Professional Documents

Culture Documents

GTAW Welding Procedure Specification

Uploaded by

Vimin PrakashOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GTAW Welding Procedure Specification

Uploaded by

Vimin PrakashCopyright:

Available Formats

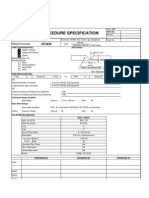

Mushrif Trading & Contracting Co.

PRELIMINARY WELDING PROCEDURE SPECIFICATION (PWPS)

( As per ASME SEC- IX)

Welding Procedure Specification No.:

Supporting PQR No : N/A

Revision No.:

Revision No.:

Date :

Welding Process (es) : GTAW

Joint Details ( QW 402)

Joint Design

Single Vee Butt

Groove Design

Refer drawing

Backing (Yes / No)

Date :

Type (s) : Manual

Joint Design ( QW- 402 )

35o +2.5o

Typical

T

T

No

1.8 + 0.6 mm

1 0.8-2.4

mm mm

BASE METALS ( QW-403 )

P No.: 1 Group No. 1&2 to P No. 8 Group No.2

Specification type & Grade

API 5L Gr.B/A 106 Gr.B /A234 WPB/A105 or Equivalent

To

Specification type & Grade

A312 TP 310 /ASTM A403 WP310S or Equivalent

Thickness Range qualified

Base Metal

1.5 to 6.10 mm

Diameter range

Groove : All sizes

Others

None

Fillet :

All Sizes

FILLER METALS ( QW - 404 )

ROOT

FILL/CAP

Spec. No. (SFA)

5.9

5.9

AWS No (Class)

ER 309L

ER 309L

F. No

A. No

1.6, 2.4 mm

1.6, 2.4 mm

Approved manufacturer

Approved manufacturer

Size of Filler Metal

Filler metal trade name

Deposited weld metal for groove

3.05 mm

Thickness range for groove qualified

Upto 6.10 mm

Thickness range of Fillet

All Thk.

Electrode Flux (Class)

N/A

N/A

Flux trade Name

N/A

N/A

Bare solid

Bare solid

None

None

N/A

N/A

Filler metal product form

Consumable Insert

Others

POSITION ( QW-405 )

Position of Groove

All Thk.

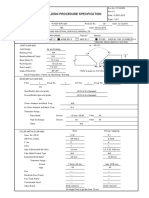

POST WELD HEAT TREATMENT ( QW - 407 )

All positions

WPS-MTC-005B, Rev.-0 28 Aug.-2007

Temperature Range

N/A

Page 3 of 3

Mushrif Trading & Contracting Co.

PRELIMINARY WELDING PROCEDURE SPECIFICATION (PWPS)

( As per ASME SEC- IX)

Welding Progression

Uphill

Position(s) of Fillet

All positions

Time Range

PREHEAT ( QW- 406 )

N/A

TECHNIQUE ( QW - 410 )

10 C

Preheat Temp. Min

Inter pass Temp. Max.

175

Preheat Maintenance

10O C

Sting or Weave bead

Root

Others

Orifice or Gas cup size

No-5 to No-8

Initial and other pass cleaning

String

Weave

By wire brushing/and grinding

GAS ( QW - 408 )

Shielding

Gas

%Composition

Argon

99.995%

Trailing

Flow rate

10 - 15 LPM

None

Argon

Backing

99.995%

10 - 15 LPM

ELECTRICAL CHARACTERISTICS ( QW- 409 )

Current AC or DC

Amps (Range)

DC

Oscillation

N/A

Contact Tube to work distance

N/A

Multiple or Single pass ( per side)

Volts (Range) see table

Tungsten Electrode size and type

2.4 mm dia

2% (Thoriated)

Mode of Metal transfer for GMAW

N/A

Electrode Wire feed speed range

N/A

Welding

Process

N/A

Multi pass

Polarity : DCEN (GTAW)

see table

Weld

Layer (s)

Method of Back Gouging

Electrode /

Diameter in

Filler Metal

( mm )

Class

Multiple or Single Electrode

Single

Travel speed range

see table

Other

Polarity

Amp.

Range

(Amps)

None

Volt

Travel Speed Range

Range

( mm/ min )

(Volts)

Remarks

Root Pass

GTAW ER309L

1.6

DCEN

80-120

8-10

84

Nil

Hot Pass

GTAW ER309L

1.6

DCEN

80-120

8-10

102

Nil

Fill up

GTAW ER309L

2.4

DCEN

108-132

8-10

105

Nil

Caping

GTAW ER309L

2.4

DCEN

103-126

8-10

89

Nil

MUSHRIF

KOC

Name

WPS-MTC-005B, Rev.-0 28 Aug.-2007

Page 4 of 3

Mushrif Trading & Contracting Co.

PRELIMINARY WELDING PROCEDURE SPECIFICATION (PWPS)

( As per ASME SEC- IX)

Designation

Signature

Date

WPS-MTC-005B, Rev.-0 28 Aug.-2007

Page 5 of 3

You might also like

- WPS GTAW Stainless SteelDocument2 pagesWPS GTAW Stainless SteelSrinivasan Muruganantham84% (31)

- WPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276Document20 pagesWPS, PQR & WPQ - Hastealloy C276 To Hastealloy C276prod41567% (6)

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- Wps SawDocument2 pagesWps Sawdevendrasingh2021100% (6)

- WPS-PQR (Er309l Mo)Document4 pagesWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- Gtaw WPQDocument3 pagesGtaw WPQMuhammadShabbirNo ratings yet

- Loading Unloading Temperature Welding ProgressionDocument5 pagesLoading Unloading Temperature Welding ProgressionRajesh Owaiyar71% (7)

- 85 TPH CFBC Boiler Operation and Maintenance ManualDocument152 pages85 TPH CFBC Boiler Operation and Maintenance ManualAamirMalik100% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- Wps Gtaw Monel b127 b164Document2 pagesWps Gtaw Monel b127 b164Srinivasan Muruganantham67% (3)

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNo ratings yet

- Electrode Qualification E 6010Document4 pagesElectrode Qualification E 6010Ranjan Kumar75% (8)

- Fit-Up Inspection Report PDFDocument1 pageFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- Welding Electrode Specification ChartDocument2 pagesWelding Electrode Specification ChartMahesh Kumar100% (2)

- Welder Identification Card: Reference Code: ASME SEC IX Company Name - TESCODocument4 pagesWelder Identification Card: Reference Code: ASME SEC IX Company Name - TESCOibrahim100% (2)

- Proposed WPSDocument2 pagesProposed WPSChisom Ikengwu100% (2)

- WPS Resrvoire Sous Pression Smaw SawDocument6 pagesWPS Resrvoire Sous Pression Smaw SawDanem HalasNo ratings yet

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- Adhesives: Standard Terminology ofDocument12 pagesAdhesives: Standard Terminology ofJOHN MARTINNo ratings yet

- Wps p91 - BhelDocument2 pagesWps p91 - BhelAshish Gupta100% (4)

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Multiple PQR QualificationDocument4 pagesMultiple PQR QualificationKarthikeyan ShanmugavelNo ratings yet

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- Aws d1.1 WPS, PQR & WQTDocument4 pagesAws d1.1 WPS, PQR & WQTWeld Bro SandeepNo ratings yet

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- According To ASME IX: Welding Procedure Specification (W.P.S)Document4 pagesAccording To ASME IX: Welding Procedure Specification (W.P.S)Mohamed SalehNo ratings yet

- Indcon Projects Electrode Qualification Procedure IOCL Gas PipelineDocument11 pagesIndcon Projects Electrode Qualification Procedure IOCL Gas PipelineAkhilesh Kumar67% (3)

- PQR SAW ProcessDocument1 pagePQR SAW Processdevendrasingh202133% (3)

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- WPS 2014-002 006 - 6G PipeDocument3 pagesWPS 2014-002 006 - 6G PipejeswinNo ratings yet

- Welder Qualification Test Certificate for Mohan ReddyDocument2 pagesWelder Qualification Test Certificate for Mohan Reddyvijay100% (1)

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- PART 66 ASME IX - Part 2 Essential Variable For Welder QualificationDocument13 pagesPART 66 ASME IX - Part 2 Essential Variable For Welder Qualificationravindra_jivaniNo ratings yet

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateDocument3 pagesWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaNo ratings yet

- List of Qualified WeldersDocument3 pagesList of Qualified WeldersdavNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocument9 pagesASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- EQT ChecklistDocument5 pagesEQT Checklistvijayachidu100% (1)

- P 91 - Welding WPSDocument2 pagesP 91 - Welding WPSSuhailshah123475% (4)

- WPS PQR ProcedureDocument31 pagesWPS PQR Proceduresudeesh kumarNo ratings yet

- Electrodes ConsumablesDocument2 pagesElectrodes Consumablesranjith_007100% (2)

- Welder Id SampleDocument1 pageWelder Id Sampledevendrasingh202157% (7)

- FCAW Overlay WPSDocument2 pagesFCAW Overlay WPSAsad Bin Ala Qatari100% (1)

- Reports - QAQC - R0Document10 pagesReports - QAQC - R0talupurumNo ratings yet

- Page No: 01: SA 240 GR 304 SA 240 GR 304Document5 pagesPage No: 01: SA 240 GR 304 SA 240 GR 304jobertNo ratings yet

- Electrode Baking RegisterDocument1 pageElectrode Baking RegisterSuresh Rathod100% (4)

- Welding Procedure Specification for SMAW of Carbon Steel Butt JointsDocument2 pagesWelding Procedure Specification for SMAW of Carbon Steel Butt JointstayyabNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Des QC 8505 Ab 08Document3 pagesDes QC 8505 Ab 08Touseef RafiqueNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaNo ratings yet

- Icp Fee Structure Effective January 2014Document1 pageIcp Fee Structure Effective January 2014Abu HurairaNo ratings yet

- API 572 Study Guide: Practice QuestionsDocument24 pagesAPI 572 Study Guide: Practice Questionsnivrutti2012100% (1)

- 2 Painting Insp - Report (PN-001)Document1 page2 Painting Insp - Report (PN-001)Vimin Prakash100% (3)

- Joint Dia Spool No. THK Sr. No Weld Joint No. ISO - Drawing No Line Class Welder IdentificationDocument34 pagesJoint Dia Spool No. THK Sr. No Weld Joint No. ISO - Drawing No Line Class Welder IdentificationVimin PrakashNo ratings yet

- Wara Pressure Maintenance Project Piping Summary SheetDocument1 pageWara Pressure Maintenance Project Piping Summary SheetVimin PrakashNo ratings yet

- Cse Capital MarketDocument1 pageCse Capital MarketVimin PrakashNo ratings yet

- SS312 Type310Document4 pagesSS312 Type310Vimin PrakashNo ratings yet

- Engg MaterialsDocument20 pagesEngg MaterialsVimin PrakashNo ratings yet

- ASME 20IX - Questions 1Document22 pagesASME 20IX - Questions 1musaismail8863No ratings yet

- 6"-WT-021-EW9A PIPING SUMMARYDocument1 page6"-WT-021-EW9A PIPING SUMMARYVimin PrakashNo ratings yet

- d5200 16pDocument8 pagesd5200 16prpcspNo ratings yet

- Emission Estimation Technique Manual: Surface CoatingDocument39 pagesEmission Estimation Technique Manual: Surface CoatingVimin PrakashNo ratings yet

- WPMP NDT Request FormDocument7 pagesWPMP NDT Request FormVimin PrakashNo ratings yet

- ASNT Exam SchedulesDocument3 pagesASNT Exam SchedulesVimin PrakashNo ratings yet

- Powder Coating Process FinalDocument6 pagesPowder Coating Process FinalRucarean PetreNo ratings yet

- Wara Pressure Maintenance Project: IndexDocument1 pageWara Pressure Maintenance Project: IndexVimin PrakashNo ratings yet

- Industrial Coating of Metal SurfacesDocument72 pagesIndustrial Coating of Metal Surfacesmp87_ing100% (3)

- 30" South Distribution Line Balance Joints For Coating ReleaseDocument15 pages30" South Distribution Line Balance Joints For Coating ReleaseVimin PrakashNo ratings yet

- Pipe Book: Wara Pressure Maintenance ProjectDocument2 pagesPipe Book: Wara Pressure Maintenance ProjectVimin PrakashNo ratings yet

- 30" South Distribution Line Balance Joints For Coating ReleaseDocument15 pages30" South Distribution Line Balance Joints For Coating ReleaseVimin PrakashNo ratings yet

- TK 24ND 001Document16 pagesTK 24ND 001Vimin PrakashNo ratings yet

- IndexDocument3 pagesIndexVimin PrakashNo ratings yet

- Book 1Document3 pagesBook 1Vimin PrakashNo ratings yet

- Deepika Calender 2014Document8 pagesDeepika Calender 2014Sudarsana Kumar VadasserikkaraNo ratings yet

- Coating Release Report (Pipe Line) : Wara Pressure Maintenance ProjectDocument60 pagesCoating Release Report (Pipe Line) : Wara Pressure Maintenance ProjectVimin PrakashNo ratings yet

- Calculation of Air Content (P/V Plot)Document2 pagesCalculation of Air Content (P/V Plot)Vimin PrakashNo ratings yet

- 16" Line Manifold No.3&4 Coating Release Report: 1 BO-J06 BO-J41 2 BO-J43 BO1-J18 3 BO1-J21 BO1-J32 4 BO1-J36 BO1-J37Document1 page16" Line Manifold No.3&4 Coating Release Report: 1 BO-J06 BO-J41 2 BO-J43 BO1-J18 3 BO1-J21 BO1-J32 4 BO1-J36 BO1-J37Vimin PrakashNo ratings yet

- 24 NewDocument174 pages24 NewVimin PrakashNo ratings yet

- E 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet SdsDocument9 pagesE 4575 Dry Ice Solid Carbon Dioxide Safety Data Sheet Sdsjohnpatt888No ratings yet

- Chapter 13 Oil Based MudsDocument65 pagesChapter 13 Oil Based Mudsمحمد أحمد عبداللطيفNo ratings yet

- Bioplastic ProjectDocument15 pagesBioplastic ProjectSarthak Verma100% (1)

- Corrosion of Iron: An Electrochemical ProcessDocument5 pagesCorrosion of Iron: An Electrochemical ProcessVickyNo ratings yet

- Wetland Assessment in KampalaDocument9 pagesWetland Assessment in KampalaBonny OgwalNo ratings yet

- Sloss Industries 1062235 M2234300 EX351 V 2Document1 pageSloss Industries 1062235 M2234300 EX351 V 2DanielDeFrancescoNo ratings yet

- MKS 112 GEN AZ7 SP 01 A Specification For PaintingDocument31 pagesMKS 112 GEN AZ7 SP 01 A Specification For PaintingĐiệnBiênNhâm100% (2)

- Syllabus 30A Fall 2014Document4 pagesSyllabus 30A Fall 2014Gabby TanakaNo ratings yet

- 3 - 2021 Thermodynamics USTH Part 2Document13 pages3 - 2021 Thermodynamics USTH Part 2Pham Duc AnhNo ratings yet

- Sintering Effect On The Performance of Tungsten-Copper Powder LinerDocument2 pagesSintering Effect On The Performance of Tungsten-Copper Powder LinermahsaNo ratings yet

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocument23 pagesMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPNo ratings yet

- Advion MSDSDocument6 pagesAdvion MSDSmoespestcontrol_mnNo ratings yet

- Msds Icr 122 LSFDocument12 pagesMsds Icr 122 LSFWisnu AbaraiNo ratings yet

- Determination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportDocument17 pagesDetermination of Core Sample Absolute Permeability Using Gas Permeameter and Liquid Fluid Practicum ReportAqsal IlhamNo ratings yet

- Manual ATN-1100 Automatic Kjeldahl Nitrogen Determination ApparatusDocument35 pagesManual ATN-1100 Automatic Kjeldahl Nitrogen Determination Apparatuschristopher lee mercadoNo ratings yet

- DISINFECTION in Health CareDocument86 pagesDISINFECTION in Health Caretummalapalli venkateswara raoNo ratings yet

- ANTHE 2021 (Engineering) Sample PaperDocument17 pagesANTHE 2021 (Engineering) Sample PaperDida CowernNo ratings yet

- Onion Cell Structure Under MicroscopeDocument2 pagesOnion Cell Structure Under MicroscopeAnirudh100% (1)

- Problem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ADocument8 pagesProblem #2b: Chromium Crystallizes With A Body-Centered Cubic Unit Cell. The Radius of ARadica AyuNo ratings yet

- Qe 22 A PDFDocument10 pagesQe 22 A PDF孙俊磊No ratings yet

- CO Capture by Absorption With Potassium CarbonateDocument23 pagesCO Capture by Absorption With Potassium CarbonatekumarNo ratings yet

- Prodinfo Antox-75-E Eng FinalDocument2 pagesProdinfo Antox-75-E Eng FinalKumar RamanNo ratings yet

- Mechanical Properties For Stainless Steel FastenersDocument3 pagesMechanical Properties For Stainless Steel FastenersGonzalo MazaNo ratings yet

- District Heating NorwayDocument8 pagesDistrict Heating Norwaymahmoud4871No ratings yet

- Nano EmulsionDocument52 pagesNano EmulsionAbdul NadeemNo ratings yet

- Acid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunDocument9 pagesAcid Cleaning For Nickel Alloys Pages From Handbook of Engineering Practice of Materials and Corrosion by Jung-Chul (Thomas) EunMohammad TaherNo ratings yet

- Kandungan Obat Merek Dagang SediaanDocument1 pageKandungan Obat Merek Dagang SediaanRaden Mas Nur HaryonoNo ratings yet

- MANUAL (Español)Document458 pagesMANUAL (Español)jose100% (1)