Professional Documents

Culture Documents

Small Water System Design Calculator

Uploaded by

Assef ZraouraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Small Water System Design Calculator

Uploaded by

Assef ZraouraCopyright:

Available Formats

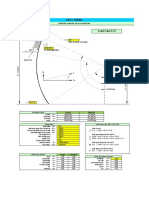

User inputs data into orange cells. Results are calculated in tan cells.

All pressures calculated in absolute units, i.e., equations contain 14.7 psi added to gauge pressures.

Effective Volume

Horizontal Tank Volumes

pre-charge pressure, P1

2

cut-in pressure, P2

cut-out pressure, P3

Gross volume of hydro tank(s), Vt

Effective draw-down volume, Ve

acceptance factor

1

psi, gage

psi, gage

psi, gage

gallons

0 gallons

#DIV/0!

Inside Diameter

Inside Side Wall Length

End Caps

Water level

Water Volume

inches

inches

select

inches above bottom

#DIV/0! gallons

Pre-charge pressure cannot be greater than cut-in pressure for pump to start, and optimal setting is about 2-4 psi below cut-in pressure to maintain system pressure.

Calculate Total Dynamic Head in distribution system to determine acceptable cut-in pressure. Note: Volume below amount needed to maintain minimum system pressure unavailable

as storage.

2

Cycle Time

Ve/((I-O)) + Ve/O

= pump on + pump off

gpm

Pump into tank, I

Demand, O

net flow, gpm

Pump ON

Pump Off

pump=demand

Pump Off

* Maximum pump cycle occurs @ demand = half pump capacity.

times in minutes

Cycles/hr

Pump OFF Cycle Time

Nc

no demand no demand no demand

* Maximum pump cycle = #DIV/0!

= Minimum pump run

Minimum pump run times: 1 min. < 5 hp 2 min., or manufacturer's recommendation.

Pump Selection

Total head:

Tank inlet above measuring point, ft

Measuring point to static water level, ft

Drawdown below static water level, ft

Dynamic head, pump to tank, ft

Low Pressure

psi

feet

0.0

High Pressure

psi

feet

0.0

0.0

0.0

Use positive values. Approximate operating point for the

pump. Find points between low and high head on pump curve

and use median for pump capacity.

peak hour demand

Page 2

peak hour demand

0.1

Page 3

peak hour flow

Page 4

peak hour flow

9.499194

Page 5

CAPACITY ANALYSIS WORKSHEET FOR HYDROPNUMATIC SYSTEMS

Persons preparing a capacity analysis report should consider, and coordinate appropriate aspects of the report with, applicable local

government comprehensive plans and applicable regional water supply plans prepared by water management districts.

Rule 62-555.320(6):

The total capacity of all water source and treatment facilities connected to a water system shall at least equal the water system's design maximum-day water

demand (including design fire flow demand if fire protection is bring provided).

Additionaly, 62-555.320(19) storage requirements apply.

For small hydro systems:

Rule 62-555.320(19)(b)2

For water systems that are using hydropneumatic tanks and that were permitted before August 28, 2003, no finished-water storage capacity is required if the

source, treatment, and finished-water pumping facilities themselves can meet peak-hour water demand for at least four consecutive hours. For systems that

are using hydropneumatic tanks, the well pump and treatment facilities almost always are designed to meet at least the peak-hour demand (which generally is

approximately four times the annual average daily demand). If the well pump and treatment facilities cannot meet the peak-hour demand, the required

effective storage volume in the hydropneumatic tank is:

{(peak-hour demand, gpm) (well pump capacity, gpm)} * (240 minutes)

For water systems that are using hydropneumatic tanks and that are permitted after August 28, 2003, no finished-water storage capacity is required if the

source, treatment, and finished-water pumping facilities themselves can meet peak-hour water demand for at least four consecutive hours and can meet peak

instantaneous demand for at least 20 minutes. For systems that are using hydropneumatic tanks, the well pump and treatment facilities almost always are

designed to meet a least the peak-hour demand (which generally is approximately four times the annual average daily demand) and should be designed to

meet the peak instantaneous demand (which generally is approximately 10 times the annual average daily demand and hence the recommendation in Section

7.2.2a of Recommended Standards for Water Works). If the well pump and treatment facilities can meet the peak-hour demand but cannot meet the peak

instantaneous demand, the required effective storage volume in the hydropneumatic tank is:

{(peak instantaneous demand, gpm) (well pump capacity, gpm )} * (20 minutes)

Projections of maximum-day or peak-hour water demand usually are made by multiplying projections of annual average daily water demand by an appropriate

peaking factor. Peaking factors vary depending upon PWS size, the extent of commercialization and industrialization, etc. Therefore, maximum-day to

average-day peaking factors should be determined specifically for each PWS by looking at past water production data for the PWS. (According to Water

Distribution Systems Handbook, which is incorporated as an engineering reference into Rule 62-555.330, F.A.C., maximum-day water demand typically ranges

from 1.5 to 3.5 times average daily water demand.) Peak-hour to average-day peaking factors should be determined specifically for each PWS based upon

flow measurement data if possible; but oftentimes, peak-hour to average-day peaking factors will have to be estimated. (According to Water Distribution

Systems Handbook, peak-hour water demand typically ranges from 2.0 to 7.0 times average daily water demand.) Finished-water storage need is the finishedwater storage capacity needed for operational equalization to meet peak water demand and comply with subsection 62-555.320(19), F.A.C., plus finished-water

storage capacity needed to meet any fire-flow requirements.

Finished-water storage needed to meet fire-flow requirements can be calculated using the equation

FS = (NFFR + MDD TPC) (NFFD)

where FS = fire storage, NFFR = needed fire-flow rate, MDD = maximum-day demand, TPC = treatment plant capacity (i.e., total maximum-day or peak

capacity of a PWSs treatment plants), and NFFD = needed fire-flow duration.

Refer to the DEP "Capacity Analysis Report Guideline (2004) for additional information.

User inputs data into orange cells. Calculation results in tan cells.

input

gpd

Average Day Demand (ADD)

Maximum Day Demand (MDD)

Peak Hourly Demand (PHD)

Peak Instantaneous Demand (PID)

Pump flow to tank

2

Storage needed for peak-hour demand none

2

Storage for peak-instantaneous demand none

Peak

Factor

0

0

0

0

Peak Factor

Range

conversions:

gpm*1440=gpd

2 1.5-3.5 (or DMDD)

4 2.0-7.0

10 110

gallons

gallons

pump=demand gpm, net flow from Hydro page

Depending on deisgn criteria, PID may also be determined using USACE "Design of Small Water Systems", Figure 4-1.

2

Refer to F.A.C. 62-555.320(19)(b)2 above for applicable storage requirements.

1

gpd/1440=gpm

gpm

gpd

0 gpd

0.0 gpm

gpm, needed fire flow rate

minutes, needed fire flow duration

0 gallons, fire storage

CHLORINE FEED RATE

Chlorine demand. If no data, assume a value in the 5-10 ppm range.

Feed pump output:

Feed rate = well pump output rate (gpm) * dosage (ppm) * 1440 (min/day) / [solution strength, % * (10,000 ppm/1% str.)]

Where:

Feed Rate = feed pump output rate (gpd)

Well Output = average well pump output (gpm) (assumed constant)

D = required dosage (demand + desired residual in distribution system, ppm)

% Cl sol'n = percentage of NaOCl in solution (off-the-shelf bleach is typically about 5%)

SS = solution strength (1 %/10,000 ppm)

User inputs data into orange cells.

Feed Rate Calcluations:

*Well Output

0

D

% Cl sol'n

SS

0

Feed Rate

0.0

gpm

ppm

percent NaOCl

ppm

gpd

* from Hydro Page

Chlorine Reservior Calculations:

Reservoir capacity:

gallons (input tank size)

Demand, pump on, pump amt refill time,

gallons

min

gallons

days

*Max. Day

0 #DIV/0!

#DIV/0! need dose

*Avg. Day

0 #DIV/0!

#DIV/0! need dose

*From Storage page

You might also like

- Stability of Generalized Jensen Functional Equation On A Set of Measure ZeroDocument12 pagesStability of Generalized Jensen Functional Equation On A Set of Measure ZeroAssef ZraouraNo ratings yet

- 806-Article Text-6772-3-10-20160205Document15 pages806-Article Text-6772-3-10-20160205Assef ZraouraNo ratings yet

- Agc Joint 5+rehausseDocument1 pageAgc Joint 5+rehausseAssef ZraouraNo ratings yet

- Properties of Hydraulic Jump Down Stream Sluice GateDocument3 pagesProperties of Hydraulic Jump Down Stream Sluice GateAssef ZraouraNo ratings yet

- Stability of Generalized Jensen Functional Equation On A Set of Measure ZeroDocument12 pagesStability of Generalized Jensen Functional Equation On A Set of Measure ZeroAssef ZraouraNo ratings yet

- Zeglami 2014Document12 pagesZeglami 2014Assef ZraouraNo ratings yet

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- 806-Article Text-6772-3-10-20160205Document15 pages806-Article Text-6772-3-10-20160205Assef ZraouraNo ratings yet

- EM 1110-2-2006 - Roller-Compacted Concrete 1Document77 pagesEM 1110-2-2006 - Roller-Compacted Concrete 1PDHLibrary100% (2)

- Analysis and Optimization of A Fixed-Tank Vehicle: D. V. Koulocheris V. K. Dertimanis K. N. SpentzasDocument8 pagesAnalysis and Optimization of A Fixed-Tank Vehicle: D. V. Koulocheris V. K. Dertimanis K. N. SpentzasAssef ZraouraNo ratings yet

- Zhen2017 PDFDocument13 pagesZhen2017 PDFAssef ZraouraNo ratings yet

- A092237 PDFDocument310 pagesA092237 PDFAssef ZraouraNo ratings yet

- Girders of Hydraulic Gates Optimal Design: SciencedirectDocument6 pagesGirders of Hydraulic Gates Optimal Design: SciencedirectAssef ZraouraNo ratings yet

- Design of Spillway Tainter Gates PDFDocument92 pagesDesign of Spillway Tainter Gates PDFAssef ZraouraNo ratings yet

- Em - 1110 2 2704Document106 pagesEm - 1110 2 2704Assef ZraouraNo ratings yet

- Design Methodology and Calculation of Tank Supports in A Heavy VehicleDocument9 pagesDesign Methodology and Calculation of Tank Supports in A Heavy VehicleAssef ZraouraNo ratings yet

- Design of Radial GateDocument11 pagesDesign of Radial Gateramkumar121100% (5)

- Dragflow ProdDocument16 pagesDragflow ProdAssef Zraoura100% (1)

- Radgate 2016Document13 pagesRadgate 2016Assef ZraouraNo ratings yet

- COMEGE Catalogue FR-En-De EmailDocument80 pagesCOMEGE Catalogue FR-En-De EmailToma ViorelNo ratings yet

- Barneto2009 PDFDocument11 pagesBarneto2009 PDFAssef ZraouraNo ratings yet

- Crochet A Oeil Cmuc 2 5Document1 pageCrochet A Oeil Cmuc 2 5Assef ZraouraNo ratings yet

- CD K 008 2009 - PenstocksDocument26 pagesCD K 008 2009 - PenstocksAssef ZraouraNo ratings yet

- Criteria For Structural Design of Barrages and WeirsDocument27 pagesCriteria For Structural Design of Barrages and WeirsVSMS867825% (4)

- e566b94d1404465f6a0fec81bf5daab1Document73 pagese566b94d1404465f6a0fec81bf5daab1Assef ZraouraNo ratings yet

- Chlorine Feed CalculatorDocument1 pageChlorine Feed CalculatorAssef ZraouraNo ratings yet

- Code GenerationDocument16 pagesCode Generationsalemabu9No ratings yet

- Chlorine Feed CalculatorDocument1 pageChlorine Feed CalculatorAssef ZraouraNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Awwa Manuals of Water Supply Practices SetDocument3 pagesAwwa Manuals of Water Supply Practices Setthl498100% (1)

- Stormwater Management Guidance Manual Ver 2.0Document392 pagesStormwater Management Guidance Manual Ver 2.0uei-marine100% (4)

- 10 - 0201 Aqua-Nova Lo - Res PDFDocument4 pages10 - 0201 Aqua-Nova Lo - Res PDFjl181No ratings yet

- Onjunctive Use of Surface & Groundwater and Managed Aquifer Recharge TechniquesDocument40 pagesOnjunctive Use of Surface & Groundwater and Managed Aquifer Recharge TechniquessakthivelNo ratings yet

- Clean Water and SanitationDocument2 pagesClean Water and SanitationRamzan Alam SagarNo ratings yet

- Final Inception Report of Burtiwang Land Pooling by EditsDocument61 pagesFinal Inception Report of Burtiwang Land Pooling by EditssurendramaharjanNo ratings yet

- What Are Intake StructuresDocument6 pagesWhat Are Intake StructuresAnkush PendhariNo ratings yet

- Goal 6: Clean Water and SanitationDocument3 pagesGoal 6: Clean Water and SanitationNazakat HussainNo ratings yet

- Water Supply EngineeringDocument2 pagesWater Supply EngineeringAnil Marsani50% (2)

- Kent QnetDocument22 pagesKent QnetParamesh SandeepNo ratings yet

- Report of Industrial Visit at BELUR MATHDocument3 pagesReport of Industrial Visit at BELUR MATHSîdDhàñt SätYãmNo ratings yet

- Water Safety PlansDocument12 pagesWater Safety PlansAmjad PervazNo ratings yet

- Geberit Filling ValvesDocument12 pagesGeberit Filling ValvesAdrian TurcuNo ratings yet

- Spiilway + Emergency Spillway-1Document35 pagesSpiilway + Emergency Spillway-1niaNo ratings yet

- SCIRT 6 Month Work ScheduleDocument8 pagesSCIRT 6 Month Work ScheduleDiacNo ratings yet

- Ds80 WCX CadDocument122 pagesDs80 WCX CadTrong Hieu Nguyen100% (1)

- Uttarakhand Emergency Assistance Project-IND - 3055 Water Supply Sector Short Note On Project DescriptionDocument3 pagesUttarakhand Emergency Assistance Project-IND - 3055 Water Supply Sector Short Note On Project DescriptionManoj BishtNo ratings yet

- Mumbai Water Supply ManagementDocument21 pagesMumbai Water Supply ManagementNeel Mehta100% (1)

- LLDA Clearance Application FormDocument2 pagesLLDA Clearance Application FormMykka ArtillagaNo ratings yet

- Ukkadam STP, Coimbatore Co-Treatment Case Study: List of TablesDocument14 pagesUkkadam STP, Coimbatore Co-Treatment Case Study: List of TablesVikram SKNo ratings yet

- Australian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsDocument8 pagesAustralian Standard: National Plumbing and Drainage Part 1.1: Water Supply - Performance RequirementsVăn AnhNo ratings yet

- IGUNGA Water DemandDocument4 pagesIGUNGA Water DemandInnocent RevocatusNo ratings yet

- Fire Fighting Design RequirementsDocument47 pagesFire Fighting Design RequirementsAshokNo ratings yet

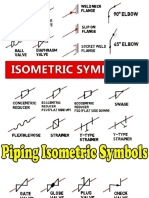

- Piping Isometric SymbolsDocument15 pagesPiping Isometric SymbolsleonciomavarezNo ratings yet

- Water Project Aplication To Global HandDocument7 pagesWater Project Aplication To Global HandLoic NgashiNo ratings yet

- Sampling and Analysis of Industrial Waste Water and ReuseDocument6 pagesSampling and Analysis of Industrial Waste Water and ReuseimaniNo ratings yet

- Coliform BacteriaDocument4 pagesColiform BacteriasjsshipNo ratings yet

- Water Manual Vol III v120130Document192 pagesWater Manual Vol III v120130Rich'kid AListadoNo ratings yet

- DWSD Lifeline Plan - June 2022Document12 pagesDWSD Lifeline Plan - June 2022Malachi BarrettNo ratings yet

- NX VFCDocument24 pagesNX VFCtienNo ratings yet