Professional Documents

Culture Documents

Open Vs Closed Impellers

Uploaded by

Anonymous CMS3dL1T0 ratings0% found this document useful (0 votes)

741 views2 pagespumps

Original Title

Open vs Closed Impellers

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentpumps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

741 views2 pagesOpen Vs Closed Impellers

Uploaded by

Anonymous CMS3dL1Tpumps

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

m J o h n s t o n pump Company

Closed vs. Semi-open Impeller Design

Why are there two types of centrifugal impellers used in vertical pumps?

What are the advantages and the

limitations of each type?

What types should I be using?

These are the types of questions often asked, and

we will try to give some insight into the best applications for each impeller design. This will then help

you make a decision as to the type of impeller you

should be employing on a particular application.

What happens when an impeller is set too close to a

bowl in each of the different designs?

In the semi-open design, dragging will wear metal

from the vanes, and the impeller will never be able to

produce the original capacity at the design head. If

we think of the impeller vanes in terms of performance, then the head in terms of diameter, we need

to understand that the thickness of the vane, which

sets the setting between shroud and bowl, is what

develops capacity. The length of the vane is what

develops pressure or head. Thus, a larger diameter

impeller with the same vane angle will produce additional pressure and the reason for selecting a 12"

pump over a 10" pump on a given higher head application.

Once the vanes have been machined off by friction

The enclosed impeller has two shrouds (sides) with the bowl, they are never able to produce the

whereas a semi-open impeller has only the top original capacity. Another consideration is that the

shroud. The lower side of the semi-open impeller is shaft is subject to the thrust developed by the pump.

dependent upon setting the vanes of the impeller as This value varies directly to the change in total dyclose to the bowl as possible without allowing the namic head and the thrust may be great enough to

impeller to drag. Thus, with the impeller set just above stretch the shaft. On deeper setting applications,

the drag point, a minimum amount of fluid is allowed because of the longer shafting length involved, this

to by-pass between the high pressure side and the value becomes quite pronounced and care must be

lower pressure on the inlet side. From this it is easy taken in a setting to make certain that the pump is

to understand that to obtain the design head per set high enough so that the additional shaft length

stage, it is necessary to have this setting within the caused by thrust will not drag the impellers. Needlimitations set up by manufacturer for this type of less to say, on deeper setting equipment this makes

equipment. This is easy enough to do on a single it rather difficult to determine the exact setting to utistage and even a two-stage pump, but as additional lize. This is because theoretical information is used

stages are added, it becomes more and more diffi- for the shaft stretch and the initial setting is detercult to hold all of the impellers to the exact clearance mined by measuring the shaft at the adjusting nut.

Any system head change will alter the thrust because

to obtain optimum performance.

of the performance change; thus, the impeller could

On the other hand, an enclosed impeller with its bot- drag.

tom shroud has the thickness of this shroud lost to

the fluid passage. The distance between the two On the attached design, if the dragging of the botshrouds is always maintained as it is set by the vanes' tom shroud does occur, it will not affect the perforthickness. No matter how many stages are em- mance of the pump once it is corrected. m

this drag effect will greatly increase the power

ployed, as long as the impellers are clearing the

bowls, the performance will be maintained. This is requirements and may even cause the starter's overbecause of the side seal effect of the impeller ring. loads to kick out. Thus, one needs to use extreme

This means that the clearance between wear ring care in making this setting. There is a forgiveness

and impeller is constant even when the adjustment factor connected with the attached design. On deeper

in setting distance from the bowl to the impeller is set units, it is even possible to utilize an ammeter to

determine the exact point and condition when the

varied.

impeller is free. There would be a decided drop off

Thus, it can easily be seen that for most multistage in power usage at this point over the power used

pumps, the enclosed design impeller is probably the when the impeller is set too low and dragging on the

bowl. Generally the efficiency, head, capacity and

one to select.

VTPa.6

You might also like

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreFrom EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreRating: 4.5 out of 5 stars4.5/5 (11)

- Multistage Pump RepairDocument5 pagesMultistage Pump RepairCheyanSathishNo ratings yet

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- Astm D7928 - 17Document25 pagesAstm D7928 - 17shosha100% (2)

- Pumping Abrasives With Progressive CavityDocument8 pagesPumping Abrasives With Progressive CavitySanny Astari100% (1)

- Choosing The Perfect Performance CamshaftDocument9 pagesChoosing The Perfect Performance CamshaftDesotoJoe100% (1)

- Shaft Deflection in Centrifugal PumpsDocument2 pagesShaft Deflection in Centrifugal PumpsPieter van der WaltNo ratings yet

- Mek 2Document44 pagesMek 2Gaurav ShuklaNo ratings yet

- Pump Impeller Trimming AspectsDocument17 pagesPump Impeller Trimming AspectsUdhayakumar VenkataramanNo ratings yet

- PUMP SHAFT DEFLECTION EXPLAINEDDocument3 pagesPUMP SHAFT DEFLECTION EXPLAINEDMine RHNo ratings yet

- Pushrods The Key To PerformanceDocument4 pagesPushrods The Key To PerformanceJerson T. AltovarNo ratings yet

- Pump Clinic 43Document3 pagesPump Clinic 43fnahas_bhNo ratings yet

- Roll KraftDocument6 pagesRoll KraftAndiniPermanaNo ratings yet

- Pump TrainingDocument15 pagesPump TrainingdalayeliNo ratings yet

- Thrust in Vertical Turbine PumpsDocument5 pagesThrust in Vertical Turbine PumpsKamal Arab100% (1)

- Pros and Cons - Horizontal Split Case PumpsDocument5 pagesPros and Cons - Horizontal Split Case PumpsjarrydNo ratings yet

- Introduction of Rotary PumpDocument5 pagesIntroduction of Rotary PumpRashid JalalNo ratings yet

- 07 Pompe Marfa PDFDocument25 pages07 Pompe Marfa PDFSorescu Radu VasileNo ratings yet

- How An SU WorksDocument5 pagesHow An SU WorksKenmillicanNo ratings yet

- Rod Ratio KinematicsDocument6 pagesRod Ratio KinematicsJameel KhanNo ratings yet

- Closed vs Open Impeller Design AdvantagesDocument3 pagesClosed vs Open Impeller Design Advantagesucb2_ntpcNo ratings yet

- Learn Engineering - Centrifugal PumpDocument5 pagesLearn Engineering - Centrifugal PumpmecoolguysNo ratings yet

- Quick A Easy Guide: To Hydraulic Pump Technology and SelectionDocument3 pagesQuick A Easy Guide: To Hydraulic Pump Technology and SelectionGustavNo ratings yet

- Design of Sucker Rod Pump for Offshore Oil WellDocument13 pagesDesign of Sucker Rod Pump for Offshore Oil Wellpramod_prasad_3No ratings yet

- Correct Pump InstallationDocument6 pagesCorrect Pump InstallationEry GatotNo ratings yet

- Basic Internship Problem in Ies EngineeringDocument7 pagesBasic Internship Problem in Ies EngineeringrobelNo ratings yet

- Cylinder Head Design and Modification - Getting StartedDocument4 pagesCylinder Head Design and Modification - Getting StartedBruno BambinetiNo ratings yet

- Coupling Design Selection Guide for Turbomachinery ApplicationsDocument11 pagesCoupling Design Selection Guide for Turbomachinery ApplicationsVivek RathodNo ratings yet

- Twin Screw Vs Centrifugal & Reciprocating ArticleDocument12 pagesTwin Screw Vs Centrifugal & Reciprocating ArticlecaratorresmNo ratings yet

- Centrifugal Pump.......... Very ImpDocument22 pagesCentrifugal Pump.......... Very Impavi07me4uNo ratings yet

- 325 Lanzhou 3NB1300C Instruction Manual PDFDocument21 pages325 Lanzhou 3NB1300C Instruction Manual PDFOilGasManNo ratings yet

- ShaftingDocument3 pagesShafting41vaibhavNo ratings yet

- Belt Drives CalculationDocument15 pagesBelt Drives CalculationmalharNo ratings yet

- Tib 19 Submersible Motor Pumps Vs Lineshaft TurbinesDocument5 pagesTib 19 Submersible Motor Pumps Vs Lineshaft Turbinesmeeraksam42No ratings yet

- Pneumatic Actuators: For Power, Motion and ControlDocument162 pagesPneumatic Actuators: For Power, Motion and ControlJulian LajaraNo ratings yet

- SAG Mill ComponentsDocument7 pagesSAG Mill ComponentsRodrigo GarcíaNo ratings yet

- Variable Geometry Turbochargers (VGTS) Are A Family ofDocument19 pagesVariable Geometry Turbochargers (VGTS) Are A Family ofdevhxNo ratings yet

- Turbo Systems 102 GuideDocument7 pagesTurbo Systems 102 GuidePetar PavićNo ratings yet

- Pump System CurveDocument6 pagesPump System CurveMohan MalavNo ratings yet

- PEOS and POs of Mechanical Engineering ProgrammeDocument19 pagesPEOS and POs of Mechanical Engineering ProgrammeHimanshuAgarwalNo ratings yet

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- All About ImpellersDocument9 pagesAll About ImpellersMohammad RizwanNo ratings yet

- Selecting Centrifugal Slurry Pump BasedDocument6 pagesSelecting Centrifugal Slurry Pump BasedRodrigo GarcíaNo ratings yet

- Types of Impellers in Centrifugal PumpsDocument11 pagesTypes of Impellers in Centrifugal PumpsMohamed Badian TraoreNo ratings yet

- Impellers SelectionDocument0 pagesImpellers Selectionpeach5No ratings yet

- MEO Class 2 Orals Function 4 & 6 Q & ADocument8 pagesMEO Class 2 Orals Function 4 & 6 Q & Aneeraj118578% (9)

- ClutchDocument5 pagesClutchyudhisthar0110% (1)

- Positive Displacement Vs Centrifugal PumpDocument11 pagesPositive Displacement Vs Centrifugal PumpArslan BhattiNo ratings yet

- Cam ViceDocument50 pagesCam ViceAakash Dindigul100% (1)

- 400 Bad Request 400 Bad Request Nginx/1.2.9Document64 pages400 Bad Request 400 Bad Request Nginx/1.2.9aminNo ratings yet

- Chapter 4. Principles of Screw Compressor DesignDocument11 pagesChapter 4. Principles of Screw Compressor DesignNgọc Vi CaoNo ratings yet

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- Wood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingFrom EverandWood Turning - The Lathe and Its Accessories, Tools, Turning Between Centres Face-Plate Work, Boring, PolishingNo ratings yet

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- A Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesFrom EverandA Book of Helpful Tips on Overhauling a Vintage Engine - Including Car, Motorbike and Lawn Mower EnginesRating: 5 out of 5 stars5/5 (1)

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IiFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiNo ratings yet

- Amarillo Endurance-OM-09.2022Document8 pagesAmarillo Endurance-OM-09.2022Anonymous CMS3dL1TNo ratings yet

- Cavitation - Thoma GraphDocument1 pageCavitation - Thoma GraphAnonymous CMS3dL1TNo ratings yet

- Engine PumpsDocument4 pagesEngine PumpsAnonymous CMS3dL1TNo ratings yet

- Dewatering PumpDocument5 pagesDewatering PumpAnonymous CMS3dL1TNo ratings yet

- M7L7 PDFDocument8 pagesM7L7 PDFRANJINI02VNo ratings yet

- MS 400, MS 650: Series Submersible MixerDocument25 pagesMS 400, MS 650: Series Submersible MixerAnonymous CMS3dL1TNo ratings yet

- High Temp PumpsDocument4 pagesHigh Temp PumpsAnonymous CMS3dL1TNo ratings yet

- Pump Column Loss ChartDocument2 pagesPump Column Loss ChartAnonymous CMS3dL1TNo ratings yet

- Typical Pump Speed Torque Curve and FormulaDocument1 pageTypical Pump Speed Torque Curve and FormulaAnonymous CMS3dL1TNo ratings yet

- DespieceDocument1 pageDespieceAnonymous CMS3dL1TNo ratings yet

- Submersible Extra High Head Pump: Max. 230m Head and Excellent Durability, Optimum For High Head ApplicationsDocument2 pagesSubmersible Extra High Head Pump: Max. 230m Head and Excellent Durability, Optimum For High Head ApplicationsAnonymous CMS3dL1TNo ratings yet

- Catalog IA117 EDocument5 pagesCatalog IA117 EAnonymous CMS3dL1TNo ratings yet

- Mixer Input DataDocument6 pagesMixer Input DataAnonymous CMS3dL1TNo ratings yet

- Catalog IA117 EDocument5 pagesCatalog IA117 EAnonymous CMS3dL1TNo ratings yet

- 1103-Flygt-Compact Mixers-MixingDocument8 pages1103-Flygt-Compact Mixers-MixingcartagliNo ratings yet

- Mixer Theory 1Document5 pagesMixer Theory 1Anonymous CMS3dL1TNo ratings yet

- Audex CatalogueDocument16 pagesAudex CatalogueAnonymous CMS3dL1TNo ratings yet

- Mixer SelectDocument11 pagesMixer SelectAnonymous CMS3dL1TNo ratings yet

- MMR (50Hz) Data Booklet IA158-ADocument15 pagesMMR (50Hz) Data Booklet IA158-AAnonymous CMS3dL1TNo ratings yet

- AerationDocument9 pagesAerationfriends1xo123No ratings yet

- Catalog Ib102-G KtzeDocument5 pagesCatalog Ib102-G KtzeAnonymous CMS3dL1TNo ratings yet

- Click Back to Continental EnginesDocument1 pageClick Back to Continental EnginesAnonymous CMS3dL1TNo ratings yet

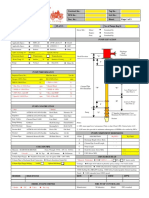

- Fire Pump: Client: Plant: No. of Pumps Req'dDocument3 pagesFire Pump: Client: Plant: No. of Pumps Req'dAnonymous CMS3dL1TNo ratings yet

- Folleto KTZ - ENDocument4 pagesFolleto KTZ - ENAnonymous CMS3dL1TNo ratings yet

- Hazardous or Classified LocationsDocument1 pageHazardous or Classified LocationsAnonymous CMS3dL1TNo ratings yet

- Dry Pit Screen FlowDocument2 pagesDry Pit Screen FlowAnonymous CMS3dL1TNo ratings yet

- KTZ Ktze KTD Ib107-EDocument11 pagesKTZ Ktze KTD Ib107-EAnonymous CMS3dL1TNo ratings yet

- Guideline For The Selection of Vacuum PumpsDocument6 pagesGuideline For The Selection of Vacuum PumpsAnonymous CMS3dL1TNo ratings yet

- Nozzle Flowmeter Calculation For Liquids. ISO-5167 EquationDocument4 pagesNozzle Flowmeter Calculation For Liquids. ISO-5167 EquationAnonymous CMS3dL1TNo ratings yet

- NPSH MarginDocument5 pagesNPSH MarginKCFUNGNo ratings yet

- Analyze and Design Sewer and Stormwater Systems with SewerGEMSDocument18 pagesAnalyze and Design Sewer and Stormwater Systems with SewerGEMSBoni ClydeNo ratings yet

- ArDocument26 pagesArSegunda ManoNo ratings yet

- Case Study IndieDocument6 pagesCase Study IndieDaniel YohannesNo ratings yet

- ALXSignature0230 0178aDocument3 pagesALXSignature0230 0178aAlex MocanuNo ratings yet

- Civil Service Exam Clerical Operations QuestionsDocument5 pagesCivil Service Exam Clerical Operations QuestionsJeniGatelaGatillo100% (3)

- Brochure en 2014 Web Canyon Bikes How ToDocument36 pagesBrochure en 2014 Web Canyon Bikes How ToRadivizija PortalNo ratings yet

- Exercise-01: JEE-PhysicsDocument52 pagesExercise-01: JEE-Physicsjk rNo ratings yet

- !!!Логос - конференц10.12.21 копіяDocument141 pages!!!Логос - конференц10.12.21 копіяНаталія БондарNo ratings yet

- Strategies For StartupDocument16 pagesStrategies For StartupRoshankumar BalasubramanianNo ratings yet

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocument564 pagesPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuNo ratings yet

- Problem Set SolutionsDocument16 pagesProblem Set SolutionsKunal SharmaNo ratings yet

- Indian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesDocument7 pagesIndian Standard: Pla Ing and Design of Drainage IN Irrigation Projects - GuidelinesGolak PattanaikNo ratings yet

- 02 Slide Pengenalan Dasar MapinfoDocument24 pages02 Slide Pengenalan Dasar MapinfoRizky 'manda' AmaliaNo ratings yet

- Combined Set12Document159 pagesCombined Set12Nguyễn Sơn LâmNo ratings yet

- WWW - Commonsensemedia - OrgDocument3 pagesWWW - Commonsensemedia - Orgkbeik001No ratings yet

- Shopping Mall: Computer Application - IiiDocument15 pagesShopping Mall: Computer Application - IiiShadowdare VirkNo ratings yet

- Eye Bags ReliefDocument27 pagesEye Bags ReliefNatsu DragneelNo ratings yet

- Assignment Gen PsyDocument3 pagesAssignment Gen PsyHelenNo ratings yet

- Why Choose Medicine As A CareerDocument25 pagesWhy Choose Medicine As A CareerVinod KumarNo ratings yet

- Qad Quick StartDocument534 pagesQad Quick StartMahadev Subramani100% (1)

- A Guide To in The: First AidDocument20 pagesA Guide To in The: First AidsanjeevchsNo ratings yet

- Paper SizeDocument22 pagesPaper SizeAlfred Jimmy UchaNo ratings yet

- Use Visual Control So No Problems Are Hidden.: TPS Principle - 7Document8 pagesUse Visual Control So No Problems Are Hidden.: TPS Principle - 7Oscar PinillosNo ratings yet

- Role of PAODocument29 pagesRole of PAOAjay DhokeNo ratings yet

- Key Fact Sheet (HBL FreedomAccount) - July 2019 PDFDocument1 pageKey Fact Sheet (HBL FreedomAccount) - July 2019 PDFBaD cHaUhDrYNo ratings yet

- Alignment of Railway Track Nptel PDFDocument18 pagesAlignment of Railway Track Nptel PDFAshutosh MauryaNo ratings yet

- OS LabDocument130 pagesOS LabSourav BadhanNo ratings yet

- Philippine Army BDU BidDocument2 pagesPhilippine Army BDU BidMaria TeresaNo ratings yet

- SDS OU1060 IPeptideDocument6 pagesSDS OU1060 IPeptideSaowalak PhonseeNo ratings yet