Professional Documents

Culture Documents

Masonry Structure Design Requirements

Uploaded by

Ahmed Ben HmidaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masonry Structure Design Requirements

Uploaded by

Ahmed Ben HmidaCopyright:

Available Formats

Chapter 11

MASONRY STRUCTURE DESIGN REQUIREMENTS

11.1 GENERAL

11.1.1 Scope. The design and construction of reinforced and plain masonry components and systems

and the materials used therein shall comply with the requirements of this chapter. Masonry shall be

designed in accordance with the requirements of ACI 530/ASCE 5/TMS 402. Masonry construction

and materials shall be in accordance with the requirements of ACI 530.1/ASCE 6/TMS 602. Inspection

and testing of masonry materials and construction shall be in accordance with the requirements of

Chapter 2.

11.1.2 References. The following documents shall be used as specified in this chapter.

ACI 530/ASCE 5/TMS 402

Building Code Requirements for Masonry Structures (ACI 53002/ASCE 5-02/TMS 402-02), American Concrete Institute/American

Society of Civil Engineers/The Masonry Society, 2002.

ACI 530.1/ASCE 6/TMS 602

Specification for Masonry Structures (ACI 530.1-02/ASCE 6-02/TMS

602-02), American Concrete Institute/American Society of Civil

Engineers/The Masonry Society, 2002.

ACI 318

Building Code Requirements for Structural Concrete, American

Concrete Institute, 2002, excluding Appendix A.

11.2 GENERAL DESIGN REQUIREMENTS

11.2.1 Classification of shear walls. Masonry walls, unless isolated from the lateral force resisting

system, shall be considered shear walls and shall be classified in accordance with this section.

11.2.1.1 Ordinary plain (unreinforced) masonry shear walls. Ordinary plain (unreinforced) masonry

shear walls shall satisfy the requirements of Section 1.13.2.2.1 of ACI 530/ASCE 5/TMS 402.

11.2.1.2 Detailed plain (unreinforced) masonry shear walls. Detailed plain (unreinforced) masonry

shear walls shall satisfy the requirements of Section 1.13.2.2.2 of ACI 530/ASCE 5/TMS 402.

11.2.1.3 Ordinary reinforced masonry shear walls. Ordinary reinforced masonry shear walls shall

satisfy the requirements of Section 1.13.2.2.3 of ACI 530/ASCE 5/TMS 402.

11.2.1.4 Intermediate reinforced masonry shear walls. Intermediate reinforced masonry shear walls

shall satisfy the requirements of Section 1.13.2.2.4 of ACI 530/ASCE 5/TMS 402.

11.2.1.5 Special reinforced masonry shear walls. Special reinforced masonry shear walls shall satisfy

the requirements of Section 1.13.2.2.5 of ACI 530/ASCE 5/TMS 402.

11.2.1.6 Shear keys. Add the following new Sec. 1.13.2.2.5 (d) to the Sec. 1.13.2.2.5 of ACI

530/ASCE 5/TMS 402. The surface of concrete upon which a special reinforced masonry shear wall is

constructed shall have a minimum surface roughness of 1/8 in. (3 mm). Shear keys are required when

the calculated tensile strain in vertical reinforcement from in-plane loads exceeds the yield strain under

load combinations that include seismic forces based on an R factor equal to 1.5. Shear keys that satisfy

the following requirements shall be placed at the interface between the wall and the foundation:

1.

The width of the keys shall be at least equal to the width of the grout space,

2.

The depth of the keys shall be at least 1.5 in. (38 mm),

3.

The length of the key shall be at least 6 in. (152 mm),

4.

The spacing between keys shall be at least equal to the length of the key,

183

2003 Provisions, Chapter 11

5.

The cumulative length of all keys at each end of the shear wall shall be at least 10

percent of the length of the shear wall (20 percent total),

6.

At least 6 in. (150 mm) of a shear key shall be placed within 16 in. (406 mm) of each

end of the wall, and

7.

Each key and the grout space above each key in the first course of masonry shall be

grouted solid.

11.2.2 Modifications to ACI 530/ASCE 5/TMS 402 and ACI 530.1/ASCE 6/TMS 602.

11.2.2.1 Additional definitions. Add the following definitions to Sec. 1.6 of ACI 530/ASCE 5/TMS

402:

Actual dimension The measured dimension of a designated item (e.g., a designated masonry unit or

wall).

Cleanout An opening to the bottom of a grout space of sufficient size and spacing to allow removal of

debris.

Cover Distance between surface of reinforcing bar and face of member.

Effective period Fundamental period of the structure based on cracked stiffness.

Hollow masonry unit A masonry unit whose net cross-sectional area in any plane parallel to the

bearing surface is less than 75 percent of the gross cross-sectional area in the same plane.

Plastic hinge The zone in a structural member in which the yield moment is anticipated to be

exceeded under loading combinations that include earthquake. The zone in a masonry element in which

earthquake energy is dissipated through the development of inelastic strains and curvatures.

Reinforced masonry Masonry construction in which reinforcement acts in conjunction with the

masonry to resist forces. Masonry in which the tensile resistance of masonry is neglected and the

resistance of the reinforcing steel is considered in resisting applied loads.

Solid masonry unit A masonry unit whose net cross-sectional area in any plane parallel to the bearing

surface is 75 percent or more of the gross cross-sectional area in the same plane.

Special moment frame A moment resisting frame of masonry beams and masonry columns within a

plane with special reinforcement details and connections that provides resistance to lateral and gravity

loads.

Specified Required by construction documents.

Stirrup Shear reinforcement in a beam or flexural member.

11.2.2.2 Additional notation. Add the following notation to Sec. 1.5 of ACI 530/ASCE 5/TMS 402:

dbb =

diameter of the largest beam longitudinal reinforcing bar passing through, or anchored in,

the special moment frame beam-column intersection.

dbp

diameter of the largest column (pier) longitudinal reinforcing bar passing through, or

anchored in, the special moment frame beam-column intersection.

hx

height of structure above the base level to level x.

hb

beam depth in the plane of the special moment frame.

hc

cross-sectional dimension of grouted core of special moment frame member measured

center to center of confining reinforcement.

Lc

length of coupling beam between coupled shear walls.

nominal moment strength at the ends of the coupling beam.

unfactored shear force due to gravity loads.

M1,M2

Vg

184

Masonry Structure Design Requirements

11.2.2.3. Delete Article 1.3 AE from ACI 530.1/ASCE 6/TMS 602.

11.2.2.4. Add the following exception after the second paragraph of Sec. 3.2.5.5 of ACI 530/ASCE

5/TMS 402.

Exception: A nominal thickness of 4 in. (102 mm) shall be permitted where load-bearing reinforced

hollow clay unit masonry walls satisfy all of the following conditions.

1. The maximum unsupported height-to-thickness or length-to-thickness ratios do not exceed 27,

2. The net area unit strength exceeds 8,000 psi (55 MPa),

3. Units are laid in running bond,

4. Bar sizes do not exceed No. 4 (13 mm),

5. There are no more than two bars or one splice in a cell, and

6. Joints are not raked.

11.2.2.5. Add the following new Sec. 1.15.3 to ACI 530/ASCE 5/TMS 402:

1.15.3 Separation joints. Where concrete abuts structural masonry and the joint between the materials

is not designed as a separation joint, the concrete shall be roughened so that the average height of

aggregate exposure is 1/8 in. (3 mm) and shall be bonded to the masonry in accordance with these

requirements as if it were masonry. Vertical joints not intended to act as separation joints shall be

crossed by horizontal reinforcement as required by Sec. 1.9.4.2.

11.2.2.6. Add the following new Article 3.5 G to ACI 530.1/ASCE 6/TMS 602:

3.5 G. Construction procedures or admixtures shall be used to facilitate placement and control

shrinkage of grout.

11.2.2.7. Replace Sec. 3.2.3.4(b) and 3.2.3.4(c) of ACI 530.1/ASCE 6/TMS 602 with the following:

(b) A welded splice shall be capable of developing in tension 125 percent of the specified yield

strength, fy, of the bar. Welded splices shall only be permitted for ASTM A706 steel reinforcement.

Welded splices shall not be permitted in plastic hinge zones of intermediate or special reinforced walls

or special moment frames of masonry.

(c) Mechanical splices shall be classified as Type 1 or Type 2 according to Sec. 21.2.6.1 of ACI 318.

Type 1 mechanical splices shall not be used within a plastic hinge zone or within a beam-column joint

of intermediate or special reinforced masonry shear walls or special moment frames. Type 2 mechanical

splices shall be permitted in any location within a member.

11.2.2.8. Add the following new Sec. 3.2.3.4.1 and 3.2.3.4.2 to ACI 530/ASCE 5/TMS 402:

3.2.3.4.1 Lap splices shall not be used in plastic hinge zones. The length of the plastic hinge zone shall

be taken as at least 0.15 times the distance between the point of zero moment and the point of maximum

moment.

3.2.3.4.2 Bars spliced by non-contact lap splices shall not be spaced transversely farther apart than the

lesser of one-fifth the required length or 8 in. (203 mm).

11.2.2.9. Add the following new Sec. 3.2.2(h) to ACI 530/ASCE 5/TMS 402:

(h) For out-of-plane bending, the width of the equivalent stress block shall not be taken greater than 6

times the nominal thickness of the masonry wall or the spacing between reinforcement, whichever is

less.

11.2.2.10. Add the following new Sec. 3.2.7 to ACI 530/ASCE 5/TMS 402:

3.2.7 Flanged shear walls

3.2.7.1 Effective width. Where wall intersections are constructed in accordance with Sec. 1.9.4, the

effective flange width for design shall be determined in accordance with this section.

185

2003 Provisions, Chapter 11

3.2.7.2 Compression. The width of flange considered effective in compression on each side of the web

shall be taken equal to 6 times the thickness of the flange or the actual width of the flange on that side,

whichever is less.

3.2.7.3 Tension. The width of flange considered effective in tension on each side of the web shall be

taken equal to 3/4 of the wall height or the actual width of the flange on that side, whichever is less.

11.2.2.11. Add the following new Sec. 3.2.4.2.6 to ACI 530/ASCE 5/TMS 402:

3.2.4.2.6 Coupling beams. Structural members that provide coupling between shear walls shall be

designed to reach their moment or shear nominal strength before either shear wall reaches its moment or

shear nominal strength. Analysis of coupled shear walls shall comply with accepted principles of

mechanics.

The design shear strength, Vn, of the coupling beams shall satisfy the following criterion:

Vn

1.25 ( M 1 + M 2 )

Lc

+ 1.4Vg

where:

M1 and M2

nominal moment strength at the ends of the beam;

Lc

length of the beam between the shear walls; and

Vg

unfactored shear force due to gravity loads.

The calculation of the nominal flexural moment shall include the reinforcement in reinforced concrete

roof and floor systems. The width of the reinforced concrete used for calculations of reinforcement

shall be six times the floor or roof slab thickness.

11.2.2.12. Add the following new Sec. 3.2.5 to ACI 530/ASCE 5/TMS 402:

3.2.5 Deep flexural member detailing. Flexural members with overall-depth-to-clear-span ratio

greater than 2/5 for continuous spans or 4/5 for simple spans shall be detailed in accordance with this

section.

3.2.5.1. Minimum flexural tension reinforcement shall conform to Sec. 3.2.4.3.2.

3.2.5.2. Uniformly distributed horizontal and vertical reinforcement shall be provided throughout the

length and depth of deep flexural members such that the reinforcement ratios in both directions are at

least 0.001. Distributed flexural reinforcement is to be included in the determination of the actual

reinforcement ratios.

11.2.2.13. Add the following new Sec. 1.13.7.4 to ACI 530/ASCE 5/TMS 402:

1.13.7.4 For structures in Seismic Design Category E or F, corrugated sheet metal anchors shall not be

used.

11.2.2.14. Revise Sec. 1.13.3.2 of ACI 530/ASCE 5/TMS 402/ to read as follows.

The calculated story drift of masonry structures due to the combination of design seismic forces and

gravity loads shall not exceed the allowable story drift a for masonry walls shown in Table 4.5-1 of

the 2003 NEHRP Recommended Provisions.

11.2.2.15. Add the following section to ACI 530/ASCE 5/TMS 402:

1.13.4.3 Anchoring to masonry. Anchorage assemblies connecting masonry elements that are part of

the seismic force resisting system to diaphragms and chords shall be designed so that the strength of the

186

Masonry Structure Design Requirements

anchor is governed by steel tensile or shear yielding. Alternatively, the anchorage assembly may be

designed to be governed by masonry breakout or anchor pullout provided that the anchorage assembly is

designed to resist not less than 2.5 times the factored forces transmitted by the assembly.

11.2.2.16. Revise the following Sec. 3.1.4.4 of ACI 530/ASCE 5/TMS 402:

3.1.4.4 Anchor bolts For cases where the nominal strength of an anchor bolt is controlled by masonry

breakout or masonry pryout, shall be taken as 0.50. For cases where the nominal strength of an anchor

bolt is controlled by anchor bolt steel, shall be taken as 0.90. For cases where the nominal strength of

an anchor bolt is controlled by anchor pullout, shall be taken as 0.65.

11.2.2.17. Revise the following Sec. 3.1.6.3 of ACI 530/ASCE 5/TMS 402:

3.1.6.3 Nominal shear strength of headed and bent-bar anchor bolts The nominal shear strength,

Bvn, shall be computed by Eq. (3-8) (strength governed by masonry breakout) and Eq. (3-9) (strength

governed by steel), and shall not exceed 2.0 times that computed by Eq. (3-4) (strength governed by

masonry pryout). In computing the capacity, the smallest of the design strengths shall be used.

11.2.2.18. Revise the following commentary to Sec. 3.1.6.3 of ACI 530/ASCE 5/TMS 402:

3.1.6.3 Nominal shear strength of headed and bent-bar anchor bolts The shear strength of a headed

or bent-bar anchor bolt is governed by yield and fracture of the anchor steel, or by masonry shear

breakout, or by masonry shear pryout. Steel strength is calculated conventionally using the effective

tensile stress area (that is, threads are conservatively assumed to lie in the critical shear plane). Under

static shear loading, bent-bar anchor bolts (J- or L-bolts) do not exhibit straightening and pullout. Under

reversed cyclic shear however, available research3.1 suggests that straightening and pullout may occur.

11.3 SPECIAL MOMENT FRAMES OF MASONRY

Special moment frames of masonry shall be designed and detailed in accordance with the requirements

of Sec. 3.2 of ACI 530/ASCE 5/TMS 402 and this section.

Special moment frames shall be fully grouted and constructed using open-end hollow -unit concrete

masonry or hollow-unit clay masonry.

Column nominal moment strength shall not be less than 1.6 times the column moment corresponding to

the development of beam plastic hinges, except at the foundation level. The column axial load

corresponding to the development of beam plastic hinges and including factored dead and live loads

shall not exceed 0.15 An f m The plastic hinge zone shall be assumed equal to the depth of the member.

11.3.1 Calculation of required strength. The calculation of required strength of the members shall

be in accordance with principles of engineering mechanics and shall consider the effects of the relative

stiffness degradation of the beams and columns.

11.3.2 Flexural yielding. Flexural yielding shall be limited to the beams at the face of the columns and

to the bottom of the columns at the base of the structure.

11.3.3 Materials. Neither Type N mortar nor masonry cement shall be used.

11.3.4 Reinforcement

11.3.4.1. The nominal moment strength at any section along a member shall not be less than 1/2 of the

higher moment strength provided at the two ends of the member.

11.3.4.2. Lap splices are permitted only within the center half of the member length. Lap splices are not

permitted in transverse reinforcement in beams, in plastic hinge zones in the column or in the beamcolumn joint.

11.3.4.3. Welded splices and mechanical connections may be used for splicing the reinforcement at any

section, provided that not more than alternate longitudinal bars are spliced at a section and the distance

between splices on alternate bars is at least 24 in. (610 mm) along the longitudinal axis and shall comply

with the requirements of Section 11.3.7.4.

187

2003 Provisions, Chapter 11

11.3.4.4. Reinforcement shall have a specified yield strength of 60,000 psi (414 MPa). The actual yield

strength shall not exceed 1.3 times the specified yield strength.

11.3.5 Beams

11.3.5.1 Compression limit. The factored axial compression force on the beam shall not exceed 0.10

times the net cross-sectional area of the beam, An, times the specified compressive strength, f m .

11.3.5.2 Shear. The value of Vm shall be zero within any plastic hinge zone and in any columns

subjected to net factored tension loads. The depth of the plastic hinge zone shall be assumed equal to the

member depth..

11.3.5.3 Reinforcement ratio. The reinforcement ratio for beams that connect vertical elements of the

seismic-force-resisting system shall not exceed the lesser of 0.15

f m

fy

or that determined in

accordance with Sec. 3.2.3.5.1 of ACI 530/ASCE 5/TMS 402. All reinforcement in the beam and

adjacent to the beam in a reinforced concrete roof or floor system shall be used to calculate the

reinforcement ratio.

11.3.5.4 Proportions. The clear span for the beam shall not be less than 4 times its depth.

The nominal depth of the beam shall not be less than 4 units or 32 in. (813 mm), whichever is greater.

The nominal depth to nominal width ratio shall not exceed 4.

Nominal width of the beams shall equal or exceed all of the following criteria:

1.

8 in. (203 mm),

2.

width required by Sec. 3.2.4.2.5 of ACI 530/ASCE 5/TMS 402 , and

3.

1/26 of the clear span between column faces.

11.3.5.5 Longitudinal reinforcement.

11.3.5.5.1. Longitudinal reinforcement shall not be spaced more than 8 in. (203 mm) on center.

11.3.5.5.2. Longitudinal reinforcement shall be uniformly distributed along the depth of the beam.

11.3.5 5.3. The minimum reinforcement ratio shall be 130/fy, where fy is in psi (the metric equivalent is

0.90/fy, where fy is in MPa).

11.3.5. 5.4. At any section of a beam, each masonry unit through the beam depth shall contain

longitudinal reinforcement.

11.3.5.6 Transverse reinforcement

11.3.5.6.1. Transverse reinforcement shall be one-piece and shall be hooked around top and bottom

longitudinal bars and shall be terminated with a standard 180-degree hook.

11.3.5.6.2. Within an end region extending one beam depth from Special Moment Frame column faces

and in any region at which beam plastic hinges may form during seismic or wind loading, the maximum

spacing of transverse reinforcement shall not exceed one-fourth the nominal depth of the beam.

11.3.5.6.3. The maximum spacing of transverse reinforcement shall not exceed the lesser of 1/2 the

nominal depth of the beam or the spacing required for shear strength.

11.3.5.6.4. The minimum transverse reinforcement ratio shall be 0.0015.

11.3.5.6.5. The first transverse bar shall not be more than 4 in. (102 mm) from the face of the column.

11.3.6 Columns

188

Masonry Structure Design Requirements

11.3.6.1 Compression limit. Factored axial compression force on the Special Moment Frame column

corresponding to the development of beam plastic hinges shall not exceed 0.15 times the net crosssectional area of the column, An, times the specified compressive strength. The compressive stress shall

also be limited by the maximum reinforcement ratio.

11.3.6.2 Proportions. The nominal dimension of the column parallel to the plane of the Special

Moment Frame shall not be less than two full units or 32 in. (810 mm), whichever is greater and shall

not exceed 96 in.

The nominal dimension of the column perpendicular to the plane of the Special Moment Frame shall not

be less than 8 in. (203 mm) or 1/14 of the clear height between beam faces, whichever is greater.

The clear-height-to-depth ratio of column members shall not exceed 5.

11.3.6.3 Longitudinal reinforcement

11.3.6.3.1. A minimum of 4 longitudinal bars shall be provided at all sections of every Special Moment

Frame column member.

11.3.6.3.2. The flexural reinforcement shall be uniformly distributed across the member depth.

11.3.6.3.3. The nominal moment strength at any section along a member shall be not less than 1.6 times

the cracking moment strength and the minimum reinforcement ratio shall be 130/fy, where fy is in psi

(the metric equivalent is 0.90/fy, where fy is in MPa).

11.3.6.3.4. Vertical reinforcement in wall-frame columns shall be limited to a maximum reinforcement

ratio equal to the lesser of

0.15

f m

fy

or that determined in accordance with Sec. 3.2.3.5 of Section

1.13.2.2.5 of ACI 530/ASCE 5/TMS 402. The minimum vertical reinforcement in wall-frame columns

shall be 0.002 times the gross cross section.

11.3.6.4 Lateral reinforcement.

11.3.6.4.1. Transverse reinforcement shall be hooked around the extreme longitudinal bars and shall be

terminated with a standard 180-degree hook.

11.3.6.4.2. The spacing of transverse reinforcement shall not exceed 1/4 the nominal dimension of the

column parallel to the plane of the Special Moment Frame.

11.3.6.4.3. The minimum transverse reinforcement ratio shall be 0.0015.

11.3.6.4.4. Lateral reinforcement shall be provided to confine the grouted core when compressive

strains caused by the factored axial and flexural loads at the design story drift, ), exceed 0.0015. The

unconfined portion of the cross section with a strain exceeding 0.0015 shall be neglected when

computing the nominal strength of the section. The total cross sectional area of rectangular tie

reinforcement for the confined core shall be not less than 0.9 shc

f m

. Alternatively, equivalent

f yh

confinement which can develop an ultimate compressive strain of 0.006 may substituted for rectangular

tie reinforcement.

11.3.7 Beam-column intersections

11.3.7.1 Proportions. Beam-column intersection dimensions in masonry special moment frames shall

be proportioned such that the special moment frame column depth in the plane of the frame satisfies Eq.

11.3-1:

hc >

4800d bb

f g

(11.3-1)

189

2003 Provisions, Chapter 11

where:

hp

column depth in the plane of the special moment frame, in.;

dbb

diameter of the largest beam longitudinal reinforcing bar passing through, or

anchored in, the special moment frame beam-column intersection, in.; and

f g

specified compressive strength of grout, psi (shall not exceed 5,000 psi

(34.5MPa) for use in Eq. 11.3-1).

The metric equivalent of Eq. 11.3-1 is

hc >

400d bb

f g

where hp and dbb are in mm and f g is in MPa.

Beam depth in the plane of the frame shall satisfy Eq. 11.3-2:

hb >

1800d bp

f g

(11.3-2)

where:

hb

beam depth in the plane of the special moment frame, in.;

dbp

diameter of the largest column longitudinal reinforcing bar passing through, or

anchored in, the special moment frame beam-column intersection, in.; and

f g

specified compressive strength of grout, psi (shall not exceed 5,000 psi (34.5

MPa) for use in Eq. 11.3-2).

The metric equivalent of Eq. 11.3-2 is

hb >

150d bp

f g

where hb and dbp are in mm and f g is in MPa.

11.3.7.2 Shear strength. The design shear strength, Vn, of the beams and columns shall not be less

than the shear corresponding to the development of 1.4 times the nominal flexural strength of the

member, except that the nominal shear strength need not exceed 2.5 times Vu. The nominal shear

strength of beam-column intersections shall exceed the shear calculated assuming that the stress in all

flexural tension reinforcement of the special moment frame beams at the column face is 1.4 fy .

Vertical shear forces may be considered to be carried by a combination of masonry shear-resisting

mechanisms and truss mechanisms involving intermediate column reinforcing bars.

The nominal horizontal shear stress at the beam-column intersection shall not exceed the lesser of 350

psi (2.5 MPa) or 7 f m (the metric equivalent is 0.58 f m MPa)

11.3.7.3 Horizontal reinforcement. Beam longitudinal reinforcement terminating in a special moment

frame column shall be extended to the far face of the column and shall be anchored by a standard hook

bent back into the special moment frame column.

190

Masonry Structure Design Requirements

Special horizontal shear reinforcement crossing a potential diagonal beam-column shear crack shall be

provided such that:

As

0.5V

fy

jh

(11.3-3)

where:

As

cross-sectional area of reinforcement;

Vjh

total horizontal joint shear; and

fy

specified yield strength of the reinforcement .

Special horizontal shear reinforcement shall be anchored by a standard hook around the extreme special

moment frame column reinforcing bars.

11.4 GLASS-UNIT MASONRY AND MASONRY VENEER

11.4.1 Design lateral forces and displacements. Glass-unit masonry and masonry veneer shall be

designed and detailed to satisfy the force and displacement requirements of Sec. 6.3.

11.4.2 Glass-unit masonry design.

11.4.2.1. The requirements of Chapter 7 of ACI 530/ASCE 5/TMS 402. shall apply to the design of

glass unit masonry. The out-of-plane seismic strength shall be considered to be the same as the strength

to resist wind pressure as specified in Sec. 7.3 of ACI 530/ASCE 5/TMS 402.

11.4.3 Masonry veneer design.

11.4.3.1. The requirements of Chapter 6 of ACI 530 shall apply to the design of masonry veneer.

11.4.3.2. For structures in Seismic Design Category E, corrugated sheet metal anchors shall not be

used.

11.5 PRESTRESSED MASONRY

11.5.1. Prestressed masonry shall be designed in accordance with of ACI 530/ASCE 5/TMS 402

Chapter 4.

191

2003 Provisions, Chapter 11

This page is intentionally left blank

192

You might also like

- 68rfe IntroductionDocument71 pages68rfe IntroductionThePokeOne83% (6)

- The Filipino FamilyDocument11 pagesThe Filipino FamilyTiger Knee97% (37)

- ASTM C1552 Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingDocument5 pagesASTM C1552 Capping Concrete Masonry Units, Related Units and Masonry Prisms For Compression TestingMohamed MeraounaNo ratings yet

- 3259r ACI 91 PDFDocument27 pages3259r ACI 91 PDFAnonymous Ybg3qa100% (2)

- Astm e 1155 14Document8 pagesAstm e 1155 14Adán Vera GoNo ratings yet

- Harajuku: Rebels On The BridgeDocument31 pagesHarajuku: Rebels On The BridgeChristian Perry100% (41)

- Epoxy-Coated Steel Dowels For Concrete PavementDocument5 pagesEpoxy-Coated Steel Dowels For Concrete PavementDanZel DanNo ratings yet

- Standard Practice For The Design and Construction of Reinforced Concrete Storm Sewer Pipe (RCP) Part 1: GeneralDocument23 pagesStandard Practice For The Design and Construction of Reinforced Concrete Storm Sewer Pipe (RCP) Part 1: GeneralAnony MousNo ratings yet

- Astm E72 E72-15Document13 pagesAstm E72 E72-15cristobal aguilar100% (1)

- WRI Manual of Standard Practice 109497Document38 pagesWRI Manual of Standard Practice 109497Maximiliano Rivas AlferoNo ratings yet

- Cold Weather Concreting: Reported by ACI Committee 306Document23 pagesCold Weather Concreting: Reported by ACI Committee 306Miguel DominguezNo ratings yet

- WHAT Is Plastic Shrinkage CrackingDocument2 pagesWHAT Is Plastic Shrinkage CrackingMikel MenesesNo ratings yet

- Ncma Tek: Glossary of Concrete Masonry Terms TEK 1-4Document6 pagesNcma Tek: Glossary of Concrete Masonry Terms TEK 1-4Heriberto Yau BNo ratings yet

- Evaluating Water-Resistive Barrier (WRB) Coatings Used Under Exterior Insulation and Finish Systems (EIFS) or EIFS With DrainageDocument5 pagesEvaluating Water-Resistive Barrier (WRB) Coatings Used Under Exterior Insulation and Finish Systems (EIFS) or EIFS With DrainageAhmad Zubair RasulyNo ratings yet

- MPI Maintenance Repainting ManualDocument18 pagesMPI Maintenance Repainting ManualnzarNo ratings yet

- VV016042 Service Manual OS4 PDFDocument141 pagesVV016042 Service Manual OS4 PDFCamilo Andres Uribe Lopez100% (1)

- E329 PDFDocument10 pagesE329 PDFINARQ1979No ratings yet

- Portland Cement: Standard Specification ForDocument9 pagesPortland Cement: Standard Specification ForThurain Aung KyawNo ratings yet

- 190102-DC10.5-Expansive and Stable Soils-Public ReviewDocument66 pages190102-DC10.5-Expansive and Stable Soils-Public Reviewvõ hoàng thái100% (1)

- ACI 315R-94: Reported by ACI Committee 315Document1 pageACI 315R-94: Reported by ACI Committee 315DIDIER ANGEL LOPEZ RINCONNo ratings yet

- ACI 530 QuestionsDocument3 pagesACI 530 QuestionsEduardo De Castro Cruz Jr.100% (1)

- ASTM C-845 Expansive Hydraulic Cement1Document3 pagesASTM C-845 Expansive Hydraulic Cement1Hsaam HsaamNo ratings yet

- Determining F Floor Flatness and F Floor Levelness Numbers: Standard Test Method ForDocument8 pagesDetermining F Floor Flatness and F Floor Levelness Numbers: Standard Test Method Forrenzo_macherNo ratings yet

- Astm C42/C42M - 04Document6 pagesAstm C42/C42M - 04AbelClarosNo ratings yet

- Tips For Designers PDFDocument5 pagesTips For Designers PDFSushil DhunganaNo ratings yet

- Metallic Materials for FGD SystemsDocument21 pagesMetallic Materials for FGD SystemsClaudia MmsNo ratings yet

- Astm C954Document3 pagesAstm C954Cj Elamparo100% (1)

- Astm A615Document6 pagesAstm A615Muhammad sheryarNo ratings yet

- Description and Job SpecificationDocument10 pagesDescription and Job SpecificationAhmed Ben HmidaNo ratings yet

- Rigid Pavement Design IntroductionDocument24 pagesRigid Pavement Design IntroductionSheikh Nouman Mohsin Ramzi100% (1)

- HDL Coder™ ReferenceDocument487 pagesHDL Coder™ ReferenceVictor Colpo NavarreteNo ratings yet

- Concrete Streets Guide SpecsDocument24 pagesConcrete Streets Guide SpecswickremasingheNo ratings yet

- BooksDocument1 pageBooksnotevaleNo ratings yet

- C76M 14Document11 pagesC76M 14diego rodriguezNo ratings yet

- Aci 308-92 PDFDocument11 pagesAci 308-92 PDFjf2587No ratings yet

- Facture C3 ShineDocument1 pageFacture C3 ShineAhmed Ben HmidaNo ratings yet

- Strength and Stress-Strain Characteristics of Traditional Adobe Block and Masonry PDFDocument9 pagesStrength and Stress-Strain Characteristics of Traditional Adobe Block and Masonry PDFmanish_shashikantNo ratings yet

- Design and Construction of Highway Pavement Joint SystemsDocument27 pagesDesign and Construction of Highway Pavement Joint SystemsJun JunNo ratings yet

- Automorphic Representations and L-Functions For The General Linear Group - Volume 2cDocument210 pagesAutomorphic Representations and L-Functions For The General Linear Group - Volume 2cluisufspaiandreNo ratings yet

- 05 Askeland ChapDocument10 pages05 Askeland ChapWeihanZhang100% (1)

- 2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409Document16 pages2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409AnisahNo ratings yet

- Astm C14 PDFDocument4 pagesAstm C14 PDFBrahim Rabaj0% (1)

- California Title 24, Part 1 Administrative Code 264pp 6x9tradeDocument264 pagesCalifornia Title 24, Part 1 Administrative Code 264pp 6x9tradeTom AstaNo ratings yet

- Standard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementDocument7 pagesStandard Specification For Deformed and Plain Low-Alloy Steel Bars For Concrete ReinforcementJose Fernando Huayhua ApfataNo ratings yet

- D 2527 - 83 R01 - Rdi1mjc - PDFDocument2 pagesD 2527 - 83 R01 - Rdi1mjc - PDFsabaris ksNo ratings yet

- C 636 - 04 Installation of Metal Ceiling Suspension Systems ForDocument4 pagesC 636 - 04 Installation of Metal Ceiling Suspension Systems ForJavier Salinas SepúlvedaNo ratings yet

- C 1064 ASTM - TemperatureDocument2 pagesC 1064 ASTM - TemperatureJohn StanleyNo ratings yet

- SP15 99Document1 pageSP15 99Orlando Manriquez LNo ratings yet

- Roberto C. A. Pinto and Kenneth C. Hover Frost and Scaling Resistance of High-Strength ConcreteDocument75 pagesRoberto C. A. Pinto and Kenneth C. Hover Frost and Scaling Resistance of High-Strength ConcreteFaroq MaraqaNo ratings yet

- C1032 - 06Document2 pagesC1032 - 06Black GokuNo ratings yet

- 3-AC428-Acceptance Criteria For ModularDocument24 pages3-AC428-Acceptance Criteria For ModularEric ChienNo ratings yet

- CEVA 250-Phyzite 380Document1 pageCEVA 250-Phyzite 380hernie w. vergel de dios jrNo ratings yet

- Renderoc TgxtraDocument2 pagesRenderoc TgxtratalatzahoorNo ratings yet

- C933 PDFDocument2 pagesC933 PDFDIAZCORDOBANo ratings yet

- SF Building Facade Inspection RequirementsDocument2 pagesSF Building Facade Inspection RequirementsANo ratings yet

- C1064C1064MDocument3 pagesC1064C1064Mmanil_5No ratings yet

- Design Specifications for Sound BarriersDocument26 pagesDesign Specifications for Sound BarriersbatteekhNo ratings yet

- Tek 18-01B5 PDFDocument8 pagesTek 18-01B5 PDFMohamed HNo ratings yet

- C511 PDFDocument3 pagesC511 PDFsujeeth kumarNo ratings yet

- ICC ESR-1385 For Kwik Bolt 3 Expansion Anchors For Masonry Approval Document ASSET DOC LOC 23Document5 pagesICC ESR-1385 For Kwik Bolt 3 Expansion Anchors For Masonry Approval Document ASSET DOC LOC 23Anonymous eoQuq9tNo ratings yet

- Cold-Formed Steel Slip Track DesignDocument4 pagesCold-Formed Steel Slip Track DesignZebNo ratings yet

- C924MDocument3 pagesC924MRufo Casco0% (1)

- K-Series Final 030911Document54 pagesK-Series Final 030911Alvaro Alexis Mendoza PradaNo ratings yet

- ASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementDocument2 pagesASTM A184 Welded Deformed Steel Bar Mats For Concrete ReinforcementAmanda Ariesta Aprilia100% (1)

- Controlled Low Strength MaterialDocument4 pagesControlled Low Strength MaterialDevrim GürselNo ratings yet

- Construction Issues: Anchoring MEP Items Into Suspended SlabsDocument2 pagesConstruction Issues: Anchoring MEP Items Into Suspended SlabsMario SandovalNo ratings yet

- ASTM Cone Penetrometer HandbookDocument11 pagesASTM Cone Penetrometer HandbookAlejandro Sierra GarcíaNo ratings yet

- ACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteDocument10 pagesACI 303.1-97 Standard Specification For Cast-In-Place Architectural ConcreteZaki 'Eki' MuliawanNo ratings yet

- Significant Changes in ACI 318-11Document4 pagesSignificant Changes in ACI 318-11cabpcabpNo ratings yet

- Geometrical DescriptionDocument1 pageGeometrical DescriptionAhmed Ben HmidaNo ratings yet

- Geometrical DescriptionDocument1 pageGeometrical DescriptionAhmed Ben HmidaNo ratings yet

- Node Displacement Summary: Job No Sheet No RevDocument1 pageNode Displacement Summary: Job No Sheet No RevAhmed Ben HmidaNo ratings yet

- Fill in RulesDocument1 pageFill in RulesAhmed Ben HmidaNo ratings yet

- Cementatious Grout DASDocument3 pagesCementatious Grout DASAhmed Ben HmidaNo ratings yet

- RESOLTECH Chemical Resistance GuideDocument45 pagesRESOLTECH Chemical Resistance GuideAhmed Ben HmidaNo ratings yet

- 7357.what's New in STAAD Foundation Advanced 61Document27 pages7357.what's New in STAAD Foundation Advanced 61Panneer Selvam EaswaranNo ratings yet

- Structural steel shapes and propertiesDocument176 pagesStructural steel shapes and propertiesAhmed Ben HmidaNo ratings yet

- SA Journal of Tech 2016Document90 pagesSA Journal of Tech 2016mack_eausNo ratings yet

- Thrust BlockDocument3 pagesThrust BlockAhmed Ben HmidaNo ratings yet

- AaaaaaaaaaaaaaaaaaaaaaDocument32 pagesAaaaaaaaaaaaaaaaaaaaaaAhmed Ben HmidaNo ratings yet

- Geometrical Description: WATER TANK Geometry DEGASSER GeometryDocument1 pageGeometrical Description: WATER TANK Geometry DEGASSER GeometryAhmed Ben HmidaNo ratings yet

- Ferraillage plan de poteaux et dalles béton arméDocument1 pageFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNo ratings yet

- EPD Mineral Wool Panel PRMDocument7 pagesEPD Mineral Wool Panel PRMAhmed Ben HmidaNo ratings yet

- Aciers Mottard 1 6 PDFDocument2 pagesAciers Mottard 1 6 PDFAhmed Ben HmidaNo ratings yet

- Hand Calculations 2 Way Flat Plate SlabDocument18 pagesHand Calculations 2 Way Flat Plate SlabAhmed Ben HmidaNo ratings yet

- Ferraillage plan de poteaux et dalles béton arméDocument1 pageFerraillage plan de poteaux et dalles béton arméAhmed Ben HmidaNo ratings yet

- Geometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Document2 pagesGeometric Properties of The Cross-Section Parameter Value: Interval of The Stresses Values: (,) KN/CM 2 - 6,66e+2Ahmed Ben HmidaNo ratings yet

- Sustainability at HDRDocument4 pagesSustainability at HDRAhmed Ben HmidaNo ratings yet

- Structural Enterprise Infographic 0417Document1 pageStructural Enterprise Infographic 0417Ahmed Ben HmidaNo ratings yet

- TrnsLine PDFDocument495 pagesTrnsLine PDFMomayKradookkradicNo ratings yet

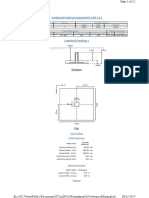

- Isolated Footing Design (ACI 318-11) : ElevationDocument12 pagesIsolated Footing Design (ACI 318-11) : ElevationAhmed Ben HmidaNo ratings yet

- Peyrot WindDocument25 pagesPeyrot WindMuhannad AbdulRaoufNo ratings yet

- Pole LoadingDocument27 pagesPole LoadingKho C AhlNo ratings yet

- Above Ground Pipe Installation With Non-Restrained JointsDocument36 pagesAbove Ground Pipe Installation With Non-Restrained JointsWerner100% (1)

- Sika Casestudy HighstrengthDocument7 pagesSika Casestudy HighstrengthAhmed Ben HmidaNo ratings yet

- FLOWTITE Install GuideDocument72 pagesFLOWTITE Install GuideRanjit RjtNo ratings yet

- 4439 Chap01Document28 pages4439 Chap01bouthaina otNo ratings yet

- NCERT Solutions For Class 12 Flamingo English Lost SpringDocument20 pagesNCERT Solutions For Class 12 Flamingo English Lost SpringHarsh solutions100% (1)

- X32 Digital Mixer: Quick Start GuideDocument28 pagesX32 Digital Mixer: Quick Start GuideJordán AstudilloNo ratings yet

- SPH3U Formula SheetDocument2 pagesSPH3U Formula SheetJSNo ratings yet

- Sankalp Sanjeevani NEET: PhysicsDocument11 pagesSankalp Sanjeevani NEET: PhysicsKey RavenNo ratings yet

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- BCMEDocument9 pagesBCMEVenkateshwaran VenkyNo ratings yet

- TG KPWKPDocument8 pagesTG KPWKPDanmar CamilotNo ratings yet

- Feyzin Oil Refinery DisasterDocument8 pagesFeyzin Oil Refinery DisasterDavid Alonso Cedano EchevarriaNo ratings yet

- CANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenDocument6 pagesCANAVAN' and VESCOVI - 2004 - CMJ X SJ Evaluation of Power Prediction Equations Peak Vertical Jumping Power in WomenIsmenia HelenaNo ratings yet

- New Wordpad DocumentDocument6 pagesNew Wordpad DocumentJonelle D'melloNo ratings yet

- Camp ApplianceDocument1 pageCamp ApplianceflyzalNo ratings yet

- Important instructions on judicial procedure from Narada SmritiDocument6 pagesImportant instructions on judicial procedure from Narada SmritirohitNo ratings yet

- Mobile-Friendly Cooperative WebDocument7 pagesMobile-Friendly Cooperative WebWahyu PNo ratings yet

- Packetfence Network Devices Configuration Guide: For Version 3.5.0Document76 pagesPacketfence Network Devices Configuration Guide: For Version 3.5.0René FabricioNo ratings yet

- Impacts of DecarbonizationDocument2 pagesImpacts of DecarbonizationCM SoongNo ratings yet

- JASA SREVIS LAPTOP Dan KOMPUTERDocument2 pagesJASA SREVIS LAPTOP Dan KOMPUTERindimideaNo ratings yet

- School readiness assessmentDocument10 pagesSchool readiness assessmentJave Gene De AquinoNo ratings yet

- Ivf Market in IndiaDocument15 pagesIvf Market in IndiaSunil Tak100% (1)

- (Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Document4 pages(Salim Ross) PUA 524 - Introduction To Law and The Legal System (Mid Term)Salim RossNo ratings yet

- Advantages of Computerizing and Networking ComputersDocument5 pagesAdvantages of Computerizing and Networking ComputersIn BioNo ratings yet

- Year 2 - Push and Pull FPDDocument18 pagesYear 2 - Push and Pull FPDRebecca LNo ratings yet