Professional Documents

Culture Documents

Cable Installation, Glanding, Terminating & Testing"

Uploaded by

Mohan PrasadOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Installation, Glanding, Terminating & Testing"

Uploaded by

Mohan PrasadCopyright:

Available Formats

http://ecmweb.

com/basics/breaking-down-basics-cable-pulling

http://egt.net.au/apprentices/workplace-health-safety/safety-alerts/

https://www.google.com/#q=Cable+Stand+safety

Cable pulling jobs should be

commencement of the cable pull

All workers must be involved in the completion

assessment/JSA prior to commencing the cable pull

Conduct a pre-start meeting to ensure all workers understand the

requirements, their duties and the hazard controls that are place

Nominate a team leader for each cable pull

The Site Supervisor must inspect all cable pull set ups and routes prior

to commencement of the cable pull

Ensure cable stands and rollers are suitable for the task (Retained

cable drum shaft, solid drum stands and rollers rated for the weight of

the cable drums, roller assemblies are welded set up by competent

personnel

Ensure cable stands are on firm and level footing

Ensure the cable is pulled from the bottom of the drum

Where cables enter pits or go around corners minimize friction by the

use of roller guides and lubricant

Ensure any cable pulling rope and tackle is correctly rated and suitable

for the job

The team leader is the only person that can commence the cable pull

however anybody can call a stop to the operation

Follow directions from your team leader

carefully

planned

prior

of

to

the

risk

Once the cable pull has commenced, continue the pull at a steady

pace, and

Do not stand in the line of the pull and keep a safe distance from the

cable drums

Do not become distracted or complacent

Do not move from a safe position, or investigate problems unless the

cable pull has stopped

Where communication in the team is via radios or similar electronic

devices this should done by personnel with that specific role

Wear correct PPE, including gloves

Damaged cables, sockets and plugs must be removed from service immediately.

Electrical equipment must not be pulled or lifted by the cable, the connections may

become broken and create a hazard.

All cables must be adequately protected against external mechanical damage where

there is a risk of damage.

Adequate fusing or excess protection, e.g. circuit breakers, must be provided for all

fixed and portable equipment.

The use of multi socket boxes is to be avoided wherever possible.

The mains power supply must be disconnected before attempting to move electrical

equipment.

All electrical cables shall be neatly tied off where necessary so as not to present a

trip hazard. Where such wiring must run across floors it must be protected by

saddles, conduit or armouring. Extension cables, when used, must be routed so as

not to cause tripping hazards.

Flammable liquids must not be stored or used close to live electrical components.

Only CO2 or dry powder fire extinguishers can be used to fight electrical fires (red

cylinders with black or blue labels respectively).

All electrical equipment must be fully earthed.

Live electrical parts of machinery must be screened or guarded.

All electrical equipment must be fitted with appropriately rated residual current

devices.

All electrical fittings must be rated for the environment in which they are to be used.

Consideration must be given to exposure of the equipment to wet conditions,

extremes

of

temperature,

potentially

flammable

atmospheres,

etc.

Portable

equipment must be connected by means of a socket outlet suitable for the

environment in which it is used.

All portable tools, cables etc. must be regularly inspected. Check equipment before

use for any sign of damage and report defects immediately.

All electrical equipment should be turned off when not is use and overnight, unless

this is not possible for safety or operational reasons. Electrical sources powering

equipment that cannot be turned off under normal circumstances for safety or

operational reasons must be clearly signed as such at the power supply point.

Repairs and Maintenance

It is prohibited for any person other than a fully competent electrician or technician to

effect repairs to electrical equipment within the University. Under no circumstances

must untrained employees attempt to effect repairs to electrical equipment.

Any person carrying out any work on the electrical installation or any accessories or

equipment connected thereto should isolate the equipment. Live working is not

permitted, unless carried out by competent persons under the auspices of a Buildings

Office issued Electrical Permit To Work.

All electrical works must be carried out in accordance with the guidelines of The

Electro-Technical Council of Ireland.

All electrical wiring and electrical equipment within the University must be inspected

and maintained in accordance with the manufacturers instructions.

You might also like

- SK200-8 YN11 Error CodesDocument58 pagesSK200-8 YN11 Error Codest544207189% (37)

- OP-COM Board Fuel Consumption CorrectionDocument5 pagesOP-COM Board Fuel Consumption Correctionsport190196667% (3)

- Material Take Off - FINALDocument5 pagesMaterial Take Off - FINALHafizi HZnumismaticNo ratings yet

- Battery Room Design Review Checklist 2014Document3 pagesBattery Room Design Review Checklist 2014candratrikusuma100% (1)

- Copperbelt Company VacanciesDocument9 pagesCopperbelt Company Vacanciesjoseph katongoNo ratings yet

- Electrical Safety Work PracticesDocument5 pagesElectrical Safety Work PracticesAjay KrishnanNo ratings yet

- Problems PDFDocument246 pagesProblems PDFJasdeep singhNo ratings yet

- SWP-03 Electrical Safety DaimanDocument4 pagesSWP-03 Electrical Safety DaimanHassan AbdullahNo ratings yet

- Transformer 1 MosDocument5 pagesTransformer 1 MosMohamedAhmedFawzyNo ratings yet

- Power Cable Jointing: Novatex Limited SOP / E&I / 17Document3 pagesPower Cable Jointing: Novatex Limited SOP / E&I / 17OSAMANo ratings yet

- Test Procedure TXDocument4 pagesTest Procedure TXVasu100% (1)

- Lockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentDocument2 pagesLockout - Tagout (LOTO) Annual Inspection and Training Assessment Checklist Department: Shop: Location: EquipmentSayed Saad ShehataNo ratings yet

- 7-JSA - 33 - KV - HT - Panel Breaker MaintenneceDocument17 pages7-JSA - 33 - KV - HT - Panel Breaker MaintenneceVivek SinghNo ratings yet

- CT Install TransformadorDocument4 pagesCT Install TransformadorNishant SinhaNo ratings yet

- Section 26 11 13-Unit Sub-Stations PDFDocument10 pagesSection 26 11 13-Unit Sub-Stations PDFmasoodaeNo ratings yet

- LV Cable Pre-Commissioning Method StatementDocument6 pagesLV Cable Pre-Commissioning Method StatementMohamed KasemNo ratings yet

- CT Testing Procedures Download: Insulation Resistance, Characteristics, Loop Resistance, Primary Injection TestsDocument2 pagesCT Testing Procedures Download: Insulation Resistance, Characteristics, Loop Resistance, Primary Injection TestsEngr Zainulabidin KaimkhaniNo ratings yet

- Electrical Safety Standards For LV-MV-HV Part-1)Document12 pagesElectrical Safety Standards For LV-MV-HV Part-1)Suresh UmadiNo ratings yet

- Job Description: Job Title: Electrical Supervisor Ma/MrDocument2 pagesJob Description: Job Title: Electrical Supervisor Ma/MrMohd Shukri0% (1)

- Electrical Safety Audit: Action NeededDocument2 pagesElectrical Safety Audit: Action NeededTarique SaifullahNo ratings yet

- Method Statement For Cable Laying, Glanding and TerminationDocument12 pagesMethod Statement For Cable Laying, Glanding and TerminationSajid Raza100% (1)

- TR 06 Test Reports-1Document13 pagesTR 06 Test Reports-1Siva SankarNo ratings yet

- DC Cable LayingDocument8 pagesDC Cable LayingAhamed UmarNo ratings yet

- CEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTDocument6 pagesCEC ELECTRICAL ENGINEERING SDN BHD HT/HV CABLING WORK METHOD STATEMENTtanaNo ratings yet

- Special Tool Risk AssessmentDocument1 pageSpecial Tool Risk Assessmentgangadharan000No ratings yet

- JSA - Low Voltage PanelDocument19 pagesJSA - Low Voltage PanelASLAM MULANINo ratings yet

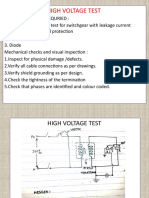

- HV TestDocument4 pagesHV TestNaveedNo ratings yet

- Electrical Safety Laws 2019Document4 pagesElectrical Safety Laws 2019mamillapalli sri harshaNo ratings yet

- Hvac CVDocument2 pagesHvac CVsarfaraz055No ratings yet

- Digital Testing of HV Circuit BreakerDocument21 pagesDigital Testing of HV Circuit Breakervamshi4all100% (10)

- Jsa D. G. INSTALLATIONDocument5 pagesJsa D. G. INSTALLATIONRavi thokalNo ratings yet

- Switch Gear SafetyDocument16 pagesSwitch Gear SafetyAnila SadasivanNo ratings yet

- Mobile Equipment Hazards-ADocument25 pagesMobile Equipment Hazards-ALuis PallerosNo ratings yet

- EXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615Document31 pagesEXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615safetydmrcNo ratings yet

- Safety During ConstructionDocument38 pagesSafety During Constructiongaurang1111No ratings yet

- Testing of Transformer Oil and Winding Temperature IndicatorsDocument6 pagesTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyNo ratings yet

- MV Cable Insulation and VLF Test Report-Is1-C.b-circuit 1Document2 pagesMV Cable Insulation and VLF Test Report-Is1-C.b-circuit 1Ahmed RabaaNo ratings yet

- Protecting Yourself Arc FlashDocument6 pagesProtecting Yourself Arc Flashgerald_mahadeoNo ratings yet

- NDPL Safety ManualDocument103 pagesNDPL Safety ManualvntjbpNo ratings yet

- Jha For Rmu Cleaning WorkDocument4 pagesJha For Rmu Cleaning Workmartins73100% (1)

- SMS-06-GD-0268 Working Around Electrical Equipment v3Document88 pagesSMS-06-GD-0268 Working Around Electrical Equipment v3Sourp VartanNo ratings yet

- MS 220kVLCCPanelBCFDRD07 PDFDocument12 pagesMS 220kVLCCPanelBCFDRD07 PDFSuprodip DasNo ratings yet

- Electrical Maintenance & Testing Hazard IdentificationDocument10 pagesElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaNo ratings yet

- N16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSDocument5 pagesN16319 - New Risk Assessment For Accessing The Substations For Identification of Route For Laying New FOC and To Locate The Position of The New FOTBSAntaryami Singh GoondiNo ratings yet

- Generator Earthing and Stator Earth Fault Protection - EEPDocument13 pagesGenerator Earthing and Stator Earth Fault Protection - EEPABHINAV SAURAVNo ratings yet

- JSA E&I 3..electrical Equipment Installation (Lighting)Document6 pagesJSA E&I 3..electrical Equipment Installation (Lighting)AmyNo ratings yet

- Jha For - TransformerDocument7 pagesJha For - Transformermujahid1137No ratings yet

- Preventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFDocument6 pagesPreventing and Identifying Potential Failures of Dead Break Elbows in Wind Farm Application - Brian - Peyres PDFSatadal DashNo ratings yet

- Electrical Risk AssessmentDocument4 pagesElectrical Risk AssessmentanisaanNo ratings yet

- 11kv Rmu PDFDocument27 pages11kv Rmu PDFSanda KinithiNo ratings yet

- Wr2 ChecklistDocument14 pagesWr2 Checklistvaithy2011No ratings yet

- Maintaining Electrical SystemsDocument8 pagesMaintaining Electrical SystemsHealthyCut FarmsNo ratings yet

- El32 Safe Isolation 2017Document182 pagesEl32 Safe Isolation 2017sriramNo ratings yet

- ED-P1 Licensing and Competency AuthorizationDocument22 pagesED-P1 Licensing and Competency AuthorizationMohammed Zubair0% (1)

- Electrical Safety - ConstructionDocument45 pagesElectrical Safety - Constructionlouiscouto123No ratings yet

- Ts108 Technical Standard For Distribution Equipment and Transformer RoomsDocument30 pagesTs108 Technical Standard For Distribution Equipment and Transformer RoomsHimdad TahirNo ratings yet

- Electrical Safety Precaution PDFDocument1 pageElectrical Safety Precaution PDFMahmoud ElturkyNo ratings yet

- Electrical Safety: Case StudyDocument4 pagesElectrical Safety: Case StudyAdedokun Opeyemi SodiqNo ratings yet

- Electrical ILO FactSheet Electrical SafetyDocument4 pagesElectrical ILO FactSheet Electrical SafetyEhsan MazharNo ratings yet

- Electrical SafetyDocument3 pagesElectrical SafetyPerwez21No ratings yet

- Uyo Transmission StationDocument19 pagesUyo Transmission StationDon SagaciousNo ratings yet

- SW Hse Sop05 Electrical Safety ProcedureDocument3 pagesSW Hse Sop05 Electrical Safety ProcedurePRAVINTH SNo ratings yet

- Temporary Labour Camps - EHS RequirementsDocument8 pagesTemporary Labour Camps - EHS RequirementsMohan PrasadNo ratings yet

- Transport Safety WorkplaceDocument9 pagesTransport Safety WorkplaceNadeem NadeemNo ratings yet

- PDF PageDocument1 pagePDF PageMohan PrasadNo ratings yet

- Africa Oil HSE Management System PDFDocument30 pagesAfrica Oil HSE Management System PDFzbhdzpNo ratings yet

- PG Diploma - Environmental Health & HygineDocument1 pagePG Diploma - Environmental Health & HygineMohan PrasadNo ratings yet

- Boggabri Investigation ReportDocument79 pagesBoggabri Investigation ReportMohan PrasadNo ratings yet

- PDF PageDocument1 pagePDF PageMohan PrasadNo ratings yet

- Sri Ramachandra Institute of Higher Education and Research: Our HistoryDocument2 pagesSri Ramachandra Institute of Higher Education and Research: Our HistoryMohan PrasadNo ratings yet

- Essentials of HSE Management SystemsDocument2 pagesEssentials of HSE Management SystemsMohan PrasadNo ratings yet

- Sri Ramachandra Institute of Higher Education and Research: Our HistoryDocument2 pagesSri Ramachandra Institute of Higher Education and Research: Our HistoryMohan PrasadNo ratings yet

- Safe Work Practice - Fueling Equipment: GeneralDocument2 pagesSafe Work Practice - Fueling Equipment: GeneralAbinesh ABNo ratings yet

- Safe Work Practice - Fueling Equipment: GeneralDocument2 pagesSafe Work Practice - Fueling Equipment: GeneralAbinesh ABNo ratings yet

- Boggabri Investigation ReportDocument79 pagesBoggabri Investigation ReportMohan PrasadNo ratings yet

- QUALITATIVE & QUANTITATIVE EXPOSURE ASSESSMENT - CorityDocument5 pagesQUALITATIVE & QUANTITATIVE EXPOSURE ASSESSMENT - CorityMohan PrasadNo ratings yet

- Trash, Recycling, & Waste - The Disposal Guide - Purple Fig CleanersDocument8 pagesTrash, Recycling, & Waste - The Disposal Guide - Purple Fig CleanersMohan PrasadNo ratings yet

- Chemical Storage Color CodesDocument6 pagesChemical Storage Color CodesMohan PrasadNo ratings yet

- Illumination. - Occupational Safety and Health AdministrationDocument3 pagesIllumination. - Occupational Safety and Health AdministrationMohan PrasadNo ratings yet

- 17 WeldingDocument18 pages17 WeldingMohan PrasadNo ratings yet

- 17 WeldingDocument18 pages17 WeldingMohan PrasadNo ratings yet

- Flammable andDocument8 pagesFlammable andMohan PrasadNo ratings yet

- 17 WeldingDocument18 pages17 WeldingMohan PrasadNo ratings yet

- HSA COP Confined Space 2010Document38 pagesHSA COP Confined Space 2010John FitzGeraldNo ratings yet

- Flammable andDocument8 pagesFlammable andMohan PrasadNo ratings yet

- Confined SpaceDocument17 pagesConfined SpaceKunal JaiswalNo ratings yet

- Soil InvestigationDocument57 pagesSoil InvestigationMohan PrasadNo ratings yet

- Flammable andDocument8 pagesFlammable andMohan PrasadNo ratings yet

- HSA COP Confined Space 2010Document38 pagesHSA COP Confined Space 2010John FitzGeraldNo ratings yet

- Underground cable installation equipment proceduresDocument10 pagesUnderground cable installation equipment proceduresMoe NagaNo ratings yet

- Logistics CaseDocument29 pagesLogistics CaseMohan PrasadNo ratings yet

- Current Monitoring Series CMR - Current Control: Ordering InformationDocument5 pagesCurrent Monitoring Series CMR - Current Control: Ordering InformationPrasadPurohitNo ratings yet

- Plantilla WPS (GMAW-MIG) Junta VDocument1 pagePlantilla WPS (GMAW-MIG) Junta Vjhojan garciaNo ratings yet

- PIPENET VISION SPRAY MODULE TRAINING MANUALDocument48 pagesPIPENET VISION SPRAY MODULE TRAINING MANUALElton Situmeang50% (2)

- ICOLD Review of WCD Report on Dams and DevelopmentDocument5 pagesICOLD Review of WCD Report on Dams and DevelopmentNazakat HussainNo ratings yet

- Reference List AW Offshore Installation SYS 2007-08-16Document10 pagesReference List AW Offshore Installation SYS 2007-08-16Sugeng WahyudiNo ratings yet

- ASME - Middle-East-Training-Brochure PDFDocument32 pagesASME - Middle-East-Training-Brochure PDFMohamed F MorsyNo ratings yet

- Type FL Low Profile NTC Temperature Sensor: AmphenolDocument3 pagesType FL Low Profile NTC Temperature Sensor: Amphenolmauricio alfonsoNo ratings yet

- Gat Test 26-3-22 PDFDocument8 pagesGat Test 26-3-22 PDFRitesh Raj PandeyNo ratings yet

- Acd (Microproject Report)Document42 pagesAcd (Microproject Report)Gaurav SapkalNo ratings yet

- Wattstopper Sensor The Most Advanced Energy Saving TechnologyDocument7 pagesWattstopper Sensor The Most Advanced Energy Saving TechnologyDemo Only100% (1)

- Komatsu Hydraulic Excavator Pc850se 8 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc850se 8 Shop Manualleon100% (41)

- PHYSICSDocument3 pagesPHYSICSAndrew NibungcoNo ratings yet

- ThermodynamicsDocument341 pagesThermodynamicsjonathan2788100% (4)

- Eastern Visayas State University-Ormoc City CampusDocument3 pagesEastern Visayas State University-Ormoc City Campuskhellian villameroNo ratings yet

- A380-LEVEL III - ATA 26 Fire - Smoke DetectionDocument42 pagesA380-LEVEL III - ATA 26 Fire - Smoke DetectionAbolfazl Mazloomi100% (2)

- Assignment-Research 2-MJD-MALLARIDocument9 pagesAssignment-Research 2-MJD-MALLARIMark MallariNo ratings yet

- TP48200A-HD15A6 & HD15A7 & HD15A8 & HD15A9 & HT15A5 & HT15A6 & DX15A1 & HX15A1 V500R001 User Manual 01 PDFDocument116 pagesTP48200A-HD15A6 & HD15A7 & HD15A8 & HD15A9 & HT15A5 & HT15A6 & DX15A1 & HX15A1 V500R001 User Manual 01 PDFEla TorquataNo ratings yet

- Drill Exam ComboDocument79 pagesDrill Exam ComboMakiber100% (2)

- Gates em Ingles 2010Document76 pagesGates em Ingles 2010felipeintegraNo ratings yet

- Thermiculite BrochureDocument8 pagesThermiculite BrochureXuan TruongNo ratings yet

- Diesel Engine Technical SpecificationsDocument3 pagesDiesel Engine Technical SpecificationsFahad MohammedNo ratings yet

- He165 (A4)Document4 pagesHe165 (A4)KennethWilfredoVegaOviedoNo ratings yet

- GEA PHE NT enDocument2 pagesGEA PHE NT enVLASTAR100% (2)

- TOBUL OandMsheet052909v2Document5 pagesTOBUL OandMsheet052909v2Walter JosephNo ratings yet

- Offshore Wind PowerDocument22 pagesOffshore Wind PowerS. M. IsrafilNo ratings yet

- Introduction to Coiled Tubing (1-24Document24 pagesIntroduction to Coiled Tubing (1-24SallyCahyatiNo ratings yet

- Cambridge International AS Level: Environmental Management 8291/12Document12 pagesCambridge International AS Level: Environmental Management 8291/12zohaibNo ratings yet