Professional Documents

Culture Documents

Bolted Connection Fatigue

Uploaded by

Mahfuzur RahmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bolted Connection Fatigue

Uploaded by

Mahfuzur RahmanCopyright:

Available Formats

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

S.F. Stiemer

FATIGUE FAILURE OF BOLTED CONNECTIONS

ABSTRACT

An overview of the fatigue process and behaviour of fatigue loading is

given. Bolted connections in both tension and shear are discussed in

detail with emphasis placed on the location of failure, fatigue design

curves, influence of preloading, joint stiffness, and contact area. Anchor

bolts are also briefly discussed. Design requirements as per CSA S16.199 and AISC LRFD-1999 are given. Various methods on how to

minimize fatigue problems are presented.

INTRODUCTION

Under certain conditions a material may fail due to the repeated

application of loads that are not large enough to cause failure in a single

application. This phenomenon is referred to as fatigue failure. The

existence of fatigue failure implies that, under repeated stresses,

materials undergo some internal progressive, permanent structural

changes. Fatigue failures are often more dangerous than other typical

failures because they generally occur suddenly, without significant prior

deformations. Figure 1 shows a fatigue induced fracture surface.

Fatigue failure in bolted connections is generally caused by repeated

cycles of tension loading. Although failures under repeated cyclic

compression loads are know, these are rare and will be ignored in this

discussion.

9/9/2015

Figure 1. Fracture surface of a typical paper clip broken by 6 cycles of

repeated bending (80x).1

THE FATIGUE PROCESS

Fatigue failure will only occur if the following essential conditions are

present: cyclic tensile loads, stress levels above a threshold value, fatigue

susceptible material, and a flaw in the material. If these conditions are

present, then the following events can occur, leading to fatigue failure

(Figure 2):

1. Crack initiation

2. Crack growth

3. Crack propagation

4. Final rupture

PAGE 1 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

S.F. Stiemer

crack to propagate into the still undamaged material ahead of it. The

crack only propagates a finite distance in each loading cycle; this

advance may by as much as 25 m/cycle.1 The back stresses exerted on

the material during unloading cause deformation markings often called

striations or beach marks, as shown in Figure 3.

Figure 2. Fatigue sequence - the stages of failure are: (1) initiation,

(2) growth, (3) propagation, and (4) rupture. 2

2.1

CRACK INITIATION

Generally, fatigue cracks will originate on a free surface at a point of

high stress concentration in the material. This may often be due to a preexisting flaw in the material; or perhaps a human made discontinuity,

such as the root of a thread, a tool mark, corrosion, or any point at which

there is a sharp change in size or shape of the material. It would be safe

to say that no connection is entirely free from defects of this type.

2.2

CRACK GROWTH

As the part is subjected to cyclic tensile loads, the material around the

stress concentrations undergoes a slip mechanism. Slip occurs by the

movement of dislocation displacement of the atomic matrix. Under

cyclic loading, reverse slip on adjacent slip planes may lead to the

formation of extrusions and intrusions at the surface. These will act as

the starting point of the crack. Initially the crack will grow along the slip

plane, but will eventually change direction until it is growing in a plane

perpendicular to the principle tensile stress.

2.3

CRACK PROPAGATION

Fatigue cracks will propagate under shear and tensile loads, but not under

compressive loading since these cracks will close rather than open.

During each tensile loading cycle, very high stresses occur at the crack

tip (due to the stress concentrating effect of the sharp crack), causing the

9/9/2015

Figure 3. Micrograph of fatigue fracture, with characteristic beach

marks.1

2.4

FINAL RUPTURE

The crack grows more rapidly as stress levels increase. The process of

crack growth is repeated until the crack reaches some critical length, at

which time a sudden failure occurs, in either a ductile or brittle manner,

depending on the characteristics of the material.

The fatigue life of a bolt and connection depends a great deal on the

location and magnitude of the initial crack, but more importantly on

factors such as bolt and joint stiffness, initial preload, alloy content, heat

treatment, location and magnitude of external tension loads, etc.

Therefore, there is a lot of scatter in the fatigue life of a bolted

connection, making it difficult to accurately determine.

PAGE 2 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

BEHAVIOUR OF FATIGUE LOADING

The fatigue life, or endurance, of a material refers to the number of

repeated cycles of loading (N) that a material will undergo before it fails.

N will depend on the particular set of loading conditions. However, the

general rule of thumb is that the higher the fatigue stress levels, the fewer

number of loading cycles are required to cause failure. In most well

designed bolted joints, however, fatigue failure will occur under highcycle loading. Fatigue data is most commonly presented in terms of S-N

curves (maximum stress versus the number of cycles), as shown in

Figure 4.

Figure 4. S-N Curve for varying magnitude of altering stress. 2

As Figure 4 shows, the material undergoes a definite fatigue limit. That

is, it may withstand infinite cycles of loading without failing, as long as

the applied stress is less than the fatigue limit. Although S-N curves are

often produced based on tension loading along the axis of the fastener, it

is important to recognize that if the fastener is subjected to some other

form of stress as well as tension, its fatigue life will be adversely

affected. Shear stress for example, would make it more susceptible to

fatigue. There are many factors that will affect the fatigue life, each

resulting in a different S-N curve. The major factors in order of

importance that affect fatigue life are:

9/9/2015

S.F. Stiemer

1. Shape of the connection.

2. Magnitude of stress excursions or variations.

3. Mean stress level.

4. Choice of material.

Other conditions such as corrosive environments and extreme

temperatures also can affect the fatigue performance.

BOLTED CONNECTIONS LOADED IN TENSION

A typical bolted connection loaded in tension is shown in Figure 5.

Figure 5. Bolted connection loaded in tension. 3

4.1

LOCATION OF FAILURE

The tread in a bolt acts as a notch and therefore a high stress

concentration is caused at the root of the tread. At locations where two

threads meet the stress concentrations can be even higher, i.e. at the

runout of the thread and where the thread and nut first engages the thread

of the bolt. In addition, the head-shank transition is also a stress

concentration.

PAGE 3 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

A bolt and nut loaded axially, as shown in Figure 6, has three possible

fatigue crack initiation locations:

a. Head-shank transition

b. Runout of thread

c. Thread at nut

Figure 6. Axially loaded bolt with possible fatigue crack locations. 3

In standard bolts, the radius at the bolt-head shank transition is usually

large enough to prevent fatigue cracks at this point.

Normally, if fatigue cracks occur, they will be located at the first

engagement of the threads of the bolt and nut (point c in Figure 6), and

can be 2 to 4 times the mean value. 3 This is due to the load transfer from

nut to bolt. The contacting thread faces of the bolt and nut will give rise

to extra bending stresses in the threads. Also, the load is unevenly

distributed between the contacting faces of the bolt and nut, with the

stresses being higher at the first thread of engagement. This will depend

on the thread form, pitch, and differences in Youngs modulus where

different materials are used. The load transfer can become more uniform

by plastic deformation of the bolt.

4.2

THE INFLUENCE OF PRELOAD AND JOINT STIFFNESS

A bolt in a connection will see a portion of any external load, Fb,

applied to the joint. The magnitude of the mean load on the bolt depends

on the preload of the bolt. The magnitude of the load excursion (Fb)

depends on:

1. The magnitude of the external tension load.

2. The bolt-to-joint stiffness ratio (Kb/Kj).

9/9/2015

S.F. Stiemer

3. Whether or not the external tension load exceeds the critical load

required to separate the joint (depends on the magnitude of the

initial preload).

The effect of preloading, where there is tensile loading on the bolted

connection, is illustrated for a flange connection in Figures 7 and 8. The

thickness of the flange is assumed to be large enough to neglect bending

flexibility and possible prying forces.

Figure 7. Flange connection with non-preloaded bolts. 3

Figure 8. Flange connection with preloaded bolts. 3

Where there is no preload, (Figure 7), and thus no contact force on the

facing surfaces of the flanges, the external tensile force F t applied on the

connection will be transferred directly to the bolts, F b. Therefore, there

will be a variation of the force in the bolts and a corresponding

displacement between the opposing flanges. The connection can be

considered to act as a two-spring system.

PAGE 4 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

In the case with a preload force Fv, this force will initially be in

equilibrium with the contact force F c on the contact area of the flanges,

(Figure 8). These two flanges act like one as long as the external load F t

is less than the preload F v. As a result, the external load applied to the

bolts will change very little. As shown in the diagram, the increase in the

external force is compensated largely by a decrease of the contact force

Fc and small increases in the forces in the bolt F b. Only the elastic

deformation of the two flanges will cause change in the bolt load. The

flanges, however, are relatively stiff compared to the bolt area and

therefore this effect is minimal. But, the load in the bolts will increase

rapidly as soon as the contact surfaces separate due to the external force

surpassing the preload force F v. When this has occurred the situation is

equivalent to the non-preloaded case. As long as the external load F t is

below the preload force Fv the situation can be considered as a threespring system.

The amount of variation of the forces in the bolts due to the variation in

the external load is dependent on the stiffness ratio of the flange and bolt

(Figure 9). The more flexible the bolt, the less force variation it will

undergo. Using more washers or using spring washers will increase the

bolts length, thereby making the bolt more flexible. Inserting gaskets

between the flanges will make the flange assembly more flexible, leading

to possible detrimental effects. The flange thickness must also be

adequate to reduce bending flexibility; otherwise the location on the

contact forces may become critical.

4.3

S.F. Stiemer

Figure 9. The effect of varying F b and Kb /Kj ratios. (Note that the initial

preload is the same in each case). 2

THE INFLUENCE OF THE LOCATION OF THE CONTACT AREA

When the bolts of the connection are subjected to a preload force, contact

forces are induced on the connecting surface. The location of the

developed contact forces will affect the fatigue life of the connection.

Figures 10 and 11 shows an example where the flange thickness is much

smaller than in Figures 7 and 8 and is, therefore, more susceptible to

bending. In this figure, introducing shims develops contact forces. In

both cases, the bolts are tightened to the same preload. A schematic

model of the relevant spring system is shown in Figure 10, while Figure

11 shows the measured bolt forces with respect to an external load.

Figure 10. Flange connection with different location of contact forces. 3

9/9/2015

PAGE 5 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

S.F. Stiemer

In general the most favourable condition with respect to the fatigue

resistance is to have the contact area as close as possible to where the

tensile force is acting. This is shown in Figure 12.

Figure 11. Measured bolt forces with respect to an external load.

(Dashed line represents FT, solid line represents FB). 3

4.3.1

Contact Area at the Centre

When the contact force is located in the centre, Figure 10a, there is

effectively a very stiff spring in the middle compared to the two flexible

springs representing the flexible bolts and flange edges. This situation is

very similar to having a very low Kb /Kj ratio, and the variation of

magnitude in the bolts will not be too great if the preload force is not

exceeded. This is shown in Figure 11a, with the applied external tension

force plotted in a dashed line, and the force in the bolt plotted with a

solid line.

4.3.2

Contact Area at the End of Flanges

When the contact force is located near the edge of the flanges, Figure

10b, the stiffness of the bolts is relatively large compared to the outer

flange. This situation is very similar to having a relatively high K b /Kj

ratio, and as a result the variation of the external force will cause

variation of the bolt forces of nearly equal magnitude, as shown in Figure

11b.

9/9/2015

Figure 12. Different locations of contact area: Going from (a) to (c) the

bolts will experience more load variation with the same

variation of the external forces. 3

BOLTED CONNECTIONS LOADED IN SHEAR

A typical bolted connection loaded in shear is shown in Figure 13. In

these types of connections, load is transferred from one piece to the other

via cover plates.

5.1

5.1.1

LOAD TRANSFER AND STRESS CONCENTRATION

Non-Preloaded Bolts

In the case of non-preloaded bolts, the applied force is transferred via

bearing between the plates and the shank of the bolt, as indicated in

Figure 13a. These types of connections are inadequate for variable loads

that change sign as significant displacements will occur due to the

clearance between the hole and bolt shank. Load transfer of this type is

very concentrated at the location were the shank bears against the holes.

PAGE 6 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

In these connections the stress is concentrated around the hole. Since the

bolt shank is also loaded in bearing, it too will experience high stress

concentrations, (Figure 14a).

5.1.2

S.F. Stiemer

Preloaded Bolts

When the bolts are preloaded, the applied force is transferred by friction

between the plate surfaces. High Strength Friction Grip Bolts (HSFG) are

used to obtain the necessary compressive stresses between the plates to

enable the load to be transferred by friction. The load is transferred over

a large area around the bolt (Figure 14b), and therefore the load transfer

is not as great as in the non-preloaded bolt case. These types of

connections can be used when the variable load changes sign.

For preloaded-bolts there are no stress concentration at the hole. In fact

the stresses may even be less than the nominal stresses. This is due to the

fact that the load has been transferred to an area around the hole.

5.2

5.2.1

LOCATION OF FAILURE

Non-Preloaded Bolts

The crack will occur at the hole due to the large stress concentration.

Another potential failure location could be in the bolt as a result of the

variable shear load applied to the shank at the shear plane. If this type of

connection is used, the threaded part of the bolt should not be located in

the shear plane, as the notch effect could drastically reduce the fatigue

resistance, (Figure 14a).

5.2.2

Pre-Loaded Bolts

In the case of non-preloaded bolts, the stress concentrations do not

generally occur near the hole. The contact pressure decreases radially

from the hole. Fatigue cracks will usually develop in the gross section of

the plate (see Figure 14b), were the contact pressure is not high enough

to prevent slip.

Figure 13. Example of a bolted connection loaded in shear. 3

9/9/2015

PAGE 7 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

5.3

S.F. Stiemer

FATIGUE DESIGN CURVE FOR BOLTS IN SHEAR

In the case of non-preloaded bolts, there are two possible failures the

shank of the bolts and the gross section of the plate. Both should be

checked against relevant design curves. Canadian and American design

codes provide information for fatigue failure of gross plate crosssections, but none is available for failure of a bolt shank in shear.

In the case of preloaded bolts, the bolts themselves will not fail provided

that the pre-load is sufficient to prevent slip in the connection. The plates

fall into the same design category as in the non-preloaded case. However,

since the failure does not occur near the holes, the gross section of the

plate can be used for calculating fatigue stresses.

ANCHOR BOLTS

Anchor bolts have some different fatigue resistance characteristics in

comparison to the normal bolts that have been discussed thus far.

Test results have shown that the bolt diameter and the thread size do not

influence fatigue behaviour; the fatigue lives were almost identical as

normal bolts. 3

The way the bolt is formed also affects the fatigue resistance. Anchor

bolts with rolled threads perform better than those with cut threads. This

is due to the residual compressive stresses that are formed when the bolt

has been rolled. Also, cut threads leave a sharp notch at the location of

thread termination, which acts as a potential point of stress concentration.

The number of nuts also affects fatigue performance. More nuts can

substantially increase the connections resistance.

Another important factor that must be taken into account is the effect of

prying action, which will increase the applied force.

Figure 14. Stress and possible crack location of a bolted connection

loaded in shear. 3

9/9/2015

PREDICTING FATIGUE LIFE

There are several methods for predicting fatigue life; essentially they all

involve the concept of the gradual accumulation of damage during the

process of cyclic loading. The two most common methods are based on

linear cumulative damage, and the Palmgren Miners Rule.

The linear cumulative damage is based on specific S-N data for each

particular specimen type. This method is adopted in many design codes

PAGE 8 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

S.F. Stiemer

including the Canadian CSA S16.1-94 and American AISC LRFD-1999,

which are discussed in a later section. A formatted spreadsheet has also

been developed to implement the fatigue requirements of these codes.

The Palmgren Miner rule is used to determine the level of fatigue

damage.

In the calculation procedure, the existing number of stress cycles n i are

divided by the allowed number of stress cycles N i, and added for each

stress cycle. If this total is less than 1.0 the connection has not failed in

fatigue. Miners rule follows the expression:

7.1

CSA S16.1-94 FATIGUE REQUIREMENTS4

Fatigue requirements are addressed in Section 14 of the CSA S16.1-94.

The code states that fatigue is generally not a design consideration for

buildings such as commercial or residential. However, industrial

buildings may have members, such as crane girders, for which fatigue is

a design consideration; other structures such as amusement rides and sign

supports, for example may also be susceptible to fatigue.

When looking at the fatigue limit state, emphasis is placed on fatigue

cracks that result from live load effects and those that result in local

distortions. It is also important to determine the number of cycles to

which a detail may be subjected.

When carrying out the fatigue resistance analysis, only variable and

impact loads contribute to the stress range. Further, the designer only

needs to consider regions that are subjected to tensile stresses or stress

reversals. Compressive stress regions may be ignored.

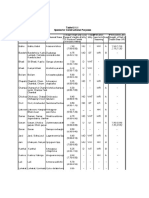

Fatigue design in this specification is based on experimental data in

which various fatigue susceptible details were tested to develop

corresponding S-N curves. Details are assigned to one of eight stress

range categories (A to E1). Appendix K illustrates various details and

gives some guidance on how to assign a detail to a category. Figure 15

shows the allowable stress range versus the number of stress cycles for

each category.

9/9/2015

Figure 15. CSA fatigue resistances for categories A to E1 CSA S16.1-94

The fatigue life of a detail is inversely proportional to the cube of the

stress range for values above the constant threshold stress range. The

detail is considered to be satisfactory in fatigue if the applied stress range

is less than that corresponding to the expected number of cycles of

loading for the design life of the structure, as shown below.

f sr F sr

1

F sr

3Fsr

Fsrt

2

nN

fsr = calculated stress range at the detail due to the passage of the fatigue

load

Fsr = fatigue resistance, including adjustment for the number of stress

range cycles for each passage of load

= fatigue life constant pertaining to the detail category [Table 4(a)]

PAGE 9 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

n = number of stress range cycles at given detail passage of the moving

load [Table 4(b)]

N = number of passages of the moving load

Fsrt = constant amplitude threshold stress range [Table 4(a)]

For the fatigue resistance of high strength tension bolts, the code requires

that the bolts are tensioned to the required pre-load and that prying action

is considered.

From reviewing the detail categories given in Appendix K, we can see

that the code gives very little guidance on how to check a bolted

connection for fatigue resistance. It is left up to the designer to use

his/her judgement.

7.2

AISC LRFD-1999 FATIGUE REQUIREMENTS5

Fatigue requirements are addressed in Section K3 of the AISC LRFD1999. The AISC fatigue criteria are very similar to those found in CSA

S16.1-94; however, there are additional requirements given for bolts and

threaded parts.

The considered stress range is defined as the magnitude of the change in

stress due to the application or removal of the unfactored live load. In the

case of a stress reversal, the stress range shall be computed as the

numerical sum of maximum repeated tensile and compressive stresses or

the numerical sum of maximum shearing stresses of opposite direction at

the point of probable crack initiation. 5

No evaluation of fatigue resistance is required if the live load stress range

is less than the threshold stress range, F TH, or if the number of cycles of

application of live load is less than 2 x 104.

As in the CSA S16.1-94, the fatigue life of a detail is inversely

proportional to the cube of the stress range for values above the constant

threshold stress range. The detail is considered to be satisfactory on

fatigue if the applied stress range is less than that corresponding to the

expected number of cycles of loading for the design life of the structure,

as shown below. (Note all calculations shown are in SI units).

.

9/9/2015

S.F. Stiemer

F SR F TH

1

F SR

C f 327

N

FSR = design stress range, (MPa)

FTH = threshold fatigue stress range, maximum stress range for indefinite

design life [Table A-K.3.1], (MPa)

Cf = Constant [Table A-K3.1]

N = number of stress range fluctuations in design life

= number of stress range fluctuations per day x 365 x years of design

life

The AISC LRFD also has additional requirements for bolts and threaded

parts. For mechanically fastened connections loaded in shear, the

maximum range of stress in the connected material at service loads shall

not exceed the design stress computed using the equation given above.

For high-strength bolts, common bolts, and threaded anchor bolts with

cut, ground or rolled threads, the maximum range of tensile stress on the

net tensile area from applied axial load and moment plus load due to

prying action shall not exceed the design stress range computed using the

equation above. The factor Cf shall be taken as 3.9 x 108 (as for category

E). The threshold stress, F th shall be taken as 48 MPa (as for category

D). The net tensile area for metric bolts is given as:

At

db 0.9382P 2

P = pitch, (mm/thread)

db = nominal diameter (body or shank diameter), (mm)

When dealing with bolts and threaded parts, the designer must also

consider any prying action and the relative stiffness of the connected

parts.

Although the AISC LFD does provide a little more guidance than the

CSA S16.1-94, it still does not adequately take into account all of the

PAGE 10 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

S.F. Stiemer

effects, which may influence the fatigue life of a bolted connection. It is,

therefore, left to the designers to use their professional judgment.

MINIMIZING FATIGUE PROBLEMS

There are many steps that a designer can take to minimize fatigue related

problems. Each of these is related to the conditions that are necessary for

fatigue to occur: cyclic tensile loads, stresses above an endurance limit, a

susceptible material, and an initial flaw. In general, most of the steps that

we can take are intended to reduce stress levels (and concentrations)

and/or to reduce the load excursion seen by the bolt.

8.1

MINIMIZING STRESS LEVELS

The following are just a few of the steps that a designer can take to

minimize stress levels. Many of these are incorporated in fatigue

resistant fasteners, which are available from some fastener

manufacturers.

Rolling treads instead of cutting them provides a smother thread finish

(fewer initial cracks). The rolling process induces a residual compressive

stress in the bolts, which acts as a compressive preload, thereby helping

to reduce the tensile load excursions.

A generous fillet between the head and shank will reduce stress

concentrations. The exact shape is also important; an elliptical fillet, for

example, is better than a circular one. 2 Increasing the radius of a circular

fillet will also help

If the face of the nut, the undersides of the bolt head, and/or joint surface

are not perpendicular to the thread axis and the boltholes, the fatigue life

can be seriously affected.2

Bolts under tension see stress concentrations at the head-to-shank fillet,

first threads to engage the nut, and at the thread run-out. Anything that

may impose additional loading to these regions will be detrimental. Some

of these situations are shown in Figure 16.

Figure 16. Joints should be designed so that maximum loads do not fall

on stress concentration points of the fastener.2

The thread run-out should be gradual rather than abrupt. It has been

suggested that a taper of 15o should be used to minimize stress

concentrations at this critical point (Figure 17). 2

Figure 17. Thread run-out should be gradual.2

Anything that can be done to minimize corrosion will reduce the

possibilities of crack initiation and/or crack growth and will, therefore,

extend fatigue life.

9/9/2015

PAGE 11 OF 12

Steel Design

FATIGUE FAILURE OF BOLTED CONNECTIONS

Figure 18 shows a proposed fastener, which, because of its geometry, can

greatly reduce stress concentrations and, therefore increase the fatigue

life of the connection.

S.F. Stiemer

determine if the applied stress range is within the desired limit for a

required number of load cycles. This may be relatively accurate for

normal steel members or welded connections; however, it does not

adequately address bolted connections, as there are numerous connection

types that do not fall under a prescribed design category. It is therefore

up to the designers to use their judgment or undergo further rigorous

analysis in order to determine if the connection is adequate to resist

fatigue.

By minimizing stress levels or reducing load variations, the designer may

make the connection less prone to fatigue failure.

REFERENCES

Figure 18. Flanges, dished, and undercut nut and bolt head used to

improve stress distribution.2

8.2

Young J., Mindess S, Gray R. and Bentur A. 1998. The Science and

Technology of Civil Engineering Materials. Prentice Hall: 152-175.

REDUCING LOAD VARIATIONS

Nothing can help extend the fatigue life of a bolt or joint more

dramatically than a reduction in load variations.

It will greatly help to correctly identify and apply the maximum safe

preload that the joint can withstand. Minimizing the bolt-to-joint stiffness

ratio, (as well as proper location of contact forces), so that the load

excursions and external loads will be seen by the joint and not the bolt

will reduce fatigue problems.

CONCLUSIONS

Fatigue failure of bolted connections is a serious problem in steel

structures, as the failure happens suddenly without prior warning. It

occurs in areas were the applied stress is cyclic and tensile in nature, and

where there is a stress concentration.

Bolted connections are commonly used in both tension and shear, each

with varying fatigue characteristics. The fatigue life of the connection

depends on many factors including: the magnitude of the varying applied

load, duration of the varying load, fastener geometry, preloading of the

bolt, relative stiffness of the bolt and joint and the contact area.

Designing to withstand fatigue related failures are addressed in both the

Canadian CSA S16.1-94 and American AISC LRFD-1999 design codes.

These codes provide a method that is based on experimental testing to

9/9/2015

Bickford J. 1990. An Introduction to the Design and Behaviour of

Bolted Joints, 2nd Edition. Marcel Dekker: 467-494.

3

http://www.kuleuven.ac.be/bwk/materials/Teaching/master/toc.htm,

November 2003.

4

Canadian Institute of Steel Construction. 1997. Handbook of Steel

Construction, 7nd Edition. CISC.

5

American Institute of Steel Construction. 1999. Load and Resistance

Factor Design Specification for Steel Buildings. CISC.

10 CREDITS

The text above has been based on a term project done by Mr. Chris

Meisl for the CIVL510 course in 2003.

PAGE 12 OF 12

You might also like

- Brittle Fracture in Steel StructuresFrom EverandBrittle Fracture in Steel StructuresG.M. BoydNo ratings yet

- Fatigue of Threaded Fasteners: Alex Hudgins Brad James, FasmDocument5 pagesFatigue of Threaded Fasteners: Alex Hudgins Brad James, Fasmyh1.yuNo ratings yet

- Embrittlement of Engineering AlloysFrom EverandEmbrittlement of Engineering AlloysC.L. BriantNo ratings yet

- F F B C: Atigue Ailure OF Olted OnnectionsDocument12 pagesF F B C: Atigue Ailure OF Olted OnnectionsOmar OmarNo ratings yet

- Handbook of Fatigue Crack Propagation in Metallic StructuresFrom EverandHandbook of Fatigue Crack Propagation in Metallic StructuresRating: 5 out of 5 stars5/5 (1)

- 11 - Leo Vega Bolt Failure AnalysisDocument35 pages11 - Leo Vega Bolt Failure AnalysissymkimonNo ratings yet

- Mechanical Failure of Materials 9789814560375-c2Document23 pagesMechanical Failure of Materials 9789814560375-c2Recep Vatansever0% (1)

- Avoiding Bolt Failures PDFDocument2 pagesAvoiding Bolt Failures PDFyh1.yuNo ratings yet

- Modern Metallography: The Commonwealth and International Library: Metallurgy DivisionFrom EverandModern Metallography: The Commonwealth and International Library: Metallurgy DivisionRating: 5 out of 5 stars5/5 (1)

- Mechanical Failure ModesDocument28 pagesMechanical Failure ModesSankara Rao67% (3)

- Systematic Analysis of Gear Failures PDFDocument241 pagesSystematic Analysis of Gear Failures PDFtheerapat patkaew100% (1)

- Spontaneous Unfastening and Fatigue of Bolted Joints PDFDocument3 pagesSpontaneous Unfastening and Fatigue of Bolted Joints PDFIvan KlyuchkaNo ratings yet

- Failure Analysis Master Course V1Document21 pagesFailure Analysis Master Course V1manu6969aNo ratings yet

- 2018 Book FractographyAndFailureAnalysis PDFDocument172 pages2018 Book FractographyAndFailureAnalysis PDFDavid Casarrubias A100% (4)

- FractographyDocument17 pagesFractographysultanrandhawa100% (3)

- ASTM - STP436 Electron FractographyDocument236 pagesASTM - STP436 Electron Fractographyacadjournals. comNo ratings yet

- ASM - Failure Analysis of Engineering Structures Methodology and Case HistoriesDocument204 pagesASM - Failure Analysis of Engineering Structures Methodology and Case Historiesvelinov100% (16)

- Fracture and FatigueDocument15 pagesFracture and FatigueZou JiaweiNo ratings yet

- Fatigue Failure of Bolts: How Design and Manufacture Affect PerformanceDocument2 pagesFatigue Failure of Bolts: How Design and Manufacture Affect PerformancekkaranagNo ratings yet

- Fractography SteelDocument42 pagesFractography SteelRebeccaNandaNo ratings yet

- Technical Brief: Avoiding Bolt Failures: F E A T U R EDocument2 pagesTechnical Brief: Avoiding Bolt Failures: F E A T U R EkanosriNo ratings yet

- ISO bearing damage classificationsDocument63 pagesISO bearing damage classificationskcp1986100% (2)

- Avoiding Bolt FailuresDocument2 pagesAvoiding Bolt FailuresShreyas IyengarNo ratings yet

- Chapter 8 Failure Analysis and PreventionDocument76 pagesChapter 8 Failure Analysis and Preventionminh_bk0101100% (1)

- Failure Analysis of AISI 410 Stainless-Steel Piston Rod in Spillway Floodgate (2019)Document12 pagesFailure Analysis of AISI 410 Stainless-Steel Piston Rod in Spillway Floodgate (2019)Dzaky ArizsaNo ratings yet

- Failure AnalysisDocument7 pagesFailure AnalysisbefoaNo ratings yet

- ASM Practical Fractography PDFDocument159 pagesASM Practical Fractography PDFmarcotulio123100% (9)

- Fastener FailuresDocument3 pagesFastener FailuresWylliam Diel WagnerNo ratings yet

- Filter Press Bolt Failure AnalysisDocument13 pagesFilter Press Bolt Failure AnalysisJB MadeleineNo ratings yet

- An Introduction To Failure Analysis For Metallurgical EngineersDocument21 pagesAn Introduction To Failure Analysis For Metallurgical EngineersNavneet SharmaNo ratings yet

- Fatigue Crack Propagation in Steels of Various Yield StrengthsDocument7 pagesFatigue Crack Propagation in Steels of Various Yield StrengthsRodrigo Marin100% (1)

- Fatigue Resistance of High Strength Bolts With Large DiametersDocument8 pagesFatigue Resistance of High Strength Bolts With Large Diametersmutlu_seçerNo ratings yet

- Steel Grain Size CalculationDocument17 pagesSteel Grain Size CalculationtechneoNo ratings yet

- Bolt FailuresDocument7 pagesBolt Failuresstan80No ratings yet

- Decomposition of Austenite in Austenitic Stainless SteelsDocument13 pagesDecomposition of Austenite in Austenitic Stainless SteelsregistrosegNo ratings yet

- Failure Analysis Introduction for Metallurgical EngineersDocument21 pagesFailure Analysis Introduction for Metallurgical EngineersFelipe Novais100% (1)

- Scientific Study of Mechanical Relaxation of Residual Stress PDFDocument120 pagesScientific Study of Mechanical Relaxation of Residual Stress PDFAli HusseinNo ratings yet

- Preload in Bolted JointsDocument88 pagesPreload in Bolted JointsZulfiqar Ali100% (1)

- Heat Treatment Methods for Commercial Engineering SteelsDocument34 pagesHeat Treatment Methods for Commercial Engineering SteelsmeNo ratings yet

- Review of Creep Resistant SteelsDocument4 pagesReview of Creep Resistant SteelsAleš NagodeNo ratings yet

- How To Analyze Gear FailuresDocument9 pagesHow To Analyze Gear FailuresHudson Saldanha SpiffNo ratings yet

- Atlas of Microstructures: Characterization of AlloysDocument46 pagesAtlas of Microstructures: Characterization of AlloysSerkan Apay100% (1)

- Shaft Root Cause Shaft FailureDocument14 pagesShaft Root Cause Shaft FailureSuvek Kumar100% (2)

- 1.the Basics of Ferrous MetallurgyDocument83 pages1.the Basics of Ferrous MetallurgyfenasikerimNo ratings yet

- Chapter 2 Bolted ConnectionsDocument29 pagesChapter 2 Bolted ConnectionsKishan Purohit100% (1)

- Failure Mechanism of High Temperature Components in Power PlantsDocument10 pagesFailure Mechanism of High Temperature Components in Power PlantstazzorroNo ratings yet

- Investigation of Microstructures and Properties ofDocument4 pagesInvestigation of Microstructures and Properties oftiagoness85No ratings yet

- Reverted austenite causes fastener corrosionDocument3 pagesReverted austenite causes fastener corrosionmp87_ingNo ratings yet

- Fracture Mechanics and Steady Load Failure Theory SummaryDocument17 pagesFracture Mechanics and Steady Load Failure Theory Summaryapi-3710585100% (3)

- 10 Commandments Gear FailureDocument1 page10 Commandments Gear Failurerashm006ranjan100% (1)

- Applied Engineering Failure Analysis - Theory and Practice (2015)Document358 pagesApplied Engineering Failure Analysis - Theory and Practice (2015)Nader Asgar Pangarungan Mamaroba88% (8)

- Receive Hardcopy Magazine PublicationDocument3 pagesReceive Hardcopy Magazine PublicationInspection EngineerNo ratings yet

- Bearing Failure 1Document8 pagesBearing Failure 1Kumar SwamiNo ratings yet

- An Excellent Reference On Fastener DesignDocument32 pagesAn Excellent Reference On Fastener DesignSuthirak SumranNo ratings yet

- Plastic Deformation, Flow Stress and FormabilityDocument35 pagesPlastic Deformation, Flow Stress and FormabilityAnna100% (1)

- An Introduction To Failure Analysis For Metallurgical EngineersDocument21 pagesAn Introduction To Failure Analysis For Metallurgical Engineersrpadhra8803No ratings yet

- Failure AnalysisDocument78 pagesFailure AnalysisrR2Cc100% (1)

- Fractography of Ceramic and Metal FailureDocument415 pagesFractography of Ceramic and Metal FailureKhaled BOUALINo ratings yet

- Feed Mill Raw Material Warehouse Variation ReportDocument1 pageFeed Mill Raw Material Warehouse Variation ReportMahfuzur RahmanNo ratings yet

- 30m-210-10EPA V1 InfoDocument3 pages30m-210-10EPA V1 InfoMahfuzur RahmanNo ratings yet

- Chapter 1Document8 pagesChapter 1Mahfuzur RahmanNo ratings yet

- Table 6.11.1 (6) - CDocument2 pagesTable 6.11.1 (6) - CMahfuzur RahmanNo ratings yet

- 40M Base Plate 210kph 1m2 V1.0Document34 pages40M Base Plate 210kph 1m2 V1.0Mahfuzur RahmanNo ratings yet

- Table 6.11.1 Species For Constructional PurposesDocument3 pagesTable 6.11.1 Species For Constructional PurposesMahfuzur RahmanNo ratings yet

- Tower Calculation 5Document92 pagesTower Calculation 5Mahfuzur RahmanNo ratings yet

- Crep MNSRK37Document6 pagesCrep MNSRK37Mahfuzur RahmanNo ratings yet

- 40M Base Plate 210kph 1m2 V1.0Document34 pages40M Base Plate 210kph 1m2 V1.0Mahfuzur RahmanNo ratings yet

- New Chattri Hall Edited by Mahfuz 22.06.2021Document501 pagesNew Chattri Hall Edited by Mahfuz 22.06.2021Mahfuzur RahmanNo ratings yet

- Chapter 12Document33 pagesChapter 12Mahfuzur RahmanNo ratings yet

- Chapter 11Document38 pagesChapter 11Mahfuzur RahmanNo ratings yet

- Chapter 10 (6) - BDocument52 pagesChapter 10 (6) - BMahfuzur RahmanNo ratings yet

- Chapter 10 (6) - CDocument44 pagesChapter 10 (6) - CMahfuzur RahmanNo ratings yet

- Chapter 7Document23 pagesChapter 7Mahfuzur RahmanNo ratings yet

- Chapter 9Document23 pagesChapter 9Mahfuzur RahmanNo ratings yet

- Chapter 6Document78 pagesChapter 6Mahfuzur RahmanNo ratings yet

- Chapter 10 (6) - ADocument63 pagesChapter 10 (6) - AMahfuzur RahmanNo ratings yet

- Chapter 5Document24 pagesChapter 5Mahfuzur RahmanNo ratings yet

- Chapter 4Document46 pagesChapter 4Mahfuzur RahmanNo ratings yet

- Chapter 4Document46 pagesChapter 4Mahfuzur RahmanNo ratings yet

- Chapter 3Document28 pagesChapter 3Mahfuzur RahmanNo ratings yet

- Chapter 2Document69 pagesChapter 2Mahfuzur RahmanNo ratings yet

- Chapter 2Document69 pagesChapter 2Mahfuzur RahmanNo ratings yet

- Chapter 5Document24 pagesChapter 5Mahfuzur RahmanNo ratings yet

- Appendix ADocument13 pagesAppendix AMahfuzur RahmanNo ratings yet

- Chapter 1Document24 pagesChapter 1Mahfuzur RahmanNo ratings yet

- Chapter 3Document28 pagesChapter 3Mahfuzur RahmanNo ratings yet

- Chapter 1Document24 pagesChapter 1Mahfuzur RahmanNo ratings yet

- AppendicesDocument14 pagesAppendicesMahfuzur RahmanNo ratings yet

- Koya University: (Viscosity & Yield Point)Document11 pagesKoya University: (Viscosity & Yield Point)zazoNo ratings yet

- Compatibility and SuperpositionDocument10 pagesCompatibility and SuperpositionAngela Christine DensingNo ratings yet

- Word Design of ProjectDocument381 pagesWord Design of ProjectSantosh Basnet100% (1)

- 08 - Friction Pendulum Seismic Isolation BearingsDocument4 pages08 - Friction Pendulum Seismic Isolation BearingsciscoNo ratings yet

- Asme B31.4 - Allow Stress Sa - Factor FDocument1 pageAsme B31.4 - Allow Stress Sa - Factor Fjoaquin torrano veraNo ratings yet

- Column N Foundation DesignDocument26 pagesColumn N Foundation DesignSA023No ratings yet

- 500dia PileDocument49 pages500dia PileHemant SonawadekarNo ratings yet

- Upheaval Buckling CalculationDocument6 pagesUpheaval Buckling Calculationheldermanuel100100% (2)

- Engineering Materials and Testing IIDocument37 pagesEngineering Materials and Testing IILorie Mae BelloNo ratings yet

- Simply supported beam bending and shear verificationDocument7 pagesSimply supported beam bending and shear verificationmn4webNo ratings yet

- Design of Column and Lacings for Axial and Bending LoadsDocument160 pagesDesign of Column and Lacings for Axial and Bending LoadsVignesh VenkatasubramanianNo ratings yet

- Torsion, Bending and Buckling of Steel Beams by Trahair 1997Document6 pagesTorsion, Bending and Buckling of Steel Beams by Trahair 1997fahmi aballiNo ratings yet

- Strip Footing and Beam Design at Grid C-CDocument3 pagesStrip Footing and Beam Design at Grid C-CSujal MaharjanNo ratings yet

- Hagia Sophia Earthquake AnalysisDocument15 pagesHagia Sophia Earthquake AnalysisMudith RakhechaNo ratings yet

- Nav Composites 02-Flexture Concrete CompositesDocument29 pagesNav Composites 02-Flexture Concrete Compositesendah anggraeniNo ratings yet

- Buckling of Woven Fabric - NewDocument27 pagesBuckling of Woven Fabric - NewShovan Das100% (3)

- Steel MidtermDocument3 pagesSteel MidtermDave JarangueNo ratings yet

- Hinge DesignDocument2 pagesHinge Designpare222No ratings yet

- Chapter One: Introduction, Materials and Design ConceptsDocument12 pagesChapter One: Introduction, Materials and Design Conceptsdilnessa azanawNo ratings yet

- 113 - Pounding - Croatia 2012 Civil-Comp - RCB and Khatami - Final PaperDocument15 pages113 - Pounding - Croatia 2012 Civil-Comp - RCB and Khatami - Final PaperRui CbNo ratings yet

- Dynamic Practical Lab Report Cantilever BeamDocument17 pagesDynamic Practical Lab Report Cantilever BeamKam Chee Chin100% (3)

- Introduction to Prestressed Concrete TechniquesDocument20 pagesIntroduction to Prestressed Concrete TechniquesHezb KhanNo ratings yet

- Som MCQDocument14 pagesSom MCQVignesh Vicky0% (2)

- Structural Design of Transfer StructuresDocument125 pagesStructural Design of Transfer StructuresTùng HìNo ratings yet

- Analysis and Design of DRBDocument13 pagesAnalysis and Design of DRBACES JEEL CENDA�ANo ratings yet

- A Review of Elastic-Plastic Contact MechanicsDocument30 pagesA Review of Elastic-Plastic Contact MechanicspeaceshadyNo ratings yet

- Beam Design and Vibration AnalysisDocument9 pagesBeam Design and Vibration AnalysisjatinNo ratings yet

- Von Mises TrescaDocument6 pagesVon Mises TrescaAlvin Garcia PalancaNo ratings yet

- 30 Non-Metallic Pipe Design CalculationDocument12 pages30 Non-Metallic Pipe Design CalculationRiyan EsapermanaNo ratings yet

- Simulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachDocument15 pagesSimulation of Crack Propagation in API 5L X52 Pressurized Pipes Using XFEM-Based Cohesive Segment ApproachAmmarul NafikNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (137)

- Advanced Modelling Techniques in Structural DesignFrom EverandAdvanced Modelling Techniques in Structural DesignRating: 5 out of 5 stars5/5 (3)

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Green Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsFrom EverandGreen Roofs, Facades, and Vegetative Systems: Safety Aspects in the StandardsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Marine Structural Design CalculationsFrom EverandMarine Structural Design CalculationsRating: 4.5 out of 5 stars4.5/5 (13)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Built: The Hidden Stories Behind Our StructuresFrom EverandBuilt: The Hidden Stories Behind Our StructuresRating: 4 out of 5 stars4/5 (27)

- Design and Construction of Soil Anchor PlatesFrom EverandDesign and Construction of Soil Anchor PlatesRating: 5 out of 5 stars5/5 (1)

- Pile Design and Construction Rules of ThumbFrom EverandPile Design and Construction Rules of ThumbRating: 4.5 out of 5 stars4.5/5 (15)

- Climate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingFrom EverandClimate Adaptation Engineering: Risks and Economics for Infrastructure Decision-MakingNo ratings yet

- Piezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringFrom EverandPiezocone and Cone Penetration Test (CPTu and CPT) Applications in Foundation EngineeringNo ratings yet

- Advanced Design Examples of Seismic Retrofit of StructuresFrom EverandAdvanced Design Examples of Seismic Retrofit of StructuresRating: 1 out of 5 stars1/5 (1)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- Bridge Engineering: Classifications, Design Loading, and Analysis MethodsFrom EverandBridge Engineering: Classifications, Design Loading, and Analysis MethodsRating: 4 out of 5 stars4/5 (16)

- 3D Concrete Printing Technology: Construction and Building ApplicationsFrom Everand3D Concrete Printing Technology: Construction and Building ApplicationsNo ratings yet

- Matrix Methods for Advanced Structural AnalysisFrom EverandMatrix Methods for Advanced Structural AnalysisRating: 5 out of 5 stars5/5 (1)

- Offshore Pipelines: Design, Installation, and MaintenanceFrom EverandOffshore Pipelines: Design, Installation, and MaintenanceRating: 4.5 out of 5 stars4.5/5 (2)

- Pipeline Planning and Construction Field ManualFrom EverandPipeline Planning and Construction Field ManualRating: 5 out of 5 stars5/5 (3)

- Experiment and Calculation of Reinforced Concrete at Elevated TemperaturesFrom EverandExperiment and Calculation of Reinforced Concrete at Elevated TemperaturesRating: 5 out of 5 stars5/5 (2)