Professional Documents

Culture Documents

Calculation of Electrode Consumption

Uploaded by

hgolestaniCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation of Electrode Consumption

Uploaded by

hgolestaniCopyright:

Available Formats

General Information

Calculation of electrode consumption

In the tables, joint cross section, theoretical joint volume and kg weld metal per metre length

of welded joint are given. The electrode consumption per metre of welded joint is obtained by

dividing the number of kg of weld metal by N, where N is the kg of weld metal per kg of

electrode and is given for each electrode on their respective pages.

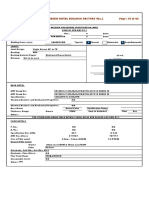

Square butt joints: Joint volumes and weld metal weights

Position

Flat

Flat

Horizontal-Vertical

Horizontal-Vertical

Overhead

10

Plate

thickness

mm

Gap

mm

1

1.5

2

3

0

0.5

1

1.5

1

1.5

2

3

0

0.5

1

1.5

4

5

6

7

2

2

2.5

3

4

5

6

7

4

5

6

7

4

5

6

7

Volume/length

cm3/m

Weight/length weld

metal kg/m

2

3

4

7

0.02

0.02

0.03

0.05

2.5

4

5

9.5

0.02

0.03

0.04

0.07

10.5

16

18

21

0.08

0.13

0.14

0.16

2

2

2.5

3

17

21

27

36

2

2.5

3

3

2

2

2.5

3

22

25

32

42

9

10.5

13

16

0.13

0.16

0.21

0.28

0.17

0.20

0.25

0.33

0.07

0.08

0.10

0.13

11

2

2

2

189

227

341

91

120

135

151

42

51

66.5

78.5

11.5

16.5

23

33.5

170

208

313

83

110

123

132

40

48

62

71.5

11

16

21.5

32.5

Flat

50

1.33

1.63

2.46

0.65

0.86

0.97

1.04

0.31

0.38

0.49

0.56

0.09

0.13

0.17

0.26

223

271

411

107

141

160

180

49

60.5

77.5

92

13

19.5

27

39

204

247

375

97.5

130

146

157

46.5

56

72

83.5

12.5

19

25.5

38

Flat

60

1.60

1.94

2.94

0.77

1.02

1.15

1.23

0.37

0.44

0.57

0.66

0.10

0.15

0.20

0.30

Flat

Flat

Vertical

Horizontal-Vertical

Overhead

Position

612

> 12

> 8

> 8

> 10

Plate thickness

mm

0.10

0.15

0.15

0.15

0.10

Weight/length

kg/m

3.25

4

3.25

3.25

3.25

263

320

488

125

165

188

211

57

70

90

107

15

22.5

31

45

276

334

510

134

171

197

223

59.5

75.5

96.5

113

16.5

24.5

37

49

Vertical

70

Electrode diam

mm

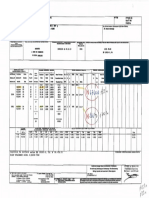

The first run and backing run V-joints: Weld metal weights

1 Theoretical volume cm3/m

2 Actual joint volume cm3/m (taking account of transverse shrinkage)

3 Deposited weld metal kg/m

2

2

2

2

18

20

25

12

14

15

16

1.5

1.5

2

2

1

1

1

1.5

Gap

mm

8

9

10

11

4

5

6

7

Plate

thickness

mm

Calculation of electrode consumption

Single V-joints: volumes and weld metal weights

2.17

2.62

4.00

1.05

1.34

1.55

1.75

0.47

0.59

0.76

0.89

0.13

0.19

0.29

0.38

308

376

577

145

193

219

247

65.5

81.5

104

124

320

396

606

157

204

231

257

70

87.5

109

130

18

28

38.5

56

Overhead

17.5

26

36

51.5

80

2.51

3.11

4.76

1.23

1.60

1.81

2.02

0.55

0.69

0.86

1.02

0.14

0.22

0.30

0.44

223

271

411

107

141

160

180

49

60.5

77.5

92

13

19.5

27

39

233

281

425

113

159

171

186

56

65

81

96.5

14.5

21

30

42

1.83

2.21

3.34

0.89

1.17

1.34

1.46

0.44

0.51

0.64

0.76

0.11

0.16

0.24

0.33

Horizontal-Vertical

60

Calculation of electrode consumption

Corner welds: Actual joint volumes and weld metal weights

Plate

thickness

Section

size

2

3

4

5

6

7

8

9

10

11

12

15

18

20

22

25

2

4.5

8

12.5

18

24.5

32

40.5

50

60.5

72

113

162

200

242

323

mm

mm2

cm3/m

3.5

7

9

13

18.5

25.5

33

41.5

51.5

63

74.5

116

167

206

248

329

kg/m

0.03

0.05

0.07

0.10

0.15

0.20

0.26

0.33

0.40

0.49

0.58

0.91

0.31

1.62

1.95

2.58

cm3/m

3

7

9

13.5

19.5

26.5

34.5

43

53.5

67

79

123

174

206

255

331

kg/m

0.02

0.05

0.07

0.11

0.15

0.21

0.27

0.34

0.42

0.53

0.62

0.97

1.37

1.62

2.00

2.60

cm3/m

3.5

7

9.5

14.5

21

27.5

36

45.5

56

72

84.5

132

190

227

275

370

kg/m

cm3/m

kg/m

kg/m

cm3/m

kg/m

0.03

0.05

0.07

0.11

0.16

0.22

0.28

0.36

0.44

0.57

0.66

1.04

1.49

1.78

2.16

2.90

3.5

7.5

10.5

16

22

31.5

40.5

51

64

78.5

93

141

204

252

204

405

0.03

0.06

0.08

0.13

0.17

0.25

0.32

0.40

0.50

0.62

0.73

1.11

1.60

1.98

2.39

3.18

Fillet welds: Actual joint volumes and weld metal weights

T

Throat

thickness

Section

size

2

2.5

3

3.5

4

4.5

5

5.5

6

6.5

7

7.5

8

9

10

11

12

13

14

15

4

6.5

9

12.5

16

20.5

25

30.5

36

42.5

49

56.5

64

81

100

121

144

169

196

225

mm

12

mm2

cm3/m

5

7.5

10.5

14

18

22.5

27.5

33.5

40

46.5

54.5

60.5

70

88

108

131

155

179

207

237

kg/m

0.04

0.06

0.08

0.11

0.14

0.18

0.22

0.26

0.31

0.37

0.43

0.47

0.55

0.69

0.85

1.03

1.22

1.41

1.62

1.86

cm3/m

6

8.5

12.5

16

21

26

31.5

37

42

49.5

57

65

73.5

94

114

138

162

190

224

248

kg/m

0.05

0.07

0.10

0.13

0.16

0.20

0.25

0.29

0.33

0.39

0.45

0.51

0.58

0.74

0.89

1.08

1.27

1.49

1.76

1.95

cm3/m

5.5

8

11

15

19.5

24.5

30.5

36

43

51

56

64

76.5

95

116

143

169

195

227

264

0.04

0.06

0.09

0.12

0.15

0.19

0.24

0.28

0.34

0.40

0.44

0.50

0.60

0.75

0.91

1.12

1.33

1.53

1.78

2.07

5.5

8.5

12

16.5

22

26.5

33

40.5

47.5

56

65

73.5

82.5

109

130

157

188

220

257

294

0.04

0.07

0.09

0.13

0.17

0.21

0.26

0.32

0.37

0.44

0.51

0.58

0.65

0.86

1.02

1.23

1.48

1.73

2.02

2.31

Hardness Scales

STATIC INDENTATION METHODS

Vickers or

Rockwell

Diamond Pyramid

C Scale

Hardness HV,

HRC, Rc

1000

69

950

68

900

67

850

66

800

64

750

62

700

60

650

58

600

55

580

54

560

53

540

52

520

51

500

49

480

48

460

46

440

45

420

43

400

41

380

39

360

37

340

34

320

32

300

30

280

27

260

24

240

20

220

200

180

160

140

120

100

-

Hardness

B Scale

HRB, RB

98

95

92

87

82

75

67

56

Brinell

HB, HBr

Steel Ball

496

480

465

448

433

415

397

379

360

341

322

303

284

265

247

228

209

190

171

152

133

114

95

Hardness

BHN Tungsten

Carbide Ball

722

691

656

611

564

545

525

507

488

471

452

433

415

397

379

360

341

322

303

284

265

247

228

209

190

171

152

133

114

95

This table must be regarded as giving no more than a general indication of the hardness

relationships for steels.

13

You might also like

- Electrode CalculationDocument2 pagesElectrode Calculationkoyahassan100% (10)

- Access Platforms Stairs and Ladders Administrator Guide PDFDocument40 pagesAccess Platforms Stairs and Ladders Administrator Guide PDFTury IonelNo ratings yet

- Bolt and Nut StandardDocument1 pageBolt and Nut Standardcrys suryo prayogoNo ratings yet

- Calculate welding parameters and material weights for pipe and vessel fabricationDocument11 pagesCalculate welding parameters and material weights for pipe and vessel fabricationShiv Shankar ThakurNo ratings yet

- Flooded Condenser & Distillation Column Pressure ControlDocument82 pagesFlooded Condenser & Distillation Column Pressure ControlMoca Phoenix100% (1)

- Tubular Truss Design Using Steel Grades S355 and S420Document35 pagesTubular Truss Design Using Steel Grades S355 and S420Muzamil Rather100% (1)

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Welding Table WPS & PQR Check List (Sheet, 2 Pages)Document2 pagesWelding Table WPS & PQR Check List (Sheet, 2 Pages)abomanar100486375% (4)

- Nozzle Weld DepositDocument4 pagesNozzle Weld DepositmikeylesNo ratings yet

- Electrode Weight CalculationDocument1 pageElectrode Weight CalculationBiginchNo ratings yet

- Consumable CalculatorDocument3 pagesConsumable CalculatorAlpesh Tilva100% (1)

- Access Platforms Stairs and Ladders User GuideDocument74 pagesAccess Platforms Stairs and Ladders User GuidemsanthosamNo ratings yet

- Pipeline Risk Assessment Essential Elements W Sample Case0113 - tcm153-535261Document8 pagesPipeline Risk Assessment Essential Elements W Sample Case0113 - tcm153-535261Max Pawer100% (2)

- Post Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2Document15 pagesPost Weld Treatment Procedure For Piping Spools (Abj) KN Rev-2williamsenNo ratings yet

- MTH - Spec Cross-Ref Chartr1Document1 pageMTH - Spec Cross-Ref Chartr1RamuAlagappanNo ratings yet

- Electrode Consumption PDFDocument1 pageElectrode Consumption PDFharold_bhieNo ratings yet

- Chemsheets As 1138 Free Radical Substitution 2 ANS Bns28Document2 pagesChemsheets As 1138 Free Radical Substitution 2 ANS Bns28charlesma12350% (4)

- 5 Material and Traceability RecordDocument6 pages5 Material and Traceability RecordEdha Ali100% (1)

- 267 Pipe Stress Analysis ReportsDocument11 pages267 Pipe Stress Analysis ReportsRaymond MetselaarNo ratings yet

- To Commissioning Manual: Appendix No. 1Document7 pagesTo Commissioning Manual: Appendix No. 1Bassem BalghouthiNo ratings yet

- Calculating Welding WireDocument6 pagesCalculating Welding WireBoodyBedaiwe50% (2)

- Piping Database 1Document16 pagesPiping Database 1faizanAkhtarNo ratings yet

- 4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionDocument9 pages4.2. Consumable Consumption and Welding Time 4.2.1 Calculation of Electrode ConsumptionNejat Ababay50% (2)

- Calibration of Radiation Protection Monitoring InstrumentsDocument162 pagesCalibration of Radiation Protection Monitoring InstrumentsalbertoprassNo ratings yet

- Line History SheetDocument46 pagesLine History SheetBhanu Pratap Choudhury33% (3)

- Tle/Epas: Quarter 1 - Module 1Document28 pagesTle/Epas: Quarter 1 - Module 1Doone Heart Santander CabuguasNo ratings yet

- Piping Release Report (Spool For Paint)Document2 pagesPiping Release Report (Spool For Paint)Siddiqui Abdul Khaliq100% (1)

- Standard conversion factors and weight calculationsDocument17 pagesStandard conversion factors and weight calculationsRathnakrajaNo ratings yet

- Welder Visual Inspection ReportsDocument24 pagesWelder Visual Inspection ReportsKyNo ratings yet

- ASME P Material NumbersDocument1 pageASME P Material Numbersmahi1437100% (1)

- Pipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0Document15 pagesPipeline Design Criteria 40RSN 00 BD PL DSC 2001 A0hgolestaniNo ratings yet

- Welding ProceduresDocument29 pagesWelding ProceduresLaith Salman100% (1)

- Lecture 1 ElectrohydraulicsDocument62 pagesLecture 1 ElectrohydraulicsAhmedNo ratings yet

- Atomic Theories and ModelsDocument12 pagesAtomic Theories and ModelsJhana Kate Falculan100% (1)

- Thermodynamics (Prausnitz) Manual SolutionDocument195 pagesThermodynamics (Prausnitz) Manual SolutionColin Zhang78% (9)

- Electrode CalculationDocument2 pagesElectrode Calculationtejasp8388100% (1)

- A2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5Document5 pagesA2V2D5 - Condition 17 - Field Joining Program - Appendix B3 - Welding Procedure Specifications - BPP-11-WP5ochableNo ratings yet

- Weld ShrinkageDocument16 pagesWeld ShrinkageWeff JingNo ratings yet

- Welders MatrixDocument1 pageWelders Matrixalinor_tn100% (1)

- WPS 03Document2 pagesWPS 03mansoor_an100% (1)

- Electrode SelectionDocument85 pagesElectrode SelectionVaibhavNo ratings yet

- Daily Report - XLSX 01Document1 pageDaily Report - XLSX 01kishoryawaleNo ratings yet

- Welding Electrode Filter Metal CalculationDocument3 pagesWelding Electrode Filter Metal CalculationjsvrrajuNo ratings yet

- Electrode Consumption On Pipe WeldingDocument2 pagesElectrode Consumption On Pipe Weldinganjangandak2932100% (1)

- Welder Test Param19!03!201211Document151 pagesWelder Test Param19!03!201211VapaVapaNo ratings yet

- ARCC Hydrotest Packages Summary ReportDocument4 pagesARCC Hydrotest Packages Summary ReportSiddiqui Abdul KhaliqNo ratings yet

- Welding Procedure Specification and Procedure Qualification RecordDocument2 pagesWelding Procedure Specification and Procedure Qualification RecordNatdanai NorawanNo ratings yet

- Metal Chemical CompositionDocument1 pageMetal Chemical CompositionprathmeshNo ratings yet

- WPS for Welding SA-335 P11 to SA-234 WP11Document3 pagesWPS for Welding SA-335 P11 to SA-234 WP11Ganesh rohitNo ratings yet

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 pagesWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniNo ratings yet

- How To Calculate Filler Metal ConsumptionDocument3 pagesHow To Calculate Filler Metal ConsumptionASHIL PRABHAKAR100% (2)

- ASME P NumbersDocument3 pagesASME P Numbersrajesh100% (1)

- 03-01 Material TraceabilityDocument1 page03-01 Material TraceabilityAngel AngeleyeNo ratings yet

- Hydrostatic Test Procedure For Site & Commissioning HT-031-R1Document7 pagesHydrostatic Test Procedure For Site & Commissioning HT-031-R1Hatem Ragab100% (1)

- WPSPQRDocument11 pagesWPSPQR0502raviNo ratings yet

- WPQR Welding Procedure QualificationDocument3 pagesWPQR Welding Procedure QualificationThanasis KyrgiazoglouNo ratings yet

- WPS NMB 001Document6 pagesWPS NMB 001mohamed nasserNo ratings yet

- Tool Fab - WorkshopDocument347 pagesTool Fab - Workshophrdsby100% (1)

- Baking and Drying Temperature of ElectrodesDocument1 pageBaking and Drying Temperature of ElectrodesshisNo ratings yet

- Tips Wps FormatDocument5 pagesTips Wps FormatWaqas WaqasNo ratings yet

- Material Certificate Plate 16mmDocument1 pageMaterial Certificate Plate 16mmAdeoyeNo ratings yet

- WPMP NDT Request FormDocument7 pagesWPMP NDT Request FormVimin PrakashNo ratings yet

- كيفية حساب كمية سلك اللحام المطلوبةDocument6 pagesكيفية حساب كمية سلك اللحام المطلوبةMohamed AtefNo ratings yet

- 08 Koprivica Milovanovic DjekicDocument13 pages08 Koprivica Milovanovic DjekicDante FilhoNo ratings yet

- How To Calculate Filler Metal Consumption For Welding ProjectsDocument3 pagesHow To Calculate Filler Metal Consumption For Welding ProjectsEdgar Coavas PérezNo ratings yet

- Natural Frequencies and Mode Shapes of Optimized Stiffened PlatesDocument9 pagesNatural Frequencies and Mode Shapes of Optimized Stiffened PlatesGogyNo ratings yet

- AWG Vs Metric Wire SizesDocument2 pagesAWG Vs Metric Wire Sizestomgilmartin100% (1)

- Weight Per Meter of WeldDocument1 pageWeight Per Meter of Weldreza329329No ratings yet

- Calculation of Electrode ConsumptionDocument2 pagesCalculation of Electrode ConsumptionGbenga MoboladeNo ratings yet

- DynamometerDocument21 pagesDynamometerHussam El'SheikhNo ratings yet

- Quantitative Metallography Lab Report: Grain Size and Carbon Volume FractionDocument14 pagesQuantitative Metallography Lab Report: Grain Size and Carbon Volume FractionMhd. Didi Endah PranataNo ratings yet

- ME3 Torsion MechanicsDocument3 pagesME3 Torsion MechanicsWaqas AhmedNo ratings yet

- Dme I Mock Test Question BankDocument5 pagesDme I Mock Test Question BankRushikesh SwamiNo ratings yet

- IGS-M-IT-001-1 (0) Feb.2007: ApprovedDocument24 pagesIGS-M-IT-001-1 (0) Feb.2007: ApprovedhgolestaniNo ratings yet

- VGNFZ180EB MKSPDocument2 pagesVGNFZ180EB MKSPhgolestaniNo ratings yet

- Specification For Anchor Flange 40RSN 00 BD PL SPC 2006 A0Document8 pagesSpecification For Anchor Flange 40RSN 00 BD PL SPC 2006 A0hgolestaniNo ratings yet

- Administrator Command Reference ManualDocument207 pagesAdministrator Command Reference ManualhgolestaniNo ratings yet

- Specification For Seals, Centering Cradles and Insulators For Case Crossings-40RSN-00-BD-PL-SPC-2004-A0Document14 pagesSpecification For Seals, Centering Cradles and Insulators For Case Crossings-40RSN-00-BD-PL-SPC-2004-A0hgolestaniNo ratings yet

- Area Based ADP Administrator GuideDocument60 pagesArea Based ADP Administrator GuidehgolestaniNo ratings yet

- SQL Direct User GuideDocument48 pagesSQL Direct User Guidehgolestani100% (1)

- D 51857Document3 pagesD 51857hgolestaniNo ratings yet

- ImPlant-I Installation and User GuideDocument44 pagesImPlant-I Installation and User GuidehgolestaniNo ratings yet

- SQL Direct Installation GuideDocument14 pagesSQL Direct Installation GuidehgolestaniNo ratings yet

- 02 599Document19 pages02 599hgolestaniNo ratings yet

- Product Release Latest Update: Aveva Implant-I 1.7 Full Release 51857Document1 pageProduct Release Latest Update: Aveva Implant-I 1.7 Full Release 51857hgolestaniNo ratings yet

- Dike Wall Calculation Book FOR TK-302, TK-311 AND TK-380: Page: 1 of 11Document11 pagesDike Wall Calculation Book FOR TK-302, TK-311 AND TK-380: Page: 1 of 11hgolestaniNo ratings yet

- D 51857Document3 pagesD 51857hgolestaniNo ratings yet

- E Pi 140Document50 pagesE Pi 140hgolestaniNo ratings yet

- R TP 024Document24 pagesR TP 024hgolestaniNo ratings yet

- Chemical InstromentDocument133 pagesChemical InstromenthgolestaniNo ratings yet

- Fall 2013 Fee Schedule Grad INTLDocument1 pageFall 2013 Fee Schedule Grad INTLhgolestaniNo ratings yet

- Lecture 2Document16 pagesLecture 2Ahmed K JirnazNo ratings yet

- Combined - Physics AssignmentDocument25 pagesCombined - Physics Assignment387 OORJA SINGHNo ratings yet

- Data Sheet RFQ - Modec - 1415Document1 pageData Sheet RFQ - Modec - 1415mauricio carvalhoNo ratings yet

- MatterDocument22 pagesMatterRon GruellaNo ratings yet

- Class 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 MarksDocument13 pagesClass 7 Mensuration - Perimeter, Area, Volume: All Questions Are 1 Markswb csNo ratings yet

- Basics of Reservoir EngineeringDocument68 pagesBasics of Reservoir Engineeringyarra suryatejaNo ratings yet

- Pup Mar MD Answer KeyDocument10 pagesPup Mar MD Answer KeyVon Eric DamirezNo ratings yet

- Civil & Civil (Rural) Eng. 3rd SemDocument23 pagesCivil & Civil (Rural) Eng. 3rd SemArman RajNo ratings yet

- PNOZ s4.1: Safety RelaysDocument32 pagesPNOZ s4.1: Safety Relayschao wangNo ratings yet

- Implementation of The Contensou-Erismann Model ofDocument12 pagesImplementation of The Contensou-Erismann Model ofJarek PlaszczycaNo ratings yet

- Tor Qui MetroDocument68 pagesTor Qui MetroVíc Mac IINo ratings yet

- Bridge EquipmentDocument8 pagesBridge EquipmentHarshal GhumadeNo ratings yet

- KC 60335-2-11Document33 pagesKC 60335-2-11le duc huynhNo ratings yet

- Fiber Laser Recent-Improvements and Applications PhotonicsDocument21 pagesFiber Laser Recent-Improvements and Applications PhotonicsFausto EstradaNo ratings yet

- Theorems of SSLC Maths-7marksDocument21 pagesTheorems of SSLC Maths-7marksPRAJWAL GNo ratings yet

- Cyclo Gearbox CatalogueDocument24 pagesCyclo Gearbox CatalogueRonald KaliraNo ratings yet

- ExergyDocument70 pagesExergyفضائح لا تصدقNo ratings yet

- DB en Quint Oring 24dc 2x20 1x40 104623 en 06Document17 pagesDB en Quint Oring 24dc 2x20 1x40 104623 en 06Ucef Oran KherroubiNo ratings yet

- 2019-Warp-Chine On Pentamaran Hydrodynamics Considering To Reduction in Ship Power EnergyDocument6 pages2019-Warp-Chine On Pentamaran Hydrodynamics Considering To Reduction in Ship Power EnergyDAMORA RHAKASYWINo ratings yet

- What Is A Quantum Mechanical ModelDocument48 pagesWhat Is A Quantum Mechanical Modeljaeyoon shimibibiNo ratings yet

- Electron Correlation: MBPT2, CASPT2, CC, CPF.: Static Dynamic Mrpt2Document24 pagesElectron Correlation: MBPT2, CASPT2, CC, CPF.: Static Dynamic Mrpt2Sandeep KumarNo ratings yet

- ASTM D5454-11e1Document3 pagesASTM D5454-11e1Angel MurilloNo ratings yet

- E3x ZD - E65z En5 01Document12 pagesE3x ZD - E65z En5 01Teguh WidiantoNo ratings yet

- PINOYBIX SATELLITE COMMUNICATION QuestionDocument47 pagesPINOYBIX SATELLITE COMMUNICATION QuestionCamille VeaNo ratings yet