Professional Documents

Culture Documents

MAGLEV User Manual

Uploaded by

Anthony LittlehousesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MAGLEV User Manual

Uploaded by

Anthony LittlehousesCopyright:

Available Formats

Specialty Plants: MagLev

MAGLEV: Magnetic Levitation Plant

User Manual

MAGLEV User Manual

How to contact Quanser:

+1 (905) 940-3575

Telephone

+1 (905) 940-3576

Facsimile

119 Spy Court

Markham, ON

Canada L3R 5H6

http://www.quanser.com

Web

mailto://info@quanser.com

General information

MATLAB is a registered trademarks of The MathWorks, Inc.

Other brands and their products are trademarks or registered trademarks of their respective holders and should

be noted as such.

2009 Quanser Inc.

All rights reserved. This work may not be translated or copied in whole or in part without the written

permission of the copyright holder, except under the terms of the associated software license agreement. No

part of this manual may be photocopied or reproduced in any form.

The use of general descriptive names, trade names, trademarks, etc. in this publication, even if the former are

not especially identified, is not to be taken as a sign that such names as understood by the Trade Marks and

Merchandise Marks Act, may accordingly be used freely by anyone.

Printed in Canada.

Document Number: 824 Revision: 3.1 Page: ii

MAGLEV User Manual

Table of Contents

1. MAGLEV Presentation.......................................................................................................4

1.1. MAGLEV: System Description...................................................................................4

1.2. MAGLEV: Control Challenge.....................................................................................5

2. MAGLEV Component Description.....................................................................................5

2.1. Component Nomenclature...........................................................................................5

2.2. Component Description...............................................................................................7

2.2.1. Overall Enclosure (Component #1)......................................................................7

2.2.2. Electromagnet Coil (Component #2)...................................................................7

2.2.3. Pedestal Position Sensor (Component #4)...........................................................7

2.3. MAGLEV System Wiring Schematic..........................................................................8

3. MAGLEV Model Parameters..............................................................................................9

4. Wiring Procedure For The MAGLEV...............................................................................10

4.1. Cable Nomenclature...................................................................................................11

4.2. Hardware Requirements.............................................................................................13

4.3. Typical Connections For The MAGLEV System......................................................14

4.3.1. Wiring Of The Electromagnet Power Line........................................................14

4.3.2. Wiring Of The Electromagnet Feedback Sensors..............................................14

4.3.3. MAGLEV Wiring Summary..............................................................................16

5. Ball Position Sensor Calibration........................................................................................17

5.1. Calibration Model......................................................................................................17

5.2. Calibration Procedure................................................................................................18

5.2.1. Zero "Offset" Potentiometer Calibration: At Voltage Zero...............................18

5.2.2. "Gain" Potentiometer Calibration: At The Maximum Voltage..........................19

6. Obtaining Support..............................................................................................................19

7. References..........................................................................................................................19

Document Number: 824 Revision: 3.1 Page: iii

MAGLEV User Manual

1. MAGLEV Presentation

1.1. MAGLEV: System Description

The typical Magnetic Levitation plant, i.e.

MAGLEV, is depicted in Figure 1, while

levitating in air a steel ball within its

magnetic field. The MAGLEV can be

described by three distinct sections

encased in a rectangular enclosure. First,

the

upper

section

contains

an

electromagnet, made of a solenoid coil

with a steel core. Second, the middle

section consists of an inside chamber

where the magnetic ball suspension

actually takes place. One of the

electromagnet poles faces the top of a

black post upon which a one-inch steel

ball rests. The ball elevation from the post

top is measured using a photo-sensitive

sensor embedded in the post. The post is

designed in such a way that when the ball

rests on top of it, the air gap between the

ball's

top

hemisphere

and

the

electromagnet pole face is 14 mm. The

post also provides repeatable initial

conditions for control system performance

evaluation. Finally, the bottom section of

the MAGLEV apparatus houses the

system's conditioning circuitry needed, for

example, by the light intensity position

sensor. As detailed later in this manual,

both offset and gain potentiometers of the

ball position sensor are readily available

for proper calibration. A current sense

resistor is also included in the design in

order to provide for coil current

measurement if necessary.

Figure 1 MAGLEV Specialty Plant

Document Number 824 Revision: 3.1 Page: 4

MAGLEV User Manual

1.2. MAGLEV: Control Challenge

As illustrated in Figure 1, above, the purpose of the magnetic levitation experiment is to

design a control system that levitates a one-inch solid steel ball in air from the post using an

electromagnet. The controller can then track the ball position to a desired trajectory.

The system is supplied with a feedback controller tuned through pole placement but, of

course, you may design any other controller you wish. The complete mathematical

modeling and system parameters are provided to streamline the implementation of the control theory of your choice.

2. MAGLEV Component Description

2.1. Component Nomenclature

As a quick nomenclature, Table 1, below, provides a list of all the principal elements

composing the MAGLEV Specialty system. Every element is located and identified,

through a unique identification (ID) number, on the MAGLEV plant represented in Figures

2 and 3, below.

ID #

Description

ID #

Description

MAGLEV Overall Enclosure

Solenoid Coil

Coil Steel Core

Pedestal and Position Sensor

Solid Stainless Steel Ball

Interior Lights

Position

Sensor

Potentiometer

Coil Leads 4-Pin DIN Connector

10

Position Sensor Cable 6-Pin-MiniDIN Connector

11

Current Sensor Cable 6-Pin-MiniDIN Connector

12

Inside Chamber

Offset

Position Sensor Gain Potentiometer

8

Table 1 MAGLEV Component Nomenclature

Document Number 824 Revision: 3.1 Page: 5

MAGLEV User Manual

Figure 3 MAGLEV Plant: Back View

Figure 2 MAGLEV Plant: Front View

Document Number 824 Revision: 3.1 Page: 6

MAGLEV User Manual

2.2. Component Description

2.2.1. Overall Enclosure (Component #1)

The MAGLEV overall enclosure is made of aluminum. Its external dimensions are shown

in Table 2, below.

Description

Value

Unit

Overall Enclosure Height

0.277

Overall Enclosure Width

0.153

Overall Enclosure Depth

0.153

Table 2 MAGLEV Overall Dimensions

2.2.2. Electromagnet Coil (Component #2)

The electromagnet consists of a tightly wound solenoid coil made of 2450 turns of 20 AWG

magnet wire. For safe operation, it results that the coil continuous current should never

exceed 3 A. The coil inductance, resistance, dimensions, and other specifications are shown

in Table 3, below. Moreover, the electromagnet wiring, together with the current sense

resistor, can be seen in Figure 4, below.

2.2.3. Pedestal Position Sensor (Component #4)

The light-sensitive sensor measuring the steel ball vertical position consists of a NPN

silicon photodarlington. The position sensor is embedded inside the ball pedestal and

provides linear position readings over the complete ball vertical travel. Its output

measurement is processed through a signal conditioning board and made available as 0 to

5V DC signal. Its measurement sensitivity is given in Table 3, below.

Warning:

It is to be noted that the phototransistor measurement is sensitive to its environmental light

conditions. To that effect, two lights represented by components #6 in Figure 2 are present

in the chamber interior to provide repeatable and constant light conditions. However, as

detailed in a following section, a calibration of the sensor offset and gain potentiometers

(components # 7 and 8, respectively) is required to keep consistent measurements in

changing light environments. As a consequence, the user should also avoid disturbing the

light conditions inside the MAGLEV chamber by, for example, grasping the ball with

his/her whole hand inside chamber.

Document Number 824 Revision: 3.1 Page: 7

MAGLEV User Manual

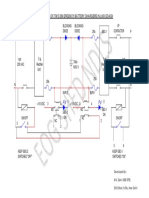

2.3. MAGLEV System Wiring Schematic

The schematic depicted in Figure 4, below, presents a wiring diagram of the MAGLEV

cable connectors in association with the system electrical components, namely, the

electromagnet coil, current sense resistor, interior lights, and photodarlington.

Figure 4 MAGLEV System Wiring Schematic

Document Number 824 Revision: 3.1 Page: 8

MAGLEV User Manual

3. MAGLEV Model Parameters

Table 3, below, lists and characterizes the main parameters (e.g. mechanical and electrical

specifications, convertion factors, constants) associated with the MAGLEV specialty plant.

Some of these parameters can be used for mathematical modeling of the MAGLEV system

as well as to obtain the steel ball's Equation Of Motion (EOM).

Symbol

Ic_max

Description

Maximum Continuous Coil Current

Value

Unit

Lc

Coil Inductance

412.5

mH

Rc

Coil Resistance

10

Nc

Number Of Turns in the Coil Wire

lc

Coil Length

0.0825

rc

Coil Steel Core Radius

0.008

Km

Electromagnet Force Constant

6.5308E-005

N.m2/A2

Rs

Current Sense Resistance

rb

Steel Ball Radius

1.27E-002

Mb

Steel Ball Mass

0.068

kg

Tb

Steel Ball Travel

0.014

Gravitational Constant on Earth

9.81

m/s2

Magnetic Permeability Constant

4 E-007

H/m

KB

Ball Position Sensor Sensitivity

(Assuming a User-Calibrated Sensor Measurement

Range from 0 to 4.95 V)

2.83E-003

m/V

2450

Table 3 MAGLEV System Model Paremeters

Document Number 824 Revision: 3.1 Page: 9

MAGLEV User Manual

4. Wiring Procedure For The MAGLEV

This section describes the standard wiring procedure for the MAGLEV specialty plant.

The following hardware, accompanying the MAGLEV, is assumed:

Power Amplifier:

Quanser UPM 2405, or equivalent.

Data Acquisition Card:

Quanser Q8 / MultiQ-PCI / MultiQ-3, or one

of the National Instruments E-Series cards, or

equivalent.

For detailed information regarding the Quanser UPM amplifier unit please refer to [1] and

for information on the Quanser Q8 DAQ please refer to [2].

The MAGLEV plant is to be used with Quanser provided amplifier units only. Use

caution if you are using a different amplifier unit than the one provided by Quanser.

If the equipment is used in a manner not specified by the manufacturer, the protection

provided by the equipment may be impaired.

Do not position the equipment so that it is difficult to operate the on/off switch on the

power amplifier.

The coil can get hot after use.

Magnetic field present around the experimental hardware when in use.

Perform all the wiring steps with the UPM and your PC both turned off.

4.1. Cable Nomenclature

Table 4, below, provides a description of the standard cables used in the wiring of the

MAGLEV.

Document Number 824 Revision: 3.1 Page: 10

MAGLEV User Manual

Cable

Designation

Description

5-pin-DIN

to

RCA

This cable connects an analog

output of the data acquisition

terminal board to the power

module for proper power

amplification.

4-pin-DIN

to

6-pin-DIN

This cable connects the output of

the

power

module,

after

amplification, to the desired

actuator (e.g. electromagnet).

One end of this cable contains a

resistor

that

sets

the

amplification

gain.

When

carrying a label showing "5", at

both ends, the cable has that

particular amplification gain.

6-pin-miniDIN

to

6-pin-miniDIN

This cable carries analog signals

from one or two plant sensors to

the UPM, where the signals can

be either monitored and/or used

by an analog controller. The

cable also carries a 12VDC line

from the UPM in order to power

a

sensor

and/or

signal

conditioning circuitry.

Figure 5 "From Digital-To-Analog" Cable

Figure 6 "To Load" Cable Of Gain 5

Figure 7 "From Analog Sensors" Cable

Document Number 824 Revision: 3.1 Page: 11

MAGLEV User Manual

Cable

Designation

Description

5-pin-DIN

to

4xRCA

This cable carries the analog

signals, previously taken from

the plant sensors, unchanged,

from the UPM to the Digital-ToAnalog input channels on the

data acquisition terminal board.

Figure 8 "To Analog-To-Digital" Cable

Table 4 Cable Nomenclature

Document Number 824 Revision: 3.1 Page: 12

MAGLEV User Manual

4.2. Hardware Requirements

Figures 9, 10, and 11, below, show, respectively, the MultiQ-PCI Terminal Board, the

MAGLEV plant back, and the Universal Power Module (UPM-2405), all connected with

the necessary cabling to interface to and use the MAGLEV plant.

Figure 9 MultiQ-PCI Terminal Board Connections

Figure 10 Back MAGLEV Connections

Figure 11 Universal Power Module: UPM2405

The Quanser UPM-2405 is capable of providing the required power to the MAGLEV coil.

Document Number 824 Revision: 3.1 Page: 13

MAGLEV User Manual

However, it should be used in conjunction with a "To Load" cable of gain 5 (i.e. 4-pinDIN-to-6-pin-DIN cable), as described in Table 4, above.

Together with the power supply for the amplifier, all Quanser power modules are equipped

with a 1-ampere 12-volt regulated DC power supply for signal conditioning of external

analog sensors. The connectors are also fully compatible with our quick-connect system

enabling you to switch from one experiment to another quickly and efficiently.

4.3. Typical Connections For The MAGLEV System

4.3.1. Wiring Of The Electromagnet Power Line

The "power" line wiring of the MAGLEV electromagnet consists of two connections, as described below:

1. Connect the "From Digital-To-Analog" Cable Cable #1:

The "From Digital-To-Analog" cable is the 5-pin-DIN-to-RCA cable described in Table

4 and shown in Figure 5. Connect the RCA end of this cable to the Analog Output 0

(i.e. DAC # 0) of your data acquisition card terminal board and its 5-pin-DIN connector

to the socket labelled "From D/A" on the UPM2405. These two connections are

illustrated by cable #1 in Figures 9 and 11, above.

2. Connect the "To Load" Cable Of Gain 5 Cable #2:

The "To Load" cable of gain 5 is the 4-pin-DIN-to-6-pin-DIN cable described in Table 4

and shown in Figure 6. First, connect the cable 4-pin-DIN connector to the MAGLEV

Coil Connector, which is shown as component #9 in Figure 3. Then connect the cable 6pin-DIN connector to the UPM socket labelled "To Load". The connection to the UPM

is illustrated by cable # 2 in Figure 11, above.

4.3.2. Wiring Of The Electromagnet Feedback Sensors

The MAGLEV system contains two feedback sensors. One is a small current sense resistor

in series with the coil. The other is a photodarlington embedded in the chamber pedestal

and providing the ball position signal. Both current sensor and photodarlington are wired to

one 6-pin-mini-DIN socket each, as seen in the wiring schematic in Figure 4. Pictures of the

same 6-pin-mini-DIN socket are available in Figure 3, where they are represented as components #11 and #10, respectively.

To connect these two analog sensors, follow the steps described below:

Document Number 824 Revision: 3.1 Page: 14

MAGLEV User Manual

1. Connect the "From Analog Sensors" Cable Cable #4:

The "From Analog Sensors" cable is the 6-pin-mini-DIN-to-6-pin-mini-DIN cable

described in Table 4 and shown in Figure 7. First connect one end of the cable to the

Sensor Connector, located at the back of the MAGLEV and which is shown as

component #10 in Figure 3. Then connect the cable's other end to the UPM socket

labelled "S1 & S2", which is contained inside the UPM "From Analog Sensors" front

panel. These connections are illustrated by cable #4 in Figures 10, and 11, above.

2. Connect the "From Analog Sensors" Cable Cable #5:

The "From Analog Sensors" cable is the 6-pin-mini-DIN-to-6-pin-mini-DIN cable

described in Table 4 and shown in Figure 7. First connect one end of the cable to the

Current Sense Connector, located at the back of the MAGLEV and which is shown as

component #11 in Figure 3. Then connect the cable's other end to the UPM socket

labelled "S3", which is contained inside the UPM "From Analog Sensors" front panel.

These connections are illustrated by cable #5 in Figures 10, and 11, above.

3. Connect the "To Analog-To-Digital" Cable Cable #3:

The "To Analog-To-Digital" cable is the 5-pin-DIN-to-4xRCA cable described in Table

4 and shown in Figure 8. First, connect the cable 5-pin-DIN connector to the UPM

socket labelled "To A/D", as illustrated by cable #3 in Figure 11, above. The other end

of the cable is split into four RCA connectors, each one labelled with a single digit

ranging from one to four. This numbering corresponds to the four possible analog sensor

signals passing through the UPM, namely S1, S2, S3 and S4. In order for the analog

signals to be used in software, you should then connect all four RCA connectors to the

first four analog input channels of your data acquisition card terminal board.

Specifically, connect S1 to Analog Input 0, S2 to Analog Input 1, S3 to Analog Input

2, and S4 to Analog Input 3, as illustrated by cable #3 in Figure 9, above.

In other words, the ball position is sensed using A/D #0 through the UPM analog channel

S1, and the coil current is sensed using A/D #2 through the UPM analog channel S3.

Document Number 824 Revision: 3.1 Page: 15

MAGLEV User Manual

4.3.3. MAGLEV Wiring Summary

Table 5, below, sums up the connections detailed in the two previous subsections.

Cable #

From

To

Signal

DAC #0

UPM "From D/A"

Control signal to the UPM.

UPM "To Load"

MAGLEV "Coil"

Power leads to the coil.

UPM "To A/D"

Terminal Board:

S1 to ADC #0

S3 to ADC #2

Position and current feedback

signals to the data acquisition

terminal board, through the UPM.

MAGLEV "Sensor"

UPM "S1 & S2"

Position feedback signal to the

UPM.

MAGLEV "Current"

UPM "S3"

Current feedback signal to the

UPM.

4

5

Table 5 MAGLEV Wiring Summary

Document Number 824 Revision: 3.1 Page: 16

MAGLEV User Manual

5. Ball Position Sensor Calibration

The photosensitive ball position sensor is calibrated at the factory but may need

re-adjustment when you receive it, or under changing external light conditions.

The position voltage measured on the UPM channel S1 should be zero when the ball is

resting on the black post, while it should be between 4.75 Volts and 4.95 Volts when the

ball is held up by (or stuck to) the electromagnet. Such a procedure results in a precisely

known conversion factor relating ball displacement to sensor output voltage.

5.1. Calibration Model

The Simulink model used to control the electromagnet current, as required by the

calibration procedure explained hereafter, is depicted in Figure 12, below.

Figure 12 Position Sensor Calibration Diagram

Document Number 824 Revision: 3.1 Page: 17

MAGLEV User Manual

Such a controller diagram is used to generate the calibration real-time code as described in

the following sections. The actual Simulink controller diagram files are available in the

"Calibration" directory under the name type q_cal_maglev.mdl.

5.2. Calibration Procedure

The calibration procedure detailed in the following subsections is to calibrate the two

potentiometers, namely "Offset" and "Gain", shown in Figure 2, above, as components #7

and #8, respectively. The Offset and Gain potentiometers are part of the signal conditioning

circuitry of the photodarlington used as a position sensor for the steel ball.

In order to run the calibration procedure, first ensure that the MAGLEV system is wired as

previously described. Then power up the UPM2405. The two lights inside the chamber

should go on. The calibration should be carried out under normal external light conditions

at the location where you are planning to use the apparatus. You may also use a level to

level the MAGLEV rig, so that both electromagnet axis and gravity force acting on the steel

ball are aligned. You are now ready to proceed.

5.2.1. Zero "Offset" Potentiometer Calibration: At Voltage Zero

Follow the steps below to calibrate the Offset Potentiometer:

1.

2.

3.

4.

5.

6.

7.

8.

9.

If it is not yet present, place the steel ball on the post inside the MAGLEV chamber.

Run the MATLAB software.

Open the Simulink model named q_cal_maglev.mdl.

Build the model by clicking on the Incremental build button found in the Simulink

toolbar. This can be alternatively done by clicking on QuaRC in the menu bar and

selecting Build.

Make sure the Switch Trigger block in the model is set to a value of 1.

Once the model is successfully built, click on the Connect to target button and

then on the Start real-time code button both found in the Simulink toolbar.

This sets the electromagnet current to zero. This current can be monitored in the Ic

(A) display block found in the model.

Using a potentiometer adjustment tool (i.e. a small flat-end screwdriver), manually

adjust the offset potentiometer screw on the MAGLEV enclosure to obtain zero

Volts on the Vb (V) display block. Turning the offset potentiometer screw

clockwise increases the voltage Vb, and vice-versa.

Once a value of zero is obtained for Vb, stop the model by clicking on the Stop

real-time code button found in the Simulink toolbar.

Document Number 824 Revision: 3.1 Page: 18

MAGLEV User Manual

5.2.2. "Gain" Potentiometer Calibration: At The Maximum Voltage

Follow the steps below to calibrate the Gain Potentiometer:

1. If it is not yet present, place the steel ball on the post inside the MAGLEV chabmer.

2. Make sure the Switch Trigger block in the Simulink model q_cal_maglev.mdl is set

to a value of 2.

3. Run the Simulink model by clicking on the Connect to target button and then on

the Start real-time code button both found in the Simulink toolbar.

4. This sets the electromagnet current to 2.0 A. This should cause the steel ball to jump

up to the electromagnet core face and stay there, attaining the other limit of its

displacement range. If the ball does not jump up, you can give it a small lift. You

can now calibrate the gain potentiometer if necessary.

5. Using a potentiometer adjustment tool (i.e. a small flat-end screwdriver), manually

adjust the gain potentiometer screw on the MAGLEV enclosure to obtain anywhere

between 4.75 and 4.95 Volts on the Vb display block in the Simulink model.

Turning the potentiometer screw counter-clockwise increases the voltage Vb, and

vice-versa.

6. Once you are done with the calibration process, stop the model by clicking on the

Stop real-time code button found in the Simulink toolbar.

6. Obtaining Support

Note that a support contract may be required to obtain technical support. To obtain

support from Quanser, go to http://www.quanser.com and click on the Tech Support link.

Fill in the form with all requested software version and hardware information and a description of the problem encountered. Submit the form. Be sure to include your email address

and a telephone number where you can be reached. A qualified technical support person

will contact you.

7. References

[1] Quanser. UPM User Manual

[2] Quanser. Q4/Q8 Data Acquisition Board User Manual

Document Number 824 Revision: 3.1 Page: 19

You might also like

- Appendix G Matrices, Determinants, and Systems of EquationsDocument11 pagesAppendix G Matrices, Determinants, and Systems of EquationsPablo Granda OrtizNo ratings yet

- IELTS Reading Characteristics and Task TypesDocument8 pagesIELTS Reading Characteristics and Task TypesAnthony LittlehousesNo ratings yet

- Autumn 2017 English Courses for Bioimage Processing, Information Security, IT Service Management and Integrated ElectronicsDocument5 pagesAutumn 2017 English Courses for Bioimage Processing, Information Security, IT Service Management and Integrated ElectronicsAnthony LittlehousesNo ratings yet

- IELTS Reading Characteristics and Task TypesDocument8 pagesIELTS Reading Characteristics and Task TypesAnthony LittlehousesNo ratings yet

- Tanner Tools TutorialDocument64 pagesTanner Tools TutorialAnthony LittlehousesNo ratings yet

- Tanner Tools Tutorial PDFDocument115 pagesTanner Tools Tutorial PDFAnthony LittlehousesNo ratings yet

- Tanner Tools Tutorial PDFDocument115 pagesTanner Tools Tutorial PDFAnthony LittlehousesNo ratings yet

- Appendix G Matrices, Determinants, and Systems of EquationsDocument11 pagesAppendix G Matrices, Determinants, and Systems of EquationsPablo Granda OrtizNo ratings yet

- PCB DesignDocument137 pagesPCB Designmichael higgins100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- UV Ink AdhesionDocument3 pagesUV Ink AdhesionnerbitNo ratings yet

- Half-Bridge Mosfet Driver IC IRS2153 (1) D Datasheet: Homemade Circuit ProjectsDocument17 pagesHalf-Bridge Mosfet Driver IC IRS2153 (1) D Datasheet: Homemade Circuit ProjectsHerbert LopesNo ratings yet

- Chiller MemoryDocument21 pagesChiller MemoryminguelameazzaNo ratings yet

- Origin and Packaging of Integrated CircuitsDocument4 pagesOrigin and Packaging of Integrated CircuitsKhenjie ResmaNo ratings yet

- ABB Automatic Power Factor Correction Capacitor BankDocument12 pagesABB Automatic Power Factor Correction Capacitor BankchinithNo ratings yet

- LineTroll 110Tμr User GuideDocument16 pagesLineTroll 110Tμr User Guideluhusapa-1No ratings yet

- Ahmed Mohamed Ahmed Morsy DR / Hazem Hassan ENG / Sherry HeshmatDocument31 pagesAhmed Mohamed Ahmed Morsy DR / Hazem Hassan ENG / Sherry Heshmatahmed morsyNo ratings yet

- 1 s2.0 S0079670013001196 Main PDFDocument77 pages1 s2.0 S0079670013001196 Main PDFDivyaratanKumarNo ratings yet

- Title: Encoder Instructional AimsDocument7 pagesTitle: Encoder Instructional Aimssuv_fame100% (4)

- NTE2409 Silicon PNP Transistor General Purpose Amp, Surface Mount (Compl To NTE2408)Document2 pagesNTE2409 Silicon PNP Transistor General Purpose Amp, Surface Mount (Compl To NTE2408)Maikel GonzálezNo ratings yet

- ACV 700 Frequency Converters Service Instructions Code: 3AFY 58054496 R0125 REV BDocument81 pagesACV 700 Frequency Converters Service Instructions Code: 3AFY 58054496 R0125 REV B育霖No ratings yet

- Gs33m50f30-40e 008Document18 pagesGs33m50f30-40e 008Saadullah SiddiquiNo ratings yet

- Chapter 12 Metallic-Cable-Transmission-Media PDFDocument36 pagesChapter 12 Metallic-Cable-Transmission-Media PDFNico RobinNo ratings yet

- DPR 50 MWP Rajasthan Thin Film 12-6-10-1-LibreDocument98 pagesDPR 50 MWP Rajasthan Thin Film 12-6-10-1-LibreValmik SoniNo ratings yet

- Top 200 electrical engineering interview questionsDocument20 pagesTop 200 electrical engineering interview questionsOhm Kumar100% (4)

- Lasers in EndoDocument144 pagesLasers in EndoPawan D Tekale100% (1)

- JKM615 635N 78HL4 BDV F7 enDocument2 pagesJKM615 635N 78HL4 BDV F7 enhira.smjafferNo ratings yet

- Signal Multiplier Icc312Document2 pagesSignal Multiplier Icc312supermannonNo ratings yet

- Experiment 1 Docx - Comp EngDocument26 pagesExperiment 1 Docx - Comp Engapi-344058913No ratings yet

- MCC based on Rittal Ri4PowerDocument2 pagesMCC based on Rittal Ri4PowerHungTruongNo ratings yet

- Radiation Detection & Measurement I: Types of DetectorsDocument35 pagesRadiation Detection & Measurement I: Types of Detectorssnoobper100% (1)

- Interlocking Emergency Battery Chargers LHB CoachDocument1 pageInterlocking Emergency Battery Chargers LHB CoachDilpalNo ratings yet

- Datasheet STP290 VD PolyDocument2 pagesDatasheet STP290 VD PolyIsraelo PueblaNo ratings yet

- LT2A - 15 - Krisna Surya Pamungkas - SolderDocument2 pagesLT2A - 15 - Krisna Surya Pamungkas - SolderMuhammad Hanif HidayatNo ratings yet

- Infrared Led Based Non Invasive Blood GlucometerDocument5 pagesInfrared Led Based Non Invasive Blood GlucometerYến Nhi Nguyễn ThịNo ratings yet

- Philips+22PFL3403-10+Chassis+TPS1 4E+LA+LCD PDFDocument53 pagesPhilips+22PFL3403-10+Chassis+TPS1 4E+LA+LCD PDFparutzu0% (1)

- Moeller EASY PLC Programming TutorialDocument17 pagesMoeller EASY PLC Programming Tutorialmamaligosu1No ratings yet

- Electrical Part ListDocument11 pagesElectrical Part ListCompucel Ingenieria0% (1)

- CH 08Document10 pagesCH 08chaitanyacheggNo ratings yet