Professional Documents

Culture Documents

MIG Welding Machine

Uploaded by

SAATISHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MIG Welding Machine

Uploaded by

SAATISHCopyright:

Available Formats

Department of Mechanical Engineer

ing

MEFD211 MANUFACTURING PROCESSES LAB

SEMESTER 1 2015/2016

NAME & ID:

LAB ACTIVITY:

1.

Objectives

SECTION:

2.

Equipment and

GROUP: DATE:

tools Sketc

3.

4.

Safety hprecaution

Kindly please refer the MEFB 121 General Lab Report Guidelines for the details.

5.

Procedure

6.

Resul

1 Objectives

t

7.

Discussion

8.

Conclusion

To learn how to use the MIG welding machine correctly and properly. 9. Format & Overall

quality

To learn how to melt the iron as taught.

To make a straight welded line on the metal.

To make a thin welded line on the metal

List and sketch of equipment and tools

Marks

5

10

10

5

15

20

15

10

10

100

Department of Mechanical Engineer

ing

Sketch:

Safety Precautions:

Wear PPE during the welding time

For welding always wear the welding mask to prevent face from getting burn.

Do not open the mask when we are doing the welding because it get hurt our

eyes.

If the MIG welding machine occurs any problem immediately report to lab

technician.

Do not play around with the MIG welding machines nozzle because it might gives

a spark.

If one of our group mate is doing the work another member need to stand behind

the yellow line.

Always wear the welding glove before start to weld any iron.

Use the rivet blacksmith tong the hot welded iron to prevent the glove from

burning

Do not put the hot welded iron on the table because it can damage the table or

might hurt someone

Do not hold the hot welded iron without cooling it down by submerging it into the

water because it might be hot.

Procedure:

Firstly, wear all the safety equipments before proceeding to the welding session.

Listen carefully to the briefing of the lab technician about the use of MIG welding machine.

Observe carefully when the lab technician is doing the welding session so that it will easy for us

when we are doing it.

Once the lab technician is done with the briefing we will be given a piece of used iron plate,

for us to train ourselves.

Once the training session is done we can proceed to our work piece.

Make sure the iron that comes out from the nozzles is not too long, if it is too long than use the cutter

to cut it and make it short.

The MIG welding machine will only works when a button is pressed rapidly and the iron rod that

comes out from it needs to be in contact with the metal plate.

We will be given a rectangle metal plate and are told to make two straight lines on the metal plate

using the MIG welding machine.

Once we have done making two lines on the metal plate that have been told using the MIG welding

machine, using the rivet blacksmith tong to carry the metal plate to cool it down by submerging it into

the water.

Once it is fully cooled down using the vice tighten the metal plate and start to brush it.

After brushing it properly using a blacksmith hammer peel of the small piece of welded on the metal

plate.

Once it is done show the work piece to the lecturer.

Lastly, clean up the entire premises.

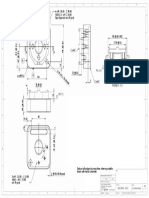

Result (attach the multi-view drawing)

Discussions

MIG welders consist of a handle with a trigger controlling a wire feed, feeding the wire from a

spool to the weld joint. The wire is similar to an endless bicycle brake cable. The wire runs

through the liner, which also has a gas feeding through the same cable to the point of arc,

which protects the weld from the air.

MIG welding is most commonly used in fabrication shops where production is high, and the

wind blowing away your gas shielding is unlikely.

MIG weld welding requires three things, electricity to produce heat, an electrode to fill the

joint, and shielding gas to protect the weld from the air. MIG welding is done using a very

small electrode that is fed continuously, while the operator controls the amount of weld being

done. In some cases when a robot takes over this process, it becomes automatic welding.

MIG welding unlike most other welding processes has one standard voltage type and polarity

type. The voltage used is D/C direct current, much like the current in a car battery. Direct

current flows in one direction, from the negative (-) to the positive (+).

The polarity used is also standard and that is D/C electrode (+) positive. This means that the

handle is the positive side of the circuit, or it may be said, the electricity flows from the metal

in to the welding handle.

When choosing the proper MIG wire or electrode you need to match the type of wire to the type of metal

being welded. Some other considerations are the type of transfer, position to be welded, and resistance to

abrasion. Most of the times when working as a welder the welding engineers specify the weld size and

electrode type to be used.

The most common wire used for welding carbon steel is ER 70S-6. In some cases you can weld two

different metals together. An example of this is welding 304 stainless steel to A36 carbon steel using an

electrode made of 309 stainless steel ER 309L.

Typical MIG welding electrodes are a solid wire ranging from a thickness of .023 to .045. Some are much

thicker for heavy industrial applications.

The most common sizes are:

.023

.030

.035

.045

10

Conclusions

Finally, I have learned how to use the MIG welding

machine properly and correctly without giving any

problem. The MIG welding machine is not difficult to

operate all we have to do to get a perfect lining and

thickness when we are welding an iron or a metal plate

is that we have to keep in contact with the metal plate

and the nozzle. We also need to move the nozzle slowly

so that we will get a perfect turn out.

You might also like

- Report MIG WeldingDocument12 pagesReport MIG Weldingyuwaraja0% (2)

- Case Study JUN20Document9 pagesCase Study JUN20senyapsialNo ratings yet

- Welding Report Sem3Document11 pagesWelding Report Sem3hakimNo ratings yet

- MIG WeldingDocument10 pagesMIG WeldingAlvaro Martin RamaNo ratings yet

- Mechanical Workshop Practice ReportDocument6 pagesMechanical Workshop Practice ReportMuhd AkmalNo ratings yet

- TIG Workshop ReportDocument9 pagesTIG Workshop ReportKee Zhenyuan100% (1)

- Lab Sheet Tig Mig DJF2012Document3 pagesLab Sheet Tig Mig DJF2012Rahmat Nor Mohd SharifNo ratings yet

- Discussion GmawDocument2 pagesDiscussion GmawMuhamad HafizNo ratings yet

- Conclusion Recon Refer WeldingDocument3 pagesConclusion Recon Refer WeldingIrdzat ZainiNo ratings yet

- Welding GAS ReportDocument11 pagesWelding GAS Report15 thn50% (2)

- DJF 3012 - Manufacturing Workshop Practice 2Document7 pagesDJF 3012 - Manufacturing Workshop Practice 2Leeahna JkNo ratings yet

- Gas Welding ReportDocument18 pagesGas Welding ReportAkmal AzaliNo ratings yet

- JJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Document24 pagesJJ104 Workshop Technology Chapter8 Oxy-Acetylene Welding 1Ah Tiang100% (3)

- Lab Sheet Djj5113Document27 pagesLab Sheet Djj5113Munisprasad MuniandyNo ratings yet

- Safety Tips for Arc Welding WorkshopDocument10 pagesSafety Tips for Arc Welding WorkshopHabibah ArbainNo ratings yet

- Handbook JKM Mac 2021 Complete - CompressedDocument130 pagesHandbook JKM Mac 2021 Complete - CompressedSeekNo ratings yet

- Welding ReportDocument15 pagesWelding Reportabhinavjha7No ratings yet

- OAW SMAW Flat WeldingDocument12 pagesOAW SMAW Flat WeldingHaikal SubriNo ratings yet

- Field Trip On Elect ElectDocument13 pagesField Trip On Elect ElectvictorNo ratings yet

- Fan Reverse Engineering ReportDocument7 pagesFan Reverse Engineering Reportapi-352647685100% (1)

- DJJ20053 Engineering Laboratory 1 (Electrical Technology) : Experiment 1Document4 pagesDJJ20053 Engineering Laboratory 1 (Electrical Technology) : Experiment 1roslelawati75No ratings yet

- Arc Welding Techniques ExplainedDocument4 pagesArc Welding Techniques ExplainedFaris Kadesh50% (2)

- Workshop Technology Case StudyDocument8 pagesWorkshop Technology Case StudyNagulan VegneswaranNo ratings yet

- Learn Arc and Oxy-Acetylene Welding Safety and TechniquesDocument24 pagesLearn Arc and Oxy-Acetylene Welding Safety and TechniquesMuhammad HidayaturrahmanNo ratings yet

- DJF21012 Sand Casting 1006Document15 pagesDJF21012 Sand Casting 1006Sakinah KamalNo ratings yet

- Lathe Machine ReportDocument10 pagesLathe Machine ReportSyahirahNo ratings yet

- Date: ............................................................(Assistant’s SignatureDocument8 pagesDate: ............................................................(Assistant’s SignatureThaneswaran BaluNo ratings yet

- Arc Welding Procedures Guide: 4 Steps to a Quality WeldDocument4 pagesArc Welding Procedures Guide: 4 Steps to a Quality WeldatayxjsNo ratings yet

- JJ 103 Fitting ReportDocument11 pagesJJ 103 Fitting Reportrafiah bazlaaNo ratings yet

- Report Inventor Mini ProjectDocument10 pagesReport Inventor Mini ProjectDhana KumaranNo ratings yet

- Milling Report (Indexing)Document23 pagesMilling Report (Indexing)Aiman AlifNo ratings yet

- Report FittingDocument1 pageReport FittingNordianaaida Eda67% (3)

- Arc N Gas ReportDocument25 pagesArc N Gas ReportAnahAlhabshiNo ratings yet

- DJJ 10033-Chapter 6 NewDocument43 pagesDJJ 10033-Chapter 6 NewAbbas SeuNo ratings yet

- Mechatronic Workshop Practice 1Document15 pagesMechatronic Workshop Practice 1Khairul AminNo ratings yet

- Surface GrindingDocument14 pagesSurface GrindingariefNo ratings yet

- DJJ30082 Worksheet Milling ReportDocument9 pagesDJJ30082 Worksheet Milling ReportSakinah KamalNo ratings yet

- Process and Part Analysis of Sheet Metal FoldingDocument4 pagesProcess and Part Analysis of Sheet Metal FoldingNo NameNo ratings yet

- MEM 661 - Applied Welding Engineering Individual Assignment Instruction and Guidelines CASE STUDY (Document10 pagesMEM 661 - Applied Welding Engineering Individual Assignment Instruction and Guidelines CASE STUDY (Shaikhan NadzemiNo ratings yet

- Report WeldingDocument11 pagesReport WeldingSomasundaram SomanoNo ratings yet

- Worksheet: Diploma in Mechanical EngineeringDocument13 pagesWorksheet: Diploma in Mechanical EngineeringGuna SelanNo ratings yet

- Velocity and Acceleration Lab Result (Car Ramp)Document3 pagesVelocity and Acceleration Lab Result (Car Ramp)Ugur ASİT60% (5)

- DJJ2073 THERMODYNAMICS EOC 2 SET 1 QUESTIONSDocument1 pageDJJ2073 THERMODYNAMICS EOC 2 SET 1 QUESTIONSArief IzzNo ratings yet

- Machining 2 ReportDocument11 pagesMachining 2 ReportTan Jun ZheNo ratings yet

- Case Study Djj50203 (GRP Sethu)Document14 pagesCase Study Djj50203 (GRP Sethu)Roysilva SilvaNo ratings yet

- TIG (Report)Document18 pagesTIG (Report)Mahmoud Kassab100% (2)

- Lab Report TIGDocument4 pagesLab Report TIGAlimah Azeli50% (2)

- TIG MIG Welding Lab ReportDocument6 pagesTIG MIG Welding Lab ReportSaad SaleemNo ratings yet

- CHAPTER 3wqfr3qvDocument10 pagesCHAPTER 3wqfr3qvKosigar ChelladoraiNo ratings yet

- Surface Grinding ReportDocument3 pagesSurface Grinding ReportFiqri ProductionNo ratings yet

- DJJ 10033-Chapter 5.GEARDocument34 pagesDJJ 10033-Chapter 5.GEARStepianus JtNo ratings yet

- 1.0 Title: Shield Metal Arc Welding (SMAW)Document13 pages1.0 Title: Shield Metal Arc Welding (SMAW)Exo NadiNo ratings yet

- A Lab Report On Fitting Workshop Practice PDFDocument6 pagesA Lab Report On Fitting Workshop Practice PDFSorna Kailash50% (4)

- Electro-Pneumatic Sequence ControlDocument4 pagesElectro-Pneumatic Sequence Controlshirleyna saraNo ratings yet

- GegasDocument18 pagesGegasPiraven Casanova II50% (2)

- CNC Report - Kubheran 23DKM18F2033Document10 pagesCNC Report - Kubheran 23DKM18F2033Kubheran SelvathuraiNo ratings yet

- Observations and FindingsDocument2 pagesObservations and FindingsJustin Mark AgtingNo ratings yet

- Foundry ReportDocument2 pagesFoundry ReportPreavin Kutty Thamotharan50% (2)

- Materials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985From EverandMaterials Engineering: Proceedings of the First International Symposium, University of the Witwatersrand, Johannesburg, South Africa, November 1985J. V. BeeNo ratings yet

- Mechanical Workshop Practice Mig and Tig ReportDocument16 pagesMechanical Workshop Practice Mig and Tig ReportHafiy Qursyeini100% (1)

- QT-23016 CERAPACDocument1 pageQT-23016 CERAPACSAATISHNo ratings yet

- ABC_Form_(NonIndividual)(Final)Document2 pagesABC_Form_(NonIndividual)(Final)SAATISHNo ratings yet

- MetalsDocument11 pagesMetalsSAATISHNo ratings yet

- Parts & Price To Be Used Outsibe of The Automated Booksale MachineDocument2 pagesParts & Price To Be Used Outsibe of The Automated Booksale MachineSAATISHNo ratings yet

- Engineering EthicsDocument45 pagesEngineering EthicsSAATISHNo ratings yet

- MCEB 212 TOPIC 1 - MM - Week 2 - Student's Copy2Document14 pagesMCEB 212 TOPIC 1 - MM - Week 2 - Student's Copy2SAATISHNo ratings yet

- Koch Sanitary Equip Design 2014 TC PDFDocument107 pagesKoch Sanitary Equip Design 2014 TC PDFSAATISHNo ratings yet

- Smith CH 01Document20 pagesSmith CH 01Chan Hyun ParkNo ratings yet

- Integrating Ethics Into Engineering Educ PDFDocument8 pagesIntegrating Ethics Into Engineering Educ PDFSAATISHNo ratings yet

- Computer ProgrammingDocument5 pagesComputer ProgrammingSAATISHNo ratings yet

- Chapter 2Document85 pagesChapter 2Ali SabahNo ratings yet

- Closed System Energy Analysis: Ideal Gases: AssumptionsDocument1 pageClosed System Energy Analysis: Ideal Gases: AssumptionsSAATISHNo ratings yet

- ARC Welding MachineDocument7 pagesARC Welding MachineSAATISHNo ratings yet

- NX CAD ProjectDocument1 pageNX CAD ProjectKarthik Kumar YSNo ratings yet

- Brain Pickings - An Inventory of The Meaningful LifeDocument16 pagesBrain Pickings - An Inventory of The Meaningful Lifegladis rosacia100% (1)

- The ChaserDocument3 pagesThe ChaserteosavutNo ratings yet

- Soundless Voice Piano Sheet MusicDocument3 pagesSoundless Voice Piano Sheet MusicRavenSorchess0% (1)

- AdventDocument1 pageAdventAlex GreenNo ratings yet

- Hadith of The Holy Prophet Muhammad Peace Be Upon HimDocument9 pagesHadith of The Holy Prophet Muhammad Peace Be Upon HimRaees Ali YarNo ratings yet

- The Grand Library (V2) PDFDocument37 pagesThe Grand Library (V2) PDFSpyros Soap100% (1)

- Doctrine of PrayerDocument23 pagesDoctrine of Prayerthelightheartedcalvinist6903No ratings yet

- Syrian Christians Under Islam PDFDocument247 pagesSyrian Christians Under Islam PDFHiroNo ratings yet

- Yogacara BuddhismDocument2 pagesYogacara BuddhismV.F.No ratings yet

- $sanderson KhmersDocument114 pages$sanderson KhmersRasa LingaNo ratings yet

- Sura Muzammil - Tafsir - ShiraziDocument10 pagesSura Muzammil - Tafsir - Shiraziboyluv2000No ratings yet

- Scaffolds and Ladders-Code of Safety: Indian StandardDocument7 pagesScaffolds and Ladders-Code of Safety: Indian Standardujjawal chandraNo ratings yet

- God in LiteratureDocument7 pagesGod in LiteratureJiya AshNo ratings yet

- Script - Esc, TSS, & Shs QVRDocument3 pagesScript - Esc, TSS, & Shs QVRMarcus Antonio G. IsraelNo ratings yet

- Demiroren Mall Case StudyDocument4 pagesDemiroren Mall Case StudyangelmayalNo ratings yet

- Quiz on English grammar and verb tenses under 40 charsDocument4 pagesQuiz on English grammar and verb tenses under 40 charsKaren Chinga yesquenNo ratings yet

- Rizal's Life in Asian CountriesDocument3 pagesRizal's Life in Asian CountriesJenemar0% (1)

- How Values and Virtues Shape Our Thoughts and ActionsDocument11 pagesHow Values and Virtues Shape Our Thoughts and ActionsLovely Platon CantosNo ratings yet

- Essay On Indian Culture and Tradition - Important IndiaDocument3 pagesEssay On Indian Culture and Tradition - Important IndianapinnvoNo ratings yet

- Sight Word Books Set 2: Places: Thank You For Respecting Our Terms of UseDocument12 pagesSight Word Books Set 2: Places: Thank You For Respecting Our Terms of UseStefan Razvan DinuNo ratings yet

- S19 DAP CatalogueDocument109 pagesS19 DAP CataloguepescemagroNo ratings yet

- City Builder 02 - Craftsman PlacesDocument18 pagesCity Builder 02 - Craftsman Placesskypalae100% (3)

- Christensen - Eric V Hornbostel Carl Stumpf and The Institutionalization of Comparative MusicologyDocument5 pagesChristensen - Eric V Hornbostel Carl Stumpf and The Institutionalization of Comparative MusicologyFaber Arley Franco CañaveralNo ratings yet

- Complete Transcripts Herb Fitch Beyond Words and ThoughtsDocument472 pagesComplete Transcripts Herb Fitch Beyond Words and ThoughtsFrank Valenzuela100% (5)

- The Susan B. Anthony Dollar Collector Checklist: Compliments of Littleton Coin Company, LLCDocument1 pageThe Susan B. Anthony Dollar Collector Checklist: Compliments of Littleton Coin Company, LLCosrulzNo ratings yet

- Intellectual Property Law Course OutlineDocument2 pagesIntellectual Property Law Course OutlineShivam SinghNo ratings yet

- Ganpati Mantra For A Desired JobDocument5 pagesGanpati Mantra For A Desired JobBram0% (1)

- Final Report On SLMDocument24 pagesFinal Report On SLMAnkit GroverNo ratings yet

- PNP ID Application FormDocument1 pagePNP ID Application FormJohan Stradlin Samson33% (3)