Professional Documents

Culture Documents

Power Distribution System Design Reference Data

Uploaded by

Fersh ValderramashOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Power Distribution System Design Reference Data

Uploaded by

Fersh ValderramashCopyright:

Available Formats

A-64

Cutler-Hammer

Power Distribution System Design

January 1999

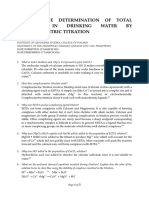

Reference Data Conductor Resistance, Reactance, Impedance

The tables below are average characteristics

based on data from several manufacturers of

copper and aluminum conductors and cable,

and also NEC Table 9. Values from different

sources vary because of operating temperatures, wire stranding, insulation materials

and thicknesses, overall diameters, random

lay of multiple conductors in conduit, conductor spacing, and other divergences in

materials, test conditions and calculation

methods. These tables are for 600-volt conductors, at an average temperature of 75C.

Other parameters are listed in the notes. For

medium-voltage cables, differences among

manufacturers are considerably greater

because of the wider variations in insulation

materials and thicknesses, shielding, jacketing, overall diameters, and the like. Therefore, data for medium-voltage cables should

be obtained from the manufacturer of the

cable to be used.

Average Characteristics of 600-Volt Conductors (Ohms per 100 Feet)

Table A45: Two or Three Single Conductors

Wire Size,

AWG or

kcmil

Copper Conductors

R

14

12

10

8

6

4

2

1

1/0

2/0

3/0

4/0

250

300

350

400

450

500

600

700

750

1000

.3130

.1968

.1230

.0789

.0490

.0318

.0203

.0162

.0130

.0104

.00843

.00696

.00588

.00512

.00391

.00369

.00330

.00297

.00261

.00247

.00220

.00780

.00730

.00705

.00691

.00640

.00591

.00548

.00533

.00519

.00511

.00502

.00489

.00487

.00484

.00480

.00476

.00467

.00458

.00455

.00448

.00441

.3131

.1969

.1232

.0792

.0494

.0323

.0210

.0171

.01340

.01159

.00981

.00851

.00763

.00705

.00619

.00602

.00595

.00546

.00525

.00512

.00493

.3130

.1968

.1230

.0789

.0490

.0318

.0203

.0162

.0129

.0103

.00803

.00666

.00578

.00501

.00380

.00356

.00310

.00275

.00241

.00247

.00198

.00624

.00584

.00564

.00553

.00512

.00473

.00438

.00426

.00415

.00409

.00402

.00391

.00390

.00387

.00384

.00381

.00374

.00366

.00364

.00358

.00353

.3131

.1969

.1231

.0791

.0493

.0321

.0208

.0168

.01360

.01108

.00898

.00772

.00697

.00633

.00540

.00521

.00486

.00458

.00437

.00435

.00405

.0833

.0530

.0335

.0267

.0212

.0170

.01380

.01103

.00936

.00810

.00694

.00618

.00548

.00482

.00409

.00346

.00308

.00250

.00509

.00490

.00457

.00440

.00410

.00396

.00386

.00381

.00375

.00366

.00360

.00355

.00350

.00346

.00355

.00340

.00331

.00330

.0835

.0532

.0338

.0271

.0216

.0175

.0143

.0117

.01008

.00899

.00782

.00713

.00650

.00593

.00542

.00485

.00452

.00414

.0833

.0530

.0335

.0267

.0212

.0170

.01380

.01097

.00933

.00797

.00688

.00610

.00536

.00470

.00395

.00330

.00278

.00230

.00407

.00392

.00366

.00352

.00328

.00317

.00309

.00305

.00300

.00293

.00288

.00284

.00280

.00277

.00284

.00272

.00265

.00264

.0834

.0531

.0337

.0269

.0215

.0173

.01414

.01139

.00980

.00849

.00746

.00673

.00605

.00546

.00486

.00428

.00384

.00350

Aluminum Conductors

Magnetic Conduit

Nonmagnetic Conduit

Magnetic Conduit

Nonmagnetic Conduit

Table A46: Three-conductor Cables (and Interlocked Armored Cable)

Wire Size,

AWG or

kcmil

Copper Conductors

R

14

12

10

8

6

4

2

1

1/0

2/0

3/0

4/0

250

300

350

400

450

500

600

700

750

1000

.3130

.1968

.1230

.0789

.0490

.0318

.0203

.0162

.0130

.0104

.00843

.00696

.00588

.00512

.00391

.00369

.00360

.00297

.00261

.00247

.00220

.00597

.00558

.00539

.00529

.00491

.00452

.00420

.00408

.00398

.00390

.00384

.00375

.00373

.00370

.00365

.00360

.00351

.00343

.00337

.00330

.00323

.3131

.1969

.1231

.0790

.0492

.0321

.0207

.0167

.0136

.0111

.00926

.00791

.00696

.00632

.00535

.00516

.00503

.00454

.00426

.00412

.00391

.3130

.1968

.1230

.0789

.0490

.0318

.0203

.0162

.0129

.0103

.00803

.00666

.00578

.00501

.00380

.00356

.00310

.00275

.00241

.00227

.00198

.00521

.00487

.00470

.00461

.00427

.00394

.00366

.00355

.00346

.00341

.00335

.00326

.00325

.00323

.00320

.00318

.00312

.00305

.00303

.00298

.00294

.3130

.1969

.1231

.0790

.0492

.0320

.0206

.0166

.0134

.0108

.00870

.00742

.00663

.00596

.00497

.00477

.00440

.00411

.00387

.00375

.00354

.0833

.0530

.0335

.0267

.0212

.0170

.01380

.01103

.00936

.00810

.00694

.00618

.00548

.00482

.00409

.00346

.00308

.00250

.00509

.00490

.00457

.00440

.00410

.00396

.00389

.00381

.00375

.00366

.00360

.00355

.00350

.00346

.00355

.00341

.00331

.00330

.0834

.0532

.0338

.0271

.0216

.0175

.0143

.0117

.01006

.00889

.00782

.00713

.00650

.00593

.00542

.00486

.00452

.00414

.0833

.0530

.0335

.0267

.0212

.0170

.01380

.01097

.00933

.00797

.00688

.00610

.00536

.00470

.00395

.00330

.00278

.00230

.00407

.00392

.00366

.00352

.00328

.00317

.00309

.00305

.00300

.00293

.00288

.00284

.00280

.00277

.00284

.00272

.00265

.00264

.0834

.0531

.0337

.0269

.0215

.0173

.01414

.01139

.00980

.00849

.00746

.00673

.00605

.00546

.00486

.00428

.00384

.00350

Aluminum Conductors

Magnetic Conduit

Nonmagnetic Conduit

Resistance and reactance are phase-to-neutral

values, based on 60 Hertz ac, 3-phase, 4-wire

distribution, in ohms per 100 feet of circuit length

(not total conductor lengths).

Based upon conductivity of 100% for copper, 61%

for aluminum.

Magnetic Conduit

Based on conductor temperatures of 75C.

Reactance values will have negligible variation

with temperature. Resistance of both copper and

aluminum conductors will be approximately 5%

lower at 60C or 5% higher at 90C. Data shown in

tables may be used without significant error

between 60C and 90C.

Nonmagnetic Conduit

For interlocked armored cable, use magnetic

conduit data for steel armor and non-magnetic

conduit data for aluminum armor.

2

Z =

X +R

For busway impedance data, see section H2 of

this catalog.

CAT.71.01.T.E

You might also like

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsFrom EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsNo ratings yet

- Arc Flash: Technical PerspectiveDocument29 pagesArc Flash: Technical Perspective최형식No ratings yet

- Willis.P PowerFactory ProtModelsDocument16 pagesWillis.P PowerFactory ProtModelsAndrewcaesarNo ratings yet

- SATURACIÓN IEC 61869-100. Ejemplo 5.2.1: M VA VADocument18 pagesSATURACIÓN IEC 61869-100. Ejemplo 5.2.1: M VA VAJIMENEZPS100% (1)

- Performance Analysis of Vpi Transformer: For ContinuousDocument6 pagesPerformance Analysis of Vpi Transformer: For ContinuousSwapan Kundu100% (1)

- Analysis of Zig-Zag Transformer Applying in The Three-Phase Four-Wire Distribution Power SystemDocument6 pagesAnalysis of Zig-Zag Transformer Applying in The Three-Phase Four-Wire Distribution Power SystemHESHAM_ELREFAIENo ratings yet

- Thermal Analysis For Underground Cable Systems Neher-McGrath vs. IEC 60287 Methods PDFDocument1 pageThermal Analysis For Underground Cable Systems Neher-McGrath vs. IEC 60287 Methods PDFgilbertomjcNo ratings yet

- Oil Circuit Breakers PF TestDocument35 pagesOil Circuit Breakers PF TestPriambudi Pujihatma100% (1)

- Transformer ANSI Curve Shift 58% PDFDocument3 pagesTransformer ANSI Curve Shift 58% PDFgilbertomjcNo ratings yet

- Operation and Installation ManualDocument70 pagesOperation and Installation ManualJosé Antonio SilvestreNo ratings yet

- Floating Neutral Impact in Power DistributionDocument9 pagesFloating Neutral Impact in Power DistributionSugeng SumarnoNo ratings yet

- Wire Products: Alumoweld Wire and StrandDocument8 pagesWire Products: Alumoweld Wire and StrandAndres FrancoNo ratings yet

- Sol Sdm02 SK Pe Ele FD 061 r01Document9 pagesSol Sdm02 SK Pe Ele FD 061 r012D EngenhariaNo ratings yet

- EPSH4 - 1031 - PS - Stability Research PDFDocument201 pagesEPSH4 - 1031 - PS - Stability Research PDFyesar laftaNo ratings yet

- A Calculation Method For Impulse Voltage Distribution in TransformerDocument10 pagesA Calculation Method For Impulse Voltage Distribution in Transformerrajfab86% (7)

- Proceedings of 8th WSEAS Conf on Instrumentation Measurement CircuitsDocument6 pagesProceedings of 8th WSEAS Conf on Instrumentation Measurement CircuitsyoganandvNo ratings yet

- Cigre WG C4303 0Document15 pagesCigre WG C4303 0Saturnino42100% (1)

- Pirelli PDFDocument24 pagesPirelli PDFFarhan ShahNo ratings yet

- Optimize Earth Fault Protection with Core Balance Current TransformersDocument3 pagesOptimize Earth Fault Protection with Core Balance Current Transformersதுரைராஜ் இலட்சுமணன்No ratings yet

- Arresters - Station Class and Intermediate PDFDocument44 pagesArresters - Station Class and Intermediate PDFMiguel Henrique Estevez SantanaNo ratings yet

- Effect of DC Testing On XLPE Insulated CablesDocument6 pagesEffect of DC Testing On XLPE Insulated Cablesnamsaigon316No ratings yet

- ANSI C37.42-1996 American National Standard Specification For High-Voltage Expulsion Type Distribution Class Fuses, Cutouts, Fuse Disconnecting Switches and Fuse LinksDocument31 pagesANSI C37.42-1996 American National Standard Specification For High-Voltage Expulsion Type Distribution Class Fuses, Cutouts, Fuse Disconnecting Switches and Fuse LinksDewram AshinsanaNo ratings yet

- Ieee 998 Parte1Document127 pagesIeee 998 Parte1Andres HerreraNo ratings yet

- Doble Tutorial - Medium Voltage Power Cables and AccessoriesDocument109 pagesDoble Tutorial - Medium Voltage Power Cables and AccessoriessulemankhalidNo ratings yet

- Dual Three-Winding Transformer Equivalent Circuit Matching Leakage MeasurementsDocument9 pagesDual Three-Winding Transformer Equivalent Circuit Matching Leakage MeasurementsDiegoNo ratings yet

- Induction Motor Starting Analysis Comparison Using ETAPDocument8 pagesInduction Motor Starting Analysis Comparison Using ETAPTosikur RahmanNo ratings yet

- Essential Differences Between IEC 60909 and ANSIIEEE C37 SeriesDocument4 pagesEssential Differences Between IEC 60909 and ANSIIEEE C37 Seriesyeprem82No ratings yet

- TechRef OverheadLineConstantsDocument24 pagesTechRef OverheadLineConstantsWalter CataldoNo ratings yet

- Typical Surge Arrester VI Characteristic Plotting Excel WorkbookDocument12 pagesTypical Surge Arrester VI Characteristic Plotting Excel Workbookhey_frindNo ratings yet

- Products l3 Oskf Ansi 71503 v1 enDocument4 pagesProducts l3 Oskf Ansi 71503 v1 enSergiu Aparatu100% (2)

- BUS Ele Tech Lib Conductor Protection Wire Cable Protection 1Document3 pagesBUS Ele Tech Lib Conductor Protection Wire Cable Protection 1Víctor RojasNo ratings yet

- (1981) - Single Phase Switching Tests On The AEP 765 KVDocument7 pages(1981) - Single Phase Switching Tests On The AEP 765 KVluan balbinoNo ratings yet

- Normas pruebas equipos subestacionesDocument4 pagesNormas pruebas equipos subestacionesCristianMedinaNo ratings yet

- Three Winding Transformer Test System-EPRI-2017-Rev4Document18 pagesThree Winding Transformer Test System-EPRI-2017-Rev4Jorge TorresNo ratings yet

- Three Phase Transformer Model For TransientsDocument10 pagesThree Phase Transformer Model For TransientsYeissonSanabriaNo ratings yet

- Dry Type Transformer TestingDocument4 pagesDry Type Transformer TestingGary Martin100% (1)

- Ieee STD c57!19!00 2004 Ieee StandardDocument27 pagesIeee STD c57!19!00 2004 Ieee StandardEdison Villarruel CuchoNo ratings yet

- 09 MaschinenfabrikReinhausen On LoadTap ChangerDocument28 pages09 MaschinenfabrikReinhausen On LoadTap Changerhardian syaputraNo ratings yet

- Cold Load Pick-Up - Theory and Industry PracticesDocument30 pagesCold Load Pick-Up - Theory and Industry PracticesamirrezafeyziNo ratings yet

- Protection of Rotating AC Equipment Against Travelling WavesDocument7 pagesProtection of Rotating AC Equipment Against Travelling WavespwmvsiNo ratings yet

- Dawalibi Earth Resistivity PDFDocument9 pagesDawalibi Earth Resistivity PDFRaul Marihuan GonzálezNo ratings yet

- Power Balance and Choice of Power Supply Solutions PDFDocument88 pagesPower Balance and Choice of Power Supply Solutions PDFajayi micheal sundayNo ratings yet

- Ansi C92.1 (1982)Document16 pagesAnsi C92.1 (1982)juanita sanchez buitragoNo ratings yet

- Bucholz Relay Detailed GuideDocument12 pagesBucholz Relay Detailed GuideUsman SaeedNo ratings yet

- T A P S: Down Loaded From IEEE Web PageDocument38 pagesT A P S: Down Loaded From IEEE Web Pageharshveer84No ratings yet

- 3ap1 DTC: - Dead Tank CompactDocument18 pages3ap1 DTC: - Dead Tank CompactFidel AgüeroNo ratings yet

- MU040 - KRT EngHandbook Lowres PDFDocument24 pagesMU040 - KRT EngHandbook Lowres PDFRajendra Prasad ShuklaNo ratings yet

- Prima Automation (I) Pvt. Ltd. Ampere-Busbar Selection ChartDocument3 pagesPrima Automation (I) Pvt. Ltd. Ampere-Busbar Selection ChartPower MuruganNo ratings yet

- CYMGRD Optimal Design of Substation Grounding GridsDocument5 pagesCYMGRD Optimal Design of Substation Grounding Gridsjaneth lozanoNo ratings yet

- Sizing of Power Cables For Circuit Breaker Controlled Feeders (Part 3) - EEP PDFDocument21 pagesSizing of Power Cables For Circuit Breaker Controlled Feeders (Part 3) - EEP PDFNatarajan ViswanathanNo ratings yet

- Magnetic Saturation PDFDocument6 pagesMagnetic Saturation PDFDaniel MemijeNo ratings yet

- Maintenance Testing Specifications For Electrical Power DistributionDocument15 pagesMaintenance Testing Specifications For Electrical Power DistributionalanNo ratings yet

- Manual Controlador C90Document442 pagesManual Controlador C90Fabián MejíaNo ratings yet

- Analysis of The Root Causes of Transformer Bushing FailuresDocument7 pagesAnalysis of The Root Causes of Transformer Bushing FailuresSamwel MmariNo ratings yet

- Winter 2011Document128 pagesWinter 2011baoHVLABNo ratings yet

- Trafo Spec PDFDocument56 pagesTrafo Spec PDFMohammad Fadhil KoesputraNo ratings yet

- Reactive Power Compensation: A Practical GuideFrom EverandReactive Power Compensation: A Practical GuideRating: 5 out of 5 stars5/5 (1)

- Structural Engineering Design Criteria: Appendix 10BDocument33 pagesStructural Engineering Design Criteria: Appendix 10BErnesto MarinNo ratings yet

- Shackles: 5150 - Nut & Bolt Bow ShackleDocument1 pageShackles: 5150 - Nut & Bolt Bow ShackleAlthaf R100% (1)

- Thermal fatigue and brittle fracture mechanismsDocument3 pagesThermal fatigue and brittle fracture mechanismsSimbu Arasan100% (1)

- Why Carbon Fits in Octahedral Void of BCC Iron and Solubility in FCC vs BCCDocument2 pagesWhy Carbon Fits in Octahedral Void of BCC Iron and Solubility in FCC vs BCCSrinivasulu PuduNo ratings yet

- Welding ErrorsDocument42 pagesWelding ErrorsNDTInstructorNo ratings yet

- 2007-Catálogo Burndy ConectoresDocument724 pages2007-Catálogo Burndy ConectoresAlexis ArayNo ratings yet

- Duralumin Poles Are Preferred To Those Made of FiberglassDocument1 pageDuralumin Poles Are Preferred To Those Made of FiberglassAnca TruţaNo ratings yet

- A Historical Overview of Steel Tempering ParametersDocument53 pagesA Historical Overview of Steel Tempering ParametersAlexis Guzmán MéndezNo ratings yet

- Avail 9 WDocument1 pageAvail 9 WnistianaNo ratings yet

- ITRI Pub 602Document14 pagesITRI Pub 602martinpsNo ratings yet

- Iso 4948 1 1982Document4 pagesIso 4948 1 1982surya zenNo ratings yet

- BS en 755-7 1995 TablesDocument6 pagesBS en 755-7 1995 TablesestabejaNo ratings yet

- DDALCA-01 - Return To The Ghost Tower of InvernessDocument41 pagesDDALCA-01 - Return To The Ghost Tower of InvernessTyraen the BlackNo ratings yet

- Solenoid Valves 3/2 551 553Document12 pagesSolenoid Valves 3/2 551 553frghertyertyergfhdftyertyNo ratings yet

- Exercícios CallisterDocument66 pagesExercícios CallistermicrovilosidadesNo ratings yet

- Standards SpreadsheetDocument14 pagesStandards Spreadsheetyulianus_srNo ratings yet

- Catalogsheet Baseline BL 10Document2 pagesCatalogsheet Baseline BL 10api-221502147No ratings yet

- Determination of Water Hardness by Complexometric TitrationDocument3 pagesDetermination of Water Hardness by Complexometric TitrationJunko TsukudaNo ratings yet

- Carbon Steel 1030 Availability from North American SuppliersDocument4 pagesCarbon Steel 1030 Availability from North American SuppliersShailendra SharmaNo ratings yet

- Resistance Seam WeldingDocument7 pagesResistance Seam WeldingaashulhedaNo ratings yet

- Chem (Final)Document17 pagesChem (Final)Jaynie Lee VillaranNo ratings yet

- Astm f436 Type 1Document1 pageAstm f436 Type 1seenudesignNo ratings yet

- Broom Manufacture Machine: StartDocument62 pagesBroom Manufacture Machine: StartHaziq PazliNo ratings yet

- As 7703 Iso Fe Serie enDocument8 pagesAs 7703 Iso Fe Serie enprihartono_diasNo ratings yet

- Rittal TS Spec Guide 2011Document16 pagesRittal TS Spec Guide 2011senthil031277No ratings yet

- Die Casting Guide: Processes, Advantages & ApplicationsDocument10 pagesDie Casting Guide: Processes, Advantages & ApplicationsJimyVillaNo ratings yet

- Dye Pentrant Test ProcedureDocument6 pagesDye Pentrant Test ProcedurePer DCNo ratings yet

- Anglais ScientifiqueDocument4 pagesAnglais Scientifiqueali BourenaneNo ratings yet

- Parklamp Inch Tube Clamp Visual IndexDocument20 pagesParklamp Inch Tube Clamp Visual Indexsunil601No ratings yet

- Most of The Answers Have Been Rounded Up or Rounded Down To Three Significant Figures (3Sf) Question 1: (A) Mno + 8H + 5fe MN + 5fe + 4H ODocument10 pagesMost of The Answers Have Been Rounded Up or Rounded Down To Three Significant Figures (3Sf) Question 1: (A) Mno + 8H + 5fe MN + 5fe + 4H Ohany mohamedNo ratings yet