Professional Documents

Culture Documents

BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5

Uploaded by

Santoshkumar GuptaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BGR-PPD-208-EL-FQP-0553, REV0 - 28.01.2015 - Action 5

Uploaded by

Santoshkumar GuptaCopyright:

Available Formats

1 of 4

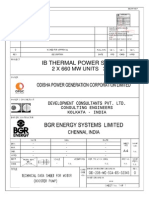

DEVELOPMENT CONSULTANTS

PRIVATE LIMITED

Reviewed for general conformance with Contract

drawings and specifications.

ACTION :

1 Approved

BGR ENERGY SYSTEMS LIMITED

Disapproved.

Approved except as

noted. Forward final

drawing.

For information/reference

only.

Approved except as

noted. Resubmission

required.

Information category with

comments. Resubmission

required.

Approval of Contract documents by the Consultant shall

not relieve the Seller of his responsibility for any errors

and fulfilment of Contract requirements.

POWER PROJECTS DIVISION

Digitally signed by Shouvik

Patari

DN: cn=Shouvik Patari,

o=DCPL, ou=DCPL,

email=shouvikp@in.dclgroup.

com, c=IN

Date: 2015.01.28 12:06:04

+05'30'

PROJECT : 2 X 660 MW IB TPS, JHARSUGUDA

FIELD INSPECTION AND TEST PLAN & CHECK LIST

FOR

EARTHING SYSTEMS

PREPARED BY

REVIEWED BY

D.ARUN BHARATH

APPROVED BY

K.SUBRAMANIAN

K.KALYANARAMAN

P - Perform

IR-Inspection Report

GRN-Goods receipt note

H-Hold

W - Witness

S- Surveillance

TR- Test Report

LB-Log Book

V - Verification

SR - Site register

P.O - Purchase Order

IMIR - Inward Material Inspection Report

R - Review

S - Surveillance

D.C - Delivery Challan

IRN - Inspection Release Note

RW-Random Witness PR-Protocol

TR-Test report

FITP - Field Inspection And Test Plan

A - An Activity checked & Cleared by Owner QA/QC /

BGRESL QA/QC

C - An Activity checked & Cleared by BGRESL Execution / Sub Contractor

B - An Activity checked & Cleared by Owner Executive Group / BGRESL Execution

DOCUMENT NO

: BGR/PPD/208/EL/FQP/0553

REVISION

: 00

DATE

: 13.01.2015

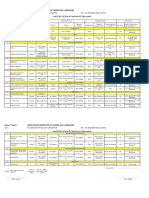

2 of 4

FIELD INSPECTION AND TEST PLAN & CHECK LIST

Package : EARTHING SYSTEM

S.NO

Item/Component & Operation

Doc No

:BGR/PPD/208/EL/FQP/0553

Rev No

: 00

Date

: 13.01.2015

Class of

Check

Type of check

PROJECT: 2X660 MW IB THERMAL POWER STATION

CUSTOMER: ODISHA POWER GENERATION CORPORATION

LIMITED

Inspecting Agency

Quantum/

Frequency

of check

Ref documents &

Acceptance std

Format of

Record

Remarks

SUB

Contractor

BGRESL

OPGCL

1.0

Receipt

1.1

Verify MDCC issued by BGR/OPGC(If

applicable), BGR&OPGC verified test

reports,Dispatch documents (LR & packing List

etc )

Visual

100%

PO,MDCC & LR/All the

documents shall be

available

IMIR

1.2

Veirfy the Dimesions of the Earthing

Conductors & Down conductors (MS Rods,

Galvanised MS Flats, Etc)

Measurement

Random (3

samples /lot)

PO,MDCC,IRN/ Material

shall confirm to IRN

IMIR

1.3

Verify the toatal Quantity in Kg/Mtons in

weighing Bridge with truck and tally with

packing list

Meaurement

100%

MDCC,IRN

IMIR

1.4

Veirfy the materials such as welding electrodes

and anti corrossion paints

Visual

100%

PO,MDCC/ IRN

IMIR

2.0

STORAGE

2.1

Ensure that Earthing Conductors are stored in

a covered space/outdoor in a well-drained &

raised area with firm surface

Visual

100%

FITP

,,,

2.2

Ensure that the storage area is free from

water logging.

Visual

100%

FITP

,,,

2.3

Ensure that the material is stored seperately

as per the type and dimensions and not mixed

up

Visual

100%

FITP

,,,

2.4

Consumables such as welding electrodes and

Anti corrosive painst shall be stored well

ventilated dry indoor area

100%

FITP

,,,

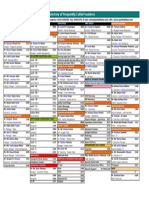

3 of 4

FIELD INSPECTION AND TEST PLAN & CHECK LIST

Package : EARTHING SYSTEM

S.NO

Item/Component & Operation

PROJECT: 2X660 MW IB THERMAL POWER STATION

Doc No

:BGR/PPD/208/EL/FQP/0553

Rev No

: 00

Date

: 12.01.2015

CUSTOMER: ODISHA POWER GENERATION CORPORATION

LIMITED

Class of

Check

Type of check

Quantum/

Frequency

of check

Ref documents &

Acceptance std

Format of

Record

Inspecting Agency

SUB

Contractor

BGRESL

OPGCL

3.0

ERECTION /INSTALLATION

3.1

Ensure the availability of approved Earthing

layouts of the respective area

Visual

100%

Check List

3.2

Ensure that the approved materials(type and

diemensions) are mobilized

Visual

Random Check

Check List

3.3

Ensure the availability of "Work permit" for the

respective area

Visual

100%

Check List

3.4

Ensure that the ground grid of the respective

area is installed at a depth of not less than

1000mm below finished grade during

installation

Measurement

100%

Check List

RW

3.5

verify the installation of Earth

Electrodes(auxiliary) during installation & pits

after installation at specifed points

Visual

100%

Check List

RW

3.6

Ensure that the Ground conductors welded

joints above and below ground(Before back

filling) are coated with 2 coats of anti

corrosive paintings

Visual

Random

Check List

3.7

Ensure the availability of riser projecting 300

mm above ground at specified points

Measurement

100%

Check List

3.8

Ensure the availability of two risers for each

floor and two distinctive earth terminals for

each equipments

Visual

100%

Check List

3.9

Ensure the connection of internconnected

earth flats above ground with risers

Visual

100%

Check List

3.10

Ensure the availabilty of grid extension for

connecting to the main plant grid

Visual

100%

Check List

EF -02

EF -03

Appd Drg /Method

Statement

4.0

TESTING OF INSTALLATION

4.1

Measurement of Earth pit resistance with and

without grid

Testing

100%

4.2

Verification of Earthing system continuity

Testing

100%

Appd Drg /Method

Statement

Remarks

OPGC Witness is

only for earth pits

4 of 4

FIELD CHECK LIST FOR EARTHING SYSTEM

AREA

DATE

ELEVATION

REPORT NO

DRAWING NO

SL.No

Description of Check

Verify the availability of approved Earthing layouts of the respective area

Check that the approved materials(type and diemensions) are mobilized

Verify the availability of "Work permit" for the respective area

Check that the ground grid of the respective area is installed at a depth of not less

than 1000mm below finished grade during installation

verify the installation of Earth Electrodes during installation & pits after installation at

specifed points

Verify that the Ground conductors welded joints above and below ground(Before back

filling) are coated with 2 coats of anti corrosive paintings

Check the availability of riser projecting 300 mm above ground at specified points

Check the availability of two risers for each floor and two distinctive earth terminals for each

equipments

Verify the connection of internconnected earth flats above ground with risers

10

Verify the availabilty of grid extension for connecting to the main plant grid

11

Measurement of Earth pit resistance with and without grid (Test report shall be

enclosed)

12

Verification of Earthing system continuity (Test report shall be enclosed)

BGRESL

OBSERVATION

Remarks

/ NA

OPGCL

You might also like

- Inspection and test plan for groundingDocument12 pagesInspection and test plan for groundingAbat SayekeyevNo ratings yet

- Cable Tray Load Calculation PDFDocument10 pagesCable Tray Load Calculation PDFu5ur5zoro5luNo ratings yet

- QA&QC-DT-FRMC-020 Foundation Work of Transmission LineDocument2 pagesQA&QC-DT-FRMC-020 Foundation Work of Transmission LineTariq Ali SialNo ratings yet

- QA&QC-DT-FRMC-009 Mouting Structure Installation RecordDocument1 pageQA&QC-DT-FRMC-009 Mouting Structure Installation RecordTariq Ali SialNo ratings yet

- Electrical Works Grounding ITPDocument3 pagesElectrical Works Grounding ITPUtku Can KılıçNo ratings yet

- User Manual - Online Wiring Certificates-Rev3Document12 pagesUser Manual - Online Wiring Certificates-Rev3Tony Ras Mwangi100% (1)

- Inspection and Test Plan for Mars CS PackageDocument17 pagesInspection and Test Plan for Mars CS PackageMariah PearsonNo ratings yet

- ITP-Line Hardware - Sample Test PDFDocument3 pagesITP-Line Hardware - Sample Test PDFPrabhakar Sv100% (1)

- KP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFDocument3 pagesKP-00+++-CQ712-B7358-Rev 0-ITP For DS PDFUtku Can KılıçNo ratings yet

- Cable Tray InstallationDocument1 pageCable Tray InstallationNaeemNo ratings yet

- Fichtner PDFDocument76 pagesFichtner PDFbacuoc.nguyen356No ratings yet

- Pipeline Electrical Installation Inspection MethodsDocument7 pagesPipeline Electrical Installation Inspection Methodscherif yahyaouiNo ratings yet

- Mos T&C EarthingDocument20 pagesMos T&C EarthingAhanaf TahmidNo ratings yet

- Inspection and Tests Plan: OPGW 60mm, 24coresDocument3 pagesInspection and Tests Plan: OPGW 60mm, 24coresErika Rafani WibowoNo ratings yet

- 66kv Ha & de Type Tower Foundation DrawidngDocument2 pages66kv Ha & de Type Tower Foundation DrawidngBAWA ALEXNo ratings yet

- Minute of MeetingDocument1 pageMinute of MeetingiwanNo ratings yet

- Field Installation, Inspection & Test PlanDocument2 pagesField Installation, Inspection & Test PlanSaiful Ahda100% (1)

- Foundation Details For 220 KV - A TypeDocument11 pagesFoundation Details For 220 KV - A TypeRatnam Sk100% (1)

- Erection BOQ SaranDocument339 pagesErection BOQ SaranBudoy SmithNo ratings yet

- Sample Form Inspection ChecklistDocument5 pagesSample Form Inspection Checklistadolf001No ratings yet

- Blackall Aerodrome Lighting QuotationDocument53 pagesBlackall Aerodrome Lighting Quotationgraceenggint8799No ratings yet

- DTTN Dt1 PC Rfi ST 0100Document1 pageDTTN Dt1 PC Rfi ST 0100Tariq Ali SialNo ratings yet

- QAP For Overall Mechanical ActivitiesDocument2 pagesQAP For Overall Mechanical ActivitiesMaheshwar polepallyNo ratings yet

- QA&QC-DT-FRMC-014 Mouting Structure Material RecordDocument1 pageQA&QC-DT-FRMC-014 Mouting Structure Material RecordTariq Ali SialNo ratings yet

- ITP 935 MV Switchgears - Rev 1Document6 pagesITP 935 MV Switchgears - Rev 1Zaid RNo ratings yet

- Minor Electrical Installation Works - RedDocument2 pagesMinor Electrical Installation Works - RedSeby SebastianNo ratings yet

- Bar Chart For Gis 23 Iinfocity IIDocument4 pagesBar Chart For Gis 23 Iinfocity IIdineshsoni29685No ratings yet

- KP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationDocument1 pageKP-00+++-CQ712-B7907 - Rev.0 - ITP - MV Switchgear InstallationUtku Can KılıçNo ratings yet

- Work Method Statement: Installation of Site Perimeter FencingDocument9 pagesWork Method Statement: Installation of Site Perimeter FencingStansilous Tatenda NyagomoNo ratings yet

- Erection BOQ - SaranDocument339 pagesErection BOQ - SaranPrasanna kumar subudhiNo ratings yet

- Method Statement FOR Testing and Commissioning: Grounding SystemDocument3 pagesMethod Statement FOR Testing and Commissioning: Grounding SystemNon Etabas Gadnatam100% (1)

- Project: Instrument Junction Box InstallationDocument2 pagesProject: Instrument Junction Box InstallationAhmad DagamsehNo ratings yet

- Itp Ralgo HssDocument5 pagesItp Ralgo Hssmark quijlvoNo ratings yet

- 400kV Cable Technical Data SheetDocument23 pages400kV Cable Technical Data SheetantaryamisinghNo ratings yet

- Dokgoro K1785 Method StatementDocument6 pagesDokgoro K1785 Method StatementJackie van SchalkwykNo ratings yet

- Verificat Installation of Power and Control Cables - CELIN - Black Sea - IrakDocument8 pagesVerificat Installation of Power and Control Cables - CELIN - Black Sea - IrakAlinaIordacheNo ratings yet

- Handover CertificateDocument1 pageHandover CertificateAnonymous lYh4o1ybNo ratings yet

- Pgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Document6 pagesPgcdc-40-003-089 Continuity and Insulation Resistance Test - 1660264288Manuel DizonNo ratings yet

- Solidworks Report of Light PoleDocument12 pagesSolidworks Report of Light PoleThahir ShahNo ratings yet

- Feasibility Report for Solar PV Installation on Rooftop in Greater NoidaDocument6 pagesFeasibility Report for Solar PV Installation on Rooftop in Greater NoidaSlnko EnergyNo ratings yet

- Handover To QAQC-Anand KumarDocument6 pagesHandover To QAQC-Anand KumarAnonymous fBkcEze1No ratings yet

- J910-YL16-P0AB-145714 500kV Cable List & Connection For Diameter 4, Rev. 1 (ARWC)Document176 pagesJ910-YL16-P0AB-145714 500kV Cable List & Connection For Diameter 4, Rev. 1 (ARWC)Devy MangimbaNo ratings yet

- Earthing and Bonding Method StatementDocument4 pagesEarthing and Bonding Method StatementMusthafa Shaik100% (1)

- IMS 448-EQCL - Transformer Installation Checklist Rev01Document1 pageIMS 448-EQCL - Transformer Installation Checklist Rev01zhangjieNo ratings yet

- 000 SP Pi02 0221Document10 pages000 SP Pi02 0221Samuel ValbuenaNo ratings yet

- Cathodic ProtectionDocument13 pagesCathodic Protectionnamanvyas21No ratings yet

- KP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Document3 pagesKP-00+++-CQ712-B7359-132kV Electrical Works (Switchyard Current and Voltage Transformer)Utku Can KılıçNo ratings yet

- ChecklistDocument35 pagesChecklistShashi Kant Singh100% (1)

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocument10 pagesSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalTariqMalikNo ratings yet

- B1 - Geotechnical Report 1Document18 pagesB1 - Geotechnical Report 1riz2010No ratings yet

- Substation Construction Project Project ScheduleDocument12 pagesSubstation Construction Project Project Schedulefran.obando1332No ratings yet

- Method Statement for Installing AIS SwitchgearDocument22 pagesMethod Statement for Installing AIS SwitchgearAbat SayekeyevNo ratings yet

- 2013 04 19 CIK Checklist ErectionDocument19 pages2013 04 19 CIK Checklist ErectionAde Y SaputraNo ratings yet

- Activity Schedule of ESSDocument17 pagesActivity Schedule of ESSkumar100% (1)

- Prime Electric Ltd's State-of-the-Art Transformer Manufacturing FacilityDocument29 pagesPrime Electric Ltd's State-of-the-Art Transformer Manufacturing FacilitynaveenchamarthyNo ratings yet

- Air Cooled Condensing Unit Checklist: Mr. Aden LiuDocument45 pagesAir Cooled Condensing Unit Checklist: Mr. Aden LiuADEN LIUNo ratings yet

- Grounding Works ITP Inspection PlanDocument2 pagesGrounding Works ITP Inspection PlanElisco Pher SalmasanNo ratings yet

- QES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & DrawingDocument2 pagesQES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & Drawingrupesh417No ratings yet

- Template (Electrical Works)Document10 pagesTemplate (Electrical Works)Anonymous Qu7LeENo ratings yet

- FQP - Civil NewDocument13 pagesFQP - Civil NewVenkatesh MudragadaNo ratings yet

- Builders List For Website DisplayDocument2 pagesBuilders List For Website DisplayjkahamedNo ratings yet

- Latest Battery ChecklistDocument4 pagesLatest Battery ChecklistSantoshkumar GuptaNo ratings yet

- Switchyard Tower Structure Installation - RV 01Document15 pagesSwitchyard Tower Structure Installation - RV 01Santoshkumar GuptaNo ratings yet

- Comments Reply SheetDocument3 pagesComments Reply SheetSantoshkumar GuptaNo ratings yet

- Ep 3 GN 107 006 Typical SLD of LTSWGRDocument10 pagesEp 3 GN 107 006 Typical SLD of LTSWGRSantoshkumar GuptaNo ratings yet

- OPGC Comments On Method Statement For 400 KV Switch Yard Structural InstallationDocument2 pagesOPGC Comments On Method Statement For 400 KV Switch Yard Structural InstallationSantoshkumar GuptaNo ratings yet

- 3200 Amps Temparature Rise TestDocument10 pages3200 Amps Temparature Rise TestSantoshkumar GuptaNo ratings yet

- PM 11.04.2016Document3 pagesPM 11.04.2016Santoshkumar GuptaNo ratings yet

- 630 Amps Short Circuit TestDocument21 pages630 Amps Short Circuit TestSantoshkumar GuptaNo ratings yet

- EPD-391-506-E001 Rev00Document5 pagesEPD-391-506-E001 Rev00Santoshkumar GuptaNo ratings yet

- Method Statement Earthing Rev03 Signed Cover SheetDocument1 pageMethod Statement Earthing Rev03 Signed Cover SheetSantoshkumar GuptaNo ratings yet

- BGR PPD 0208 El MQP 0494 r2 Mitp 400kv Swyd STR Cat 1Document4 pagesBGR PPD 0208 El MQP 0494 r2 Mitp 400kv Swyd STR Cat 1Santoshkumar GuptaNo ratings yet

- Skeleton GrammarDocument19 pagesSkeleton GrammardiemnganNo ratings yet

- Kohet e Foljes - 1Document21 pagesKohet e Foljes - 1Shqipni etnike 1912No ratings yet

- HE-10821-16605-D - R1 (Approved) - 07.11.14Document5 pagesHE-10821-16605-D - R1 (Approved) - 07.11.14Santoshkumar GuptaNo ratings yet

- 415V PMCC/MCC, 415V Ac & 220V DC DB/SVB/FB, 220V DC Starter: 2X660Mw Ib Valley Tps Data Sheet LV SwitchgearDocument14 pages415V PMCC/MCC, 415V Ac & 220V DC DB/SVB/FB, 220V DC Starter: 2X660Mw Ib Valley Tps Data Sheet LV SwitchgearSantoshkumar GuptaNo ratings yet

- HE-10821-16605-D - R0 (Commented) - 09.06.14Document2 pagesHE-10821-16605-D - R0 (Commented) - 09.06.14Santoshkumar GuptaNo ratings yet

- Ep 3 GN 107 001R1Document14 pagesEp 3 GN 107 001R1Santoshkumar GuptaNo ratings yet

- Exciter Outline - 01450001115 - EOL - REV01 - 09.12.2014 - Action 5Document1 pageExciter Outline - 01450001115 - EOL - REV01 - 09.12.2014 - Action 5Santoshkumar GuptaNo ratings yet

- 01660570011C203 - R1 (Approved) - 07.11.14Document1 page01660570011C203 - R1 (Approved) - 07.11.14Santoshkumar GuptaNo ratings yet

- GID 208 ME GAF DS 50323 Characteristic Curves R2 Cat 1Document6 pagesGID 208 ME GAF DS 50323 Characteristic Curves R2 Cat 1Santoshkumar GuptaNo ratings yet

- 01660570008C203 - R0 (Commented) - 09.06.14Document1 page01660570008C203 - R0 (Commented) - 09.06.14Santoshkumar GuptaNo ratings yet

- IB Thermal Power Station Units 3 & 4 Odisha Power GenerationDocument1 pageIB Thermal Power Station Units 3 & 4 Odisha Power GenerationSantoshkumar GuptaNo ratings yet

- Gid 208 Me Sga Ds 52347 r0 Perf. Curves Booster Cat 1Document5 pagesGid 208 Me Sga Ds 52347 r0 Perf. Curves Booster Cat 1Santoshkumar GuptaNo ratings yet

- GID 208 ME GAF DS 50322 Raw Water Motor Datasheet R2 Cat 2Document6 pagesGID 208 ME GAF DS 50322 Raw Water Motor Datasheet R2 Cat 2Santoshkumar GuptaNo ratings yet

- Gid 208 El Aca XK 58353 r0 420kv CKT BKR CTRL Cat 6Document13 pagesGid 208 El Aca XK 58353 r0 420kv CKT BKR CTRL Cat 6Santoshkumar GuptaNo ratings yet

- Booster Pump Motor Technical Data Sheet ReviewedDocument7 pagesBooster Pump Motor Technical Data Sheet ReviewedSantoshkumar GuptaNo ratings yet

- IB Thermal Power Station Units 3 & 4 Odisha Power GenerationDocument1 pageIB Thermal Power Station Units 3 & 4 Odisha Power GenerationSantoshkumar GuptaNo ratings yet

- Master Drawing List-TRYDocument276 pagesMaster Drawing List-TRYSantoshkumar GuptaNo ratings yet

- Reading and Listening 2Document4 pagesReading and Listening 2Hải Anh TạNo ratings yet

- Maximizing Oredrive Development at Khoemacau MineDocument54 pagesMaximizing Oredrive Development at Khoemacau MineModisa SibungaNo ratings yet

- Past The Shallows EssayDocument2 pagesPast The Shallows EssaycaitlinNo ratings yet

- Pictorial History of AOTADocument5 pagesPictorial History of AOTAThe American Occupational Therapy Association0% (4)

- Life Overseas 7 ThesisDocument20 pagesLife Overseas 7 ThesisRene Jr MalangNo ratings yet

- Q1 Tle 4 (Ict)Document34 pagesQ1 Tle 4 (Ict)Jake Role GusiNo ratings yet

- December - Cost of Goods Sold (Journal)Document14 pagesDecember - Cost of Goods Sold (Journal)kuro hanabusaNo ratings yet

- Indonesia Organic Farming 2011 - IndonesiaDOCDocument18 pagesIndonesia Organic Farming 2011 - IndonesiaDOCJamal BakarNo ratings yet

- Base para Detectores de Humo y Temperatura KIDDE KI-SBDocument2 pagesBase para Detectores de Humo y Temperatura KIDDE KI-SBAnderson CastañedaNo ratings yet

- Tutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)Document3 pagesTutorial 7: Electromagnetic Induction MARCH 2015: Phy 150 (Electricity and Magnetism)NOR SYAZLIANA ROS AZAHARNo ratings yet

- Maual de Servicio TV LG 32lf15r-MaDocument31 pagesMaual de Servicio TV LG 32lf15r-MaJaime E FernandezNo ratings yet

- Solcon Catalog WebDocument12 pagesSolcon Catalog Webquocviet612No ratings yet

- Venus in MulaDocument2 pagesVenus in MulaGovind BallabhNo ratings yet

- Goals Editable PDFDocument140 pagesGoals Editable PDFManuel Ascanio67% (3)

- Aplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaDocument15 pagesAplikasi Berbagai Jenis Media Dan ZPT Terhadap Aklimatisasi Anggrek VandaSihonoNo ratings yet

- Analysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Document2 pagesAnalysis of Heavy Metals Concentration in Landfill Soil IJERTV8IS120019Eustache NIJEJENo ratings yet

- Directory of Frequently Called Numbers: Maj. Sheikh RahmanDocument1 pageDirectory of Frequently Called Numbers: Maj. Sheikh RahmanEdward Ebb BonnoNo ratings yet

- Abortion and UtilitarianismDocument4 pagesAbortion and UtilitarianismBrent Harvey Soriano JimenezNo ratings yet

- Đề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiDocument17 pagesĐề Thi Thử THPT 2021 - Tiếng Anh - GV Vũ Thị Mai Phương - Đề 13 - Có Lời GiảiHanh YenNo ratings yet

- ABSCESSDocument35 pagesABSCESSlax prajapatiNo ratings yet

- Black Girl Magic: Over 200+ AffirmationsDocument229 pagesBlack Girl Magic: Over 200+ AffirmationsDestiny S. Harris100% (2)

- Hotel Housekeeping EQUIPMENTDocument3 pagesHotel Housekeeping EQUIPMENTsamahjaafNo ratings yet

- Life Sciences Part 1 CSIR JRF NET GATE DBT PDFDocument132 pagesLife Sciences Part 1 CSIR JRF NET GATE DBT PDFPavani Reddy68% (22)

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)

- Alok ResumeDocument3 pagesAlok Resumealok choudharyNo ratings yet

- Material Handling EquipmentsDocument12 pagesMaterial Handling EquipmentsRahul SheelavantarNo ratings yet

- Aging and Elderly IQDocument2 pagesAging and Elderly IQ317537891No ratings yet

- Medpet Pigeon ProductsDocument54 pagesMedpet Pigeon ProductsJay Casem67% (3)

- Tumors of The Central Nervous System - VOL 12Document412 pagesTumors of The Central Nervous System - VOL 12vitoNo ratings yet

- Nursing Diagnosis TemplateDocument6 pagesNursing Diagnosis Templatesdk6972No ratings yet