Professional Documents

Culture Documents

Ohs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised by

Uploaded by

adiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ohs Form 005 Safe Work Method Statement (SWMS) : This SWMS Has Been Developed and Authorised by

Uploaded by

adiCopyright:

Available Formats

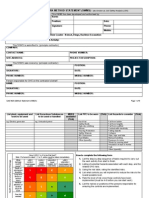

OHS FORM 005 SAFE WORK METHOD STATEMENT (SWMS) also known as Job Safety Analysis (JSA)

This SWMS has been developed and authorised by:

Name:

Company Name:

Position:

Date:

ABN:

Signature:

Phone:

Mobile:

DESCRIPTION OF WORK ACTIVITY:

Concrete Placement (General)

Trades involved with undertaking this Work Activity:

This SWMS is submitted to: (principle contractor)

COMPANY:

CONTACT NAME:

PHONE NUMBER:

SITE ADDRESS:

PROJECT DESCRIPTION:

This SWMS was review by: (principle contractor)

NAME:

POSITION:

SIGNATURE:

DATE:

PHONE NUMBER:

MOBILE NUMBER:

Person responsible for OHS on the contractors behalf:

NAME:

POSITION:

SIGNATURE:

DATE:

PHONE NUMBER:

MOBILE NUMBER:

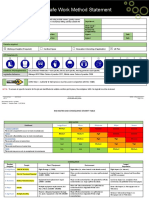

Safe Work Method Statement (SWMS)

Page 1 of 1

List plant, equipment and

tools to be used

eg. Electric generator

List Hazardous Substances

to be used or handled

MSDS

available?

(Tick)

eg. Unleaded petrol

Hard Hat

Safety Boots

High-visy clothing

Gloves

Hearing Protection

Safety Glasses

30+ Sunscreen

Dust Masks

Other (specify):

Health Risks and Likelihood of Damage

How LIKELY is it to be that bad?

Note: If a hazard is rated 1, 2 or 3, action must be taken immediately.

What

damage

could it

cause?

Death or

permanent

disability

Long term

illness or

serious

injury

Medical

attention or

several

days off

work

First Aid

needed

VERY

LIKELY

VERY

UNLIKELY

LIKELY

UNLIKELY

Could happen

anytime

Could

happen

sometimes

Could

happen, but

only rarely

Could happen, but

probably never will

Safe Work Method Statement (SWMS)

List PPE to be worn

(Tick) List Hazards to consider

(Tick)

Fall from ladder

Fall from heights

Fall from scaffold

Contact with electricity

Falling objects

Collapse

Slips, trips and falls

Manual handling

Exposure to noise

Struck by moving plant

Inhalation of dust or fumes

Cuts

Other (specify):

How to complete the following form

1. List the step-by-step sequence of tasks required to carry out

the work activity from start to finish.

2. Listing of potential hazards associated with each step, and the

related OHS risks.

3. Using the risk table, rating the identified risks.

4. List what controls you will implement to reduce the risks to the

lowest possible level.

5. Rate the level of risk once those controls have been

implemented (must be 4-6 before you can start work).

6. List the names or positions of the persons responsible for

ensuring the controls are implemented.

Page 2 of 2

1.

2.

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Entry to Site

Entry to unsafe area

Report to site office for site induction.

Risk assessment of site conditions.

Unloading Equipment

Movement of site

personnel, vehicles, plant

& equipment

Fall from vehicle

Manual handling injuries,

cuts, splinters & abrasions

3.

Controls Implemented

Setting out / up

equipment

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Training of all employees

Training employees in manual handling and team

lifting

Wear gloves (PPE)

Being struck by equipment

Crush hands

Training employees in manual handling

The use of P.P.E equipment such as gloves

Team lifting

Slips, trips & falls

Unload equipment on a level clear area

Trips & falls

Ensure site is clear of any debris, obstructions.

Define & barricade work area & fall areas

4.

Drilling piers

Hit by auger or bobcat

excavator

Only suitably trained personnel to work with plant

Plant & equipment to be maintained, operator

must be licensed

Fall in holes

Safe Work Method Statement (SWMS)

The training and use of P.P.E equipment such as

high visible vests, hard hats

Personnel to be trained on relevant works.

Site Induction

Page 3 of 3

5.

Placing Concrete in piers

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Run over by concrete

pump or trucks

Controls Implemented

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Truck drivers to be made aware of site entry,

driver to be aware of the whereabouts of the

offsider

Reverse siren to be in working order on concrete

pumps & trucks.

Relevant personnel to be in sight of driver at all

times

Pump operators to supply maintenance checklist &

log books

6.

Installing pegs for edge

boards

Back injury from using

sledgehammer.

All relevant personnel to be trained in the use and

shown the correct procedure in using a

sledgehammer.

Missing target when using

sledgehammer.

Use P.P.E equipment

Cuts, splinters and

abrasions

Training in manual handling and correct use of

sledgehammer

Arm & shoulder injuries

Training in manual handling

Keep hands and limbs out of rage

Workers to keep others in sight

Safe Work Method Statement (SWMS)

Page 4 of 4

7.

8.

Installation of formwork

Benching / fill slab

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Back and shoulder injuries

Injury from nail gun

Hit by materials

Hit by machines / plant

Back and shoulder injury

Controls Implemented

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Training in manual handling

Keep hands and limbs out of range.

Workers to keep others in sight

Training in the use of shovels and wheelbarrows.

P.P.E equipment eye protection.

Eye injury from dust

Sunburn

9.

10.

11.

12.

Laying of plastic

Carrying steel

Cutting and placing steel

Set up of electrical leads

Safe Work Method Statement (SWMS)

Slips and Trips

Back and shoulder

injuries.

Sun protection P.P.E equipment such as

sunscreen hats and shirts.

Clear waste materials from work area.

Care taken when walking on plastic.

Training provided in cutting and placing steel.

Cuts and abrasions.

Back and shoulder

injuries.

Training provided in cutting and placing steel.

Cuts and abrasions from

trips & slipping on steel.

Care taken when stepping over formwork onto

steel or plastic.

Cuts from cut ends of

steel.

Wear gloves (PPE)

Tripping over leads

Training in the set up of electrical leads.

Page 5 of 5

13.

Grinder use

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Controls Implemented

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Pieces of metal

penetrating eyes

P.P.E. equipment use wear ear and eye

protection

Electrocution

Training in correct use of grinder

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Electrical test & tagging. Register of all equipment

14.

15.

16.

Use of Oxy Acetylene

Tying Steel

Installing bar chains

Burns

Wear Gloves

Sparks hitting eyes

High visibility vests to be removed prior to using

Oxy Acetylene as the vests are highly flammable.

Wear safety glasses (PPE)

Explosion and Fire

All Oxy Acetylene equipment to have flash back

arrestors and have fire extinguishers

accompanying them.

Cuts and abrasions

Wear gloves

Penetrating wounds

Bar caps to be installed on all exposed vertical

bars.

Back Injury

Bend knees as placing chairs under reo bar

All relevant personnel to be trained in manual

handling

Clear all waste materials

Safe Work Method Statement (SWMS)

Page 6 of 6

17.

Set up of concrete pump

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Placing Concrete

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Concrete pump (boom

line) not stable and tipping

over

Truck drivers / operators to be made aware of site

entry, driver to be aware of the whereabouts of the

offsider and site personnel.

Machine failure

Reverse siren to be in working order on concrete

pump

Set up of concrete pump

(continued)

18.

Controls Implemented

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Pump operators to supply maintenance checklist

and log books

Concrete pump to be set up in accordance with

the Code of Practice. (concrete pumps are to be

registered with WorkCover)

Hit by concrete

No persons to be standing in front of concrete

hose

Back injury from shovelling

Relevant personnel shown correct posture for

shovelling

Concrete burns

Avoid contact to skin, wash skin and clothing after.

Sun burn, skin cancer, eye

damage

Safe Work Method Statement (SWMS)

Sun protection P.P.E equipment such as sun

cream, hats, shirts , sunglasses to be worn

Page 7 of 7

19.

Identify any potential hazards

associated with each step and

any related risks. Detail the hazards

and risks in this column, and enter

the risk rating in the next column.

Run over by concrete

pump or truck

Controls Implemented

Decide what controls to use to eliminate or minimise the risks.

Detail the controls in this column, and enter the revised risk rating in

the next column.

Note: If the risk rating is still 1-3, do not begin work.

Revised Risk

Rating (1-6)

Beak the job down into steps.

List the steps in this column.

Hazard Identification

Initial Risk

Rating (1-6)

STEP

Job Step

Person

Responsible

Truck drivers to be made aware of site entry.

Relevant personnel to be in sight of drivers at all

times.

Personnel to be trained in the use of hazardous

substances e.g. cement.

20.

THESE ARE STANDARD SWMS, THEY MUST BE MODIFIED TO SUIT YOUR WORKERS, YOUR EQUIPMENT AND

YOUR SITE.

Safe Work Method Statement (SWMS)

Page 8 of 8

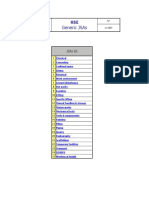

CHECKLIST OF ITEMS THAT MAY BE REQUIRED FOR THIS WORK ACTIVITY

QUALIFICATIONS

TRAINING

Codes of Practice

CODES OF PRACTICE OR AS/NZS

STANDARDS TO BE COMPLIED WITH

OHS Consultation

OHS Induction Training for Construction

Amenities for Construction Work

Australian Standard

AS 1012

Safe Work Method Statement (SWMS)

Page 9 of 9

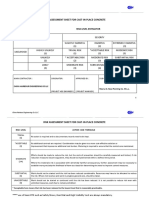

Declaration by contractors & workers:

1. I have been consulted and assited in the development of this SWMS.

2. I have been given the opportunity to comment on the content of this SWMS.

3. I have read and understand how I am to carry out the activities listed in this SWMS.

4. I have been supplied with the personal protective equipment identified on this SWMS and I have been given training in the safe use of this equipment.

5. I have read and understand the requirements set out in the mateial safety data sheets for the hazardous substances identified in this SWMS.

NAME:

Safe Work Method Statement (SWMS)

SIGNATURE:

DATE:

Page 10 of 10

You might also like

- Safe Work Method Statement TemplateDocument3 pagesSafe Work Method Statement TemplateJonasNo ratings yet

- SWMS - PlumberDocument7 pagesSWMS - PlumberSiddiqueShaikhNo ratings yet

- OHS SWMS Form 005 ExcavationDocument8 pagesOHS SWMS Form 005 Excavationazlinaz100% (2)

- Plumber - Drainer SWMSDocument12 pagesPlumber - Drainer SWMSallen2912100% (1)

- Concrete Formwork Suspended SlabDocument5 pagesConcrete Formwork Suspended SlabKate HopleyNo ratings yet

- Very Very Good Risk Assessment EnvironmentDocument8 pagesVery Very Good Risk Assessment EnvironmentSalley Bukhari100% (1)

- Steel FixingDocument5 pagesSteel Fixingrishanmulky88% (8)

- SWMS DemolitionDocument18 pagesSWMS Demolitionalee0007100% (1)

- Risk Assessment For Partition MarkingDocument5 pagesRisk Assessment For Partition Markingkhalid14No ratings yet

- SWMS Scaffold FixedDocument11 pagesSWMS Scaffold FixedEdha AliNo ratings yet

- Excavations: Job Safety AnalysisDocument5 pagesExcavations: Job Safety AnalysisJICKNo ratings yet

- Project Baseline Risk Assessment REF DIA61362019RFPDocument26 pagesProject Baseline Risk Assessment REF DIA61362019RFPThandabantu Magengelele100% (1)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 pagesJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- HAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBDocument7 pagesHAZARD IDENTIFICATION & RISK ASSESSMENT FOR EXCAVATION OF ROAD WITH TLBCharles LambNo ratings yet

- Risk Assessment 5 Use of Mob Elevating Working Platform (MewDocument1 pageRisk Assessment 5 Use of Mob Elevating Working Platform (Mewjamilhse7759No ratings yet

- Concrete Pour Risk AssessmentDocument3 pagesConcrete Pour Risk Assessmentridminj0% (1)

- Jsa - ExcavationDocument7 pagesJsa - ExcavationNOOR AISYA AMIRA ZUKAFLI100% (1)

- Painting (General Safety) SWMS 10183-4 - SAMPLEDocument6 pagesPainting (General Safety) SWMS 10183-4 - SAMPLEKunal PanchalNo ratings yet

- Safe lifting operationsDocument6 pagesSafe lifting operationsvsfchanNo ratings yet

- Scaffold - Erection, Use & Dismantling-RADocument15 pagesScaffold - Erection, Use & Dismantling-RAAl AminNo ratings yet

- 7-Block Work Risk Assessment ReportDocument7 pages7-Block Work Risk Assessment ReportSyed Ali Hassan100% (4)

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Environmental, Health and Safety Risk AssessmentDocument2 pagesEnvironmental, Health and Safety Risk AssessmentAdnan100% (2)

- JSA's ModelsDocument56 pagesJSA's ModelsSaberDjet80% (5)

- Detailed Excavation Installation of Formwork & Reinforcement ConcretingDocument29 pagesDetailed Excavation Installation of Formwork & Reinforcement ConcretingRio Handoko100% (2)

- Roof Waterproofing Risk AssessmentDocument6 pagesRoof Waterproofing Risk AssessmentFrancis VinojNo ratings yet

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- RISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONDocument12 pagesRISK ASSESSMENT FOR 10 VILLA CONSTRUCTIONFrancis Enriquez Tan50% (6)

- Incident Report: Proj. N. Unit Document Code Serial NDocument1 pageIncident Report: Proj. N. Unit Document Code Serial NSyed Ali HassanNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- Jsa Civil Work (00000002)Document6 pagesJsa Civil Work (00000002)Ali AlahmaNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementianllagasNo ratings yet

- HS014 - Portable Electrical Equipment InspectorDocument1 pageHS014 - Portable Electrical Equipment InspectorRetselisitsoe100% (3)

- Rebar Job Hazard AnalysisDocument1 pageRebar Job Hazard Analysisjoker batmanNo ratings yet

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Safe Work Method Statement - Formwork and ConcretingDocument8 pagesSafe Work Method Statement - Formwork and ConcretingAnonymous gmNTrHsNo ratings yet

- RC Pipes Installation SafetyDocument15 pagesRC Pipes Installation SafetyTaiwo Oshin100% (1)

- SWMSElevated Work PlatformsDocument4 pagesSWMSElevated Work PlatformsRay LeeNo ratings yet

- Safe Work Method StatementDocument11 pagesSafe Work Method StatementJNo ratings yet

- Typical JHA FormDocument5 pagesTypical JHA FormNasrullah Jan100% (4)

- 1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002Document3 pages1 (Hazard Analysis) For Earth Works Gurun Jsa G 001 Rev 002nurul sarahNo ratings yet

- Risk Assesment For Steel FixingDocument6 pagesRisk Assesment For Steel FixingAzhar Mushtaq33% (3)

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- Risk Assessment - Backfilling Around Foul Sewer and Storm Warter ManholesDocument6 pagesRisk Assessment - Backfilling Around Foul Sewer and Storm Warter Manholesloveson70950% (2)

- HSE TRA-04 Steel Reinforcement and Shuttering WorksDocument6 pagesHSE TRA-04 Steel Reinforcement and Shuttering WorksQusai Khalil Abu Awad100% (1)

- Safe Work Method Statement for Fall Risk Construction TasksDocument8 pagesSafe Work Method Statement for Fall Risk Construction Tasksdumb2471817100% (1)

- Ironbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy FlooringDocument12 pagesIronbark: Safe Work Method Statement No. WMS-570 Task: Work Practice - Epoxy Flooringklp_kedarpNo ratings yet

- Brick/Block Work Hazards AssessmentDocument40 pagesBrick/Block Work Hazards AssessmentGyanendra Srivastava0% (1)

- TBT-Driving in FogDocument2 pagesTBT-Driving in FogImran KhanNo ratings yet

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- Cast-In Place Concrete - Risk Assessment SheetDocument3 pagesCast-In Place Concrete - Risk Assessment SheetYash SharmaNo ratings yet

- Risk AssessmentDocument3 pagesRisk AssessmentAkinbami Olorunnifemi100% (1)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Confined Space Rescue PlanDocument2 pagesConfined Space Rescue PlankhurramNo ratings yet

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (2)

- SAFE LIFTING WITH SCISSOR LIFTDocument6 pagesSAFE LIFTING WITH SCISSOR LIFTjokerseri100% (3)

- OHSMS - Questions and AnswersDocument17 pagesOHSMS - Questions and AnswersPrakash PatelNo ratings yet

- Artificial Intelligence A Modern Approach 3rd Edition Russell Solutions ManualDocument36 pagesArtificial Intelligence A Modern Approach 3rd Edition Russell Solutions Manualsurnameballistah9g4ce100% (27)

- Ariston Ecosf109 19509154400 - GB CZ SK GRDocument60 pagesAriston Ecosf109 19509154400 - GB CZ SK GRionNo ratings yet

- Intel® Core™2 Quad Processor Q9550 (12M Cache, 2.83 GHZ, 1333 MHZ FSB) SpecificationsDocument5 pagesIntel® Core™2 Quad Processor Q9550 (12M Cache, 2.83 GHZ, 1333 MHZ FSB) SpecificationsRobert FarkasNo ratings yet

- Advances in Experimental Social Psychology, Volume 52 PDFDocument349 pagesAdvances in Experimental Social Psychology, Volume 52 PDFJose LuisNo ratings yet

- Method Statement - 23apr18Document5 pagesMethod Statement - 23apr18hinitahNo ratings yet

- Gradska Kultura 1Document487 pagesGradska Kultura 1Владимир ПетковићNo ratings yet

- Standoblue Base Coat Colors With Use of Mix 130 Silk Silver: Working Process: Special Effect Standoblue BasecoatDocument3 pagesStandoblue Base Coat Colors With Use of Mix 130 Silk Silver: Working Process: Special Effect Standoblue BasecoatMee MeeNo ratings yet

- FDA AssignDocument9 pagesFDA AssignZhainna SilvestreNo ratings yet

- Waste Classification Using Convolutional Neural Network On Edge DevicesDocument5 pagesWaste Classification Using Convolutional Neural Network On Edge DevicesInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Understanding the Multidimensional SelfDocument20 pagesUnderstanding the Multidimensional SelfJuan Dela CruzNo ratings yet

- Case 10-1 Improving Performance: California-Illini Manufacturing Company (CI)Document17 pagesCase 10-1 Improving Performance: California-Illini Manufacturing Company (CI)Lina Nurulazqia100% (1)

- Shaheen Public H/S School Mirpur Mathelo CH # 07 Work Power and Energy By: Laghari Zoheb HassanDocument40 pagesShaheen Public H/S School Mirpur Mathelo CH # 07 Work Power and Energy By: Laghari Zoheb HassanLaghari Hassan XohebNo ratings yet

- Vertical Cross Section ChartDocument1 pageVertical Cross Section Charthamza elomariNo ratings yet

- MOD UK Railway Permanent Way Design and Maintenance - Issue 4Document189 pagesMOD UK Railway Permanent Way Design and Maintenance - Issue 4plaxisNo ratings yet

- Hse Management SystemDocument8 pagesHse Management SystemJamie LucasNo ratings yet

- Mdu 1Document3 pagesMdu 1Gaurang Agrawal0% (1)

- 9701 s02 ErDocument14 pages9701 s02 ErHubbak KhanNo ratings yet

- Proposal WorkDocument13 pagesProposal Workmolla derbewNo ratings yet

- Industrial Gases and AcidsDocument5 pagesIndustrial Gases and AcidscarlNo ratings yet

- Scepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtDocument31 pagesScepticism and Animal Rationality: The Fortune of Chrysippus' Dog in The History of Western ThoughtNicolás Antonio Rojas CortésNo ratings yet

- Innovative Alternative StrategiesDocument29 pagesInnovative Alternative StrategiesstanleyrasneggerNo ratings yet

- CDMA Telephone TroubleshootingDocument30 pagesCDMA Telephone Troubleshootingsaboor ashraf100% (1)

- CV - Sanjana DhaidwalDocument1 pageCV - Sanjana DhaidwalPayal KathiawadiNo ratings yet

- Seven QC Tools Tool #5: Part 1-Run ChartDocument6 pagesSeven QC Tools Tool #5: Part 1-Run ChartAnkur DhirNo ratings yet

- Meditation GuideDocument168 pagesMeditation Guideaade100% (1)

- How To Do Magic That Works by Genevieve DavisDocument114 pagesHow To Do Magic That Works by Genevieve DavisFarzad ArabiNo ratings yet

- CPSA Sales Institute Key Competencies in SalesDocument1 pageCPSA Sales Institute Key Competencies in Salesmiguel8blancoNo ratings yet

- Project Report BCA Final Year-AayushDocument36 pagesProject Report BCA Final Year-Aayushaayush83% (6)

- 06.07 Review and Critical ThinkingDocument2 pages06.07 Review and Critical ThinkingmarielaNo ratings yet