Professional Documents

Culture Documents

2 - Iect0909

Uploaded by

Mohd Yazid Mohamad YunusOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2 - Iect0909

Uploaded by

Mohd Yazid Mohamad YunusCopyright:

Available Formats

Mindanao Journal of Science and Technology Vol.

12 (2014) 12-24

A Survey on the Implementation of Safety Standards

of On-going Construction Projects in

Cagayan de Oro City, Philippines

Ruel R. Cabahug

College of Engineering and Architecture

Mindanao University of Science and Technology

Cagayan de Oro City, 9000 Philippines

ruel_cabahug2@yahoo.com

Date received: July 28, 2013

Revision accepted: January 24, 2014

___________________________________________

Abstract

A survey using structured questionnaires and actual field visits was conducted to

various on-going projects in Cagayan de Oro City in the year 2011. A total of 375

respondents from 36 contractors were subjected to the questionnaires which included

project managers, project engineers, foremen, carpenters, masons, equipment

operators, welders, steel men, electricians and laborers. Apart from the data

obtained from questionnaires, actual field visits were conducted to gather further

information using the checklist of Occupational Health and Safety Standard practices

of the Department of Labor and Employments Department Order No. 13. Results

revealed that in actual field condition, the standard safety practices were poorly

implemented and in most cases, the standard safety requirements were just taken for

granted. While the contractors were obliged to do their part in educating and

promoting health and safety practices in the construction sites, this study proved

otherwise.

Keywords: construction, construction management, safety, health and safety, health

and safety in construction, occupational health and safety

1. Introduction

There is a booming construction activity in almost all major cities of the

country, including Cagayan de Oro City. As part of the development, the

most cities today are facing the challenges of urbanization. Several

infrastructure developments are already taking place and some are in

progress of construction. These include: bridges, flyovers, malls, high rise

buildings and other structures.

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

While Cagayan de Oro City is enjoying the progress brought by the

development, through infrastructure, it is sad to note that construction

projects are not implemented safely over these years. Construction is still

one of the most dangerous land-based work sectors in the country. Fatal

accidents such as falls from height, accidents involving construction

equipment, excavation accidents, electrocution, and being struck by moving

objects are still the common causes of accidents in the construction industry

(Anon, 2011; Bianca, 2011; Bumpress, 2011).

These fatal and serious injuries happened because the construction industry

does not have enough people that have been trained to oversee safety (Grace,

2010). Most contractors choose to ignore safety assurance system (Susak,

2018; Argy, 2010). While the government is trying to push the Occupational

Safety and Health Standards for the last few years (Laguesma, 1998), it can

be noted that such compliance is not improving the accident rates in the

construction industry (Anon, 2009; Swanson, 2011).

This study focuses on the actual implementation of Safety Standards

required in the Construction site. The area of focus is in Cagayan de Oro

City, of which it can be also noted that it may be what other cities of this

country are also doing.

The aim of this study is to assess and evaluate the construction companies

(Contractors) in Cagayan de Oro City in their implementation of safety

standards in their projects. Specifically, the following objectives are

considered:

1.

To assess and evaluate the safety conditions and practices of

construction workers the project site while project is on-going;

2.

To promote safety standard procedures in actual implementation of

the project site.

2. Methodology

This study uses qualitative method of research through a structured survey

questionnaire and checklists for a safe environment at the worksite. The

questionnaires were distributed to construction workers, which included:

laborers, carpenters, masons, electricians, foremen, engineers and managers.

13

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

In order to address the first objective, respondents were visited on the actual

construction sites and data were collected through the questionnaires.

As to the second objective, the findings and results can help the researcher to

draw potential recommendations to promote the safety standard practices in

actual implementation of the project site.

3. Results and Discussion

This study has involved thirty six (36) construction firms in Region 10 of

which 30 of these firms were located and had the project constructed in

Cagayan de Oro City. It includes 23 companies with vertical structure

projects and 7 firms with horizontal structure projects.

A total of 375 construction workers were being surveyed for this study. The

respondents included two (2) project manager, five (5) engineers, two (2)

safety staffs, six (6) heavy equipment operators, three (3) crane operators,

three (3) electricians, twenty four (24) foreman sixty nine (69) masons,

seventy nine (79) carpenters, eighteen (18) steel men, twenty three (23)

welders and one hundred forty one (141) laborers. These respondents were

taken randomly upon visiting and observing different on-going projects in

the city.

Safety training and seminars are presented in Table 1. It shows that 124

respondents had participated safety training and seminars especially the preconstruction safety training which was conducted before they start to work

the project. However, 144 of these respondents have not undergone safety

training and seminars.

A large percentage (38.40%) of the workforce has not attended training and

seminars on safety. This means that a large number of workers are unaware

of the dangers that are based on them in the worksite. There is a serious need

for the workers who are currently working in the jobsites to undertake safety

training and seminars in order to provide guidance and protection at their

respective workplaces.

Table 2 shows the skills certificates that the construction workers had. The

heavy equipment operators presented their TESDA certificates thereby

proving that most construction operators of heavy equipment in this city, are

capable ofdoing their jobs. This also provided insights that contractors are

hiring qualified equipment operators through the presentation of certificates.

14

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

Table 1. Safety training and seminar acquired

Training and Seminars

Frequency

Percentage

Fire Protection Seminar

17.00

4.53

First Aid Seminar

17.00

4.53

Safety Training Methods

58.00

15.47

Safety Management Technique

13.00

3.47

Crane & Elevator Safety Inspection

2.00

0.53

Pre-Construction Safety Training

124.00

33.07

No training/seminar attended

144.00

38.40

Table 2. Skills certificate acquired

Skills Certificate

Frequency

Percentage

Heavy Equipment Operator

6.00

100

Crane Operator Certificate

3.00

100

TESDA Certificate

60.00

28.17

Penalties for violating safety practices were presented in Table 3. There were

231 respondents that had worked in the construction project site with safety

program. It was shown that the common penalties the construction workers

get for a first offense was they were warned and not allowed to work on site,

while for second offense was still warned and not allowed to work on site

but some also said that they were suspended for the second offense. In the

third offense, some say that they were suspended and, others say that they

were terminated in their work without any benefits taken from the company.

This practices are typical practices for penalizing workers who commit

violations in worksites. However, it is noted that penalties were applied

when accidents already happened. Employers are quick to pinpoint the

blame to the workers who already had an accident. For non-fatal accidents

and injuries, it is easier to blame the injured for committing the safety

violation, thereby, imposing the penalties would only add insultto the

injury.

It is important that violations should not be taken for granted in order to

impose on the workers the importance of safe practices in the workplace,

because what they are protecting in return is their own lives.

15

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

Table 3. Penalties for violating safety practices

Penalties

Frequency

Percentage

Warned but still allowed to work on site

0.00

0.00

Warned and not allowed to work on site

79.00

34.19

50.00

21.65

First Offense

Suspension

Second Offense

Warned but still allowed to work on site

0.00

0.00

Warned and not allowed to work on site

67.00

29.00

Suspension

62.00

26.96

Termination

0.00

0.00

Warned but still allowed to work on site

0.00

0.00

Warned and not allowed to work on site

0.00

0.00

Suspension

67.00

29.00

Termination

62.00

26.96

Third Offense

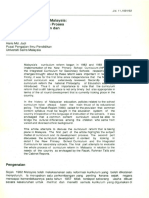

The survey identified four common injuries that usually happened in the

worksite. These were wounds (due to accidental cuts from sharp tools, etc.),

abrasion, bruising, and punctured by nails. In Figure 1, the most common

injuries experienced by the respondents during the execution of their work at

the construction sites is presented. The most common injury is punctured by

nails at 79.73%. Followed by abrasion (74.13%), wounds or cuts from sharp

objects or tools (72%) and bruise due to hitting hard objects at the worksite

(61.60%). Others injuries that were experienced by some of the construction

workers were laceration, burns and electrocution. The fracture usually

happens during a fall accident. These injuries were experienced by the

workers who did not use personal protective equipment while working on

the site.

It should be noted that several cases of injuries have been observed,

especially when workers were allowed to work without proper protective

equipment (PPE). This finding provided confirmation that contractors have a

lax attitude in dealing with worker safety precautions and use of PPEs. The

highest cause of injury recorded is on punctured by nails. This could have

been prevented by simply wearing a pair of steel toe shoes. Further

observations at work the site, confirmed that workers are allowed to wear

rubber shoes and even sandals for work.

16

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

100

90

80

70

60

50

40

30

20

10

0

Common Injuries

72.00 %

79.73%

74.13%

61.60%

21.87%

11.20%

1.33%

Figure 1. Percentage of common injuries experienced by the respondents at the

construction site

To understand the situation at the worksite when accidents happen, a

question on who administers first aid was asked. In Table 4, the person who

had given medical attention to the injuries of the construction workers is

presented. More than half of the respondents say that no one treat their

injuries but themselves. The result showed that only few construction sites in

Cagayan de Oro City had an attending nurse or first aider in the project site.

It is evident that medical personnel are usually not a requirement in

construction sites. Contractors do not provide medical personnel assistance

to the injured workers on the site. This is prevalent in most cases that only

co-workers were the ones who help the injured.

Table 4. Frequency and percentage of personnel who gave medical attention to the

injured worker

Personnel

Frequency

Percentage

Nurse/First Aider

57.00

15.20

Co-worker

104.00

27.73

None

214.00

57.07

Table 5 shows the safety practices that the construction firms should do on

daily basis, such as toolbox meeting, physical exercise and checking of

personal protective equipment. In the current situation, toolbox meeting is a

17

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

Table 5. Safety practices that should be done daily

Safety Practices

Toolbox Meeting

Physical Exercise

Checking of PPE

Frequency

Percentage

Daily

82.00

21.87

Oftentimes

79.00

10.40

Never

254.00

67.73

Daily

50.00

13.33

Oftentimes

22.00

5.87

Never

303.00

80.80

Daily

50.00

13.33

Oftentimes

41.00

10.93

Never

284.00

75.73

practice that is not common to the contracting activity in the field. It was

noted that only 21% practice daily toolbox meeting at the worksite. While a

large number (67%) did not engage in this practice.

Physical exercise as a routine in the worksite is not being practiced by

workers. One of the reasons, is that most workers will be doing more of their

physical activities during the entire day's work. This normal job, in fact, are

activities that are more exhausting for workers, thus physical exercise

routine can be eliminated in the daily program.

Interestingly, checking of PPEs is not performed in most of the workers at

the job sites. Somehow, there is a neglect on the contractors part in looking

around for minimizing the risks of accidents of its workers. One sad part of

this study is the confirmation that the safety of workers is being neglected by

the construction site managers and engineers.

Table 6 presents a tabulation on managing risks. It was noted that 24

construction sites had a boundary fence. Seven companies had a poster and

safety signs and warnings, six companies had a toolbox meeting every

morning, three companies had a fence for excavated areas and openings,

proper storage and labeled of materials and arrangement in collecting and

disposing of waste and two had a first aid kit adequately stocked. Only one

company had posted their emergency telephone numbers.

It is noticeable that perimeter fence is usually constructed round the

boundary of the construction site. Basically, it is always done so because it is

18

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

Table 6. Risk management on the hazards in construction area

Managing risks at the construction area

Frequency

Percentage

Poster and Safety signs/warnings

7.00

25.00

Toolbox Meeting

6.00

21.43

First Aid Kit

2.00

7.14

Emergency Telephone Numbers

1.00

3.57

Boundary Fence

24.00

85.71

Fence for excavated areas and openings

3.00

10.71

Proper Storage and Labeled of Materials

3.00

10.71

Arrangement in collecting and disposing of waste

3.00

10.71

always a payitem (perimeter fence) such that contractor will always

construct this in order to get paid. Other than being a paid item, perimeter

fence prevents outsiders to roam around the project site causing dangers to

them or preventing untoward incidents such as thief of materials, workers

property and others.

While it is considered a need in the project site to require all workers to use

protective personal equipment at all times, not all workers are doing so (see

Table 7). Site observations have confirmed that not all workers at the

construction site are observing the strict rule of Safety First as the slogan

of the Construction Industry. The use of hard hat is one necessary

requirement for construction workers. But construction managers do not give

this with an utmost attention. The same is true to other personal protective

gadgets needed for the job. One of the reasons for tolerating workers without

protective gears at work is the confusion on who provided these items to

workers. While big construction companies provide protective gears, other

small-scale companies are asking their workers to provide for their own.

This is where tolerance comes in because most often, workers failed to

provide for their own because of lack of financial capability due to low wage

rates. In other cases, it can be seen that some workers are using broken hard

hats, damage shoes, etc. Just for the sake of wearing them, but not for the

purpose of protecting them in case accidents happen.

In high structure projects, it is necessary to provide control measures for fall

protections. Observations at the worksites confirmed that only few

contractors are concerned with safety for workers at elevated projects.

19

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

Table 7. Usage of personal protective equipment

2-5: Personal Protective Equipment

Frequency

Percentage

Safety Helmet

10.00

35.71

Eye Protection

5.00

17.86

Ear Protection

3.00

10.71

Face Shield

3.00

10.71

Safety Vest/Jacket

3.00

10.71

Safety Harness

2.00

7.14

Safety Shoes

10.00

35.71

Aprons

2.00

7.14

Gloves

3.00

10.71

Dust/Gas Respirators

1.00

3.57

Table 8 shows the construction site that uses control measures for fall

accidents. It is a sad reality that even with the campaign for massive

awareness by informing the construction industry about the consequences of

not providing safety measures to the detriment of its workers, construction

managers are still hesitant to apply the required measures necessary for the

safe implementation of the project. One of the reasons that often mentioned

is that these safety measures often add to the indirect cost of the project

thereby reducing the possible profit of the project.

Table 8. Frequency and percentage of control measures for fall accidents in the

construction site

Control Measures for fall accidents

20

Frequency

Percentage

Guardrail

3.00

10.71

Warning Barrier

2.00

7.14

Handrail

2.00

7.14

Ladder Cage

2.00

7.14

Anchorage Point

0.00

0.00

Lifeline

2.00

7.14

Fall Arrestors

3.00

10.71

Lanyard

2.00

7.14

Shock Absorber

0.00

0.00

Safety Net

2.00

7.14

Safety Mesh

1.00

3.57

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

In many cases, such mind-setting of contractors and project managers often

lead to maximized profits as long as there are no fatal accidents that may

happen to the project.

Most of the construction companies at the site did not provide fire prevention

and control measures in the project site. About 70 percent have not made an

effort of equipping the site with fire prevention and control items (see Table

9). The absence of fire prevention and control gadgets may be due to the

reason that it is unusual for construction projects to get into fire accidents.

Somehow, contractors are playing with the idea that fire accidents never

happen in their kind of project, that providing fire extinguishers, fire alarm

system, etc. are additional cost that may be avoided to optimize profitability

of the project.

Table 9. Frequency and percentage of fire prevention and control measures in the

project site

Fire Prevention and Control

Frequency

Percentage

Fire extinguishers

5.00

17.86

Fire alarms

1.00

3.57

Storage of flammable liquids

2.00

7.14

None

20.00

71.43

4. Conclusions and Recommendations

The survey has provided this study with enough data to confirm the

conditions regarding the safety practices of construction workers at the

workplace. The following conclusions are derived:

1.

Safety Trainings and Seminar. The survey findings showed that the

majority of the construction workers in Cagayan de Oro City has

not attended trainings and seminar regarding health and safety

practices. There is a great need to persuade contractors and

employers to educate their workforce on the risks of their workers

not being able to understand the dangers of their workplace.

2.

Skills Certificate of Heavy Equipment Operators. The survey

provided a good evidence that construction employers are keen in

21

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

making sure that equipment operators were hired because they have

the skills to perform their job as proven also from the TESDA

certification they possessed.

22

3.

Penalties for Violating Safety Practices. The contractors have a

policy for penalizing safety violations. However, the violations

usually are being imposed when accidents had already happened.

4.

Common Injuries. The survey identified four common injuries that

usually happened in the worksite. These were wounds (due to

accidental cuts from sharp tools, etc.), abrasion, bruising, and

punctured by nails due to non-wearing of proper shoes at the

worksite. It was noted that most of these injuries could have been

avoided by proper wearing of the personal protective gears should

these gears have been strictly required from the workers.

5.

Daily Safety Practices at the Worksite. Among the daily safety

practices that has been observed by the construction workers at the

site are: 1. Toolbox meeting; and checking of PPEs of workers.

However, only the well-established construction companies do this

practice while medium and small scale contractors did not consider

these practices as necessary. The physical exercises for workers

were not an acceptable practice because the management and

workers agree that the tasks that they do are more than enough for

physical exercise of the body.

6.

Risk Management of Hazards in the Construction Area. The survey

identified boundary fencing or perimeter fence is the most

commonly adopted measures to minimize the risk in the

construction area. However, finding also suggested that this

measure became common because perimeter fence was usually a

pay item of the project, thereby contractors were more than willing

to perform it because of the corresponding return for this work item.

7.

Use of Personal Protective Equipment (PPEs). Construction at the

worksite were not strictly required to wear their hard hats, except

for the established contractors. This survey concluded that PPEs are

not yet well introduced at the work sites because contractors have

been lenient in requiring their workers to use protective gears in the

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

workplace. This leniency by construction managers have been the

cause of injuries and accidents of workers in the worksites.

8.

Control Measures for Fall Accidents. This survey concludes that

control measure for fall protection has not been properly

implemented at the worksites. Only few contractors showed

interests in addressing safety precautionary measures by providing

guard rails, hand rails, ladder cage, lifelines, safety nets, and others.

9.

Fire Prevention and Control. This survey confirmed that

contractors in Cagayan de Oro City did not consider equipping their

workplace with fire prevention measures and devices. There is a

need to educate contractors, construction managers and

professionals on the importance of fire hazards in the workplace.

As a summary, the researchers concluded that the implementation of safety,

standard in the construction projects in Cagayan de Oro City needs more

improvements and a more stringent regulation of safety laws to push the

construction industry/firms to follow safety and implement safety standards

in the site before starting the execution of the project.

The results of this study have shown that contractors needed work on

educating their workers in the standard safety practices. It is necessary that

the government agencies involved in construction health and safety laws

must enforce a more stringent regulation to push the construction industry to

follow or implement safety standard or the Department Order No. 13 Series

of 1998 Guidelines Governing Occupational Safety and Health in the

Construction Industry before starting their projects.

The following intervention is recommended in order to promote safety

standard practices on the site:

1.

It is recommended that all construction workers shall be

required to undertake a seminar on health and safety in the

construction workplace. This seminar shall be a requirement

for hiring by the contractors/employers.

2.

At the university level, a series of seminars shall be prepared in

consultation with the safety practitioners to be delivered to the

construction workers. This intervention will definitely improve

the safety practices in the construction industry of the country.

23

R. R. Cabahug / Mindanao Journal of Science and Technology Vol. 12 (2014) 12-24

6. Acknowledgement

This research was successfully conducted through the efforts of the civil

engineering students who gathered the data on the field and observed the

work conditions of the project sites as part of their requirement in Special

Problems. Thanks to Leonivi M. Bahan, Mark Julian Dawis, Ern John C.

Llacuna and Cyril D. Tuhod.

7. References

Anonymous (2004). Health and Safety at Work in the Construction Industry. From:

http://www.eccenet.org. Retrieved on October 2004.

Anonymous 1 (2009). 3 Construction Companies Share Best Practices in Safety.

From: http:// www.buildings.com.Retrieved on February 2009.

Anonymous (2010). Occupational Safety and Health Center (OSHC) Conducts

Construction Safety Training for Department of Public Works and Highways

(DPWH). From: http://www.oshc.dole.gov.ph.

Argy, D. (2010).The Importance of Construction Safety Training. From: http://www.

ezinearticles.com.

Bianca, A. (2011). Why is Safety Important in Construction? From:http://www

.ehow.com.

Bumpress, B. (2010). Common Construction Hazards From:http://www.ehow.com.

Retrieved on September 26, 2010.

Grace, F.M. (2010). Accidents Prevention in Construction. From: http://www.ezi

nearticles.com).

Laguesma, B. (1998). Department Order No. 13 Series of 1998 Guidelines Governing

Occupational Safety and Health in the Construction Industry.

Susak, G. (2008). What are the Causes of Construction Accidents? From: http://ww

w.ezinearticles.com).

Swanson, B. (2011). How to Promote Construction Safety? From: http://www.ehow

.com. Retrieved on April 28, 2011.

24

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Employee SatisfactionDocument88 pagesEmployee SatisfactionDick Jefferson Ocampo PatingNo ratings yet

- Demo Script - Employee Central OverviewDocument27 pagesDemo Script - Employee Central Overviewxanhdo_abcxyz100% (1)

- Employee turnover factors and retention strategiesDocument4 pagesEmployee turnover factors and retention strategiesVikram Khatri25% (4)

- PT&T VS NLRC G.R. No. 118978, 23 May 1997Document1 pagePT&T VS NLRC G.R. No. 118978, 23 May 1997Belen GaoatNo ratings yet

- 118 Floreza v. OngpinDocument3 pages118 Floreza v. OngpinElmore OrnelasNo ratings yet

- Historical & Developmental Role of ILO in SocietyDocument17 pagesHistorical & Developmental Role of ILO in SocietySheheryar KhanNo ratings yet

- Hotel Paris Case Study: Improving Guest Services to Boost RevenuesDocument3 pagesHotel Paris Case Study: Improving Guest Services to Boost RevenuesPrina Chopra75% (4)

- Top Star Bakery: Bumanglag - Del Campo - PascualDocument37 pagesTop Star Bakery: Bumanglag - Del Campo - PascualAdrian Ray Del CampoNo ratings yet

- SJVN Employee Absentism ReportDocument57 pagesSJVN Employee Absentism Reportsudhanshu chhajta100% (1)

- CTC Break-Up PDFDocument5 pagesCTC Break-Up PDFJatinder SadhanaNo ratings yet

- Ujian Mac TMP Tahun 5Document89 pagesUjian Mac TMP Tahun 5Mohd Yazid Mohamad YunusNo ratings yet

- How to make chemical solutions from solidsDocument6 pagesHow to make chemical solutions from solidsMohd Yazid Mohamad YunusNo ratings yet

- KTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Document1 pageKTM KOMUTER FARES EFFECTIVE DEC 2ND 2015Hamka HidayahNo ratings yet

- Lab SignageDocument11 pagesLab SignageMohd Yazid Mohamad YunusNo ratings yet

- Jurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)Document7 pagesJurnal Teknologi: Nilai Profesionalisme Bakal Guru Berteraskan Indikator Standard Guru Malaysia (SGM)jayanthanNo ratings yet

- Matecconf Ibcc2016 00107Document9 pagesMatecconf Ibcc2016 00107Mohd Yazid Mohamad YunusNo ratings yet

- Jilid 11 Artikel 01Document15 pagesJilid 11 Artikel 01munirahNo ratings yet

- Job Application Form - IIUM SchoolsDocument1 pageJob Application Form - IIUM SchoolsMohd Yazid Mohamad YunusNo ratings yet

- KLSM KBSM KSSMDocument1 pageKLSM KBSM KSSMMohd Yazid Mohamad YunusNo ratings yet

- Paper Keng RazakDocument19 pagesPaper Keng RazakNur MajNo ratings yet

- Ask Bab 3Document50 pagesAsk Bab 3Mohd Yazid Mohamad YunusNo ratings yet

- Application Form Osh Award 2016Document23 pagesApplication Form Osh Award 2016Mohd Yazid Mohamad YunusNo ratings yet

- Construction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaDocument19 pagesConstruction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaMohd Yazid Mohamad YunusNo ratings yet

- Rizwan 2015Document63 pagesRizwan 2015Mohd Yazid Mohamad YunusNo ratings yet

- Construction Safety and Health Factors at The Industry Level: The Case of SingaporeDocument19 pagesConstruction Safety and Health Factors at The Industry Level: The Case of SingaporeMohd Yazid Mohamad YunusNo ratings yet

- Job Application FormDocument4 pagesJob Application FormMohd Yazid Mohamad YunusNo ratings yet

- Paper Keng RazakDocument19 pagesPaper Keng RazakNur MajNo ratings yet

- Assessment of Safety and Health Measures (Shassic Method) in Construction SitesDocument9 pagesAssessment of Safety and Health Measures (Shassic Method) in Construction SitesMohd Yazid Mohamad YunusNo ratings yet

- Ijaiem 2015 01 11 16Document10 pagesIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- TS07K Muiruri Mulinge 6847 PDFDocument14 pagesTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusNo ratings yet

- Rizwan 2015Document63 pagesRizwan 2015Mohd Yazid Mohamad YunusNo ratings yet

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 pagesResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusNo ratings yet

- TS07K Muiruri Mulinge 6847 PDFDocument14 pagesTS07K Muiruri Mulinge 6847 PDFMohd Yazid Mohamad YunusNo ratings yet

- Ijerph 14 00045Document17 pagesIjerph 14 00045Mohd Yazid Mohamad YunusNo ratings yet

- Research Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranDocument15 pagesResearch Methodologies For Studying The Informal Aspects of Construction Project Organisations Thayaparan GajendranMohd Yazid Mohamad YunusNo ratings yet

- Ch2 Literature ReviewDocument11 pagesCh2 Literature ReviewMohd Yazid Mohamad YunusNo ratings yet

- Construction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaDocument19 pagesConstruction Safety Assessment Framework For Developing Countries: A Case Study of Sri LankaMohd Yazid Mohamad YunusNo ratings yet

- 555Document4 pages555Mohd Yazid Mohamad YunusNo ratings yet

- Challenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsDocument21 pagesChallenges and Needs For Support in Managing Occupational Health and Safety From Managers' ViewpointsMohd Yazid Mohamad YunusNo ratings yet

- Ijaiem 2015 01 11 16Document10 pagesIjaiem 2015 01 11 16International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 1064 2017 Federal Civil Servants ProclamationDocument32 pages1064 2017 Federal Civil Servants ProclamationHanamariam Fantu100% (1)

- Ops Mgmt Key Ch2Document14 pagesOps Mgmt Key Ch2Katherine50% (2)

- Case AnalysisDocument4 pagesCase Analysiskarylanne kabristanteNo ratings yet

- Police Supervisor Interview QuestionsDocument13 pagesPolice Supervisor Interview Questionsselinasimpson89No ratings yet

- Legal Aspects of Business Exam QuestionsDocument13 pagesLegal Aspects of Business Exam QuestionsRahul CharanNo ratings yet

- Evaluation of Training & RetrainingDocument3 pagesEvaluation of Training & RetrainingNischal ChhabriaNo ratings yet

- Cable Glands for Harsh EnvironmentsDocument1 pageCable Glands for Harsh EnvironmentsGolfkung PairojNo ratings yet

- 260 Odango Vs ANTECODocument2 pages260 Odango Vs ANTECOPiaNo ratings yet

- Lidia EndedluTHE FINAL FINALDocument72 pagesLidia EndedluTHE FINAL FINALnatud6No ratings yet

- Labour Laws in PakistanDocument4 pagesLabour Laws in Pakistanhelperforeu100% (1)

- Appraisal Performance CommentsDocument7 pagesAppraisal Performance CommentsDolly RamieNo ratings yet

- Pay Slip Dec 2019Document25 pagesPay Slip Dec 2019Badarpur SchoolNo ratings yet

- Kenneth E. Hare v. ProPublicaDocument12 pagesKenneth E. Hare v. ProPublicaKen HareNo ratings yet

- Personnel ManagementDocument11 pagesPersonnel ManagementkipkoechgedionNo ratings yet

- 28098v3a Learners GuideDocument36 pages28098v3a Learners Guideapi-324415177No ratings yet

- Position:: Recruitment Manager/Asst. Manager/Team Leader For US IT Recruitment (Night Shift)Document21 pagesPosition:: Recruitment Manager/Asst. Manager/Team Leader For US IT Recruitment (Night Shift)vikramsheelNo ratings yet

- Summer Internship GuideDocument17 pagesSummer Internship GuideNawaz SaifNo ratings yet

- How To Compute Separation PayDocument3 pagesHow To Compute Separation PayChristine BobisNo ratings yet

- Paysliper Template Grid2Document5 pagesPaysliper Template Grid2Jeeva KumarNo ratings yet

- Reference Letter Visa SampleDocument7 pagesReference Letter Visa Samplev1l0z0new1n2100% (1)