Professional Documents

Culture Documents

ContactLogic Abaqus

Uploaded by

Gustavo Yippeekayyay GusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ContactLogic Abaqus

Uploaded by

Gustavo Yippeekayyay GusCopyright:

Available Formats

Contact Logic and Diagnostics Tools

Lecture 4

L4.2

Overview

Newton Method

The Contact Algorithm

Contact Iterations

Contact Diagnostics (Visual)

Contact Diagnostics (Text)

Understanding the logic that Abaqus uses to solve contact problems is

helpful for:

Understanding output

Troubleshooting convergence problems

Tools are available in Abaqus/CAE to visualize contact output.

This greatly simplifies the troubleshooting process.

Modeling Contact with Abaqus/Standard

Newton Method

L4.4

Newton Method

The Newton method is an iterative method used to solve nonlinear

problems.

Given:

Desired load P

Ability to evaluate f(u) and K(u)

Find:

us, such that f(us) = P

Modeling Contact with Abaqus/Standard

L4.5

Newton Method

The Newton method, however, is not guaranteed to converge.

Example in which Newton iterations diverge:

Load

Goal: find this point

P

Diverging!

Applied load

Displacement

Starting point

Load applied in 1 increment

Increase the likelihood of convergence by decreasing load increment.

Use multiple load increments to achieve desired total load.

Load

Load

P

P1

Displacement

Displacement

Half load in 1st increment

Remaining load in 2nd incr.

Modeling Contact with Abaqus/Standard

L4.6

Newton Method

Abaqus automatically adjusts the load increment size.

Goal: Find converged solution robustly and efficiently with respect to the

number of iterations.

Basic idea: Track convergence rate in order to determine when to

increase or decrease load increment size.

User suggests increment size; Abaqus tries to optimize it.

Slow convergence

or divergence

Reduce

increment size

Convergence in few

iterations

Increase

increment size

Modeling Contact with Abaqus/Standard

L4.7

Newton Method

Contact causes kinks in the load vs. displacement curve.

There is a slope discontinuity upon change in contact status.

As a result, contact changes interrupt overall convergence rate tracking.

Undeformed shape

3. Compress tip

2. Contact

rigid surface

1. Bend beam

P

Deformed shape

(Mises stress contours)

Challenging for

Newton method!

Modeling Contact with Abaqus/Standard

L4.8

Newton Method

Severe discontinuity iterations (SDIs)

An SDI is an iteration during which contact constraints change state

(open/closed, stick/slip)

Idea is to filter out contact effects from convergence rate tracking

The logic to adjust the increment size treats SDIs separately

Separate counts for

SDIs and non-SDIs

Status (.sta) file

for the previous

example (beam

contact)

1st attempt did not

convergereduce Dt

2nd attempt at first

incr. converges

Increase Dt due to

fast convergence

DP = (Dt/T) Pfinal

Converged incr. with

contact activated

Total step

time=1.0

Trend toward larger

Dt after contact is

established

Modeling Contact with Abaqus/Standard

The Contact Algorithm

L4.10

The Contact Algorithm

Hard contact pressure vs. overclosure:

Contact

pressure

Hard contact

Compliant

Non-compliant

Penetration

distance

Gap distance

Penetration for

open contacts

Tensile stress for

closed contacts

Default behavior: SDIs do not block convergence

Convert SDI: small penetrations/tensile stresses trigger contact status

changes (& SDIs) but do not necessarily block convergence

Without Convert SDI

Contact status changes (SDIs) block convergence

Modeling Contact with Abaqus/Standard

L4.11

The Contact Algorithm

Schematic of behavior within an increment (default behavior)

Begin

increment

Identify initially

active contact

constraints

Newton

iterations

Yes

No

(Reduce increment

size and try again)

Identify changes

3

in contact

constraint status

Form and

solve system

of equations

Determine if

tending toward

convergence

No

Check if

solution has

converged

(At least one

convergence criterion

is not satisfied)

Modeling Contact with Abaqus/Standard

End

increment

Yes

(Within

convergence

tolerances)

L4.12

The Contact Algorithm

Default contact algorithm (refer to flowchart on previous page):

1

Determine the initial contact state at each point (closed or open).

For first increment of a step, based on initial model state; otherwise,

based on solution extrapolation (if any)

Calculate the stiffness, imposing contact constraints accordingly. Form

the system of equations and pass through the equation solver.

Are contact pressures and clearances consistent with the assumed

contact state?

Contact status changes (open/closed or stick/slip) often cause

significant changes to the system of equations

Iterations with contact status changes are flagged as severe

discontinuity iterations (SDIs)

Modeling Contact with Abaqus/Standard

L4.13

The Contact Algorithm

4

Has convergence been achieved?

By default, Abaqus quantifies the contact incompatibilities

associated with SDIs. These incompatibilities must be sufficiently

small to achieve convergence with respect to the contact state.

Also have to ensure that the force residuals and solution corrections

are sufficiently small to achieve equilibrium.

If the contact state and equilibrium conditions satisfy their respective

convergence criteria, the increment is complete.

5

If convergence is not achieved, is it likely to be achieved?

Abaqus evaluates trends, such as the number of contact status

changes in successive iterations, to determine whether or not to

continue iterating or cut back the increment size.

If convergence is likely, update the contact constraints based on 3

and the stiffness, and re-solve the system of equations; otherwise,

try again with a smaller increment size.

Modeling Contact with Abaqus/Standard

L4.14

The Contact Algorithm

The default limit on total SDIs per

increment is 50.

In principle not necessary to

limit the number of severe

discontinuity iterations.

Sophisticated criteria determine

whether iteration should be

continued or terminated.

The default limit for the

maximum number of severe

discontinuity iterations is 50,

which in practice should always

be more than the actual number

of iterations in an increment.

Modeling Contact with Abaqus/Standard

Contact Iterations

L4.16

Contact Iterations

Contact iterations can be used instead of regular severe discontinuity

iterations to speed up computations.

Regular severe discontinuity iterations involve costly assembly and

factorization of the global stiffness matrix.

With contact iterations, the displacement correction is obtained by

changing only the global right-hand side of the matrix equation.

When the number of contact elements changing status from

open to closed and vice versa is small, this approach is more

effective.

Abaqus determines automatically whether contact iterations are

more efficient than regular SDIs.

Contact iterations can be especially effective for the solution of large

linear elastic frictionless contact problems that require many severe

discontinuity iterations.

Modeling Contact with Abaqus/Standard

L4.17

Contact Iterations

Schematic of behavior within an increment with contact iterations

Begin

increment

3a

Identify initially

active contact

constraints

Newton

iterations

Yes

No

(Reduce increment

size and try again)

Identify changes

3

in contact

constraint status

Form and

solve system

of equations

Determine if

tending toward

convergence

No

Check if

solution has

converged

(At least one

convergence criterion

is not satisfied)

Modeling Contact with Abaqus/Standard

End

increment

Yes

(Within

convergence

tolerances)

L4.18

Contact Iterations

Contact algorithm with contact iterations:

3a

Are contact pressures and clearances consistent with the assumed

contact state?

When the number of contact elements changing status from open to

closed and vice versa is small, "contact iterations" are an effective

alternative to regular SDIs

Perform "nested" iterations without re-assembling and re-factoring

the global stiffness matrix

Stiffness changes due only to contact state changes; effect

introduced through RHS of the matrix equation

Continue until no changes in contact state or number of contact

iterations is exhausted

Modeling Contact with Abaqus/Standard

L4.19

Contact Iterations

Range of effectiveness

Most effective

Linear elastic geometrically linear small-sliding

contact problems.

Materially nonlinear geometrically linear smallsliding contact problems.

Linear elastic geometrically nonlinear finite-sliding

contact problems.

Materially nonlinear geometrically nonlinear finitesliding contact problems.

Modeling Contact with Abaqus/Standard

Less effective

L4.20

Contact Iterations

Usage:

*SOLUTION TECHNIQUE,

TYPE=CONTACT ITERATIONS

correction_factor, n_max

where

correction_factor = factor on

the upper limit of the number of

contact status changes to solve,

for the contact iteration to be

effective; and

n_max = maximum number of

contact iterations per trial

Modeling Contact with Abaqus/Standard

L4.21

Contact Iterations

Example: engine bulkhead with

1.4 M dofs

Many bodies, connected by

contact pairs and *TIE

Contact iteration improves the

solution time

Linear elastic

(NLGEOM=NO)

Frictionless, small-sliding

contact

Time to factorize is

greater than to obtain the

right-hand side solutions

Without

contact

iterations

With

contact

iterations

Wallclock time (min.)

177

97

# SDIs

10

# Contact iterations

Modeling Contact with Abaqus/Standard

L4.22

Contact Iterations

Example: engine block with 2.6 M dofs

Only nonlinearities are elastic-plastic

gasket and small-sliding contact

Contact to be resolved in many areas

(gasket, bolts, rings, etc.)

Also run with linear gasket behavior

NLGEOM=NO

Gasket behavior

# Contact

iterations

# Equilibrium

iterations

Wallclock time speedup

factor with contact iterations

Elasticplastic

Linear

1.47

5.20

Modeling Contact with Abaqus/Standard

Plastic strain

in gasket

L4.23

Contact Iterations

Limitations:

can be used only with the static solution procedure;

require the use of the direct sparse solver;

cannot be used with coupled analyses with the separated solution

technique;

cannot be used with sparse format matrix input and assemblage; and

the following features cannot use contact iterations:

contact with friction

points that are permitted to violate contact conditions

points that are released from contact by overconstraint checks

debond contact

Modeling Contact with Abaqus/Standard

Contact Diagnostics (Visual)

L4.25

Contact Diagnostics (Visual)

Contact diagnostics example using Abaqus/CAE

Reference: Example Problem 1.3.4, Deep drawing of a cylindrical cup

Modeling Contact with Abaqus/Standard

L4.26

Contact Diagnostics (Visual)

Visual diagnostics are available in the Visualization module of

Abaqus/CAE.

Step 3, Increment 6: 5 iterations (3

involve SDIs)

Modeling Contact with Abaqus/Standard

L4.27

Contact Diagnostics (Visual)

Constrained nodes want

to open: incompatible

contact state

Toggle on to see the locations

in the model where the contact

state is changing.

Modeling Contact with Abaqus/Standard

L4.28

Contact Diagnostics (Visual)

Slave nodes that slip; stick/slip

messages cause SDIs only if

Lagrange friction is used or if

slip reversal occurs.

Modeling Contact with Abaqus/Standard

L4.29

Contact Diagnostics (Visual)

Contact incompatibilities are

quantified: max force

error for constrained nodes

The contact force error is

larger than the time-average

force (=3137; will see this

shortly) contact

incompatibility too large

Modeling Contact with Abaqus/Standard

L4.30

Contact Diagnostics (Visual)

Contact incompatibilities are

quantified: max penetration

error for unconstrained nodes

The maximum penetration error is

much smaller than the

displacement correction (=1.68e-5)

Modeling Contact with Abaqus/Standard

L4.31

Contact Diagnostics (Visual)

Not only is the contact incompatibility

too large, but force equilibrium has not

been achieved either.

The force residual is larger

than the time-average force,

as is the estimated contact

force error (seen previously)

Modeling Contact with Abaqus/Standard

L4.32

Contact Diagnostics (Visual)

4 additional iterations are required, two of which

are SDIs (involve contact incompatibilities).

In the final iteration, both the contact and

equilibrium checks pass and the increment

converges.

Modeling Contact with Abaqus/Standard

Contact Diagnostics (Text)

L4.34

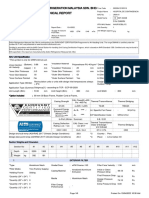

Contact Diagnostics (Text)

Contact diagnostics example using the message ( .msg) file

Reference: Example Problem 1.3.4, Deep drawing of a cylindrical cup

Status (.sta) file:

SUMMARY OF JOB INFORMATION:

MONITOR NODE:

200 DOF: 2

STEP INC ATT SEVERE EQUIL TOTAL

DISCON ITERS ITERS

ITERS

1

1

1

1

1

2

2

1

1

0

1

1

3

1

1

10

0

10

3

2

1

7

1

8

3

3

1U

9

0

9

3

3

2

5

0

5

3

4

1

3

1

4

3

5

1

2

3

5

3

6

1

3

2

5

3

7

1

4

1

5

3

8

1

6

1

7

3

9

1

3

4

7

3

10

1U

4

0

4

3

10

2

7

1

8

3

11

1

3

2

5

.

.

.

TOTAL

TIME/

FREQ

1.00

2.00

2.01

2.02

2.02

2.02

2.03

2.04

2.05

2.07

2.10

2.14

2.14

2.16

2.18

STEP

TIME/LPF

INC OF

TIME/LPF

1.00

1.00

0.0100

0.0200

0.0200

0.0238

0.0294

0.0378

0.0505

0.0695

0.0979

0.141

0.141

0.157

0.181

1.000

1.000

0.01000

0.01000

0.01500

0.003750

0.005625

0.008438

0.01266

0.01898

0.02848

0.04271

0.06407

0.01602

0.02403

Modeling Contact with Abaqus/Standard

DOF

IF

MONITOR RIKS

0.000

0.000

-0.000600

-0.00120

-0.00120

-0.00142

-0.00176

-0.00227

-0.00303

-0.00417

-0.00588

-0.00844

-0.00844

-0.00940

-0.0108

L4.35

Contact Diagnostics (Text)

Message file, Step 3, Increment 6:

INCREMENT

6 STARTS. ATTEMPT NUMBER

1, TIME INCREMENT

1.266E-02

CONTACT PAIR (ASURF,BSURF) NODE 167 IS NOW SLIPPING.

CONTACT PAIR (ASURF,BSURF) NODE 171 IS NOW SLIPPING.

:

:

*PRINT, CONTACT=YES causes this detailed printout.

(Useful for troubleshooting)

Slave nodes that slip; stick/slip

messages cause SDIs only if

Lagrange friction is used or if

slip reversal occurs.

:

CONTACT PAIR (ASURF,BSURF) NODE 153 OPENS. CONTACT PRESSURE/FORCE IS -830689..

CONTACT PAIR (ASURF,BSURF) NODE 161 OPENS. CONTACT PRESSURE/FORCE IS -1.43706E+006.

CONTACT PAIR (ASURF,BSURF) NODE 165 OPENS. CONTACT PRESSURE/FORCE IS -1.03301E+006.

CONTACT PAIR (CSURF,DSURF) NODE 363 OPENS. CONTACT PRESSURE/FORCE IS -3.43767E+006.

CONTACT PAIR (ESURF,FSURF) NODE 309 IS NOW SLIPPING.

5 SEVERE DISCONTINUITIES OCCURRED DURING THIS ITERATION.

4 POINTS CHANGED FROM CLOSED TO OPEN

Due to slip reversal

1 POINTS CHANGED FROM STICKING TO SLIPPING

Modeling Contact with Abaqus/Standard

Incompatibilities

detected in the

assumed contact

state SDI

L4.36

Contact Diagnostics (Text)

Message file, Step 3, Increment 6 (cont'd):

CONVERGENCE CHECKS FOR SEVERE DISCONTINUITY ITERATION

MAX. PENETRATION ERROR -8.1463E-009 AT NODE 331 OF CONTACT PAIR (ESURF,FSURF)

Convergence checks

for contact state

MAX. CONTACT FORCE ERROR -4184.86 AT NODE 363 OF CONTACT PAIR (CSURF,DSURF)

THE ESTIMATED CONTACT FORCE ERROR IS LARGER THAN THE TIME-AVERAGED FORCE.

AVERAGE FORCE

5.350E+03

TIME AVG. FORCE

3.137E+03

LARGEST RESIDUAL FORCE

-1.200E+04

AT NODE

333

DOF

LARGEST INCREMENT OF DISP.

-7.783E-04

AT NODE

329

DOF

LARGEST CORRECTION TO DISP.

-1.684E-05

AT NODE

337

DOF

FORCE

EQUILIBRIUM NOT ACHIEVED WITHIN TOLERANCE.

AVERAGE MOMENT

ALL MOMENT

110.

TIME AVG. MOMENT

Not only is the contact incompatibility

too large, but force equilibrium has

not been achieved either

89.0

RESIDUALS ARE ZERO

LARGEST INCREMENT OF ROTATION

1.847E-33

AT NODE

100

DOF

LARGEST CORRECTION TO ROTATION

6.454E-34

AT NODE

300

DOF

THE MOMENT

Convergence checks

for equilibrium

EQUILIBRIUM EQUATIONS HAVE CONVERGED

Modeling Contact with Abaqus/Standard

L4.37

Contact Diagnostics (Text)

Four additional iterations are required; the first two are SDIs (involve

contact incompatibilities).

In the final iteration both the contact and equilibrium checks pass and

the increment converges.

CONVERGENCE

CONVERGENCE

CONVERGENCE

CONVERGENCE

CHECKS

CHECKS

CHECKS

CHECKS

FOR

FOR

FOR

FOR

SEVERE DISCONTINUITY ITERATION

SEVERE DISCONTINUITY ITERATION

EQUILIBRIUM ITERATION

1

EQUILIBRIUM ITERATION

2

2 ...

3 ...

No SDIs in these

iterations

MAX. PENETRATION ERROR -1.24301E-015 AT NODE 331 OF CONTACT PAIR (ESURF,FSURF)

MAX. CONTACT FORCE ERROR -9.94745E-005 AT NODE 331 OF CONTACT PAIR (ESURF,FSURF)

THE CONTACT CONSTRAINTS HAVE CONVERGED.

AVERAGE

LARGEST

LARGEST

LARGEST

FORCE

5.244E+03

TIME AVG. FORCE

RESIDUAL FORCE

-1.98

AT NODE

135

INCREMENT OF DISP.

-7.809E-04

AT NODE

129

CORRECTION TO DISP.

1.063E-08

AT NODE

135

THE FORCE

EQUILIBRIUM EQUATIONS HAVE CONVERGED

AVERAGE MOMENT

109.

TIME AVG. MOMENT

ALL MOMENT

RESIDUALS ARE ZERO

LARGEST INCREMENT OF ROTATION

1.925E-33

AT NODE

100

LARGEST CORRECTION TO ROTATION

-6.933E-38

AT NODE

100

THE MOMENT

EQUILIBRIUM EQUATIONS HAVE CONVERGED

3.120E+03

DOF 1

DOF 2

DOF 2

88.8

DOF

DOF

Modeling Contact with Abaqus/Standard

6

6

You might also like

- ANSYS Mechanical APDL for Finite Element AnalysisFrom EverandANSYS Mechanical APDL for Finite Element AnalysisRating: 4.5 out of 5 stars4.5/5 (8)

- Dassault Systemes Inc. Modeling Fracture and Failure With AbaqusDocument393 pagesDassault Systemes Inc. Modeling Fracture and Failure With AbaqusHichem Sof100% (1)

- Using XFEM in Abaqus To Model Fracture and Crack PropagationDocument38 pagesUsing XFEM in Abaqus To Model Fracture and Crack PropagationGustavo100% (1)

- Engineering Analysis with ANSYS SoftwareFrom EverandEngineering Analysis with ANSYS SoftwareRating: 3.5 out of 5 stars3.5/5 (5)

- The Finite Element Method: A Practical CourseFrom EverandThe Finite Element Method: A Practical CourseRating: 3.5 out of 5 stars3.5/5 (3)

- Abaqus Scripting Seminar Oct1stDocument29 pagesAbaqus Scripting Seminar Oct1stjeovan100% (1)

- Fracture Lecture of AbaqusDocument552 pagesFracture Lecture of AbaqusMohammed Abu Sufian71% (7)

- Abaqus Orphan MeshDocument22 pagesAbaqus Orphan MeshMasoud GhodratiNo ratings yet

- Solving Contact Problems With Abaqus PDFDocument163 pagesSolving Contact Problems With Abaqus PDFdashengyue100% (1)

- Prevent Negative Volume in Foam ModelsDocument9 pagesPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNo ratings yet

- Essentials of the Finite Element Method: For Mechanical and Structural EngineersFrom EverandEssentials of the Finite Element Method: For Mechanical and Structural EngineersRating: 3.5 out of 5 stars3.5/5 (9)

- Crack Control: Using Fracture Theory to Create Tough New MaterialsFrom EverandCrack Control: Using Fracture Theory to Create Tough New MaterialsNo ratings yet

- Elements of Elasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandElements of Elasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionRating: 4 out of 5 stars4/5 (1)

- Prevent Negative Volume in Foam ModelsDocument9 pagesPrevent Negative Volume in Foam ModelsGustavo Yippeekayyay GusNo ratings yet

- Linguaphone Deutsch - Study BookletDocument8 pagesLinguaphone Deutsch - Study BookletJoao AlvesNo ratings yet

- Explicit Contents LectureDocument21 pagesExplicit Contents LectureBrian Egan100% (1)

- Adaptive MeshDocument38 pagesAdaptive Meshbooks_ukNo ratings yet

- ABAQUS NumericalMethods PDFDocument53 pagesABAQUS NumericalMethods PDFwoongs73No ratings yet

- Fracture MechanicsDocument12 pagesFracture Mechanicsramachadra122No ratings yet

- Modeing Crack in Abaqus PDFDocument69 pagesModeing Crack in Abaqus PDFshahin zandNo ratings yet

- Abaqus Cae TutorialDocument33 pagesAbaqus Cae TutorialrcmmrcNo ratings yet

- Frac l09 XfemDocument58 pagesFrac l09 Xfemchingon987No ratings yet

- Abaqus Compression of A Rubber Seal WorkshopDocument8 pagesAbaqus Compression of A Rubber Seal WorkshopSandeep PahadeNo ratings yet

- Material Damage and Failure in AbaqusDocument19 pagesMaterial Damage and Failure in AbaqusVenu KishoreNo ratings yet

- Abaqus Interaction TutorialDocument13 pagesAbaqus Interaction TutorialhasibNo ratings yet

- Defining Surfaces and Contact Pairs in AbaqusDocument55 pagesDefining Surfaces and Contact Pairs in Abaquswoongs73No ratings yet

- Restart NastranDocument35 pagesRestart NastranJacob Verghese100% (2)

- VCCT For Abaqus PDFDocument14 pagesVCCT For Abaqus PDFFelipe Dornellas SilvaNo ratings yet

- Contact Modelling in LSDYNADocument35 pagesContact Modelling in LSDYNASidharth PothalNo ratings yet

- Solving Contact Problems With AbaqusDocument163 pagesSolving Contact Problems With AbaqusTounsi Twensa100% (1)

- Summer 2006: V Vo Oll.. IIX X September/October 2006Document20 pagesSummer 2006: V Vo Oll.. IIX X September/October 2006Fahmi0% (1)

- ABAQUS User Subroutines Reference ManualDocument326 pagesABAQUS User Subroutines Reference ManualAnonymous KUYGUNENo ratings yet

- ABAQUS Workshop Slides 0Document100 pagesABAQUS Workshop Slides 0Zeeshan AliNo ratings yet

- Lecture 8 - Post Buckling and Impact AnalysesDocument22 pagesLecture 8 - Post Buckling and Impact AnalysesSencu RazvanNo ratings yet

- Abaqus Modelling and AnalysisDocument12 pagesAbaqus Modelling and Analysismatmean0% (1)

- Abaqus Direct CyclingDocument7 pagesAbaqus Direct CyclingJuraj FajtaNo ratings yet

- Abaqus Composites PDFDocument21 pagesAbaqus Composites PDFranjithkrajNo ratings yet

- Kurt Miller Tod Dalrymple: Rubber Material Curve Fitting With Abaqus/CaeDocument34 pagesKurt Miller Tod Dalrymple: Rubber Material Curve Fitting With Abaqus/CaePallab Jyoti DasNo ratings yet

- LS-DYNA Tie-Break Contacts Modeling GuideDocument33 pagesLS-DYNA Tie-Break Contacts Modeling Guidemr.aikido100% (2)

- Element Type LS-DYNADocument7 pagesElement Type LS-DYNAاحمد تسنیمNo ratings yet

- 6 Composites Modelling LS-DYNA Galal-Mohamed-InDocument71 pages6 Composites Modelling LS-DYNA Galal-Mohamed-InSathi MechNo ratings yet

- Abaqus TrainingDocument23 pagesAbaqus Trainingmikael bezerra cotias dos santosNo ratings yet

- Fracture Mechanics-Book PDFDocument402 pagesFracture Mechanics-Book PDFAXEL RIVERANo ratings yet

- CONTACT Imulia PDFDocument325 pagesCONTACT Imulia PDFTố Như PhạmNo ratings yet

- Manual For Computational Exercises: TMM4160 Fracture MechanicsDocument39 pagesManual For Computational Exercises: TMM4160 Fracture Mechanicsc1315491_513486021No ratings yet

- Rubber Visco SummaryDocument19 pagesRubber Visco Summaryrufus728No ratings yet

- Abaqus WorkshopDocument10 pagesAbaqus Workshopnapoleongo71% (7)

- Abaqus 6.12: Abaqus Example Problems ManualDocument880 pagesAbaqus 6.12: Abaqus Example Problems Manualwalidnasri100% (1)

- Modern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989From EverandModern Practice in Stress and Vibration Analysis: Proceedings of the Conference Held at the University of Liverpool, 3–5 April 1989J. E. MottersheadNo ratings yet

- Introduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsFrom EverandIntroduction to the Explicit Finite Element Method for Nonlinear Transient DynamicsNo ratings yet

- Random Vibrations: Analysis of Structural and Mechanical SystemsFrom EverandRandom Vibrations: Analysis of Structural and Mechanical SystemsNo ratings yet

- Multiphysics Modelling of Fluid-Particulate SystemsFrom EverandMultiphysics Modelling of Fluid-Particulate SystemsHassan KhawajaNo ratings yet

- Computational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsFrom EverandComputational Methods in Nonlinear Structural and Solid Mechanics: Papers Presented at the Symposium on Computational Methods in Nonlinear Structural and Solid MechanicsAhmed K. NoorNo ratings yet

- Composite AlternDocument14 pagesComposite AlternGustavo Yippeekayyay GusNo ratings yet

- AoS BookOfExamplesDocument17 pagesAoS BookOfExamplesGustavo Yippeekayyay GusNo ratings yet

- Composite Materials Abaqus Analytical Solutions Eshelby 13Document12 pagesComposite Materials Abaqus Analytical Solutions Eshelby 13Gustavo Yippeekayyay GusNo ratings yet

- Simulating The Impact Behaviour of CompositeDocument1 pageSimulating The Impact Behaviour of CompositeGustavo Yippeekayyay GusNo ratings yet

- Nas122Document4 pagesNas122Gustavo Yippeekayyay GusNo ratings yet

- M Dpbhdms @MC Dw@Bs RNKTSHNM Enq 1@Mcnl 5Haq@Shnm M@KXRHR TRHMF, 2"-231 - /@qs (6Ghsd MNHRD RodbsqtlDocument19 pagesM Dpbhdms @MC Dw@Bs RNKTSHNM Enq 1@Mcnl 5Haq@Shnm M@KXRHR TRHMF, 2"-231 - /@qs (6Ghsd MNHRD RodbsqtlGustavo Yippeekayyay GusNo ratings yet

- 01 Contact NastranDocument26 pages01 Contact NastranGustavoYippeekayyayGusNo ratings yet

- Section 7 Lists: S7-1 PAT301, Section 7, September 2008 2008 MSC - Software CorporationDocument8 pagesSection 7 Lists: S7-1 PAT301, Section 7, September 2008 2008 MSC - Software CorporationGustavo Yippeekayyay GusNo ratings yet

- Nas122Document4 pagesNas122Gustavo Yippeekayyay GusNo ratings yet

- Sec00 Title TOCDocument12 pagesSec00 Title TOCGustavo Yippeekayyay GusNo ratings yet

- Patran 2010 Reference Manual Part 7: XY PlottingDocument72 pagesPatran 2010 Reference Manual Part 7: XY PlottingDonNo ratings yet

- Full Text 01Document55 pagesFull Text 01Zahi AekNo ratings yet

- Technical Data TAD734GE Technical Data TAD734GE: GeneralDocument8 pagesTechnical Data TAD734GE Technical Data TAD734GE: GeneralAndres SorinNo ratings yet

- Contact Mechanics - Wikipedia The Free EncyclopediaDocument22 pagesContact Mechanics - Wikipedia The Free EncyclopediaJigar ChaudharyNo ratings yet

- 1 - Calcuquick D.Ginsky 6.6.2005 EnglishDocument82 pages1 - Calcuquick D.Ginsky 6.6.2005 EnglishRahul ChandrawarNo ratings yet

- Ultimate Bearing Capacity of Foundation On Clays - MeyerhofDocument3 pagesUltimate Bearing Capacity of Foundation On Clays - Meyerhofsreekx0073916100% (1)

- Strain Gage RosettesDocument15 pagesStrain Gage RosettesKaleem AkhtarNo ratings yet

- (WM) L200 (Ka#,kb#)Document1 page(WM) L200 (Ka#,kb#)Gabriel HreczyńskiNo ratings yet

- Lista de Peças Compressores SchultzDocument6 pagesLista de Peças Compressores SchultzWanderson FIALHONo ratings yet

- Technical Data For Configuration REV AA en 1Document19 pagesTechnical Data For Configuration REV AA en 1Isaac GumboNo ratings yet

- Forces, Motion, and Energy: ScienceDocument39 pagesForces, Motion, and Energy: ScienceElizabeth Inocencio Facundo - SagotNo ratings yet

- 4.about Gantry Crane: 3.5 General DrawingDocument12 pages4.about Gantry Crane: 3.5 General DrawingCiprian S.No ratings yet

- Tender Document For Construction of Ghorasal 300-450 MW ... - BPDBDocument315 pagesTender Document For Construction of Ghorasal 300-450 MW ... - BPDBhumayan kabir100% (1)

- A330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APUDocument110 pagesA330 RR Trent 700 Technical Training Manual Mechanical & Avionics Course - T1+T2 (LVL 2&3) APULuiz Fernando MibachNo ratings yet

- Therm-O-Disc Bimetal-60t-Section-En-Us-5469064Document14 pagesTherm-O-Disc Bimetal-60t-Section-En-Us-5469064Phạm Thiên TrườngNo ratings yet

- Multicore Cable Schedule 21-12-01Document14 pagesMulticore Cable Schedule 21-12-01Archiford NdhlovuNo ratings yet

- Quantum Mechanics II - Homework 3Document7 pagesQuantum Mechanics II - Homework 3Ale GomezNo ratings yet

- Assignment 5: Engineering Utilities IiDocument4 pagesAssignment 5: Engineering Utilities IiRex SabersonNo ratings yet

- Daikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationDocument6 pagesDaikin Refrigeration Malaysia Sdn. Bhd participates in EUROVENT certificationSicologo CimeNo ratings yet

- Geotechnical module stresses and settlementsDocument128 pagesGeotechnical module stresses and settlementsMAAbuBakarNo ratings yet

- Unit 14 Worksheet: Engine Fundamentals Competency Unit: AURTTE004 Inspect and Service EnginesDocument6 pagesUnit 14 Worksheet: Engine Fundamentals Competency Unit: AURTTE004 Inspect and Service EnginesajayNo ratings yet

- FEMA Precast Concrete Design ExamplesDocument175 pagesFEMA Precast Concrete Design ExamplesFeras TemimiNo ratings yet

- Ball Mill For Cement GrindingDocument5 pagesBall Mill For Cement GrindingNkosilozwelo Sibanda100% (1)

- 5 Port Solenoid Valve: Reduced Power ConsumptionDocument60 pages5 Port Solenoid Valve: Reduced Power ConsumptionkrisornNo ratings yet

- Welding Machine Repairing Service in Rajkot Gujarat IndiaDocument127 pagesWelding Machine Repairing Service in Rajkot Gujarat IndiaSpandan MishraNo ratings yet

- BOQ Pengumuman 1065.RKSDocument2 pagesBOQ Pengumuman 1065.RKSDangolNo ratings yet

- 9ni 4coDocument102 pages9ni 4cosunsirNo ratings yet

- Frames of reference in physics and their usesDocument6 pagesFrames of reference in physics and their usesPrateek SharmaNo ratings yet

- Q4 Science 9 Week 1 8 PDFDocument33 pagesQ4 Science 9 Week 1 8 PDFJesiel MabagaNo ratings yet

- Instructions For Blast Analysis On Piping Systems P51 ProjectDocument5 pagesInstructions For Blast Analysis On Piping Systems P51 ProjectzahoorNo ratings yet

- Iseki Tm3200 3240 Parts ManualDocument20 pagesIseki Tm3200 3240 Parts Manualjoseph100% (53)

- CC1200Document308 pagesCC1200Teresa Marina PeraltaNo ratings yet