Professional Documents

Culture Documents

TB 1 Fly Ash Types & Benefits

Uploaded by

Sahil Grg0 ratings0% found this document useful (0 votes)

30 views1 pageCSDCSDCSDC

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCSDCSDCSDC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views1 pageTB 1 Fly Ash Types & Benefits

Uploaded by

Sahil GrgCSDCSDCSDC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Technical

Bulletin

Fly Ash Types & Benefits

The American Society for Testing and Materials (ASTM)

defines pozzolan as a siliceous or siliceous and aluminous

material, which in itself possesses little or no cementitious

value, but will, in finely divided form and in the presence of

moisture, chemically react with calcium hydroxide at ordinary

temperatures to form compounds possessing cementitious

properties.

ash on a routine basis to improve the quality of their project

and to increase their cost effectiveness.

Ready Mix Producers. A ready mix producer has several

reasons for using fly ash in concrete.

1. Fly ash can compensate for fines not found in some sands

and thereby enhance pumpability and concrete finishing.

2. Fly ash will result in a more predictable and consistent

Class F and Class C fly ash are products of the combustion of

finished product that will ensure customer acceptance.

coal in large power plants. Fly ash is collected in electrostatic

3. Fly ash offers flexibility in mix design providing a greater

precipitators or baghouses, then transferred to large silos for

range of mixes from liquid soil at 100 psi to high

shipment. When needed, fly ash is classified

strength (8,000 plus psi concrete) produced by the

by precise particle size requirements, thus

same batch plant without exotic equipment.

Fly ash is the best

assuring a uniform, quality product.

known pozzolan 4. Fly ash improves the flowability of the concrete,

Class F fly ash is available in the largest

which translates into less wear and tear on all the

in the world and producers equipment, from batching facilities to

quantities. Class F is generally low in lime,

usually under 15%, and contains a greater

trucks.

one of the most

combination of silica, alumina and iron

5. Fly ash enables the producer to customize

commonly used.

(greater than 70%) than Class C fly ash.

designs to each customers needs, thus providing the

producer a competitive advantage.

Class C fly ash normally comes from coals

which may produce an ash with higher lime content

Engineers and Architects. Engineers and architects will

generally more than 15% often as high as 30%. Elevated CaO

find that fly ash provides the following benefits:

may give Class C unique self-hardening characteristics.

1. It enables engineers and architects to provide the client

with a superior and more durable finished concrete.

Although both types of fly ash impart a wide range of qualities

2. Fly ash produces a high strength concrete that

to many types of concrete, they differ chiefly in the following

accommodates the design of thinner sections.

ways:

3. Fly ash permits design flexibility accommodating curves,

CLASS F

arches and other pleasing architectural effects.

4. The addition of fly ash to the mix is a built-in insurance

1. Most effectively moderates heat gain during concrete

for later-age strength gain in concrete.

curing and is therefore considered an ideal cementitious

material in mass concrete and high strength mixes. For

5. Fly ash ensures that the concrete will qualify as a durable

the same reason, Class F is the solution to a wide range

building material.

of summer concreting problems.

6. Fly ash contributes to the aesthetic appearance of the

2. Provides sulfide and sulfate resistance equal or superior

concrete.

to Type V cement. Class F is often recommended for use

where concrete may be exposed to sulfate ions in soil

Developers, Contractors, Owners. Fly ash concrete

and ground water.

provides the following advantages to developers, contractors

and owners:

CLASS C

1. The workability of fly ash concrete generally ensures that

1. Most useful in performance mixes, prestressed

the speed of construction is faster, which translates into

applications, and other situations where higher early

a quicker return on investment.

strengths are important.

2. Fly ash in the mix accommodates more creative designs.

2. Especially useful in soil stabilization, since Class C may

3. Since fly ash concrete is not as vulnerable to

not require the addition of lime.

deterioration or disintegration as rapidly as concrete

without fly ash, it ensures low-maintenance buildings that

Concrete manufacturers, engineers, architects, developers

will retain their value over the long-term.

and contractors all have an interest in specifying or using fly

For more information or answers to questions about the use of fly ash in specific applications,

contact your nearest Headwaters Resources Technical Sales Representative

or call 1-888-236-6236.

10701 S. River Front Parkway, Suite 300

South Jordan, UT 84095

www.flyash.com

You might also like

- Dir FDocument50 pagesDir FSahil GrgNo ratings yet

- Phone BookDocument3 pagesPhone BookSahil GrgNo ratings yet

- Delhi PincodeDocument5 pagesDelhi Pincodeharshil12No ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Hungama 15Document1 pageHungama 15Sahil GrgNo ratings yet

- Transportation Engineering Lab ManualDocument42 pagesTransportation Engineering Lab Manualउमेश गावंडे89% (9)

- HJHJBHBJKDocument97 pagesHJHJBHBJKSahil GrgNo ratings yet

- Wefewf 103-109Document8 pagesWefewf 103-109Sahil GrgNo ratings yet

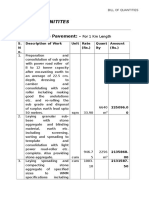

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- HCGHVJ1 - 13Document16 pagesHCGHVJ1 - 13Sahil GrgNo ratings yet

- Page 265-271 MeasurementDocument9 pagesPage 265-271 MeasurementSahil GrgNo ratings yet

- UPPCL Pay Bill Excel 2003Document3 pagesUPPCL Pay Bill Excel 2003Sahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- Page 164-166 RecommendationsDocument3 pagesPage 164-166 RecommendationsSahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- Classified List of Sale of Publication 30-11-2008Document29 pagesClassified List of Sale of Publication 30-11-2008Sahil GrgNo ratings yet

- Page 257-264 Schedule of RatesDocument11 pagesPage 257-264 Schedule of RatesSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- WritDocument1 pageWritSahil GrgNo ratings yet

- Bill of Quantities for 1 Km Flexible and Rigid PavementDocument9 pagesBill of Quantities for 1 Km Flexible and Rigid PavementSahil GrgNo ratings yet

- Paper1 East ABCFGHI PDFDocument17 pagesPaper1 East ABCFGHI PDFSatyajitMannaNo ratings yet

- Fci Key 2015Document18 pagesFci Key 2015Prakash JpNo ratings yet

- FAQsadDocument15 pagesFAQsadSahil GrgNo ratings yet

- CPWD Books and Specifications ListingDocument8 pagesCPWD Books and Specifications ListingSahil GrgNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Car NB Documents (YOPH02PC02)Document21 pagesCar NB Documents (YOPH02PC02)PaulNo ratings yet

- Theory of Elinor OstromDocument5 pagesTheory of Elinor OstromSanjana KrishnakumarNo ratings yet

- Προσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςDocument20 pagesΠροσχέδιο Έκθεσης Γ.Γ. ΟΗΕ για Καλές ΥπηρεσίεςARISTEIDIS VIKETOSNo ratings yet

- Chapter Three Business PlanDocument14 pagesChapter Three Business PlanBethelhem YetwaleNo ratings yet

- AirROC T35 D45 D50 Tech SpecDocument4 pagesAirROC T35 D45 D50 Tech SpecmdelvallevNo ratings yet

- Why The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchDocument17 pagesWhy The Bollard Pull Calculation Method For A Barge Won't Work For A Ship - TheNavalArchFederico BabichNo ratings yet

- (Lecture 10 & 11) - Gearing & Capital StructureDocument18 pages(Lecture 10 & 11) - Gearing & Capital StructureAjay Kumar TakiarNo ratings yet

- PM and Presidential Gov'ts Differ Due to Formal Powers and AppointmentDocument3 pagesPM and Presidential Gov'ts Differ Due to Formal Powers and AppointmentNikeyNo ratings yet

- TopGearDocument188 pagesTopGearbarborina10% (1)

- CAT Álogo de Peças de Reposi ÇÃO: Trator 6125JDocument636 pagesCAT Álogo de Peças de Reposi ÇÃO: Trator 6125Jmussi oficinaNo ratings yet

- Responsibility and Transfer Pricing Solving: Answer: PDocument3 pagesResponsibility and Transfer Pricing Solving: Answer: PPhielle MarilenNo ratings yet

- Urban Altoids EDC Kit v2.2.1Document2 pagesUrban Altoids EDC Kit v2.2.1richard philpNo ratings yet

- Cereal Partners World Wide (Case Presentation)Document42 pagesCereal Partners World Wide (Case Presentation)Misbah JamilNo ratings yet

- Certificate of IncorporationDocument1 pageCertificate of IncorporationVaseem ChauhanNo ratings yet

- VISIONARCHDocument3 pagesVISIONARCHJHON YDUR REMEGIONo ratings yet

- Gram-Charlier para Aproximar DensidadesDocument10 pagesGram-Charlier para Aproximar DensidadesAlejandro LopezNo ratings yet

- Data Sheet ECU-TESTDocument2 pagesData Sheet ECU-TESTmeetbalakumarNo ratings yet

- Concepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPDocument39 pagesConcepts in Enterprise Resource Planning: Chapter Six Human Resources Processes With ERPasadnawazNo ratings yet

- Design of Masonary Retaining Wall - SteppedDocument3 pagesDesign of Masonary Retaining Wall - Steppedmeenu100% (1)

- Announcement: Inter-And Intra-Sectoral Dynamics For Transforming Indian AgricultureDocument8 pagesAnnouncement: Inter-And Intra-Sectoral Dynamics For Transforming Indian AgricultureEnamul HaqueNo ratings yet

- Sheet 4Document3 pagesSheet 4Apdo MustafaNo ratings yet

- Affidavit in Support of ComplaintDocument3 pagesAffidavit in Support of ComplaintTrevor DrewNo ratings yet

- Experimental Evaluation of Hotspot Identification Methods: Wen Cheng, Simon P. WashingtonDocument12 pagesExperimental Evaluation of Hotspot Identification Methods: Wen Cheng, Simon P. WashingtonNandeesh MallapurmathNo ratings yet

- Real Estate Merger Motives PDFDocument13 pagesReal Estate Merger Motives PDFadonisghlNo ratings yet

- Chapter 5Document30 pagesChapter 5فاطمه حسينNo ratings yet

- 2018 Scaffold and Access Inspection Checklist FDocument6 pages2018 Scaffold and Access Inspection Checklist FTaufiq YahayaNo ratings yet

- Comprehensive Case 1 BKAR3033 A221Document3 pagesComprehensive Case 1 BKAR3033 A221naufal hazimNo ratings yet

- Competition Patriotism and Collaboratio PDFDocument22 pagesCompetition Patriotism and Collaboratio PDFAngga PrianggaraNo ratings yet

- 17th Edition OverviewDocument108 pages17th Edition OverviewJeremie Rameau100% (2)

- Pulau Besar Island Off Malacca CoastDocument5 pagesPulau Besar Island Off Malacca CoastLucy TyasNo ratings yet