Professional Documents

Culture Documents

ENCI425 T4 1 Composite 1

Uploaded by

jcvalenciaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENCI425 T4 1 Composite 1

Uploaded by

jcvalenciaCopyright:

Available Formats

ENCI425 Steel Structures

ENCI 425 STEEL STRUCTURES

University of Canterbury

Low-Rise Frame Design

ENCI425:

member design

second order analysis

plastic analysis

construction details

Beams

STEEL STRUCTURES

T4_L1 Composite Beams 1

Gregory MacRae

COMPOSITE BEAMS

- torsion

- composite action

- fatigue

- floor vibrations

- plate girders

Seismic Frames

+ external speakers

COMPOSITE BEAMS

Common Types of Composite Construction:

1.1 INTRODUCTION

SRC Steel Reinforced Concrete

columns are steel columns surrounded

by reinforced concrete.

Columns are generally:

(a) Slab on beam

(c) Reinforced Concrete Steel (RCS)

(b) Concrete-Filled Tube (CFT)

(d) Steel Reinforced Concrete (SRC)

COMPOSITE BEAMS

1.1 INTRODUCTION

RCS Reinforced Concrete Steel columns

are reinforced concrete columns through

which hot-formed beams pass.

- square (or circular)

- less susceptible to buckling that the steel

sections alone

- have some protection against corrosion

- increased stiffness/strength

- increased fire rating

These are addressed in NZS 3404 Ch 13. We will

COMPOSITE

BEAMS

consider gravity loading only in this class.

1.1 INTRODUCTION

Composite beams are generally made from steel

I-shapes which support a concrete slab, or a

concrete deck floor system. Because the

concrete is there, it may be used to increase the

strength of the beam.

CFT Concrete Filled Tubular columns have

- high construction speed (no formwork)

- high stiffness/strength/ductility

These are addressed in NZS 3404 Ch 13. We will

consider gravity loading only in this class.

COMPOSITE BEAMS

COMPOSITE BEAMS

Welded mesh reinforcement for crack

control, transverse load distribution and

fire resistance

Concrete cast in situ

Conventional composite construction

Headed stud connectors for shear

connection to the composite beam and,

when required, end anchorage to the slab

(from Hicks, HERA)

COMPOSITE BEAMS

(from Hicks, HERA)

COMPOSITE BEAMS

1.1 INTRODUCTION

Typical composite beams:

Reinforced Concrete

Shear studs

Steel Decking

Air

Concrete

Re-entrant profiled steel

sheet

Shear studs

I beam

I beam

Reinforced concrete

slab on beam

Concrete slab steel

decking on beam

Open trough profiled steel

sheet

Types of profiled steel sheeting defined in EN 1994-1-1

COMPOSITE BEAMS

COMPOSITE BEAMS

1.1 INTRODUCTION

1.2 COMPOSITE ACTION

(from Hicks)

Advantages of composite beams

- erection

higher flexural strength

higher flexural stiffness

(3-4.5 times)

(1.5-2.5 times)

- economy

- Safety - sheeting acts as working platform

- Fast formwork

- unpropped

- Flexibility for irregular structures

- Sheeting stabilizes beams

- Sheeting can provide all main reinforcement

- Increased span length (span:depth 25)

- Shallower steel beams (easy

accommodation of building services)

- total weight savings of 20-30% typically

- steel weight savings of 30-50% typically

- ease of modification

Two identical rectangular beams

sitting on top of each other

Each beam has depth d

and breadth b, strength fy

Displaced shape:

L

Non-Composite

Composite

Second moment of area, I:

INC = 2 x (bd3)/12

IC

= (b(2d)3)/12 = 4INC

Displacement, d:

dNC = PL3

48EINC

dC

Strength, My:

My,NC = 2 x (bd2)/6.fy

My,C = b(2d)2/6.fy = 2My,NC

dNC

4

(based on Hicks, HERA)

COMPOSITE BEAMS

COMPOSITE BEAMS

1.2 COMPOSITE ACTION - ELASTIC

1.2 COMPOSITE ACTION - ELASTIC

Where are the best locations for shear studs?

For infinitely stiff shear connectors, what strength must they have?

The maximum slip occurs at the beam ends, so this is the best place to make

connection.

To make a beam fully composite, shear connectors should have sufficient

strength and stiffness to ensure that there is no slip between the beams.

COMPOSITE BEAMS

1.2

COMPOSITE ACTION

ELASTIC Shear Review

5. FLEXURAL

MEMBERS

P

dx

Normal stress, f, is:

f = My/I

Shear stress, v, is:

v = VQ/Ib

Shear flow, q, is:

q = VQ/I

L

SFD

BMD

COMPOSITE BEAMS

1.2

COMPOSITE ACTION

ELASTIC Shear Review

5. FLEXURAL

MEMBERS

x

Rectangular Section

dx

At the centre of the section, y = 0

dx

ds = dM.y

I

dy

d

Slice along length

Cross-Section

tbdx =

M(x)+ dM

M(x)

ds = dM.y

I

dx

M(x)

Cross-Section

Net Stresses

/2

sdA

ds = dM.y

I

dy

M(x)+ dM

Slice along length

ds = dM.y

I

y y

Net Stresses

At the centre of the section:

COMPOSITE BEAMS

1.2

COMPOSITE ACTION

ELASTIC Shear Review

5. FLEXURAL

MEMBERS

dx

dx

ds = dM.y

I

dy

d

Cross-Section

M(x)

M(x)+ dM

Slice along length

yy

ds = dM.y

I

Net Stresses

The shear force per unit length of beam (or shear flow), q, is:

q = tb = VQ/(Ib) * b = VQ/I

If the studs are stiff enough to provide no slip, then the required strength per stud, Vss,

is equal to the shear flow at the stud, q, multiplied by the spacing between studs, s.

That is:

fVss > q.s

In reality, shear studs are not stiff and their strength is obtained at significant

deformations. Plastic, rather than elastic, analysis is used to find the ultimate strength.

You might also like

- Chap 1 &2Document27 pagesChap 1 &2kbromNo ratings yet

- Chapter One ConcreteDocument28 pagesChapter One ConcreteSarfraz MunirNo ratings yet

- RCC Slab Reinforcement GuideDocument22 pagesRCC Slab Reinforcement GuidelakshitaNo ratings yet

- 4th Semester RCC Notes 170745Document32 pages4th Semester RCC Notes 170745Santosh67% (3)

- STRUCTURE FOR ARCHITECTS - BEAMS, COLUMNS, SLABS & LONG SPAN STRUCTURESDocument9 pagesSTRUCTURE FOR ARCHITECTS - BEAMS, COLUMNS, SLABS & LONG SPAN STRUCTURESwafa rafiaNo ratings yet

- Composite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityDocument18 pagesComposite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityMahmoud A SalamaNo ratings yet

- Some Info On TrussesDocument9 pagesSome Info On TrussesameensderajNo ratings yet

- Steel Project 2010-2011 1st Term LECTURE01Document77 pagesSteel Project 2010-2011 1st Term LECTURE01Noaman RehanNo ratings yet

- Structural Steel Design FundamentalsDocument13 pagesStructural Steel Design FundamentalsNiña Criselle PasiaNo ratings yet

- Design of Steel Structures: An IntroductionDocument44 pagesDesign of Steel Structures: An IntroductionLathi RajNo ratings yet

- Steel: StructuresDocument29 pagesSteel: StructuresBa Thanh DinhNo ratings yet

- Prepared By:: Ir - Ts.Dr. Renga Rao KrishnamoorthyDocument33 pagesPrepared By:: Ir - Ts.Dr. Renga Rao KrishnamoorthySyahir HamidonNo ratings yet

- Composite ColumnsDocument49 pagesComposite ColumnsPrasad GN100% (2)

- Steel Innovations Workshop Explores Composite Steel-Concrete ConstructionDocument47 pagesSteel Innovations Workshop Explores Composite Steel-Concrete ConstructionRaja GopalNo ratings yet

- Composite Construction Design (ULS Only)Document93 pagesComposite Construction Design (ULS Only)CawanNeroMiranio100% (1)

- Composite Deck BridgesDocument59 pagesComposite Deck Bridgeskarpagajothimurugan100% (1)

- Ethics Team 26Document13 pagesEthics Team 26Kareem MagdyNo ratings yet

- RC design conceptsDocument32 pagesRC design conceptsSyed Yousuf AhmedNo ratings yet

- Beam DesignDocument46 pagesBeam DesignAnik Sarker100% (1)

- Steel Timber Design Design of Simply Supported Steel Section BeamDocument54 pagesSteel Timber Design Design of Simply Supported Steel Section BeamTj InumerableNo ratings yet

- RC Beam DesignDocument52 pagesRC Beam DesignnaurahimanNo ratings yet

- Space Truss. The Exterior Members of A Truss Are Called Chords, and The Diagonals AreDocument73 pagesSpace Truss. The Exterior Members of A Truss Are Called Chords, and The Diagonals AreEvodius RweyemamuNo ratings yet

- Composite Slab ReportDocument10 pagesComposite Slab ReportAhmed Moustafa AboelelaNo ratings yet

- Steel PowerPoint I (2018-2019)Document89 pagesSteel PowerPoint I (2018-2019)ohnmarzawNo ratings yet

- En 1990 (10) Iso 6707-1Document24 pagesEn 1990 (10) Iso 6707-1Andreea CălinNo ratings yet

- I BeamDocument7 pagesI BeamEdi YantoNo ratings yet

- Ijce V3i11p101Document6 pagesIjce V3i11p101Mahesh YadavNo ratings yet

- Structural Design Parameters: Jaypee Medical Centre (JMC)Document8 pagesStructural Design Parameters: Jaypee Medical Centre (JMC)Shakil AkhterNo ratings yet

- CE 5001 Structural Steel Design Lecture 01Document49 pagesCE 5001 Structural Steel Design Lecture 01Oshada Attygalle100% (1)

- Arch 220 - Steel Frame ConstructionDocument9 pagesArch 220 - Steel Frame ConstructionSheikh Mizanur RahmanNo ratings yet

- Introd-Steel Struc.Document4 pagesIntrod-Steel Struc.Fuad AhmedinNo ratings yet

- Columns Beams SlabsDocument48 pagesColumns Beams SlabsWilson Muguro100% (1)

- Prestressed Concrete DesignDocument69 pagesPrestressed Concrete DesignMuhammad Ahsan NadeemNo ratings yet

- RCC Unit-1 PDFDocument40 pagesRCC Unit-1 PDFSandeep GowdaNo ratings yet

- Steel Design Module 1 Tension and Compression MembersDocument26 pagesSteel Design Module 1 Tension and Compression Membersa.No ratings yet

- Structural Steel Design GuideDocument49 pagesStructural Steel Design GuideshalukaNo ratings yet

- Steel-Concrete Composite Columns-I: B B C CDocument24 pagesSteel-Concrete Composite Columns-I: B B C CBallok ZoltanNo ratings yet

- Composite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityDocument18 pagesComposite Structures: Dr. Hesham Fawzy Shaabn Professor, Zagazig UniversityAbdualahGameelNo ratings yet

- Design of Composite ColumnDocument17 pagesDesign of Composite Columnpragati singhNo ratings yet

- Structural - Prestressed ConcreteDocument21 pagesStructural - Prestressed Concretejaderic buisingNo ratings yet

- Design of Steel Structures: Preliminary NotesDocument23 pagesDesign of Steel Structures: Preliminary NotesIrish サルタン タムビスNo ratings yet

- AR136 LEC1 IntroductionDocument39 pagesAR136 LEC1 IntroductionAngela MaeNo ratings yet

- Notes - Lesson 4Document16 pagesNotes - Lesson 4Eddy Aba BioNo ratings yet

- Introduction To Steel DesignDocument49 pagesIntroduction To Steel DesignkumuthaNo ratings yet

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Unit 2 Part 4 - Truss and Frame Structures - no recordDocument27 pagesUnit 2 Part 4 - Truss and Frame Structures - no recordRaed JahshanNo ratings yet

- Lecture Concrete Column - Usakti 28 October 2017Document53 pagesLecture Concrete Column - Usakti 28 October 2017valentina ayuNo ratings yet

- Ce 416 File 2Document16 pagesCe 416 File 2Art IjbNo ratings yet

- Cyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsDocument11 pagesCyclic Tests On Bolted Steel Double-Sided Beam-To-Column JointsAli KhalafNo ratings yet

- Steel Truss1Document60 pagesSteel Truss1Shreyas BvNo ratings yet

- Reinforced Concrete Design Notes BS StandardsDocument37 pagesReinforced Concrete Design Notes BS StandardsMasunji Emanuel100% (1)

- RC Bridge Construction and Design FundamentalsDocument41 pagesRC Bridge Construction and Design Fundamentalstewele brhaneNo ratings yet

- Dokumen - Tips Peb-StructuresDocument36 pagesDokumen - Tips Peb-Structuresrahulshah3994No ratings yet

- LectureDocument84 pagesLectureYared AddisuNo ratings yet

- Design of Steel and Timber Structures - ExamplesDocument78 pagesDesign of Steel and Timber Structures - Examplesሃይለ ገብረስላሴ92% (73)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- XXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkFrom EverandXXth Century Sheet Metal Worker - A Modern Treatise on Modern Sheet Metal WorkNo ratings yet

- Triangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsFrom EverandTriangulation - Applied to Sheet Metal Pattern Cutting - A Comprehensive Treatise for Cutters, Draftsmen, Foremen and Students: Progressing from the Simplest Phases of the Subject to the Most Complex Problems Employed in the Development of Sheet Metal Patterns with Practical Solutions of Numerous Problems of Frequent Occurrence in Sheet Metal ShopsRating: 5 out of 5 stars5/5 (1)

- 5.8.7 Other Materials: Table 5.1Document1 page5.8.7 Other Materials: Table 5.1jcvalenciaNo ratings yet

- F 4.19 Methods of Improving The Flexural Resistance of Concrete Slabs. (A) Adding BoltedDocument1 pageF 4.19 Methods of Improving The Flexural Resistance of Concrete Slabs. (A) Adding BoltedjcvalenciaNo ratings yet

- 5.8.8 Choosing The Best Repair MaterialDocument1 page5.8.8 Choosing The Best Repair MaterialjcvalenciaNo ratings yet

- T 5.1 Properties of Repair and Overlay MaterialsDocument1 pageT 5.1 Properties of Repair and Overlay MaterialsjcvalenciaNo ratings yet

- 4.6 Strengthening Structural Slabs: Chap. 6Document1 page4.6 Strengthening Structural Slabs: Chap. 6jcvalenciaNo ratings yet

- 5.4.3 When To Use Patching: F 5.13 This Isolated Spall Can Be Repaired by Patching, Provided That Chloride Levels inDocument1 page5.4.3 When To Use Patching: F 5.13 This Isolated Spall Can Be Repaired by Patching, Provided That Chloride Levels injcvalenciaNo ratings yet

- 5.4.3 When To Use Patching: F 5.13 This Isolated Spall Can Be Repaired by Patching, Provided That Chloride Levels inDocument1 page5.4.3 When To Use Patching: F 5.13 This Isolated Spall Can Be Repaired by Patching, Provided That Chloride Levels injcvalenciaNo ratings yet

- 5.10 Systematic Maintenance Programs: Chap. 2Document1 page5.10 Systematic Maintenance Programs: Chap. 2jcvalenciaNo ratings yet

- 5.3.5 Repair of Corrosion-Related Deterioration: Chap. 2Document1 page5.3.5 Repair of Corrosion-Related Deterioration: Chap. 2jcvalenciaNo ratings yet

- 5.3.5 Repair of Corrosion-Related Deterioration: Chap. 2Document1 page5.3.5 Repair of Corrosion-Related Deterioration: Chap. 2jcvalenciaNo ratings yet

- 5.4.4 The Patching Method: How Much Concrete To Remove?Document1 page5.4.4 The Patching Method: How Much Concrete To Remove?jcvalenciaNo ratings yet

- 4.5.9 Reinforcing Beams For ShearDocument1 page4.5.9 Reinforcing Beams For ShearjcvalenciaNo ratings yet

- 5.4 Patching Spalls and Deteriorated Areas 5.4.1 IntroductionDocument1 page5.4 Patching Spalls and Deteriorated Areas 5.4.1 IntroductionjcvalenciaNo ratings yet

- Chap. 2Document1 pageChap. 2jcvalenciaNo ratings yet

- Chap. 2Document1 pageChap. 2jcvalenciaNo ratings yet

- 5.4 Patching Spalls and Deteriorated Areas 5.4.1 IntroductionDocument1 page5.4 Patching Spalls and Deteriorated Areas 5.4.1 IntroductionjcvalenciaNo ratings yet

- 3.7.2 Increasing Chances For Successful Welding: Chap. 2Document1 page3.7.2 Increasing Chances For Successful Welding: Chap. 2jcvalenciaNo ratings yet

- 5.4.4 The Patching Method: How Much Concrete To Remove?Document1 page5.4.4 The Patching Method: How Much Concrete To Remove?jcvalenciaNo ratings yet

- 3.7.3 Reinforcing Beams by Welding: A. Note That The Cover Plate Is Wider Than The Beam To Permit Horizontal FilletDocument1 page3.7.3 Reinforcing Beams by Welding: A. Note That The Cover Plate Is Wider Than The Beam To Permit Horizontal FilletjcvalenciaNo ratings yet

- Fig. 3.7bDocument1 pageFig. 3.7bjcvalenciaNo ratings yet

- F 4.16 Strengthening Concrete Beams by External PrestressingDocument1 pageF 4.16 Strengthening Concrete Beams by External PrestressingjcvalenciaNo ratings yet

- 4.6.2 Strengthening Two-Way Slabs: Fig. 4.19bDocument1 page4.6.2 Strengthening Two-Way Slabs: Fig. 4.19bjcvalenciaNo ratings yet

- F 3.9 Reinforced Beam For Example 3.2.: IgureDocument1 pageF 3.9 Reinforced Beam For Example 3.2.: IgurejcvalenciaNo ratings yet

- F 3.7 Reinforcing Existing Beams by Welding: (A) Cover Plate Welded To The BottomDocument1 pageF 3.7 Reinforcing Existing Beams by Welding: (A) Cover Plate Welded To The BottomjcvalenciaNo ratings yet

- Example 1.1: Making An Opening in Existing CMU Wall The Owner of A Nondescript SingleDocument1 pageExample 1.1: Making An Opening in Existing CMU Wall The Owner of A Nondescript SinglejcvalenciaNo ratings yet

- URM parapet and partition anchorage requirements for seismic design changesDocument1 pageURM parapet and partition anchorage requirements for seismic design changesjcvalenciaNo ratings yet

- Solution Since The Proposed Work Includes Reconfiguration of Space in The Entire Building, ItDocument1 pageSolution Since The Proposed Work Includes Reconfiguration of Space in The Entire Building, ItjcvalenciaNo ratings yet

- Live Load Analysis: Conclusion A Reasonable Recommendation To The Client Would Be That The Building ReuseDocument1 pageLive Load Analysis: Conclusion A Reasonable Recommendation To The Client Would Be That The Building ReusejcvalenciaNo ratings yet

- Ensuring Safe Structures in Risk Category IV BuildingsDocument1 pageEnsuring Safe Structures in Risk Category IV BuildingsjcvalenciaNo ratings yet

- Add 2 Nonlinear Analysis AdDocument24 pagesAdd 2 Nonlinear Analysis AductNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- Concrete Mix Design: Stage Item Reference or Values CalculationDocument8 pagesConcrete Mix Design: Stage Item Reference or Values Calculationmanish100% (1)

- IMS-Kalmatron - Ultra-High Performance Concrete (UHPC)Document2 pagesIMS-Kalmatron - Ultra-High Performance Concrete (UHPC)mcsomashekaraNo ratings yet

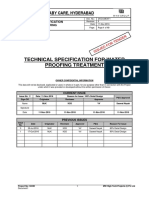

- Technical Specification For Water Proofing Treatment: Baby Care, HyderabadDocument10 pagesTechnical Specification For Water Proofing Treatment: Baby Care, HyderabadPrateek ModyNo ratings yet

- Vibration BeamDocument8 pagesVibration Beamjohan.hafiz6926No ratings yet

- Sikagrout - 220Document3 pagesSikagrout - 220Rukmana's FamilyNo ratings yet

- Bedding Sand Selection For Interlocking Concrete Pavements in Vehicular ApplicationsDocument8 pagesBedding Sand Selection For Interlocking Concrete Pavements in Vehicular Applicationsgonzalez_m_aNo ratings yet

- Preventing Chloride-Induced Reinforcement Corrosion in Marine ConcreteDocument8 pagesPreventing Chloride-Induced Reinforcement Corrosion in Marine ConcretevictorrbgNo ratings yet

- Civil Engineering JournalDocument14 pagesCivil Engineering Journaldave tafadzwa kuyeriNo ratings yet

- Tds CPD Sika Epoxy 7300 Us PDFDocument2 pagesTds CPD Sika Epoxy 7300 Us PDFyoupick10No ratings yet

- Preparation of Bar Bending Schedule (B.B.S) - Daily CivilDocument6 pagesPreparation of Bar Bending Schedule (B.B.S) - Daily CivilfelixNo ratings yet

- LiteblockDocument6 pagesLiteblockStevenNo ratings yet

- Bridge Inspection Standards in Japan and UsDocument14 pagesBridge Inspection Standards in Japan and UsAlpin MaulidinNo ratings yet

- BS 812-123 Testing Aggregates Alkali Silica ReactivityDocument18 pagesBS 812-123 Testing Aggregates Alkali Silica ReactivityAaron BriersNo ratings yet

- Seismic Rehabilitation of Damaged Reinforced Concrete Frames Using Combined Metallic Yielding Passive DevicesDocument16 pagesSeismic Rehabilitation of Damaged Reinforced Concrete Frames Using Combined Metallic Yielding Passive DevicesLuis Vilca AsenciosNo ratings yet

- G Writereaddata Eia 25042018sjwszk2mcp&empDocument43 pagesG Writereaddata Eia 25042018sjwszk2mcp&empROHAN JHANDANo ratings yet

- Torsion Design of Structural ConcreteDocument8 pagesTorsion Design of Structural ConcreteEduardo Núñez del Prado100% (1)

- TDS - Concresive 1015 PDFDocument2 pagesTDS - Concresive 1015 PDFVenkata RaoNo ratings yet

- Sor 2010 PDFDocument411 pagesSor 2010 PDFjeevendraNo ratings yet

- Concrete Aggregates: Standard Specification ForDocument8 pagesConcrete Aggregates: Standard Specification ForHasanalmahmudNo ratings yet

- Plumb Conc.Document28 pagesPlumb Conc.Muhammad AwaisNo ratings yet

- Materials 12 02149 1 1Document12 pagesMaterials 12 02149 1 1Ilhame HarNo ratings yet

- Calcium Nitrate Corrossion Inhibitor TestDocument6 pagesCalcium Nitrate Corrossion Inhibitor Testsantosh mhetreNo ratings yet

- KHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFDocument83 pagesKHRI Webinar (29-05-2020) - Pervious Concrete Pavement Systems - 29 May 20 - Dr. Krishna Prapoorna IITT PDFassistant directorNo ratings yet

- Column Base PlateDocument5 pagesColumn Base PlateGautham AllimuthuNo ratings yet

- Guru Nanak Dev Engineering College Bidar, KarnatakaDocument12 pagesGuru Nanak Dev Engineering College Bidar, KarnatakaVEERKUMARNo ratings yet

- Kodur Assessment of Fire Damaged StructuersDocument6 pagesKodur Assessment of Fire Damaged StructuersKen Su100% (1)

- Assess Structural Condition & Risk FactorsDocument23 pagesAssess Structural Condition & Risk FactorsYudi Agung NugrohoNo ratings yet

- FINAL REPORT Coastal Markets PDFDocument58 pagesFINAL REPORT Coastal Markets PDFVelina MilevaNo ratings yet

- Cement & Concrete Case Studies Reveal Early Deterioration of Portuguese Marine StructuresDocument11 pagesCement & Concrete Case Studies Reveal Early Deterioration of Portuguese Marine StructuresRossel Franklin Condori MamaniNo ratings yet