Professional Documents

Culture Documents

Turbine Method Statement

Uploaded by

SiroCivilCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turbine Method Statement

Uploaded by

SiroCivilCopyright:

Available Formats

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

CONTRACT NO:

LOCATION / FACILITY : TURBINE AREA

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

S.

No

ACTIVITY

PREPARATION

FOR

INSTALLATION

EQUIPMENTS /

TOOLS

REQUIRED

SAFETY

PRECAUTIONS

WORK

SEQUENCE

PROCEDURE

1.

2.

3.

1.

2.

3.

4.

5.

6.

1.

2.

3.

1.

2.

3.

4.

DETAIL WORK

SECOND

SHIPMENT

REMARKS

Cleaning location area project

Preparation equipment scaffolding

Preparation of materials that will be done

Scaffolding

Body harness

Stairs for level working

Helmet

Safety shoes

Glasses

Perform safety talk before doing the work

Using of body harnes for working level

Use of safety shoes to avoid because of the nails and slippery

conditions

leveling and compacting the soil at the location of turbines

Installation of peri material to be used as support of form work

Instalation of rebar work column and beam concrete work be done

before casting

Do the work of casting concrete the columns and beams

DETAILED WORK SEQUENCE

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 1 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : TURBINE AREA

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

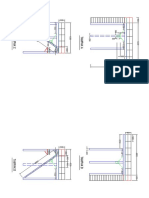

1. Column Work :

Fabrication of steel formwork concrete column and the binding rebar

site prior to work around the turbine installation.

Installation of rebar steel column assemblies that have been created

and then removed using a crane mobile to the location of the turbine

to be installed.

After reinforcement steel columns installed then do the work

formwork column removal using crane mobile to do the work

strengthened formwork column.

After work steel rebar and column formwork is installed and then do

the job done checking the column casting.

2. Beam Work :

The first work is done prior to installation of scafolding and working

steel rebar form work beam.

Second step after the completion of the working is the installation of

scafolding that serves as a peri formwork beam support of the

turbine.

Assembly of steel rebar beams carried on top of the column, so do

safety by using a body harness in doing the steel rebar working on

the turbine installation to prevent falls from height at the location of

the turbine.

Implementation of the beam and floor molding using a hanging

concrete basket to a crane of capacity 50 ton.

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 2 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : TURBINE AREA

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 3 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

LOCATION / FACILITY : TURBINE AREA

CONTRACT NO:

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 4 of 5

JOB METHOD STATEMENT

PROJECT TITLE : KARIANGAU CFSPP 2 X 15 MW

CONTRACT NO:

LOCATION / FACILITY : TURBINE AREA

DATE :

NAME OF CLIENT : PT KARIANGAU POWER

NAME OF SUBCONTRACTOR (S) : PT DUTA JASA KONSTRUKSI

JOB / ACTIVITIY :

Prepared By: PT AE MHS

Reviewed By : PT AE MHS

Approved By :

Signature

Signature

Signature

Name

Name

Name

Date

Date

Date

Reviewed By :

Signature

Name

Date

Reviewed By :

Signature

Name

Date

Reviewed By :

Signature

Name

Date

PT AE MATERIAL HANDLING SYSTEMS

Ref: AE-JMS-001

Page 5 of 5

You might also like

- Pump Room Method StatementDocument5 pagesPump Room Method StatementSiroCivilNo ratings yet

- Method Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneDocument14 pagesMethod Statement For The, Gulf Eagle Project: Installation, Commissioning & Load Testing of CraneFAYIZNo ratings yet

- Fire Hose Rack & Reel Testing ProcedureDocument2 pagesFire Hose Rack & Reel Testing ProcedureDong VanraNo ratings yet

- Method Statement For The Installation of MCC RoofDocument1 pageMethod Statement For The Installation of MCC RoofAmb Patrick OghateNo ratings yet

- Method Statement Water StorageDocument2 pagesMethod Statement Water StorageAzmi Fauzi100% (5)

- Surface GI Conduit Installation Method StatementDocument4 pagesSurface GI Conduit Installation Method StatementJaneNo ratings yet

- Method Statement For Lifting Cryognic TankDocument5 pagesMethod Statement For Lifting Cryognic TankYawar QureshiNo ratings yet

- Installation Method StatementDocument6 pagesInstallation Method StatementgururajNo ratings yet

- Multiplex Vertical Structures Method StatementDocument7 pagesMultiplex Vertical Structures Method StatementAdel SaqqaNo ratings yet

- Zee-Method Statement For Construction Steel Platform ErectionDocument8 pagesZee-Method Statement For Construction Steel Platform Erectionzeeshansheikh7No ratings yet

- Method Statement For Installtion of AgitatorsDocument17 pagesMethod Statement For Installtion of AgitatorsMurali MuvvalaNo ratings yet

- Install Insulated CladdingDocument16 pagesInstall Insulated CladdingfabinNo ratings yet

- Installation of Rockwool InsulationDocument8 pagesInstallation of Rockwool InsulationHSE RHINo ratings yet

- Procedure Installation of Grounding & Lightning System - LABUAN BAJO PDFDocument9 pagesProcedure Installation of Grounding & Lightning System - LABUAN BAJO PDFWika Djoko ONo ratings yet

- 3.1method Statment For Installation of Fire Protection System FinalDocument31 pages3.1method Statment For Installation of Fire Protection System Finalمقاول تكييف كهرباء وصحيNo ratings yet

- Method Statement For PCW Piping (Tool Install)Document4 pagesMethod Statement For PCW Piping (Tool Install)amg007No ratings yet

- Tank Erection Procedure GuideDocument5 pagesTank Erection Procedure Guidegeorge israelNo ratings yet

- Method StatementDocument4 pagesMethod StatementRichmond SantiagoNo ratings yet

- MOS For Underground Pipe Water InstallationDocument2 pagesMOS For Underground Pipe Water InstallationMukhlish AkhatarNo ratings yet

- Method Statement Reticulation PipeDocument5 pagesMethod Statement Reticulation PipeTaqiuddinHarithNo ratings yet

- Resource Deployment Plan - HehDocument2 pagesResource Deployment Plan - HehMyjaz Jaz100% (1)

- Method Statement Piping Works DABBIYADocument11 pagesMethod Statement Piping Works DABBIYAsivaparthiban100% (3)

- Metode Erection Stack & Chimney (Compatibility Mode) PDFDocument15 pagesMetode Erection Stack & Chimney (Compatibility Mode) PDFedn_mj1645No ratings yet

- ERECTION & INSTALLATION PROCEDURE ClarifierDocument23 pagesERECTION & INSTALLATION PROCEDURE ClarifierMohammad IqbalNo ratings yet

- 03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineDocument6 pages03 Dismantling of Existing Sym & Installation of New AHU With Pipe LineHimanshu NiveriyaNo ratings yet

- Underground HDPEDocument9 pagesUnderground HDPEMamado099No ratings yet

- Unloading Material Method StatementDocument4 pagesUnloading Material Method StatementPaul LadjarNo ratings yet

- Installation Of Ductile Iron Flange Type Joint MethodDocument10 pagesInstallation Of Ductile Iron Flange Type Joint MethodshahidNo ratings yet

- Building Maintenance MethodDocument7 pagesBuilding Maintenance Methodamirul8686No ratings yet

- Method Statement For Water FillDocument5 pagesMethod Statement For Water FillUmair Awan0% (1)

- MS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1Document5 pagesMS FOR INSTALLATION OF TOWER CRANE BETOX-200 Rev 1sattiNo ratings yet

- Quality Plan Method StatementDocument10 pagesQuality Plan Method Statementjamie542350% (2)

- Removing and Installing Underground Storage TanksDocument7 pagesRemoving and Installing Underground Storage TanksM Waqas Habib100% (1)

- Method Statement Log-CivilDocument1 pageMethod Statement Log-CivilDia AjjouriNo ratings yet

- METHOD STATEMENT For INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsDocument6 pagesMETHOD STATEMENT For INSTALLATION of PVC Conduits and Accessories in The Concrete Slabs, Columns, Block Works and Concrete WallsYoke Shu100% (1)

- Method of Statement For HDPE Pipe InstallationDocument2 pagesMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- WMS 001 Method Statement - Store and Office ConstructionDocument5 pagesWMS 001 Method Statement - Store and Office ConstructionSalwyn Lopis100% (1)

- Method Statement for Fabrication, Installation and Testing of Piping WorksDocument31 pagesMethod Statement for Fabrication, Installation and Testing of Piping WorksNaveed Ahmed Get-Info100% (1)

- Method Statement Steel Structure 1 4 Meg PDFDocument26 pagesMethod Statement Steel Structure 1 4 Meg PDFemeka2012No ratings yet

- Method for Removing Fire Fighting Pipes from Existing NetworkDocument1 pageMethod for Removing Fire Fighting Pipes from Existing NetworkAamer Abdul MajeedNo ratings yet

- Method Statement (PAIP 400)Document4 pagesMethod Statement (PAIP 400)Shafiq MustapaNo ratings yet

- APPENDIX 1 Issues For Method Statements in Industrial Roof WorkDocument3 pagesAPPENDIX 1 Issues For Method Statements in Industrial Roof WorkJulianna BakerNo ratings yet

- 16 0105 Construction Method StatementDocument3 pages16 0105 Construction Method StatementChun KedNo ratings yet

- MOS of Installation Rise FloorDocument13 pagesMOS of Installation Rise FloorHussam WaleedNo ratings yet

- Method Statement HDPE PDFDocument1 pageMethod Statement HDPE PDFshameemNo ratings yet

- Hydro TestDocument15 pagesHydro TestShabbir HussainNo ratings yet

- P610 Beinn Eagagach Hydroelectric Scheme Construction MethodDocument14 pagesP610 Beinn Eagagach Hydroelectric Scheme Construction MethoddjgiumixNo ratings yet

- Method Statement - Ventilation Fans-Done-3Document3 pagesMethod Statement - Ventilation Fans-Done-3sarmad00950% (2)

- Method Statement For Roofing Siding 2Document9 pagesMethod Statement For Roofing Siding 2mustafa100% (1)

- PIPE INSTALLATION MATERIALSDocument29 pagesPIPE INSTALLATION MATERIALSjanithNo ratings yet

- Method Statement of Installing I-BeamDocument1 pageMethod Statement of Installing I-BeamfaizbukhariNo ratings yet

- Method Statement for Footing Concrete PourDocument4 pagesMethod Statement for Footing Concrete PourRizky V 'dHee'No ratings yet

- Aboadze Power Project Pylon ErectionDocument7 pagesAboadze Power Project Pylon ErectionCobbinah Mark0% (1)

- Pressure Part Method StatementDocument49 pagesPressure Part Method StatementSerkan Yaşa67% (3)

- PML-D-C-50121-1 - Method of Satement Procedure For Seal Pit Work - Update Nov. 11 2014Document37 pagesPML-D-C-50121-1 - Method of Satement Procedure For Seal Pit Work - Update Nov. 11 2014Abdullah Mukhul Jihad100% (1)

- Jeffrey G. Resaba: Employment BackgroundDocument3 pagesJeffrey G. Resaba: Employment BackgroundHarry DemeterioNo ratings yet

- 007-MS For Structural Steel Assembly Warehouse, Workshops PDFDocument25 pages007-MS For Structural Steel Assembly Warehouse, Workshops PDFKöksal PatanNo ratings yet

- Joint Coating Application & Pipe Coating ProcedureDocument7 pagesJoint Coating Application & Pipe Coating Proceduregst ajahNo ratings yet

- ERSS - Method Statement of ConstructionDocument45 pagesERSS - Method Statement of ConstructionChoon Ewe LimNo ratings yet

- Project at A Glance: 3 X 660 MW Boilers and Auxiliary InstallationDocument16 pagesProject at A Glance: 3 X 660 MW Boilers and Auxiliary InstallationSumit Agrawal100% (1)

- Batching Plant Drawing Model 2Document1 pageBatching Plant Drawing Model 2SiroCivilNo ratings yet

- Batching Plant Drawing Model 2Document1 pageBatching Plant Drawing Model 2SiroCivilNo ratings yet

- Batching Plant Drawing Model 1Document1 pageBatching Plant Drawing Model 1SiroCivilNo ratings yet

- Pipe Rack Foundation DocumentsDocument3 pagesPipe Rack Foundation DocumentsSiroCivilNo ratings yet

- Mix Design 1 m3 Adukan Beton: Semen: 200 KG Pasir/Aggregat Halus: 1036.8 KG Aggregate Kasar: 1537.92 KG Air: 96 KGDocument1 pageMix Design 1 m3 Adukan Beton: Semen: 200 KG Pasir/Aggregat Halus: 1036.8 KG Aggregate Kasar: 1537.92 KG Air: 96 KGSiroCivilNo ratings yet

- Design Basis Report For Civil and Architectural Engineering PDFDocument8 pagesDesign Basis Report For Civil and Architectural Engineering PDFVijai Prasath100% (1)

- Elliott Davis Ferreira Mahdi Gorgun Semi Rigid - Structural Eng Part 1Document14 pagesElliott Davis Ferreira Mahdi Gorgun Semi Rigid - Structural Eng Part 1Luciana Barros - LeonardiNo ratings yet

- Njagi Substructures Boq 2020Document76 pagesNjagi Substructures Boq 2020michaelNo ratings yet

- Chapter One 1.1 Background of StudyDocument39 pagesChapter One 1.1 Background of StudyODII EMMANUELNo ratings yet

- Description Quantity SL NO Total Cost (INR)Document8 pagesDescription Quantity SL NO Total Cost (INR)kiran m vNo ratings yet

- Catalogue 2020 Distribution PDFDocument17 pagesCatalogue 2020 Distribution PDFBrian BryanNo ratings yet

- Slab BridgesDocument115 pagesSlab BridgesAnujith K Babu100% (1)

- Bridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Document8 pagesBridge Proper SL Item of Work Cl. No. of Unit Qty No. Mort & H'S Specification 1 2 3 4 5Hoque joynulNo ratings yet

- Topic 3Document25 pagesTopic 35p6zzgj4w9No ratings yet

- Design Guide - Users Guide - Design and Load Rating PDFDocument206 pagesDesign Guide - Users Guide - Design and Load Rating PDFGustavo Solar100% (2)

- Astm C12Document7 pagesAstm C12Karthi Keyan100% (1)

- Evaluation of Deflection in CFRP Reinforced HSC I-BeamsDocument16 pagesEvaluation of Deflection in CFRP Reinforced HSC I-BeamspadashtNo ratings yet

- SD Reinforcing Mesh Q131Document12 pagesSD Reinforcing Mesh Q131Mohand EliassNo ratings yet

- 3913 Se 2013Document1 page3913 Se 2013Victor IkeNo ratings yet

- Pcw-Ts-Pcs Design Process 2017Document89 pagesPcw-Ts-Pcs Design Process 2017Marlon ReonicoNo ratings yet

- Construction Estimate FormDocument16 pagesConstruction Estimate Formjerichochan88% (8)

- 72.core Cut Reference SP-24Document1 page72.core Cut Reference SP-24DMJ NagpurNo ratings yet

- DPWH Blue Book Volume 3Document178 pagesDPWH Blue Book Volume 3Kevin John MaximoNo ratings yet

- RC Building Structural DesignDocument3 pagesRC Building Structural DesignJaybert DumaranNo ratings yet

- Simplified DesignDocument176 pagesSimplified DesignKofi Daniel100% (2)

- XXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeDocument10 pagesXXXXXXXXXXXXXXXXXXXXXXXXXXXXXX: Method Statement: Construstion of ManholeJunaid MirNo ratings yet

- Sustainable, Rapid and Affordable Mass Housing Using GFRG' PanelsDocument5 pagesSustainable, Rapid and Affordable Mass Housing Using GFRG' PanelsMHd SaeeNo ratings yet

- Design Calculations (Singly-Reinforced Beam Design)Document4 pagesDesign Calculations (Singly-Reinforced Beam Design)John Kevin CruzNo ratings yet

- Calculation Report For Post Anchor BoltDocument7 pagesCalculation Report For Post Anchor BoltNgo Tien VinhNo ratings yet

- Buet Steel Article On RRMDocument10 pagesBuet Steel Article On RRMElafanNo ratings yet

- Number:: Evaluation SubjectDocument22 pagesNumber:: Evaluation SubjectKevin ChanNo ratings yet

- Method Statement for RCUD ConstructionDocument9 pagesMethod Statement for RCUD ConstructionFa DylaNo ratings yet

- Handout 3 12Document15 pagesHandout 3 12Raphael FreitasNo ratings yet

- S-1 General NotesDocument1 pageS-1 General NotesEngr. Robnick PaduaNo ratings yet

- Reinforced Concrete Structures Lectures: Strut and Tie & Yield Line MethodsDocument96 pagesReinforced Concrete Structures Lectures: Strut and Tie & Yield Line MethodsAnonymous cKV7P2magXNo ratings yet