scientific Research (IOSR)No ratings yet

- Women Empowerment Through Open and Distance Learning in ZimbabweDocument8 pagesWomen Empowerment Through Open and Distance Learning in ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Motivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweDocument8 pagesMotivational Factors Influencing Littering in Harare's Central Business District (CBD), ZimbabweInternational Organization of Scientific Research (IOSR)No ratings yet

- Design Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextDocument6 pagesDesign Management, A Business Tools' Package of Corporate Organizations: Bangladesh ContextInternational Organization of Scientific Research (IOSR)No ratings yet

- Substance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaDocument11 pagesSubstance Use and Abuse Among Offenders Under Probation Supervision in Limuru Probation Station, KenyaInternational Organization of Scientific Research (IOSR)No ratings yet

- Designing of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesDocument5 pagesDesigning of Indo-Western Garments Influenced From Different Indian Classical Dance CostumesIOSRjournalNo ratings yet

- Micro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaDocument3 pagesMicro Finance and Women - A Case Study of Villages Around Alibaug, District-Raigad, Maharashtra, IndiaInternational Organization of Scientific Research (IOSR)No ratings yet

- A Study On The Television Programmes Popularity Among Chennai Urban WomenDocument7 pagesA Study On The Television Programmes Popularity Among Chennai Urban WomenInternational Organization of Scientific Research (IOSR)No ratings yet

- Impression MaterialsDocument58 pagesImpression MaterialsShruti AnandNo ratings yet

- Ingress Protection TestDocument31 pagesIngress Protection Testandrez880103No ratings yet

- Wacker Silicones BrochureDocument14 pagesWacker Silicones Brochureluigi74No ratings yet

- Tremco Product Selector - Glazing MY SG (Web)Document3 pagesTremco Product Selector - Glazing MY SG (Web)Tung Thanh100% (1)

- DynatexDocument2 pagesDynatexFaizal JamalNo ratings yet

- XIAMETER OFS 0777 TDS en PDFDocument3 pagesXIAMETER OFS 0777 TDS en PDFsriatul2006No ratings yet

- Skin & Color Tools MBDocument7 pagesSkin & Color Tools MBJohana Ibarra JaramilloNo ratings yet

- Molding Large Rocks for Realistic Taxidermy DisplaysDocument4 pagesMolding Large Rocks for Realistic Taxidermy DisplaysrebootisNo ratings yet

- Clariant SUN CARE Brochure 7 - 2013Document4 pagesClariant SUN CARE Brochure 7 - 2013AvanishNo ratings yet

- Document On FinishesDocument18 pagesDocument On Finishesn.tNo ratings yet

- Wika Gauge Pressure CatalogueDocument189 pagesWika Gauge Pressure CatalogueHery FitiaNo ratings yet

- General PresentationDocument53 pagesGeneral PresentationKARIM GARAHNo ratings yet

- Petronas Vendor Approved List Jan 2018Document50 pagesPetronas Vendor Approved List Jan 2018Sumner Ting60% (5)

- Cab-O-Sil M-5 Fumed Silica: Name of Library Here Datasheet Number Hydrophilic Fumed SilicaDocument2 pagesCab-O-Sil M-5 Fumed Silica: Name of Library Here Datasheet Number Hydrophilic Fumed SilicaN ShahNo ratings yet

- Larsen Merchant CatalogueDocument36 pagesLarsen Merchant CatalogueSonNo ratings yet

- Acrabond KE45 Type RTV Silicone SealantDocument5 pagesAcrabond KE45 Type RTV Silicone SealantdrvikaasNo ratings yet

- Polymer Modification With Reactive Silicones v1407Document14 pagesPolymer Modification With Reactive Silicones v1407Thanh VuNo ratings yet

- Insulation System For Internal Con-Nectors in Gas Cooled Turbine GeneratorsDocument2 pagesInsulation System For Internal Con-Nectors in Gas Cooled Turbine GeneratorsicaanmpzNo ratings yet

- Fluorosilicone Rubber Product Selection Guide: How Can You Expand Your Design Options?Document8 pagesFluorosilicone Rubber Product Selection Guide: How Can You Expand Your Design Options?Nguyên NguyễnNo ratings yet

- 3mtm Viscoelastic Damping Polymers 112 130 PDFDocument9 pages3mtm Viscoelastic Damping Polymers 112 130 PDF1mmahoneyNo ratings yet

- Station Arrester CatalogDocument12 pagesStation Arrester Catalogkenlavie2No ratings yet

- NIWI-2703.3 Guidelines For Removing Metal Flow From Insulated JointsDocument6 pagesNIWI-2703.3 Guidelines For Removing Metal Flow From Insulated JointsCK TangNo ratings yet

- Polysiloxane Modification EN May2021 USDocument4 pagesPolysiloxane Modification EN May2021 USمحمد مقلدNo ratings yet

- HazmatDocument9 pagesHazmategarciachNo ratings yet

- Paints Applicable For Boiler Components - BergerDocument10 pagesPaints Applicable For Boiler Components - BergerVel MuruganNo ratings yet

- TL 5 X 10Document10 pagesTL 5 X 10number_25No ratings yet

- 6709 enDocument105 pages6709 enDejan MitrovićNo ratings yet

- Coatings Word April 2011Document52 pagesCoatings Word April 2011sami_sakrNo ratings yet

- Bourbon RhodeDocument3 pagesBourbon RhodeIndex.hrNo ratings yet

- Fluoropolymers, Polysiloxanes, and Polyurethanes Compared for Weather Resistance and Color RetentionDocument5 pagesFluoropolymers, Polysiloxanes, and Polyurethanes Compared for Weather Resistance and Color RetentionAnselmo RibeiroNo ratings yet