Professional Documents

Culture Documents

Baguio Sewage Treatment Plant 1

Uploaded by

Reden Salve PionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baguio Sewage Treatment Plant 1

Uploaded by

Reden Salve PionCopyright:

Available Formats

BAGUIO SEWAGE TREATMENT

PLANT

NORTH SANITARY CAMP, BAGUIO CITY

YEAR CONSTRUCTED: 1986

ESTIMATED PROJECT COST: Ranges from 1.576 Billion Yen-2.697 billion yen

DESCRIPTION OF THE SEWAGE

TREATMENT FACILITIES

After removing the coarse material by screening in the GRIT

CHAMBER, the sewage water flows into the PRIMARY

SEDEMENTATION TANK.

In the PRIMARY SEDEMENTATION TANK, 30 % of bilogical

oxygen demand (BOD) and 40% of suspended solids (SS) are

expected to be removed. The clarifier is operated continously in

this tank and the withrawal of sludge is accomplished by

intermittent operation of pumps.

The outflow from this tank then flows into the OXIDATION

DITCH which is equiped with rotors. The sewage is mixed,

agitated and aerated in this ditch. The soluble organic matter is

absorbed to be oxydized and assimalated by activated sludge.

The mixture of sewage and activated sludge is sent to the

FINAL SEDIMENTATION TANK where it is separated into liquid

and solid components.

Supernatant flows into the DISINFECTION TANK where it is

chloronated by using calcium hypopchlorite and then discharge

into the Balili River.

Part of the settled sludge in the FINAL SEDEMENTATION

TANK is drawn off by pumps to be returned to the OXIDATION

DITCH and the rest is also drawn off to be sent to the SLUDGE

THICKENER as excess sludge. The sludge from the primary

PRIMARY SEDIMENTATION TANK is mixed with the excess

sludge before entering the SLUDGE THICKENER.

The thickened sludge flows into the SLUDGE STORAGE

TANK where it is agitated by a pump to prevent settlement and

aerated to keep its aerobic condition.

The sludge is then introduced into the SLUDGE FRYING

BED which is covered with polycarbonate plate roof to accelerate

and maintain evaporation evenm during the rainy season.

MAIN FACILITIES

1

2

3

4

5

6

7

8

9

1

0

1

1

FACILITY NAME

DIMENSIONS

QUANTI

TY

1

2

(1standby

)

1(existi

ng)

INFLOW PIPE

GRIT CHAMBER

Dia. 600 mm

Parallel flow

W 2.20m x L

4.30

PRIMARY

SEDIMENTATION TANK

Radial Flow

Circular tank

Dia.21.34 m

x D 2.17 m

OXIDATION DITCH

Recirculation

flow ditch W

10.00 m x L

56.00 m x D

3.00m

FINAL

SEDIMENTATION TANK

Radial Flow

Circular tank

dia. 15.00 m

CAPACITY

Overflow rate

1.818m3/m2/day

Sedimentation time

2.17 hr.

Overflow rate 24.1

m3/m2/day

Weir rate 128 m3/m

day

BOD-SS loading

0.053 kg/SS-kg/day

BOD Volumetric

Loading: 0.186

kg/m3/day

Sludge age: 18.8

days

Aeration Time: 18.1

hr

Sludge Return ratio:

100%

Sedimentation Time

3.16 hr.

Overflow rate: 24.4

x d 3.20 m

DISINFECTION TANK

RETURN SLUDGE

PUMP

RAW SLUDGE PUMP

EXCESS SLUDGE

PUMP

DRAINAGE PUMP

SLUDGE THICKENER

1

2

1

3

SLUDGE STORAGE

TANK

SLUDGE DRYING BED

Horizontally

baffled flow

Rectangular

tank

W 2.00 m x L

6.00 m x 4

channels x

W2.00 m

m3/m2.day

Weir rate: 91.3

m3/mday

1

Contact time 16.0

min

6

2

2

Radial flow

circular tank

Dia. 5.20 m x

d 3.00 m

Rectangular

tank

W 6.00 m x L

6.00 m x D

2.50

Covered Air

Drying Bed

W 11.00 m x

L 13.50

2

2

Thickening time:

27.0 hr

Overflow rate

Storage time 2.2

days

15

Thickness of sludge

0.30 m layer

Drying time 16.3

days

ADDITIONAL INFORMATION

Tax ordinance covering sewerage

fees; CSS coverage

Number of registered sewer

concessionaires

(1951-dec. 2007)

Decentralized (onsite) systems

Outside of the sewer pipe network

(as of dec. 10)

# 2003-004 65 Barangays, fully or

partially connected

Residential: 5,119 or 59%

Commercial: 3614 or 41%

Total:8,723 (2009;9044)

9 communal septic or imhoff tanks,

serving 10 barangays (partially)

Individual septic tanks in 53

barangays found outside of BSTP

coverage area and in partially

connected barangays within the BSTP

coverage area

Total length of pipe installed and total

53.22 linear kilometers

Number of manholes as of dec 31,

2235 units

2010

Baguio Sewage treatment plant

Designed capacity: 8,60 cu.m/day

2010: average inflow: 12, 434 cu.m

per day

Designed influent BOD: 200mg/l

2010 average influent BOD: 419 mg/l

ACTUAL PICTURES 0F THE SEWAGE

TREATMENT PLANT

You might also like

- Water Treatment Plant Filtration DesignDocument25 pagesWater Treatment Plant Filtration DesignJonelou CusipagNo ratings yet

- PD 856 Sewage and Drainage IRR 1995Document19 pagesPD 856 Sewage and Drainage IRR 1995Alvin ClariNo ratings yet

- Advanced Sequencing Batch ReactorDocument2 pagesAdvanced Sequencing Batch ReactorArun ChaubeyNo ratings yet

- Filtration explainedDocument19 pagesFiltration explainedRobert Walusimbi100% (1)

- Compressive Strength of Hollow Blocks Made From Concrete Mixed With Bamboo StripsDocument11 pagesCompressive Strength of Hollow Blocks Made From Concrete Mixed With Bamboo StripsPaulineAnnLambitoUlan100% (1)

- Clean Out:: 305 MM, in Front of The CleanoutDocument4 pagesClean Out:: 305 MM, in Front of The CleanoutKevinNavidadNo ratings yet

- WWTP ReportDocument10 pagesWWTP ReportDeep SinojiyaNo ratings yet

- Performance of Dual Media Downflow Rapid Gravity FiltersDocument7 pagesPerformance of Dual Media Downflow Rapid Gravity FiltersBasproNo ratings yet

- WWTPDocument47 pagesWWTPHar Ley QuinnNo ratings yet

- Chapter 2 Design of Water Treatment Plants PDFDocument55 pagesChapter 2 Design of Water Treatment Plants PDFwedjefdbenmcveNo ratings yet

- Sludge Volume IndexDocument3 pagesSludge Volume IndexNicole Feliciano100% (1)

- Water Consumption AND Water DemandDocument40 pagesWater Consumption AND Water DemandGerlie DimayugaNo ratings yet

- STP DesignDocument5 pagesSTP DesignhiyogsNo ratings yet

- On Site Sewage Treatment (Alternative Waste Systems)Document6 pagesOn Site Sewage Treatment (Alternative Waste Systems)JhyneJazarenoAtutuboNo ratings yet

- Aqua ChlorinatorDocument2 pagesAqua ChlorinatorSumit MishraNo ratings yet

- Chemical Usage TableDocument103 pagesChemical Usage TableAlvin Kim100% (1)

- The STP Guide-Design, Operation and MaintenanceDocument74 pagesThe STP Guide-Design, Operation and MaintenanceRajesh ShenoyNo ratings yet

- 4 Water Consumption & Water DemandDocument22 pages4 Water Consumption & Water DemandLeera Lee AdorabléNo ratings yet

- Concept of Zero DischargeDocument4 pagesConcept of Zero DischargeShesharam Chouhan67% (3)

- Equivalent Water Supply Fixture UnitsDocument1 pageEquivalent Water Supply Fixture UnitsJoey MelencionNo ratings yet

- STP Process DescriptionDocument7 pagesSTP Process DescriptionkaushalNo ratings yet

- 1.1 GeneralDocument18 pages1.1 GeneralPravinAlbdusMathewNo ratings yet

- Poblacion 7, Water System, Can AvidDocument142 pagesPoblacion 7, Water System, Can AvidGodino ChristianNo ratings yet

- Waste Water Collection Methods SystemDocument9 pagesWaste Water Collection Methods SystemDaveNo ratings yet

- Seasoning of TimberDocument2 pagesSeasoning of TimberKrishnaSahNo ratings yet

- Metal Roofing Prices Philippines - PHILCON PRICESDocument1 pageMetal Roofing Prices Philippines - PHILCON PRICESjohn reyesNo ratings yet

- Veolia's Case Studies For Small Wastewater Treatment PlantsDocument15 pagesVeolia's Case Studies For Small Wastewater Treatment PlantsOswar MungkasaNo ratings yet

- Wastewater Treatment Plant DesignDocument64 pagesWastewater Treatment Plant DesignNoureddine Merah100% (3)

- ZCWD Campaign Against Illegal Water ConnectionsDocument31 pagesZCWD Campaign Against Illegal Water ConnectionsYusop B. Masdal100% (1)

- Design of Tanks and ChambersDocument13 pagesDesign of Tanks and Chamberschariot1729No ratings yet

- Chapter 4 - Soil Compaction-1Document5 pagesChapter 4 - Soil Compaction-1Yandi TVNo ratings yet

- Types of WCDocument1 pageTypes of WCCherish Taguinod AliguyonNo ratings yet

- Ch.4 Plumbing Fixtures and Fixture FittingsDocument6 pagesCh.4 Plumbing Fixtures and Fixture FittingsMac ShaikNo ratings yet

- Determine Concrete Slump with Slump TestDocument7 pagesDetermine Concrete Slump with Slump Testayat1234No ratings yet

- Gravity Water Supply System Tools Manual PDFDocument109 pagesGravity Water Supply System Tools Manual PDFBishal Pokharel100% (1)

- Meycauayan BulacanDocument2 pagesMeycauayan BulacanDalton Erick Suyosa BaltazarNo ratings yet

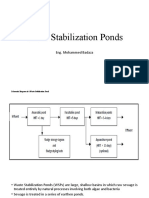

- 4 Waste Stabilization PondsDocument44 pages4 Waste Stabilization PondsEgana Isaac100% (1)

- Tsunami RXN 10-4Document5 pagesTsunami RXN 10-4Ricca Valdez BaudinNo ratings yet

- Lecture 4 Plumbing FixturesDocument57 pagesLecture 4 Plumbing FixturesSamille GarciaNo ratings yet

- Plumbing regulations for water supplyDocument2 pagesPlumbing regulations for water supplydheerajdorlikarNo ratings yet

- Water Treatment PlantDocument27 pagesWater Treatment PlantNikhil KumbharNo ratings yet

- ME LawsDocument25 pagesME LawsJamieNo ratings yet

- Kelani Right Bank Water Treatment Plant Sri LankaDocument11 pagesKelani Right Bank Water Treatment Plant Sri LankaSudeepa SumanasekaraNo ratings yet

- Expansion of Water Treatment PlantDocument20 pagesExpansion of Water Treatment PlantRohail AfzalNo ratings yet

- Discharge of WeirsDocument8 pagesDischarge of WeirsUnknownNo ratings yet

- Stormwater DrainageDocument24 pagesStormwater DrainageAvinaash Veeramah100% (1)

- Waste Water Stabilisation PondsDocument24 pagesWaste Water Stabilisation PondsRyeanKRumanoNo ratings yet

- Drainage of Irrigation Lands: Rajat Mishra Asst. Professor Civil Engineering DepartmentDocument52 pagesDrainage of Irrigation Lands: Rajat Mishra Asst. Professor Civil Engineering DepartmentDileesha WeliwaththaNo ratings yet

- Drainage QCSDocument280 pagesDrainage QCSAyman Al HasaarNo ratings yet

- 6300 LectureNotes PDFDocument312 pages6300 LectureNotes PDFAbera MamoNo ratings yet

- MethodsDocument3 pagesMethodsshin orata100% (1)

- Sequencing Batch Reactor - STPDocument4 pagesSequencing Batch Reactor - STPvinaygvmNo ratings yet

- The Practice of Civil EngineeringDocument31 pagesThe Practice of Civil EngineeringDaniella Mae De GraciaNo ratings yet

- Laboratory Activity #1: Slump Test: Cherry Belle P. HilarioDocument11 pagesLaboratory Activity #1: Slump Test: Cherry Belle P. HilarioEmanoAceNo ratings yet

- Waste Water Treatment Process & Unit DetailsDocument60 pagesWaste Water Treatment Process & Unit DetailssalmanNo ratings yet

- Project Report On Panbazar Water Treatment PlantDocument18 pagesProject Report On Panbazar Water Treatment Planttanmoy100% (1)

- Case 01Document19 pagesCase 01Rushanth ChandraboseNo ratings yet

- Onsite Sanitation: Architecture GATE SolutionDocument6 pagesOnsite Sanitation: Architecture GATE SolutionPratik ManeNo ratings yet

- Sludge processing steps and dewateringDocument21 pagesSludge processing steps and dewateringShubham BansalNo ratings yet

- Master Bedroom Design Ideas and PhotosDocument1 pageMaster Bedroom Design Ideas and PhotosReden Salve PionNo ratings yet

- BudgetDocument1 pageBudgetReden Salve PionNo ratings yet

- LaundryDocument1 pageLaundryReden Salve PionNo ratings yet

- Total Modular Expertise BrochureDocument35 pagesTotal Modular Expertise BrochureReden Salve PionNo ratings yet

- Specs For BLDG PermitDocument4 pagesSpecs For BLDG PermitReden Salve PionNo ratings yet

- Adobe Lightroom BasicsDocument12 pagesAdobe Lightroom Basicsdid_oanaNo ratings yet

- Architect's CredoDocument2 pagesArchitect's CredoReden Salve PionNo ratings yet

- PO2 Po3 PDFDocument14 pagesPO2 Po3 PDFReden Salve PionNo ratings yet

- Mods Coordins (Compatibility Mode)Document18 pagesMods Coordins (Compatibility Mode)Reden Salve PionNo ratings yet

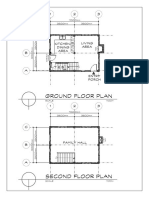

- ArchitecturalDocument1 pageArchitecturalReden Salve PionNo ratings yet

- Tadeo ElectricalDocument1 pageTadeo ElectricalReden Salve PionNo ratings yet

- House Elevation Plans Front Rear Right LeftDocument1 pageHouse Elevation Plans Front Rear Right LeftReden Salve PionNo ratings yet

- Guide To Writing SpecificationsDocument14 pagesGuide To Writing SpecificationsJov Mitch100% (1)

- Farley PerspectiveDocument1 pageFarley PerspectiveReden Salve PionNo ratings yet

- Architectural PerspectiveDocument1 pageArchitectural PerspectiveReden Salve PionNo ratings yet

- Trimester UndergraduateDocument1 pageTrimester UndergraduateReden Salve PionNo ratings yet

- Farley PlansDocument1 pageFarley PlansReden Salve PionNo ratings yet

- Guide To Writing SpecificationsDocument14 pagesGuide To Writing SpecificationsJov Mitch100% (1)

- Guide To Writing SpecificationsDocument14 pagesGuide To Writing SpecificationsJov Mitch100% (1)

- Hospital and Health Care FacilityDocument33 pagesHospital and Health Care FacilityReden Salve PionNo ratings yet

- Hospital and Health Care FacilityDocument33 pagesHospital and Health Care FacilityReden Salve PionNo ratings yet

- Bayag-O, Israel T. Gaspar, Paul M. Pion, Reden S. Arch. Robert V. Romero, Maehp, UapDocument99 pagesBayag-O, Israel T. Gaspar, Paul M. Pion, Reden S. Arch. Robert V. Romero, Maehp, UapReden Salve PionNo ratings yet

- Architectural ProgrammingDocument11 pagesArchitectural ProgrammingReden Salve PionNo ratings yet

- PNP Personal Data Sheet: Current 2 X 2 Colored Picture in Uniform With White Background Showing Rank and NameDocument6 pagesPNP Personal Data Sheet: Current 2 X 2 Colored Picture in Uniform With White Background Showing Rank and NameReden Salve PionNo ratings yet

- Adweataqaaddctranscoaadcal MirfaDocument328 pagesAdweataqaaddctranscoaadcal MirfaClark HonradoNo ratings yet

- SeminarDocument17 pagesSeminarRisvin RafeequeNo ratings yet

- Effect of Lightweight Concrete On Structural DesignDocument92 pagesEffect of Lightweight Concrete On Structural DesignRamez Bou-RizkNo ratings yet

- Cal Land Engineering, Inc. Dba Quartech Consultants: April 18, 2011 Parkway Investment, LLCDocument20 pagesCal Land Engineering, Inc. Dba Quartech Consultants: April 18, 2011 Parkway Investment, LLC63223118No ratings yet

- Heavy Duty Non-Oscillating 115vDocument2 pagesHeavy Duty Non-Oscillating 115vElias100% (2)

- Zona PanelDocument7 pagesZona PanelrobertNo ratings yet

- Bearings BookDocument96 pagesBearings BookLaurence Green100% (8)

- New Regular Contractor's License (SOLE - PROP) - 11192018Document27 pagesNew Regular Contractor's License (SOLE - PROP) - 11192018Francisco TaquioNo ratings yet

- Pompe Wilden PDFDocument184 pagesPompe Wilden PDFnicolaevictorionNo ratings yet

- Draft AgreementDocument4 pagesDraft AgreementKA25 Consultant100% (1)

- Aspect North Brightwater Property ReportDocument62 pagesAspect North Brightwater Property ReportMick MillanNo ratings yet

- Deep In-Situ Ground Improvement Using High Energy Impact Compaction (HEIC) Technology - KellyDocument6 pagesDeep In-Situ Ground Improvement Using High Energy Impact Compaction (HEIC) Technology - Kellymkon79No ratings yet

- Gulf Steel Works Assembly ListDocument36 pagesGulf Steel Works Assembly ListLalit Bom MallaNo ratings yet

- Flange Insulation PresentationDocument10 pagesFlange Insulation PresentationNadeemNo ratings yet

- Eurodrip KatalougeDocument4 pagesEurodrip KatalougebhupsjangirNo ratings yet

- Drawing ProcessDocument47 pagesDrawing ProcessMetalAnand Chelliah75% (4)

- Rate of Flow Control ValveDocument4 pagesRate of Flow Control ValveRSalehNo ratings yet

- PURECO 99 140 Envia TNPDocument42 pagesPURECO 99 140 Envia TNPCosmin BonghezNo ratings yet

- Presentation Extra STPV KapsisDocument10 pagesPresentation Extra STPV KapsisMostafa AnnakaNo ratings yet

- Hse Audit Checklist PDFDocument6 pagesHse Audit Checklist PDFnorlieNo ratings yet

- Structural Steel Shop Drawing Review, The Past and The FutureDocument8 pagesStructural Steel Shop Drawing Review, The Past and The FutureAdam JonesNo ratings yet

- HSE PLAN by HTTPSDocument52 pagesHSE PLAN by HTTPSKhuda BukshNo ratings yet

- TreeParker Installation Guidelines EnglishDocument36 pagesTreeParker Installation Guidelines EnglishTejinder KumarNo ratings yet

- Calcium Silicate Insulation For Hot Oil SystemDocument2 pagesCalcium Silicate Insulation For Hot Oil SystemalphadingNo ratings yet

- G65 and G100: Diaphragm MetersDocument4 pagesG65 and G100: Diaphragm MetersMiguel Angel Morales CastroNo ratings yet

- Construction Stage Report PDFDocument5 pagesConstruction Stage Report PDFAnonymous KRVmsq5BZBNo ratings yet

- Design and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaDocument7 pagesDesign and Proof Checking of Foundation, Substructure and Superstructure of Rail Cum Road Bridge at Munger, Bihar, IndiaGregory Cámara SánchezNo ratings yet

- Itm - Codigos SiemensDocument234 pagesItm - Codigos SiemensSantiago FarfanNo ratings yet

- Design Gambar Scaffolding 2021Document3 pagesDesign Gambar Scaffolding 2021Unggul NugratamaNo ratings yet

- Kandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Document6 pagesKandhal Q and A Part 4 On Bitumen Content of Bituminous Paving Mixes in India - Letter To Highway Colleagues - 9 August 2018Prof. Prithvi Singh KandhalNo ratings yet