Professional Documents

Culture Documents

Engine Rattles at Cold Start Up

Uploaded by

yumyum9Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engine Rattles at Cold Start Up

Uploaded by

yumyum9Copyright:

Available Formats

Service Bulletin

Applies To:

09-010

October 21, 2011

See VEHICLES AFFECTED

Engine Rattles at Cold Start-Up

(Supersedes 09-010, dated August 17, 2010, to revise the information marked by the black bars)

REVISION SUMMARY

Under REPAIR PROCEDURE, steps 24 thru 27 were

changed.

TOOL INFORMATION

Stopper (lock pin): P/N 14511-PNA-003

Tappet Adjuster: P/N 07MAA-PR70110

Tappet Locknut Wrench: P/N 07MAA-PR70120

SYMPTOM

At cold start-up, the engine rattles loudly for about

2 seconds.

PROBABLE CAUSE

The variable valve timing control (VTC) actuator is

defective.

WARRANTY CLAIM INFORMATION

The normal warranty applies.

Operation Number: 1101Z9

Flat Rate Time:

2.0 hours

Failed Part:

P/N 14310-R44-A01

Defect Code:

03214

VEHICLES AFFECTED

Symptom Code:

04201

2008 Accord L4 2/4-Door ___

ALL

Template ID:

09-010B

2009 Accord L4 2-Door

From VIN 1HGCS1...9A000001 thru

1HGCS1...9A004953

DIAGNOSIS

NOTE: If youre reading this service bulletin on ISIS

and your computer has sound, click on the picture

below to hear an example of the engine rattle.

2009 Accord L4 4-Door

From VIN 1HGCP2...9A000001 thru

1HGCP2...9A029528

From VIN JHMCP2...9C000001 thru

JHMCP2...9C010096

CORRECTIVE ACTION

Use the repair procedure in this service bulletin to

replace the VTC actuator. This procedure does not

require the complete removal of the cam chain and

associated parts as you would during a normal repair,

so the procedure is shorter.

Click to Play

PARTS INFORMATION

VTC Actuator: P/N 14310-R44-A01

REQUIRED MATERIALS

Hondabond HT Liquid Silicone Gasket

(One tube repairs about two vehicles.):

P/N 08718-0004

2011 American Honda Motor Co., Inc. All Rights Reserved

Click to Stop

1. Allow the engine oil to drain from the VTC system

by not starting the engine for at least 6 hours.

ATB 41171-47163 (1110)

1 of 5

CUSTOMER INFORMATION: The information in this bulletin is intended for use only by skilled technicians who have the proper tools, equipment,

and training to correctly and safely maintain your vehicle. These procedures should not be attempted by do-it-yourselfers, and you should not assume

this bulletin applies to your vehicle, or that your vehicle has the condition described. To determine whether this information applies, contact an

authorized Honda automobile dealer.

2. Start the engine, and immediately listen for a loud

rattle:

Do you hear a loud rattle that lasts about

2 seconds?

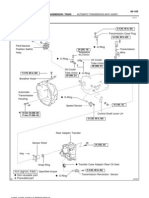

4. Remove the engine oil dipstick and the power

steering hose bracket, then disconnect the breather

hose and the brake booster vacuum hose from the

cylinder head cover.

POWER STEERING

HOSE BRACKET

Yes Go to REPAIR PROCEDURE.

No

If you hear a different noise, continue with normal

troubleshooting.

BRAKE BOOSTER

VACUUM HOSE

If you dont hear an abnormal noise, get more

information from your customer and, if needed,

continue with normal troubleshooting.

REPAIR PROCEDURE

NOTE: This procedure is in an outline form that you

can also use as a checklist for the repair. If you need

more details, bookmark the following procedures in the

20082012 Accord Service Manual, or view them

online:

Cylinder Head Cover Removal

DIPSTICK

BREATHER

HOSE

Cylinder Head Cover Installation

Valve Clearance Adjustment

1. Remove the frame (strut) brace (if equipped).

2. Remove the intake manifold cover (if equipped).

3. Remove the ignition coil cover and the ignition

coils.

IGNITION COIL

COVER

BOLTS

5. Remove the two bolts holding the EVAP canister

purge valve bracket to the cylinder head.

6. Remove the cylinder head cover.

7. Raise the vehicle on a lift.

8. Turn the front wheels or remove the right front

wheel.

9. Remove the splash shield to access the crankshaft

pulley.

10. Remove the camshaft auto-tensioner (chain case)

cover.

BOLTS

12 Nm

(8.7 lbft)

11. Rotate the crankshaft clockwise to top dead center

(TDC) No. 1 cylinder.

12. Rotate the crankshaft counterclockwise to

compress the auto-tensioner, then align the hole in

the lock and auto-tensioner, and insert a

1.2 mm (0.05 in) diameter stopper (lock pin).

LOCK

RED

IGNITION COIL

CONNECTORS

WHITE

(TDC)

AUTO-TENSIONER

2 of 5

STOPPER

(LOCK PIN)

1.2 mm

(0.05 in.)

09-010

13. Rotate the crankshaft clockwise to TDC No. 1

cylinder.

14. Lower the vehicle.

15. Mark the cam chain at the punch marks on the

exhaust camshaft sprocket and the VTC actuator.

Secure the chain to the sprocket with a wire tie.

PUNCH MARKS

WIRE TIE

EXHAUST

CAMSHAFT

SPROCKET

24. Verify that the VTC actuator is unlocked, then

install a new VTC actuator onto the camshaft

making sure it is in the unlocked position.

25. Lubricate and install the VTC actuator mounting

bolt.

26. Place the camshaft on a padded workbench with

the VTC actuator off the edge. Hold the camshaft

steady with an open end wrench, then have an

assistant torque the VTC actuator mounting bolt to

113 Nm (83 lb-ft) with the actuator in the unlocked

position.

NOTE: American Honda is in the process of

developing a special tool to hold the camshaft when

torquing the VTC actuator.

VARIABLE VALVE

TIMING CONTROL

(VTC) ACTUATOR

16. Hold the camshaft steady with an open-end

wrench, and loosen the VTC actuator mounting

bolt.

NOTE: Do not use an impact wrench to loosen or

tighten this bolt; it will damage the locking pin inside

the actuator.

17. Loosen the camshaft holder bolts, in sequence, two

turns at a time.

18. Remove the five camshaft holders.

NOTICE

Torquing the new actuator in the locked position will

damage the internal pin. If it locks before it is

torqued, then it must be unlocked prior to installing.

19. Carefully tip up the end of the intake camshaft until

there is enough slack to lift the chain off the VTC

actuator teeth.

20. Remove the intake camshaft while keeping some

tension on the chain. Lay the camshaft on a clean

workbench.

21. Secure the chain to the A/C compressor hose or

the P/S hose with a wire tie to keep it from falling

down into the front cover.

22. Remove the VTC actuator mounting bolt, and

separate the actuator from the camshaft.

23. Remove the wire ties while keeping light tension on

the chain.

27. Rotate the VTC actuator until it is in the locked

position.

28. Slide the camshaft in at an angle so the chain can

slip over the VTC actuator teeth.

09-010

3 of 5

30. Apply engine oil to the journals and caps on both

camshafts, and reinstall them.

31. Torque the camshaft holders, starting in the middle

and working your way outward in the numbered

sequence.

Torque

8 x 1.25 mm

22 Nm (16 lbft)

6 x 1.0 mm

12 Nm (8.7 lbft)

6 x 1.0 mm Bolts:

34. Remove old sealant, dry, reseal, and then reinstall

the auto-tensioner (chain case) cover.

NOTE: Wait 30 minutes before adding oil if needed,

and wait 3 hours before starting the engine.

BOLTS

12 N.m

(8.7 lb-ft)

32. Remove the lock pin from the auto-tensioner.

33. Rotate the crankshaft in the direction of engine

rotatation (clockwise) two full turns, then stop at the

white TDC mark (see step 12). Make sure the

camshafts line up as shown in step 15.

CHAIN CASE

COVER

35. Check and, if needed, adjust the valve clearance

using a tappet adjuster.

Intake: 0.21 - 0.25 mm (0.008 - 0.010 in)

Exhaust: 0.25 - 0.29 mm (0.010 - 0.011 in)

36. Then, using a tappet locknut wrench, torque the

locknuts.

Intake and Exhaust: 14 N.m (10 lb-ft)

37. Raise the vehicle.

38. Reinstall the splash shield.

39. Straighten the wheels or reinstall the right front

wheel (if removed).

40. Lower the vehicle.

4 of 5

09-010

41. Reinstall the cylinder head cover, tightening the

bolts in three steps. In the final step, tighten all

bolts, in sequence, to 12 N.m (8.7 lb-ft).

Torque

22 Nm (16 lbft)

44. Reinstall the ignition coils and the ignition coil

cover.

IGNITION COIL

COVER

BOLTS

12 Nm

(8.7 lbft)

42. Reinstall the EVAP canister purge valve bracket.

43. Reinstall the engine oil dipstick and the power

steering hose bracket, and reconnect the breather

hose and the brake booster vacuum hose.

IGNITION COIL

CONNECTORS

45. Reinstall the intake manifold cover (if equipped).

46. Reinstall the frame (strut) brace (if equipped).

Torque the bolts to 22 N.m (16 lb-ft).

POWER STEERING

HOSE BRACKET

BRAKE BOOSTER

VACUUM HOSE

NOTE: To allow time for the liquid gasket to cure,

wait 3 hours before starting the engine.

DIPSTICK

BREATHER

HOSE

09-010

BOLTS

5 of 5

You might also like

- Transmission Fluid PDFDocument5 pagesTransmission Fluid PDFLv2mackNo ratings yet

- 08 Engine MechanicalDocument80 pages08 Engine MechanicalmadcostaNo ratings yet

- 2uztrd PDFDocument33 pages2uztrd PDFbob loblawNo ratings yet

- 2008 Chevrolet HHR DTCDocument6 pages2008 Chevrolet HHR DTCTal Benyamin100% (1)

- 2007 Civic Hybrid About SafetyDocument3 pages2007 Civic Hybrid About SafetyAngel ValladaresNo ratings yet

- Mini Cooper ATF Change PDFDocument21 pagesMini Cooper ATF Change PDFLUKSmadrizNo ratings yet

- A760E Auto Trans - InstallationDocument7 pagesA760E Auto Trans - InstallationJohn Locke100% (1)

- 3.3L 6-Cyl VinDocument28 pages3.3L 6-Cyl VingypsyshortNo ratings yet

- Terminals of Ecm: E17 E16 E15 E14Document5 pagesTerminals of Ecm: E17 E16 E15 E14Martin ChilbetNo ratings yet

- P1012-Fuel Pump Delivery Pressure Too High: Theory of OperationDocument2 pagesP1012-Fuel Pump Delivery Pressure Too High: Theory of OperationYovani AcevedoNo ratings yet

- Building A 5SG EngineDocument5 pagesBuilding A 5SG Enginedhendriadi69No ratings yet

- 03-04 l4 Engine Vibration in Gear 04-024Document4 pages03-04 l4 Engine Vibration in Gear 04-024Vincent HardyNo ratings yet

- FK Blank 2.0Document122 pagesFK Blank 2.0robertoperez525No ratings yet

- Hybrid Transaxle Coolant ReplacementDocument75 pagesHybrid Transaxle Coolant Replacementpejopo100% (1)

- 2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramDocument7 pages2011 Jeep Liberty Limited 2011 Jeep Liberty Limited: Fig. 73: Transmission Control Output Wiring DiagramcarlosNo ratings yet

- Harrop Lc200-1ur InstallDocument22 pagesHarrop Lc200-1ur InstallArtur ElectroMecânicoNo ratings yet

- 1zr-Fae Engine Mechanical Service DataDocument10 pages1zr-Fae Engine Mechanical Service DataMarzena SynoradzkaNo ratings yet

- Seat Alhambra 2.0 TDi 2005-2010Document11 pagesSeat Alhambra 2.0 TDi 2005-2010marquin84No ratings yet

- JATCO CVT Transmission Diagram and PartsDocument8 pagesJATCO CVT Transmission Diagram and PartsLeigh100% (1)

- 4 Ataxle PDFDocument22 pages4 Ataxle PDFAnonymous XTkln6H100% (1)

- Volvo 850 ODB A1 Automatic Transmission DiagnosticDocument9 pagesVolvo 850 ODB A1 Automatic Transmission DiagnosticBartłomiej KilianNo ratings yet

- 05ewd PDFDocument251 pages05ewd PDFWawan SatiawanNo ratings yet

- 2AZ-FE FuelDocument43 pages2AZ-FE FuelAdedeji OluwatobilobaNo ratings yet

- Automatica FordDocument120 pagesAutomatica Fordpedro herreraNo ratings yet

- Captiva Control Valve Body Removal PDFDocument2 pagesCaptiva Control Valve Body Removal PDFBurhan udinNo ratings yet

- Prius - Power SteeringDocument12 pagesPrius - Power SteeringjorgetkyNo ratings yet

- BeltsDocument89 pagesBeltszul100% (2)

- Almera N16 TechDocument4 pagesAlmera N16 TechSpiros FousasNo ratings yet

- TL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Document4 pagesTL-80SN (AA80E) : 8 Speed RWD (Electronic Control) LS460/470, GS460/470, IS F (Lexus), Crown Majesta (Toyota)Mothana HusbanNo ratings yet

- 00 GeneralDocument24 pages00 Generalcrysttina100% (1)

- Honda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025Document8 pagesHonda OBD I Vehicles (1985 - 1995) Supported by Actron's Honda/Nissan/Toyota Code Scanner CP9025izalirunk100% (1)

- GM Obd PDFDocument3 pagesGM Obd PDFfadhelNo ratings yet

- Automatic Transaxle Troubleshooting GuideDocument293 pagesAutomatic Transaxle Troubleshooting GuideOmar RodriguezNo ratings yet

- Re4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresDocument3 pagesRe4F04A and Re4F04V Automatic Transmission (A/T) - Solenoid Valve Replacement ProceduresfulltransmissionNo ratings yet

- Technical BulletinsDocument46 pagesTechnical BulletinsjellyallsweetNo ratings yet

- 9913 Ap 34Document108 pages9913 Ap 34احمدميدوNo ratings yet

- 1000 Manual 0407Document60 pages1000 Manual 0407Dharmesh patelNo ratings yet

- Nissan Navara D40 Automatic Gearbox Oil Change - PaperblogDocument6 pagesNissan Navara D40 Automatic Gearbox Oil Change - PaperblogMary Ann UsaragaNo ratings yet

- Engine Unit Exploded View With Torque Specifications (1 of 7)Document7 pagesEngine Unit Exploded View With Torque Specifications (1 of 7)miguel100% (1)

- Cadillac Escalade 2007-2009Document60 pagesCadillac Escalade 2007-2009Владимир ЛеонгардиNo ratings yet

- Fuel Pressure Regulator Removal GuideDocument26 pagesFuel Pressure Regulator Removal GuidecjtovarNo ratings yet

- Transfer: Workshop ManualDocument92 pagesTransfer: Workshop ManualmailforspamNo ratings yet

- YD 25 Engines IssuesDocument4 pagesYD 25 Engines IssuesZauron Kent TouchitNo ratings yet

- Z Injector - Types - Nippon Denso 2Document2 pagesZ Injector - Types - Nippon Denso 2joeNo ratings yet

- 303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpDocument22 pages303-01 - 2.3L EcoBoost - Removal and Installation - Oil PumpCARLOS LIMADANo ratings yet

- 2008 Honda Accord - Powertrain - HondaDocument9 pages2008 Honda Accord - Powertrain - HondaAnonymous osZFt6PxjJNo ratings yet

- Auto Mat Ice Trans - Auto Trans F ComponentsDocument4 pagesAuto Mat Ice Trans - Auto Trans F Componentstonek9No ratings yet

- M800 OEM WRX78 Installation DocumentDocument10 pagesM800 OEM WRX78 Installation DocumentRaheel FaroukNo ratings yet

- RE4R03ADocument2 pagesRE4R03AAbbode HoraniNo ratings yet

- Manual Transmission AssemblycomponentsDocument5 pagesManual Transmission AssemblycomponentsZouhair WahbiNo ratings yet

- If Your Vehicle Needs To Be Towed: 5-1. Essential InformationDocument7 pagesIf Your Vehicle Needs To Be Towed: 5-1. Essential InformationxsmartieNo ratings yet

- How To Guide - Fitting Brembo Brakes On A StageaDocument4 pagesHow To Guide - Fitting Brembo Brakes On A StageaseastateNo ratings yet

- RX7 FD 1993 WiringDocument36 pagesRX7 FD 1993 WiringJessica Ng100% (2)

- TS TR 0075 D PDFDocument2 pagesTS TR 0075 D PDFromanjcNo ratings yet

- M6ha Mdwa Baxa MaxaDocument68 pagesM6ha Mdwa Baxa Maxagabriela DiazNo ratings yet

- Nissan GTR R35Document8 pagesNissan GTR R35Afiq FirdausNo ratings yet

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- A16-088 - Actuador VTC - Honda FIT 2015 2016Document11 pagesA16-088 - Actuador VTC - Honda FIT 2015 2016Carlos López100% (1)

- LIFEBOOK T731 Repair GuideDocument25 pagesLIFEBOOK T731 Repair Guideyumyum9No ratings yet

- Visible Body AP ManualDocument51 pagesVisible Body AP ManualvijayalakshmiramanNo ratings yet

- Chang v. Orgain Inc. ComplaintDocument33 pagesChang v. Orgain Inc. Complaintyumyum9No ratings yet

- Biochemistry & Cytology 1Document48 pagesBiochemistry & Cytology 1yumyum9No ratings yet

- FRF Barber Course MaterialsDocument94 pagesFRF Barber Course Materialsyumyum9No ratings yet

- What How Why OrgoDocument13 pagesWhat How Why Orgoyumyum9No ratings yet

- 13C NMR Spectroscopy GuideDocument5 pages13C NMR Spectroscopy GuideTux BsdNo ratings yet

- 08 Lab 1e AromaticsDocument6 pages08 Lab 1e Aromaticsyumyum9No ratings yet

- Orgo 2 SynDocument7 pagesOrgo 2 Synyumyum9No ratings yet

- Organic Chem Mechanism YlideDocument5 pagesOrganic Chem Mechanism Ylideyumyum9No ratings yet

- CentrifugationDocument60 pagesCentrifugationpinkbutter100% (3)

- Bio-RadTechNote2861 Principles of Curve FittingDocument4 pagesBio-RadTechNote2861 Principles of Curve Fittingyumyum9No ratings yet

- Alcohols and PhenolsDocument55 pagesAlcohols and Phenolsyumyum9No ratings yet

- Acid Catalyzed Reactions ImportantDocument19 pagesAcid Catalyzed Reactions ImportantPraveen TekkaliNo ratings yet

- Aromatic CompoundsDocument39 pagesAromatic Compoundsyumyum9No ratings yet

- Skeletal List - A&pDocument3 pagesSkeletal List - A&pyumyum9No ratings yet

- Alcohols and PhenolsDocument55 pagesAlcohols and Phenolsyumyum9No ratings yet

- Joints and Muscle ListDocument3 pagesJoints and Muscle Listyumyum9No ratings yet

- Darlene Rose Mneumonic For SystemsDocument2 pagesDarlene Rose Mneumonic For Systemsyumyum9No ratings yet

- VL2019201000534 DaDocument2 pagesVL2019201000534 DaEnjoy LifeNo ratings yet

- ER DiagramDocument23 pagesER Diagramapi-2757091480% (20)

- Imaging Approach in Acute Abdomen: DR - Parvathy S NairDocument44 pagesImaging Approach in Acute Abdomen: DR - Parvathy S Nairabidin9No ratings yet

- Paradigm Shift Essay 2Document17 pagesParadigm Shift Essay 2api-607732716No ratings yet

- Capacity PlanningDocument19 pagesCapacity PlanningfarjadarshadNo ratings yet

- Reflection Paper #1 - Introduction To Action ResearchDocument1 pageReflection Paper #1 - Introduction To Action Researchronan.villagonzaloNo ratings yet

- PCSE_WorkbookDocument70 pagesPCSE_WorkbookWilliam Ribeiro da SilvaNo ratings yet

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Document16 pagesTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Jazan Refinery and Terminal ProjectDocument3 pagesJazan Refinery and Terminal ProjectkhsaeedNo ratings yet

- 2002, Vol.86, Issues 4, Hospital MedicineDocument221 pages2002, Vol.86, Issues 4, Hospital MedicineFaisal H RanaNo ratings yet

- Assessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyDocument4 pagesAssessing Gross Efficiency and Propelling Efficiency in Swimming Paola Zamparo Department of Neurological Sciences, Faculty of Exercise and Sport Sciences, University of Verona, Verona, ItalyVijay KumarNo ratings yet

- Guide to Fair Value Measurement under IFRS 13Document3 pagesGuide to Fair Value Measurement under IFRS 13Annie JuliaNo ratings yet

- Laws of MotionDocument64 pagesLaws of MotionArnel A. JulatonNo ratings yet

- AVANTIZ 2021 LNR125 (B927) EngineDocument16 pagesAVANTIZ 2021 LNR125 (B927) EngineNg Chor TeckNo ratings yet

- Modul-Document Control Training - Agus F - 12 Juli 2023 Rev1Document34 pagesModul-Document Control Training - Agus F - 12 Juli 2023 Rev1vanesaNo ratings yet

- Timely characters and creatorsDocument4 pagesTimely characters and creatorsnschober3No ratings yet

- Ali ExpressDocument3 pagesAli ExpressAnsa AhmedNo ratings yet

- Give Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishDocument12 pagesGive Five Examples Each of Nature Having Reflection Symmetry and Radial Symmetry Reflection Symmetry Radial Symmetry Butterfly StarfishANNA MARY GINTORONo ratings yet

- Corn MillingDocument4 pagesCorn Millingonetwoone s50% (1)

- Class Ix - Break-Up SyllabusDocument3 pagesClass Ix - Break-Up Syllabus9C Aarib IqbalNo ratings yet

- Practical Research 2: Self-Learning PackageDocument3 pagesPractical Research 2: Self-Learning PackagePrinces BaccayNo ratings yet

- Henny Penny 500-561-600 TM - FINAL-FM06-009 9-08Document228 pagesHenny Penny 500-561-600 TM - FINAL-FM06-009 9-08Discman2100% (2)

- Common Size Analys3esDocument5 pagesCommon Size Analys3esSaw Mee LowNo ratings yet

- NOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationDocument10 pagesNOTE CHAPTER 3 The Mole Concept, Chemical Formula and EquationNur AfiqahNo ratings yet

- BoQ East Park Apartment Buaran For ContractorDocument36 pagesBoQ East Park Apartment Buaran For ContractorDhiangga JauharyNo ratings yet

- Singer NM37 57manualDocument266 pagesSinger NM37 57manualpaulkoby100% (2)

- Driving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorsDocument10 pagesDriving Continuous Improvement by Developing and Leveraging Lean Key Performance IndicatorskellendadNo ratings yet

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Document11 pagesSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaNo ratings yet

- Childrens Ideas Science0Document7 pagesChildrens Ideas Science0Kurtis HarperNo ratings yet

- USA V BRACKLEY Jan6th Criminal ComplaintDocument11 pagesUSA V BRACKLEY Jan6th Criminal ComplaintFile 411No ratings yet