Professional Documents

Culture Documents

Maintenance Alert M M MR M 0005

Uploaded by

pganoel0 ratings0% found this document useful (0 votes)

24 views1 pageThe document provides guidance on the use of breathing apparatus (BA's) during maintenance work. It states that BA's must be worn when toxic gases or oxygen deficiency are present, such as during flange breaking, leak repairs, or confined space entry. The proper use of BA's by trained personnel is mandatory when indicated on the work permit. Precautions for using BA's include selecting an air supply location upwind of gases, determining the number of air cylinders and hose lengths, planning escape routes, inspecting equipment, ensuring training and communication, and requiring a work permit. Safety is the top priority when using BA's during maintenance.

Original Description:

Maintenance Alert

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides guidance on the use of breathing apparatus (BA's) during maintenance work. It states that BA's must be worn when toxic gases or oxygen deficiency are present, such as during flange breaking, leak repairs, or confined space entry. The proper use of BA's by trained personnel is mandatory when indicated on the work permit. Precautions for using BA's include selecting an air supply location upwind of gases, determining the number of air cylinders and hose lengths, planning escape routes, inspecting equipment, ensuring training and communication, and requiring a work permit. Safety is the top priority when using BA's during maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views1 pageMaintenance Alert M M MR M 0005

Uploaded by

pganoelThe document provides guidance on the use of breathing apparatus (BA's) during maintenance work. It states that BA's must be worn when toxic gases or oxygen deficiency are present, such as during flange breaking, leak repairs, or confined space entry. The proper use of BA's by trained personnel is mandatory when indicated on the work permit. Precautions for using BA's include selecting an air supply location upwind of gases, determining the number of air cylinders and hose lengths, planning escape routes, inspecting equipment, ensuring training and communication, and requiring a work permit. Safety is the top priority when using BA's during maintenance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MAINTENANCE ALERT

MANUFACTURING DIVISION

TITLE:

ALERT: M-M-MR-M-005

Date: Feb-2014

Rev : 000

Use of Breathing Apparatus in Maintenance Works

Why & when to use BAS

On some occasions the presence of toxic gases or in

atmospheres with O2 deficiency, demands the use

of breathing apparatus with continuous air supply

for the execution of maintenance works.

Some examples of these works are:

Breaking flanges in lines with potential

presence of toxic gases

Repair / arrest leakages of toxic gases.

Entering within confines spaces with pretense

of gases or oxygen insufficiency.

Entering within reactors during catalyst

unloading.

Maintenance of Instruments when suspected

the presence of trapped toxic gases.

The proper use of the BAS by properly trained

personnel is extremely important and mandatory

when indicated by Operations in the PTW.

Precautions / preparation when using BAS

Because it is a high risk activity, a proper and

complete preparation needs to be done prior starting

the work.

Visit the job site to determine the best location for

the Air Trolley (Air Cart), preferable at ground

level, the closer to the work location and

upstream of the source of gases (check the wind

direction) ; in case of leakage, the gases should

not reach the area of the Air Trolley.

Determine the number of Air Trolleys based on

the number of BAS users, (recommended 2 users

per trolley).

Provide enough spare air cilinders, depending on

the expected duration of the works; a single Air

Trolley can provide from 30 to 45 min. to two

users.

Determine the length of the hoses to allow the

free movement of the users from the air trolley till

the work locations; special care when climbing

ladders to reach elevated locations.

Determine the escape route for a quick & safe

evacuation in case of emergency; in such cases

the air line will be disconnected, the valve of the

escape cylinder opened and the person will go to

the closest assembly point (escape cylinder will

provide 5 minutes of breathable air).

Veryfy the good conditions of the BAS and the

pressure on the air cylinder as well.

Confirm the all personnel have been trained in the

use of the BAS. A dedicated operator for the Air

Trolley need to be alllocated .

Ensure radio communication and visual contact

with the crew at the work site.

Provide a multi gas detector at the work location

A comprehesive JSA to be prepared and shared

with all the personnel taking part of the jobs.

Like any other maintenance work, do not procced

until a PTW has been issued and signed.

Safety is our first priority

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Quick Study For Computer Keyboard Short CutsDocument2 pagesQuick Study For Computer Keyboard Short Cutsmahazari100% (3)

- 737 Performance Reference Handbook - EASA EditionFrom Everand737 Performance Reference Handbook - EASA EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Compressed Air SafetyDocument4 pagesCompressed Air SafetyHareekirishnan LrkNo ratings yet

- HVACDocument9 pagesHVACMailisa FitriaNo ratings yet

- Method Statement and Risk Assessment For Electrical Cable Trench ExcavationDocument8 pagesMethod Statement and Risk Assessment For Electrical Cable Trench Excavationfehmi-fjr469650% (2)

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- LEAK TEST Method Statement Ponticelli & Total Petroleum.Document7 pagesLEAK TEST Method Statement Ponticelli & Total Petroleum.Fasola Lawal100% (4)

- Guide To The Construction Installation Operation and Maintenance of Air ReceiversDocument34 pagesGuide To The Construction Installation Operation and Maintenance of Air Receiversjosh100% (1)

- Osha PDFDocument10 pagesOsha PDFJarrod CurrinNo ratings yet

- Repairing and Maintenance Work PlanDocument5 pagesRepairing and Maintenance Work PlanMalik RiazNo ratings yet

- JSA - Chemical CleaningDocument4 pagesJSA - Chemical CleaningkrshhNo ratings yet

- Saw Cutting Concrete (Wet Method)Document1 pageSaw Cutting Concrete (Wet Method)Junard M. Lu HapNo ratings yet

- Installation of Underground 2"stainless Steel (1sdou) .Document8 pagesInstallation of Underground 2"stainless Steel (1sdou) .AldrinNo ratings yet

- Method Statement - HVAC Duct Leakage Testing ProcedureDocument7 pagesMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerNo ratings yet

- Use of Master Builders Generic Safe Work Method StatementsDocument7 pagesUse of Master Builders Generic Safe Work Method StatementsJonasNo ratings yet

- Confined Space TrainingDocument21 pagesConfined Space TrainingIvan RocoNo ratings yet

- MR Husdin Che Mat - Dosh MalaysiaDocument45 pagesMR Husdin Che Mat - Dosh Malaysiaakubestlah100% (2)

- Cost Estimating Handbook 2002Document158 pagesCost Estimating Handbook 2002garves007No ratings yet

- Vessel Cleaning ProcedureDocument9 pagesVessel Cleaning ProcedureAbdul Hakam Mohamed Yusof100% (1)

- Abrasive Blasting Safe Work PDFDocument2 pagesAbrasive Blasting Safe Work PDFamirthraj74100% (1)

- Data Science Machine LearningDocument15 pagesData Science Machine LearningmagrinraphaelNo ratings yet

- 400 Points in 400 Days: Extreme Chess Improvement for Adult PlayersDocument6 pages400 Points in 400 Days: Extreme Chess Improvement for Adult PlayersTheDreamMNo ratings yet

- CONFINED SPACEDocument7 pagesCONFINED SPACEarajanchabhadNo ratings yet

- Evoked PotentialsDocument49 pagesEvoked PotentialsparuNo ratings yet

- Ultrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentFrom EverandUltrasound Analysis for Condition Monitoring: Applications of Ultrasound Detection for Various Industrial EquipmentRating: 4.5 out of 5 stars4.5/5 (3)

- Manual Alimentador Piab PDFDocument28 pagesManual Alimentador Piab PDFsol soto100% (1)

- Learning To Program in Visual Basic and GadgeteerDocument125 pagesLearning To Program in Visual Basic and GadgeteerpganoelNo ratings yet

- Laude vs. Ginez-Jabalde (MCLE)Document29 pagesLaude vs. Ginez-Jabalde (MCLE)Justin CebrianNo ratings yet

- JSA HCK MOC Hot Tap Drilling Rev1Document6 pagesJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Manage Hospital Records with HMSDocument16 pagesManage Hospital Records with HMSDev SoniNo ratings yet

- Enclosed Space Entry Precautions Onboard ShipsDocument5 pagesEnclosed Space Entry Precautions Onboard ShipsSumit Sama100% (2)

- Method Statement FormatDocument11 pagesMethod Statement FormatPrem Preetham Dsouza100% (1)

- P 192.629 Purging of Pipeline RevisionsDocument7 pagesP 192.629 Purging of Pipeline RevisionscartarNo ratings yet

- ICAO Aerodrome Best Practice for Reducing Runway Excursion RiskDocument16 pagesICAO Aerodrome Best Practice for Reducing Runway Excursion Risknimsv1980100% (2)

- Final Mother DairyDocument59 pagesFinal Mother DairyAnup Dcruz100% (4)

- Xu10j4 PDFDocument80 pagesXu10j4 PDFPaulo Luiz França100% (1)

- Air Blowing Procedure Rev.0Document5 pagesAir Blowing Procedure Rev.0mostafaNo ratings yet

- SCUD Procedure CONST004 Purging With Gas Air or Inert GasDocument4 pagesSCUD Procedure CONST004 Purging With Gas Air or Inert GasAsan IbrahimNo ratings yet

- Air Blowing Procedure 2Document4 pagesAir Blowing Procedure 2mostafaNo ratings yet

- Abrasive (Sand) Blasting: Tool Box Safety TopicDocument4 pagesAbrasive (Sand) Blasting: Tool Box Safety TopicMohammad NaseemNo ratings yet

- Portable Pneumatic Equipment Statutory RequirementsDocument9 pagesPortable Pneumatic Equipment Statutory RequirementsUzoma FrancisNo ratings yet

- Coi Waste Water PondDocument2 pagesCoi Waste Water PondAMIRNo ratings yet

- Working in Confined Spaces: SWP-013 D1Document6 pagesWorking in Confined Spaces: SWP-013 D1Cms Stl CmsNo ratings yet

- HKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyDocument21 pagesHKMU Li Ka Shing School of Professional and Continuing Education OSH5002 Assessment Legislative Context in Occupational Health and SafetyWan Ching WongNo ratings yet

- METHOD STATEMENT FOR INSTALLION OF TRANSFORMER COHDocument5 pagesMETHOD STATEMENT FOR INSTALLION OF TRANSFORMER COHAldrige Tatenda VengesaiNo ratings yet

- 1.9 Maintenance: Adherence With This Section Is MandatoryDocument4 pages1.9 Maintenance: Adherence With This Section Is MandatoryHATEMNo ratings yet

- Safety Lecture #8 48959028805349Document8 pagesSafety Lecture #8 48959028805349Rafi Mahmoud SulaimanNo ratings yet

- A Guide To The Construction, Installation, Operation and Maintenance of Air ReceiversDocument34 pagesA Guide To The Construction, Installation, Operation and Maintenance of Air ReceiversshanmarsNo ratings yet

- Supplied-Air Respirator (SAR) Airsource Systems: National Personal Protective Technology LaboratoryDocument15 pagesSupplied-Air Respirator (SAR) Airsource Systems: National Personal Protective Technology LaboratoryraeicaNo ratings yet

- Vorplex - MST - Airblowing and Water FlushingDocument14 pagesVorplex - MST - Airblowing and Water FlushingAmirHakimRusliNo ratings yet

- Toolbox Talks What Is A Confined Space?Document16 pagesToolbox Talks What Is A Confined Space?adeeb zahidNo ratings yet

- Vacuum TrucksDocument4 pagesVacuum Trucksichal_zaidanNo ratings yet

- Underground Construction: Consumer Business ServicesDocument16 pagesUnderground Construction: Consumer Business ServicesMohamed H. JiffryNo ratings yet

- Compressed Air Working: Environment, Health and SafetyDocument3 pagesCompressed Air Working: Environment, Health and SafetyDinesh BadheNo ratings yet

- Cms-2 Detector de MonoxidoDocument17 pagesCms-2 Detector de MonoxidoJORGEALEXERNo ratings yet

- Sec 14 Compressed Air and Gas SafetyDocument9 pagesSec 14 Compressed Air and Gas SafetyEsamKhalilAlQadiNo ratings yet

- Confined Space Safety ProcedureDocument5 pagesConfined Space Safety ProcedureAhmed FodaNo ratings yet

- Facilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1Document3 pagesFacilities For Corrosion Monitoring in Process Equipment - Engineering Guide EG 19-6-1.1aminNo ratings yet

- 460LP Air Bk1Document82 pages460LP Air Bk1Ramiro Joel Quiñonez RamosNo ratings yet

- EEE 4.6 Saftey Aathi 4thDocument3 pagesEEE 4.6 Saftey Aathi 4thIhsan MohamedNo ratings yet

- MS (Pneumatic Test - Heat Exchanger)Document4 pagesMS (Pneumatic Test - Heat Exchanger)Zubair Ahmed KhaskheliNo ratings yet

- ANalyzer Shelter Tool Box TalkDocument1 pageANalyzer Shelter Tool Box TalkhomesxxxNo ratings yet

- Construction Method of Statement: Submitted By: Mega Air EnterprisesDocument12 pagesConstruction Method of Statement: Submitted By: Mega Air Enterprisesallen bernabeNo ratings yet

- Airworthiness Bulletin 30 001 Pitot Static Venturi CareDocument3 pagesAirworthiness Bulletin 30 001 Pitot Static Venturi CareExzy EditNo ratings yet

- Assignment 01 GRANADADocument3 pagesAssignment 01 GRANADAJomar Tabios GRANADANo ratings yet

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryFrom EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- De Firmian Nick-Modern Chess OpeningsDocument377 pagesDe Firmian Nick-Modern Chess Openingspganoel100% (1)

- Intorduction To Access DBDocument30 pagesIntorduction To Access DBpganoelNo ratings yet

- King Saud UniversityDocument10 pagesKing Saud UniversitypganoelNo ratings yet

- Managing ContractsDocument24 pagesManaging ContractspganoelNo ratings yet

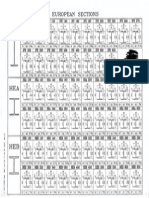

- Eurorean SectionDocument1 pageEurorean SectionpganoelNo ratings yet

- Create Maintenance Work Order (IW31)Document2 pagesCreate Maintenance Work Order (IW31)pganoelNo ratings yet

- FlangesDocument30 pagesFlangespganoelNo ratings yet

- Chess Openings For Black Explained A Complete Repertoire PDFDocument550 pagesChess Openings For Black Explained A Complete Repertoire PDFpganoel94% (33)

- Install Primavera P6 Professional R8.2Document12 pagesInstall Primavera P6 Professional R8.2pganoelNo ratings yet

- Check ValveDocument99 pagesCheck ValvepganoelNo ratings yet

- PDF 2010 Microsoft Access Intermediate Skills ManualDocument59 pagesPDF 2010 Microsoft Access Intermediate Skills Manualpganoel100% (1)

- Chapter 3Document23 pagesChapter 3pganoelNo ratings yet

- SAP Command Field: Lesson ObjectivesDocument7 pagesSAP Command Field: Lesson ObjectivespganoelNo ratings yet

- Best Practice BrianDocument30 pagesBest Practice BrianpganoelNo ratings yet

- SAP Codes for Steel GasketsDocument72 pagesSAP Codes for Steel GasketspganoelNo ratings yet

- Engineering EconomicsDocument18 pagesEngineering Economicsrco548No ratings yet

- SAP Codes for Gate Valves with Part NumbersDocument158 pagesSAP Codes for Gate Valves with Part NumberspganoelNo ratings yet

- Pipe FittingsDocument40 pagesPipe FittingspganoelNo ratings yet

- Depreciation and Corporate TaxesDocument9 pagesDepreciation and Corporate TaxespganoelNo ratings yet

- LECT12 - Engineering Economics IDocument10 pagesLECT12 - Engineering Economics IpganoelNo ratings yet

- Tube FittingsDocument4 pagesTube FittingspganoelNo ratings yet

- Engineering Economy Solved ProblemsDocument6 pagesEngineering Economy Solved ProblemsAngel OñaNo ratings yet

- Engineering EconomyDocument35 pagesEngineering EconomypganoelNo ratings yet

- Econ PE ProblemBkDocument19 pagesEcon PE ProblemBkpganoelNo ratings yet

- 1st WeekDocument89 pages1st Weekbicky dasNo ratings yet

- Philippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeDocument2 pagesPhilippine Supreme Court Acquits Man of Estafa Due to Lack of KnowledgeUrsulaine Grace FelicianoNo ratings yet

- 136 ADMU V Capulong (Roxas)Document2 pages136 ADMU V Capulong (Roxas)Trisha Dela RosaNo ratings yet

- Keyence Laser MicrometerDocument20 pagesKeyence Laser MicrometerimrancenakkNo ratings yet

- Banking Software System Monitoring ToolDocument4 pagesBanking Software System Monitoring ToolSavun D. CheamNo ratings yet

- EffectofObligations PDFDocument0 pagesEffectofObligations PDFÄnne Ü KimberlieNo ratings yet

- Management principles and quantitative techniquesDocument7 pagesManagement principles and quantitative techniquesLakshmi Devi LakshmiNo ratings yet

- Cough: by Dr. Meghana Patil (Intern Batch 2016)Document24 pagesCough: by Dr. Meghana Patil (Intern Batch 2016)Meghana PatilNo ratings yet

- ISB - PM - Week 4 - Required Assignment 4.2 - TemplateDocument2 pagesISB - PM - Week 4 - Required Assignment 4.2 - Templatesriram marinNo ratings yet

- Rheomix 141Document5 pagesRheomix 141Haresh BhavnaniNo ratings yet

- HTTP://WWW - Authorstream.com/presentation/kunalcmehta 1123128 Exim PolicyDocument2 pagesHTTP://WWW - Authorstream.com/presentation/kunalcmehta 1123128 Exim PolicyPranesh KumarNo ratings yet

- Alvarez vs. COMELECDocument5 pagesAlvarez vs. COMELECvanessa3333333No ratings yet

- Catalog CONSUDocument19 pagesCatalog CONSUVăn Nam PhạmNo ratings yet

- Loctite 270™: Technical Data SheetDocument4 pagesLoctite 270™: Technical Data SheetM Jobayer AzadNo ratings yet

- Frequently Asked Questions (And Answers) About eFPSDocument10 pagesFrequently Asked Questions (And Answers) About eFPSghingker_blopNo ratings yet

- Chapter 4-Ohm's LawDocument12 pagesChapter 4-Ohm's LawErin LoveNo ratings yet

- Gray Cast Iron Stress ReliefDocument25 pagesGray Cast Iron Stress ReliefSagarKBLNo ratings yet

- CPWD Contractor Enlistment Rules 2005 SummaryDocument71 pagesCPWD Contractor Enlistment Rules 2005 Summaryvikky717No ratings yet

- Customer Channel Migration in Omnichannel RetailingDocument80 pagesCustomer Channel Migration in Omnichannel RetailingAlberto Martín JiménezNo ratings yet

- Plastic Waste Powerpoint TemplateDocument39 pagesPlastic Waste Powerpoint TemplateVinh Lê KhảiNo ratings yet

- Project CST 383Document1,083 pagesProject CST 383api-668525404No ratings yet

- Small Clone ChorusDocument2 pagesSmall Clone ChorusamndsnaNo ratings yet

- 2 Security For CostsDocument1 page2 Security For CostsAnonymous Azxx3Kp9100% (1)