Professional Documents

Culture Documents

Otel Cu Bor Care Poate Fi Calit

Uploaded by

Miha ElaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Otel Cu Bor Care Poate Fi Calit

Uploaded by

Miha ElaCopyright:

Available Formats

Otelcuborcarepoateficalit

Otelul cu bor care poate fi calit din clasele B 13S, B 24 si B 27 poate fi calit prin intermediul tratamentului cu caldura.

Proprietatilemecanicealeoteluluicalitcuborilfacextremderezistentlauzuracauzatadeabraziunesiutilmaialespentru

aplicatiile profilate de rezistenta ridicata, marind durata de viata a structurilor si economisind costurile referitoare la

abraziunesimediulinconjurator.

Livratinstarelaminatalacaldculungimidetaieresiplacigroase.Serviciileprefabricatedisponibilepentruotelurilecubor

sunttaierea,indoirea,fatetareapentrusudare.

Aplicatii:

Placaresipiesedeschimbpentruutilajesiechipamente

Marginileplacilor

Lamesilanturi

Unelte

Transportoareelicoidale

Placiuzate

Lameleventilatorului

Informatiiledinwebsitetulnostrusuntcorecteinconformitatecupracticilesicunostintelenoastre.Comapanianuisiasumaniciunprejudiciu

cauzatdirectsauindirectcarezultataunoreroriinaplicatiiledinacestsitesaudininformatiilepublicate.Oricum,facemeforturisustinutesi

continuedeaaiguraoacuratetecatmaibunaainformatiilorprezentatesideaceeanerezervamdreptuldeafacemodificari.

Copyright2015SSABoritsaffiliates.AllRightsReserved.

Documentprintedon14.09.2015

www.ruukki.ro

Otelcuborcarepoateficalit

Dimensiuni

Formaprodusului

LungimidetaiereLivratinstarelaminatasauinstaredecapata.Inplus,bobinelesibenziletaiatepotfilivratedacase

specificaseparat.

PlacigroaseLivratinstarelaminatasauinstareaincareseaflalaparasireaatelierului.

Lungimidetaierecumarginicuimperfectiuni.

Clasedeotel

Grosimemm

Latimemm

Lungimem

B13S,B24,B27

2.513

10001860

212

Latimeamaximaafiecareiclasedeoteldepindedegrosime.

Placigroase

Clasedeotel

Grosimemm

Latimemm

Lungimem

B13S

514

19013300

215

B24

860

19013300

215

B27

680

19013300

215

Latimeamaximasiminima,precumsilungimeamaximapentrufiecareclasadeoteldepinddegrosimeaplacii.

Tolerante

Tolerantedimensionalesideforma:

Lungimidetaiere:EN10051

Placigroase:EN10029,ClasaA

Calitateasuprafetei

Produsedinplaci:EN101632ClasaA3.Suduradeconditionarenuesteutilizatainproducereaotelurilorcubor.

Lungimiledetaieresuntlivrateinstarelaminatasaudecapatasiunsa.

Placilesuntlivrateinstarelaminatasauinstareaincareseaflalaparasireaatelierului.

Proprietati

Numerele13,24si27dindenumiresereferalacontinutulmediudecarbondinasutapartedintrunprocentdinaceste

clase. Proprietatile excelente de tratament cu caldura fac otelul cu bor un material profilat ecologic pentru o serie de

aplicatii.

Testareamaterialelor

Proprietatilemecanicealeotelurilorcubornusunttestate.

Proprietatimecanicetipice

Clasedeotel

Limitalacurgere

ReHMPa

Rezistentalaintindere

RmMPa

Alungirea

A 5%

DuritateHBW

B13S

aprox.450

aprox.570

25

aprox.160

B24

aprox.400

aprox.600

25

aprox.160

B27

aprox.420

aprox.620

22

aprox.170

Otelcuborcarepoateficalit

Compozitiachimicasimicrostructura

Microstructura tipica in stare laminata la cald este feriticaperlitica. Borul (in medie 0.002%) si carbonul sunt aliaje care

contribuieinmarepartelacapacitateabunadecaliresilaproprietatiletratamentuluicucalduraaleotelurilorcubor.

Continut%(analizaasarjei)

Clasedeotel

Si

Mn

Cr

Mo

B13S1)

0.13

0.25

0.80

0.9

0.25

0.002

B24

0.24

0.25

1.20

0.3

0.002

B27

0.27

0.25

1.20

0.3

0.002

Aluminiul(Al)si/sautitanul(Ti)suntutilizatecamicroaliajepentruimbinareanitrogenului(N).

1)PentrulungimiledetaiereC=0.14Si=0.20Mn=1.10Cr=0.8siB=0.002.

Carbonechivalent(CEV),valoritipicepentrufiecarevariatiedegrosimesiformaaprodusului

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

Clasedeotel

Grosimemm

CEV

Produs

B13S

2.513

0.51

Lungimedetaiere

B24

2.513

0.51

Lungimedetaiere

B24

860

0.51

Placa

B27

2.513

0.54

Lungimedetaiere

B27

680

0.54

Placa

Pentruaoptimizaproceduradesudare,valorilecarbonuluiechivalentspecificesarjeisuntindicateindocumentuldeinspectie.

Serviciideprefabricatie

Planurilelargialeplaciisifasiei

Planurilelargialeplaciisifasieisuntexactedinpunctdevederedimensionalsigatadeasamblare.Planurilelargimaresc

procesuldeproductiealstructurilordeotelsievitautilizareainutiladematerial.

Formeplatetaiate

Formeleplatetaiatesevormicsoraintimpulinstalarii.Clientulvaprimicomponentelegatadeinstalare.Astfel,potfievitate

costurileinutilepentrumaterialesidepozitare.Dacasespecificalaplasareacomenzii,produselesuntlivrateasacumies

dinatelier,oblicesiindoite.

Fatetare

Lungimiledetaieredepreciziesiplaciletaiatedepreciziecumarginifatetatesuntcomponentecarepotfilivratedirectla

loculdeinstalare,lucrucareeconomisestetimpsireducecosturiledetransportsidedepozitare.anturilededimensiuni

exacteasigurasuduraautomataneintreruptasimontaj.

Produseindoitedinplacadeotel

Produsele indoite din placa de otel sunt componente care sunt gata sa fie livrate la locul de instalare, lucru benefic din

punct de vedere al programului, precum si al costurilor de transport si depozitare. Daca este necesar, produsele pot fi

comandate in starea la iesire din atelier, dotate cu fatete de sudare si taiate in forme. Premarcarea pieselor de instalat

faciliteazainstalarea.

Otelcuborcarepoateficalit

Processinginstructions

Welding

Boron steels can be welded in the hotrolled or hardened condition. When choosing the welding consumables, the most

importantfactoriswhetherthesteelistobeweldedbeforeorafterhardening.Inallcases,theuseoflowhydrogen,basic

fillermaterialsisrecommended,inordertoensurethatthelevelofdetrimentalhydrogenremainslow.Thesurfacesofthe

weldgroovemustbedryandclean.Inaddition,therecommendationsofthemanufacturermustbeadheredtoregarding

thestorage,useandpossibleredryingoftheconsumables.

Weldingbeforehardening

The normal instructions for the welding of highstrength steels also apply in the welding of boron steels in the hotrolled

condition.Thebestresultisobtainedusinglowhydrogenweldingconsumablesandmethods.Thebestresultisobtained

whentheweldmetalhydrogencontentHDisamaximumof5ml/100g(ENISO3690).

Carbonequivalent(CEV),typicalvaluesforeachthicknessrangeandproductform

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

Steelgrade

Thicknessmm

CEV

Product

B13S

2.513

0.51

Cutlength

B24

2.513

0.51

Cutlength

B24

860

0.51

Plate

B27

2.513

0.54

Cutlength

B27

680

0.54

Plate

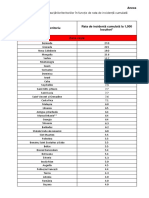

RecommendedworkingtemperaturesforweldingofhotrolledboronsteelsC(EN10112)

The advantages of common lowalloy welding consumables compared to the highalloyed and highstrength welding

consumablesaretheir lowerhardenability, reducedneedforpreheating andlowerprice. When hardened, theweldmetal

produced using normal filler materials is almost as hard as if using highstrength filler materials, but the depth of the

hardeningsmaller.Highalloyedconsumablesmustbeusedwhenadeephardenableweldmetalisrequired,orwhenwear

Otelcuborcarepoateficalit

resistanceisrequiredfromthefillermaterialintheweldedcondition.Theuseofhighalloyedconsumablescanusuallybe

limitedtothesurfacelayers.Thewearofsoftfillermaterialsmaybereducedbythelocationoftheweld.

Weldingafterhardening

The welding instructions given for Raex abrasion resistant steels in the Raex datasheet can be used in the welding of

hardenedboronsteels.Raex400canbeusedforhardenedB13SandhardenedB24andRaex500forhardenedB27.

Whenweldingboronsteelsinthehardenedcondition,anarrowbandofmaterialsofterthanthebasematerialiscreatedin

theheataffectedzone.Thewidthandhardnessofthisbanddependsontheweldingenergyandthethicknessoftheplate.

Thesofterbandinweldsmadeusingmediumenergylevelsdoesnotusuallyaffectthedurabilityoftheweld.Lowhydrogen,

basicconsumablesmustbeusedinordertoensurethatthelevelofdetrimentalhydrogenremainslow.Structureswelded

afterhardeningarenotusuallysubjectedtofurtherheattreatmentasthismayweakentheabrasionresistanceofhardened

steelcomponents.

Downloadinformationaboutweldinghotrolledsteels

Heattreatment,hardeningandtempering

Thanks to their specific alloying, boron steels have a variety of metallurgical properties that can be utilised in hardening.

Hardeningisaheattreatmentprocessthatconsistsofheating,holdingandrapidcooling.Thesteelisheatedinorderto

changetheferriticperliticmicrostructuretofullyaustenitic.Holdingtimeshouldbeappropriateforsteelthicknesstoobtain

homogenous temperature. Austenitization temperature for these steels is close to 910 930C. Rapid cooling from

austenitization temperature is called quenching. The purpose of quenching is to obtain a martensitic microstructure.

Hardenedboronsteelsarehard,strongandwearresistantstructuralmaterials.

In certain applications, hardened steel as such is only an intermediate product. The manufacture of such applications

includes further tempering. Hardening and tempering can also be jointly called temper hardening (quenching+tempering),

which is carried out in order to turn the martensitic microstructure into tempered martensite with good tensile strength

properties.Mainpurposeoftemperingistoreleaseheatandstructuralstressesthatappearedduringquenching.Tempering

makes steel slightly softer the degree of softness depends on the tempering temperature, which is the most important

parameteraffectingthemechanicalpropertiesofsteel.A temperedhardenedsteelproducthasthedesiredcombinationof

tensilestrength,hardnessandstrength.Thehardnesstemperingcurveisanessentialtoolinthemetallurgicalutilisationof

boronsteels.

As indicated in the figure below, tempering at a temperature of 500 600C clearly improves impact strength and

elongationatbreak,whereastensilestrength,yieldstrengthandhardnessarelowerthanthoseofonlyquenched.

TypicalhardnesstemperingcurvesforthehardenedsteelgradesB13S,B24andB27attheannealing

temperatureof920C

Otelcuborcarepoateficalit

Typicalmechanicalpropertiesachievedinhardeningboronsteelswhenquenchedinthetwomostcommonmedia,

oilandwater

Steel

grade

Heattreatment

condition

Yield

strength

ReN/mm2

Tensile

strength

RmN/mm2

Elongation Hardness Impactstrength

A 5%

HBW

KV

tCKV

J

B13S

Hardened,

Oil

750

950

14

300

notempering

Water 900

1200

10

370

40

50

B24

Hardened,

Oil

1250

10

340

notempering

Water 1100

1500

430

40

20

B27

Hardened,

Oil

1000

1250

380

notempering

Water 1200

1600

460

40

20

850

Thevaluesgiveninthetableareaveragesatroomtemperature.Hardeningtemperatureused920C.

Note:Hardeningresultspresentedinthetableaboveandonthiswebpageonlygivegeneralinstructionsforthehardening

andotherheattreatmentofboronsteels.ThoseusinghardeningandthermallytreatingRuukkiboronsteelsarespecialists

in their own respective fields. Customers can obtain the desired microstructure and mechanical properties for their

hardened steel products by means of productspecific selection of tempering parameters. Expertise in ones own heat

treatmentprocesscreatesastrongbasisforthecompetitivenessandcommercialsuccessofourcustomersproducts.

Forming

The boron steel B 13S and B 24 grades in hotrolled and hardened condition can be cold formed at room temperature

(+20C)undernormalengineeringshopconditionsuptothethicknessof20mm.TheB27gradecanbeformedintheas

rolledcondition.Boronsteelinthehotrolledconditionismoreformablethanhardenedboronsteel,becauseitrequiresless

bendingforce.Theminimumbendingradiiforboronsteelsandrecommendationsforhotrolledandhardenedsteelshave

beenlistedinthetable.

Coldformabilityintheasrolledconditionandashardened,usingeitherwateroroilquenching

Thickness(mm)

2.5

5

Heattreatment

condition

Thesmallestallowableinsidebendingradius(mm)

B

13S

Hotrolled

10

18

21

24

30

48

Oilhardened

15

18

21

24

30

Waterhardened

20

24

28

32

B24

Hotrolled

15

24

28

Oilhardened

20

30

Waterhardened

25

B27 Hotrolled

(5)

6

(6)

7

(7)

8

(8)

10

(10)

12

(12)

14

(14)

16

(16)

18

(18)

20

48

40

60

32

40

60

70

80

90

100

35

40

50

72

84

96

108

120

36

42

48

60

96

112

128

144

160

20

30

35

40

50

72

84

96

108

120

Oilhardened

Waterhardened

Flangingirrespectiveofrollingdirection.ItisrecommendedtocontactRuukki'sTechnicalCustomerServicepriortocoldformingofover20mmthickplates

andhardenedsteelgradeB27.

Otelcuborcarepoateficalit

Platesthickerthan20mmmustbepreheatedtherecommendedformingtemperatureis150200C.Preheatingimproves

the deformation properties of the plate and guarantees successful bending. Special care must always be taken when

formingthickorhardenedplates.

Highqualitytechnologyshouldbeusedforforming,aswearoftools,insufficientlubrication,surfacedefectsonplatesand

burrs in cut edges will impair forming quality. A basic requirement for successful flanging and bending is that, prior to

commencingwork,aplatethathasbeenstoredinacoldatmosphereisallowedtowarmupthoroughlytoroomtemperature

(+20C).

Flamecutting

Specialcaremustbetakenintheflamecuttingofboronsteelsparticularlysowhencuttinghardenedand/orthickplates.

Prior to commencing work, a plate that has been stored in a cold atmosphere is allowed to warm up thoroughly to room

temperature(+20C).Excessivehardeningcanbepreventedbymeansofpreheatingtoraisetheworkingtemperature.Itis

recommendedtoraisetheworkingtemperaturewhentheplatethicknessisover10mmorwhencuttingsteelgradesB24

or B 27.The table gives the working temperatures recommended for hardened boron steels and boron steels in the hot

rolled condition. Steel grade B 13S does not require preheating even in the hardened condition, thanks to its low carbon

equivalentvaluesandsmallplatethicknesses.

RecommendedworkingtemperaturesBoronsteelsinhotrolledconditionorhardenedboronsteels

Steelgrade

Thicknessmm

WorkingtemperatureC

B24

1030

5075

B24

(30)60

75125

B27

1080

125175

B13Sdoesnot,eveninthehardenedcondition,requirepreheatingundernormalconditions.

Whenflamecuttinghardenedboronsteels,thehardnessoftheplatesdecreasesinareaswherethetemperatureexceeds

+200C. Softening is highlighted in the flame cutting of small components. In order to prevent excessive hardening, the

cooling of the cut area must not be accelerated externally on the contrary, the process should be slowed down, if

necessary,bycoveringtheplatewith,forexample,mineralwool.

Mechanicalcutting

Inthehotrolledconditionboronsteelscanbemechanicallycutinthesamewayasstructuralsteelsofthesamestrength

grade, although the wear on cutting blades may be slightly greater. The mechanical cutting of hardened boron steels is

challenging,asthehardnessofthesteelapproachesthatofthecuttingblades.B13SandB24canbecutusingheavy,

robust machines.The mechanical cutting of B 27 is recommended only with reservation, and then only for plates whose

thicknessislessthan10mm.Thehardnessofthecuttingbladesmustbegreaterthan53HRC.Mechanicalcuttingofsmall

componentsmustbeavoided.

Machining

Boronsteelsinthehotrolledconditioncanbemachinedinthesamewayasstructuralsteelsofthecorrespondingstrength

grade.Robustmachineryandhardmetalbitsarerecommendedforthemachiningofhardenedboronsteels.Boronsteel

platescanbedrilledwithhighspeedsteelbitsifthebitgeometryandcuttingfluidarecorrectlychosen.

Furtherinformationonprocessinginthermalcuttingandflamestraighteningdatasheetandinmechanicalcuttingdatasheet.

Occupationalsafety

Specialcaremustbetakeninallstagesofhandlingandworkshopprocessingofboronsteels.Safeworkingmethodsare

particularlyimportantinbending,flangingandcutting.Thehandlinginstructionsofthesteelsupplierandsafetyinstructions

oftheworkshopmustbeadheredtoindetail.Newemployeesmustreceiveappropriatetrainingbeforetheyareallowedto

processboronsteels.

Otelcuborcarepoateficalit

Comanda&livrarea

Conditiidelivrare

Laminatelacald

Documenteleinspectiei

Ruukkilivreazaotelulcuborimpreunacuasanumitulcertificatdeanaliza.

Alternativ,lacerereaclientului,oferimfieRaportuldeincercare2.2,fieCertificatdeinspectie3.1inconformitatecuEN

10204. Informatii generale de livrare pot fi gasite in documentele Marcaje si ambalare , Testare ultrasonica sau Conditii

generaledevanzare.DocumenteledecontrolsuntconformecuEN10204.

Informatiigeneraledelivrareaoteluluilaminatlacald

Thecontentofthisdocumenthasbeencreatedfromwebpagelastupdated31.08.2014

Echipelenoastredesuporttehnicsivanzarisuntladispozitiadumneavoastrapentrumaimulteinformatiidespreproduse.Accesatisectiunea

www.ruukki.ro/Contactatine

You might also like

- Anexa La HCNSU Nr. 77 Din 30.09.2021Document5 pagesAnexa La HCNSU Nr. 77 Din 30.09.2021simodinoNo ratings yet

- TaiereaDocument1 pageTaiereaMiha ElaNo ratings yet

- Conditii Start Up YourselfDocument22 pagesConditii Start Up YourselfMiha ElaNo ratings yet

- E 6. 8.3 SM 6.4Document8 pagesE 6. 8.3 SM 6.4Miha ElaNo ratings yet

- AnuntDocument3 pagesAnuntClaudiuNo ratings yet

- Catalog Gradina Max 2017Document33 pagesCatalog Gradina Max 2017Miha ElaNo ratings yet

- Ghid Peisagistica 2008Document0 pagesGhid Peisagistica 2008G_Chiorcea100% (3)

- Proiect Schema Sun 30.03.2018 SiteDocument20 pagesProiect Schema Sun 30.03.2018 Sitenicolicescu_claudiu5152No ratings yet

- Metodologie Elaborare Deviz General 2016.12.29Document8 pagesMetodologie Elaborare Deviz General 2016.12.29bya_idNo ratings yet

- Test Clasa A IxaDocument2 pagesTest Clasa A IxaMiha ElaNo ratings yet

- Savon de Marseille Fabrication SAVCOLBERTDocument2 pagesSavon de Marseille Fabrication SAVCOLBERTMiha ElaNo ratings yet

- Leroymerlin Catalog Leroy Merlin Mobilier Gradina 2017Document55 pagesLeroymerlin Catalog Leroy Merlin Mobilier Gradina 2017Miha ElaNo ratings yet

- Kika - Cos IndustrialDocument5 pagesKika - Cos IndustrialMiha ElaNo ratings yet

- Instructiunea 34Document2 pagesInstructiunea 34Miha ElaNo ratings yet

- Procedura Din 08.08.2016 PDFDocument21 pagesProcedura Din 08.08.2016 PDFMiha ElaNo ratings yet

- Ordin 3254Document27 pagesOrdin 3254Miha ElaNo ratings yet

- R.C sM6.4 Etapa2 S01 2016Document24 pagesR.C sM6.4 Etapa2 S01 2016Miha ElaNo ratings yet

- Product Catalogue - RO PDFDocument28 pagesProduct Catalogue - RO PDFcristeadanielaNo ratings yet

- Situatie Depuneri 30.04.2017Document5 pagesSituatie Depuneri 30.04.2017Miha ElaNo ratings yet

- Sinteza Principalelor Modificări Aferente Ghidului Specific 3.1.ADocument18 pagesSinteza Principalelor Modificări Aferente Ghidului Specific 3.1.AMiha ElaNo ratings yet

- Ghidul Solicitantului SM 6 2 - 28 03 2017Document45 pagesGhidul Solicitantului SM 6 2 - 28 03 2017Manea CiprianNo ratings yet

- R.C 6.4 S01 2016Document10 pagesR.C 6.4 S01 2016Miha ElaNo ratings yet

- ANEXA 2 CERERE de Finantare - NerambursabilaDocument2 pagesANEXA 2 CERERE de Finantare - NerambursabilaAngely KaNo ratings yet

- Lista Coduri CAEN 6 4Document52 pagesLista Coduri CAEN 6 4ClaudiuNo ratings yet

- Registru de Casa FINALDocument31 pagesRegistru de Casa FINALMiha ElaNo ratings yet

- Retete Raftul Cu MiresmeDocument7 pagesRetete Raftul Cu MiresmeMiha ElaNo ratings yet

- Modif 11 07 2016Document1 pageModif 11 07 2016Miha ElaNo ratings yet

- Indicatii Financiar VANF Si RIRDocument1 pageIndicatii Financiar VANF Si RIRMiha ElaNo ratings yet

- Dulceata de Capsuni Fara ConservantDocument4 pagesDulceata de Capsuni Fara ConservantMiha ElaNo ratings yet

- Cum Sa-Ti Imbunatatesti Vizitele Pe SiteDocument25 pagesCum Sa-Ti Imbunatatesti Vizitele Pe SiteMiha ElaNo ratings yet