Professional Documents

Culture Documents

Instruction C02 78.3

Uploaded by

ВиталийКрутиковCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Instruction C02 78.3

Uploaded by

ВиталийКрутиковCopyright:

Available Formats

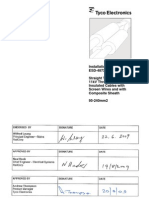

Installation Instruction

2800120-C

CELLFLEX Coaxial Cable

2800120-C

LCF/UCF 78-50 Cables

OMNI FIT C02 Connectors

Connectors

Measuring tool

Gloves

Recommended with

Straight line, smooth &

fine- teeth saw

~ 5mm

~0,2

Grease

Back-nut

SW 32 (1-1/4)

Safety precaution:

Sample picture of 716M-LCF78-C02

Instruction valid for complete C02 series

Sealing material

e.g. Tape, Sleeve etc.

Fine file

Tape

Screwdriver

O-Ring

7-16

Interface

Additionally

recommended

or

SW 32 (1-1/4)

Brush

Spring O-Ring

Knife

Body

2 x 32mm

(2 x 1-1/4)

JSTRIP-78-2

Optional

manual method

These instructions are written for qualified and experienced personnel. Please study them carefully before starting any work. Any liability or

responsibility for the results of improper or unsafe installation practices is disclaimed. Please respect valid environmental regulations for assembly and

waste disposal. Always make sure to use appropriate personal protection!

Cutting Guide

TRIM-CG-78

Sharp blade => Protective gloves required !

1

Cut off

(on Top)

or

with

Cutting

Guide

or

min. 35 mm (min. 1.4 in)

Top

max. two and a half pitches

5

21.0 21.5 mm

(0.82 0.84 in)

6

13

11

10

14

15

16

12

Weatherproofing options

17

Additional weatherproofing must be used for Lite (Aluminium) cable types

Radio Frequency Systems www.rfsworld.com

United States +1-800-321-4700 Germany +49-511-676-2000

Australia +61-3-9751-8400 Brazil +55-11-4785-2433 China + 86-21-3773-8888

Page 1 of 4

2800120-C

CELLFLEX Coaxial Cable

Connectors

Installation Instruction

2800120-C

LCF/UCF 78-50 Cables

OMNI FIT C02 Connectors

Manual installation method with standard hand tools

Keep the cable end downwards in order to prevent particles from entering during preparation.

1. Straighten the cleaned cable front part in a length of min. 200mm (8).

Remove the jacket with a knife in the length as shown (it is recommended to use the stripping tool

JSTRIP-78-2). Do not damage the outer conductor!

2. Cut off the cable on top of corrugation in a distance of max. two and a half pitches from the jacket.

Make sure to cut in a right angle to cable axis!

3. Cut and remove the jacket in the distance as shown. Do not damage the outer conductor.

4. Deburr inner- and outer conductor each from in- and outside. Remove any particles.

5. Slide the O-Ring onto cable positioned in the valley before jacket as shown. Wipe a light film of grease

on the O-Ring.

6. Push back-nut onto cable and over the O-Ring until stop (first corrugation valley is free/exposed).

7. Put Spring O-Ring into first corrugation valley of the cable.

8. Push back-nut back to the front until stop at the Spring O-Ring (Spring O-Ring is approximately covered

by its half).

9. Keep pushing the back-nut to the front while running the tip of a screw driver (rounded edges) around

the outer conductor to separate the foam and create an outer conductor flare. Flare diameter has to be

evenly round and concentrically to the cable axis.

10. The flared area (cone) has to be free of any dielectric material, if necessary bend the dielectric back to

the centre.

11. Clean the cable end, remove any particles very carefully. Tip: tape can be used additionally to remove

the finest particles.

12. Careful preparation is important especially for proper PIM performance.

13. Wipe the back nut O-Ring with a light film of grease.

14. Push connector front part onto prepared cable end; do never turn the front part!

15. Pay attention to straight position of connector parts while tightening the connector by turning the backnut only (first by hand). Never turn the front part of the connector!

16. Keep the connector body steady and tighten the back-nut of the connector by use of open end

wrenches. Tighten properly to mechanical stop (no visible gap between body and back-nut).

Keep the interface clean, do not remove the protection cap before mating.

17. Weatherproofing

Important Remarks:

Additional weather protection is necessary when installed on Lite (Aluminium) cable!

In general this is also recommended for Copper cables especially if installed outside.

Possible methods:

E.g. with Sealing tape, Weatherproofing kit or Cold Shrink Sleeve

Clean cable and connector and continue according to the applicable installation instruction.

With Heath shrink sleeve

Roughen the jacket with fine grained sandpaper (e.g. 180 grain) and clean the shrinking area e.g. with

cable cleaner. Pre-heat the cable jacket to hand warm and the connector to approx. 60C. Slide the

heat shrink sleeve into place over the connector body as shown. Shrink the sleeve with a soft yellow

flame if using a gas burner or go for hot air gun. Shrink the sleeve onto the connector by smoothly

applying a constant flame (heat) wit a circular motion until the sleeve will lay flat all around and the hot

solvent adhesive discharged all around. Continue with an even circular motion proceeding in direction of

the cable until it shrinks smoothly forming a weatherproof seal and the hot solvent adhesive discharged

all around on both ends. Note: Do not overheat especially the jacket (max. temperature = 70C,

shrinking temperature is typically around 130C).

Radio Frequency Systems www.rfsworld.com

United States +1-800-321-4700 Germany +49-511-676-2000

Australia +61-3-9751-8400 Brazil +55-11-4785-2433 China + 86-21-3773-8888

Page 2 of 4

Installation Instruction

2800120-C

CELLFLEX Coaxial Cable

2800120-C

LCF/UCF 78-50 Cables

OMNI FIT C02 Connectors

Connectors

Measuring tool

O-Ring

7-16

Interface

Additionally

recommended

Knife

or

SW 32 (1-1/4)

Tape

Brush

Spring O-Ring

Body

Recommended with

Straight line, smooth &

fine- teeth saw

Gloves

Grease

JSTRIP-78-2

Back-nut

SW 32 (1-1/4)

Sample picture of 716M-LCF78-C02

Instruction valid for complete C02 series

Safety precaution:

Trimming tool method

These instructions are written for qualified and experienced personnel. Please study them carefully before starting any work. Any liability or

responsibility for the results of improper or unsafe installation practices is disclaimed. Please respect valid environmental regulations for assembly and

waste disposal. Always make sure to use appropriate personal protection!

2 x 32mm

(2 x 1-1/4)

Universal Trimming tool

TRIM-SET-L78-C02

Sealing material

e.g. Tape, Sleeve etc.

Sharp blade => Protective gloves required !

or

Take care Sharp blades inside!

min. 4 corrugations

(in front of the blade)

min. 45 mm (min. 1.8 in)

Collet

Trim blades

Main blade

on top

2a

Top

T3

T2

Position of

collet guide

+ 2x

T1

max. two and a half pitch

21.0 21.5 mm

(0.82 0.84 in)

T1

10

11

13

12

14

360 min.

15

16

17

18

Weatherproofing options

19

Additional weatherproofing must be used for Lite (Aluminium) cable types

Radio Frequency Systems www.rfsworld.com

United States +1-800-321-4700 Germany +49-511-676-2000

Australia +61-3-9751-8400 Brazil +55-11-4785-2433 China + 86-21-3773-8888

Page 3 of 4

Installation Instruction

2800120-C

CELLFLEX Coaxial Cable

2800120-C

LCF/UCF 78-50 Cables

OMNI FIT C02 Connectors

Connectors

Installation method with Universal Trimming Tool

TRIM-SET-L78-C02

Consist of:

TRIM-U-14-78

Body:

Flaring tool: TRIM-FL78

TRIM-IL78-C02

Insert:

Insert consist of:

Blade holder:

Collet:

TRIM-IL78-C02

TRIM-IL78

Attention:

Trimming tool to be handled and

used with great care, blades are

extremely sharp!

It is recommended to use protective

gloves. Do not use great force.

Please refer to the instruction of the Universal Trimming Tool in addition!

Keep the cable end downwards in order to prevent particles from entering during preparation.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

Straighten the cleaned cable front part in a length of min. 200mm (8).

Remove the jacket with a knife in the length as shown (it is recommended to use the stripping tool JSTRIP-78-2). Do not

damage the outer conductor!

Insert cable into trimming tool, so that min. 4 corrugations are in front of the main trim blade. Position collet guide of

trimming tool in the first corrugation nearest to the trimmed cable jacket. The cable also fits properly to the complete

base of the tool. The main blade is located on the crest (top) of the corrugation.

Rotate trimming tool around the cable in direction of the arrow shown on the tool by touching tool turning points T1 and

T2 only. Do not use any additional force greater than the preset trimming tool spring tension. Once the outer conductor

is cut, continue turning the tool whereby the tool can be touched on tool turning points T1, T2 and T3 until the cable is

completely cut (outer- & inner conductor). Turn the tool min. 2 more times around the cable in order to make sure the

jacket will be cut as well. Open blade housing and remove the tool.

Cut the jacket lengthwise with knife carefully; do not damage the outer conductor. Remove the jacket.

Check trimming dimensions.

Slide the O-Ring onto cable positioned in the valley before jacket as shown. Wipe a light film of grease on the O-Ring.

Push back-nut onto cable and over the O-Ring until stop (first corrugation valley is free/exposed).

Put Spring O-Ring into first corrugation valley of the cable.

Push back-nut back to the front until stop at the Spring O-Ring (Spring O-Ring is approximately covered to its half).

Push a bit of dielectric to the centre in order to have a free space to insert the flaring pin of the tool as required for next

step.

Insert cable guide pin of the trimming tool into the cable inner conductor; make sure that the flaring pin is located

between outer conductor and foam/dielectric (in the free space made before). Keep pushing the back-nut to the front

while turning the trimming tool to flare the outer conductor and deburr the inner conductor. Flare diameter has to be

evenly round and concentrical to the cable axis.

The flared area (cone) has to be free of any dielectric material, if necessary bend the dielectric back to the centre.

Clean the cable end, remove any particles very carefully. Tip: tape can be used additionally to remove the finest

particles.

Careful preparation is important especially for proper PIM performance.

Wipe the back-nut O-Ring with a light film of grease.

Push connector front part onto prepared cable end; do never turn the front part!

Pay attention to straight position of connector parts while tightening the connector by turning the back-nut only (first by

hand). Never turn the front part of the connector!

Keep the connector body steady and tighten the back-nut of the connector by use of open end wrenches. Tighten

properly to mechanical stop (no visible gap between body and back-nut).

Keep the interface clean, do not remove the protection cap before mating.

Weatherproofing

Important Remarks:

Additional weather protection is necessary when installed on Lite (Aluminium) cable!

In general this is also recommended for Copper cables especially if installed outside.

Possible methods:

E.g. with Sealing tape, Weatherproofing kit or Cold Shrink Sleeve

Clean cable and connector and continue according to the applicable installation instruction.

With Heath shrink sleeve

Roughen the jacket with fine grained sandpaper (e.g. 180 grain) and clean the shrinking area e.g. with cable cleaner.

Pre-heat the cable jacket to hand warm and the connector to approx. 60C. Slide the heat shrink sleeve into place over

the connector body as shown. Shrink the sleeve with a soft yellow flame if using a gas burner or go for hot air gun.

Shrink the sleeve onto the connector by smoothly applying a constant flame (heat) wit a circular motion until the sleeve

will lay flat all around and the hot solvent adhesive discharged all around. Continue with an even circular motion

proceeding in direction of the cable until it shrinks smoothly forming a weatherproof seal and the hot solvent adhesive

discharged all around on both ends. Note: Do not overheat especially the jacket (max. temperature = 70C, shrinking

temperature is typically around 130C).

Radio Frequency Systems www.rfsworld.com

United States +1-800-321-4700 Germany +49-511-676-2000

Australia +61-3-9751-8400 Brazil +55-11-4785-2433 China + 86-21-3773-8888

Page 4 of 4

You might also like

- Ultimate Guide: Wiring, 8th Updated EditionFrom EverandUltimate Guide: Wiring, 8th Updated EditionRating: 3.5 out of 5 stars3.5/5 (4)

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsFrom EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsRating: 3 out of 5 stars3/5 (8)

- Cab&Chaissis ElectricalDocument323 pagesCab&Chaissis Electricaltipo3331100% (13)

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- Volvo FM Wiring DiagramDocument152 pagesVolvo FM Wiring DiagramVincent Price96% (27)

- The IEE Wiring Regulations Explained and IllustratedFrom EverandThe IEE Wiring Regulations Explained and IllustratedRating: 4 out of 5 stars4/5 (14)

- Doosan D50SC 5 EngineMaintenanceManual SB4323E00 PDFDocument366 pagesDoosan D50SC 5 EngineMaintenanceManual SB4323E00 PDFSami Enis Arıoğlu100% (2)

- BACnet GatewayDocument14 pagesBACnet GatewaySteve GrantNo ratings yet

- MHR 360° Radar Deployment ManualDocument72 pagesMHR 360° Radar Deployment ManualZayar HeinNo ratings yet

- Detailed Lesson Plan in ICT-Computer Hardware Servicing (Grade 10)Document5 pagesDetailed Lesson Plan in ICT-Computer Hardware Servicing (Grade 10)Jayvie Galang RaquelNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Parachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsFrom EverandParachute Cord Craft: Quick & Simple Instructions for 22 Cool ProjectsRating: 4 out of 5 stars4/5 (1)

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Canusa Heat Shrink Sleeve PDFDocument2 pagesCanusa Heat Shrink Sleeve PDFvaradarajck893No ratings yet

- Knots: An Illustrated Practical Guide to the Essential Knot Types and their UsesFrom EverandKnots: An Illustrated Practical Guide to the Essential Knot Types and their UsesNo ratings yet

- Mp501e PDFDocument8 pagesMp501e PDFEdgar CanelasNo ratings yet

- Ripley: Instruction SheetDocument1 pageRipley: Instruction SheetcolinyNo ratings yet

- Terminales Termocontractiles PDFDocument18 pagesTerminales Termocontractiles PDFcbeltranochoaNo ratings yet

- Welder ManualDocument14 pagesWelder ManualqwdqwawjdNo ratings yet

- Aiwa Tvc2121Document43 pagesAiwa Tvc2121Safran NuhNo ratings yet

- Assembly Instructions For Cable Gland: 755 32R4: Connection SolutionsDocument4 pagesAssembly Instructions For Cable Gland: 755 32R4: Connection Solutionspvalverdea2014No ratings yet

- Elastimold Compact I JointDocument6 pagesElastimold Compact I Jointwerawatb819No ratings yet

- Troubleshooting Manual, TS2712EN 04Document82 pagesTroubleshooting Manual, TS2712EN 04thibierozNo ratings yet

- Tost Winch Manual UltralightDocument9 pagesTost Winch Manual Ultralightcaf28035No ratings yet

- Pioneer RSM400Document69 pagesPioneer RSM400Jurie WesselsNo ratings yet

- Andrew Coaxial Cable Installation Instructions-Bulletin 17800BDocument8 pagesAndrew Coaxial Cable Installation Instructions-Bulletin 17800BMike FixNo ratings yet

- Installation Instructions for 755/775LR Elbow ConnectorsDocument5 pagesInstallation Instructions for 755/775LR Elbow Connectorsvladimir_71No ratings yet

- Stripper Wire HandHeldDocument5 pagesStripper Wire HandHeldIvana IviNo ratings yet

- Manual For Filastruder ENGLISH PDFDocument10 pagesManual For Filastruder ENGLISH PDFstavroula zarkadoulaNo ratings yet

- Fi - SCST Multimode Singlemode Connector - II PDFDocument4 pagesFi - SCST Multimode Singlemode Connector - II PDFmirkofedorNo ratings yet

- AIR-X Circuit Replacement InstructionsDocument9 pagesAIR-X Circuit Replacement InstructionsscabdNo ratings yet

- Panduit - Termination - Solutions PDFDocument124 pagesPanduit - Termination - Solutions PDFPutra Kusuma HarditoNo ratings yet

- Installation Kit Joints 11kV CablesDocument10 pagesInstallation Kit Joints 11kV CablesGuler RahimNo ratings yet

- TV-CN202 Service ManualDocument33 pagesTV-CN202 Service Manualjama35No ratings yet

- 2100d Installation GuideDocument20 pages2100d Installation GuideJazz TubaNo ratings yet

- EU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationDocument12 pagesEU3512-3X Environmental Enclosure and Light Duty Wall Mount: InstallationByron RieraNo ratings yet

- 04 Solenoid Valves Light Type Va1Document37 pages04 Solenoid Valves Light Type Va1اشرينكيل مسونكيلNo ratings yet

- HELIAX Coaxial CableDocument8 pagesHELIAX Coaxial CablehernanoygNo ratings yet

- FC-6 Operation ManualDocument4 pagesFC-6 Operation ManualbigdrsmithNo ratings yet

- LG L1733TR L1933TR Monitor Service ManualDocument35 pagesLG L1733TR L1933TR Monitor Service Manualmanlu1001565No ratings yet

- LG Flatron l1730s-l1930sDocument31 pagesLG Flatron l1730s-l1930sOscar Hernández Couoh100% (2)

- LG TFT-LCD Color Monitor FLATRON W1934S PDFDocument49 pagesLG TFT-LCD Color Monitor FLATRON W1934S PDFCriss AlbuNo ratings yet

- Tri-band HF Beam Antenna ManualDocument11 pagesTri-band HF Beam Antenna ManualOscar NavaNo ratings yet

- 93 Camry Body Repair ManualDocument135 pages93 Camry Body Repair ManualdunericNo ratings yet

- l1717sbn 17 LCD MonitorDocument27 pagesl1717sbn 17 LCD Monitorflorinescu61No ratings yet

- MTS E-Beam Evaporator ManualDocument11 pagesMTS E-Beam Evaporator ManualMarco SalvatoriNo ratings yet

- S - Hose Binding and Binding Device - MDocument5 pagesS - Hose Binding and Binding Device - Mcata1108No ratings yet

- Light CrimpDocument19 pagesLight CrimpAlejandro PerezNo ratings yet

- N219 Distances between the Receiver and the TransmitterDocument8 pagesN219 Distances between the Receiver and the Transmitterdumitrescu viorelNo ratings yet

- Esd 4873 Au 5 - 09 PDFDocument13 pagesEsd 4873 Au 5 - 09 PDFGeorge IstrateNo ratings yet

- Manual Del AerogeneradorDocument39 pagesManual Del AerogeneradorJORDY ALVARADONo ratings yet

- Aiwa Tv-c1400 Chassis Cp-005aDocument27 pagesAiwa Tv-c1400 Chassis Cp-005apetricabogdanNo ratings yet

- 3.7 Meter ASC 208VAC Tedlar DP-7SSDocument36 pages3.7 Meter ASC 208VAC Tedlar DP-7SSpower kartoffelNo ratings yet

- AI316Document4 pagesAI316pvalverdea2014No ratings yet

- 1400MM T-28 Trojan V4 Safety ManualDocument16 pages1400MM T-28 Trojan V4 Safety ManualFranco CondeNo ratings yet

- Armar Case OutdoorDocument2 pagesArmar Case Outdoorcristiandadypatria8976No ratings yet

- TVF2100NH - 09 008 432 1R2 PDFDocument39 pagesTVF2100NH - 09 008 432 1R2 PDFEfra Lan PeñaNo ratings yet

- Gland InstallDocument2 pagesGland InstalljutapolNo ratings yet

- Cable Gland Installation InstructionsDocument2 pagesCable Gland Installation InstructionsJairo WilchesNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Cetop 3 Argo HytosDocument4 pagesCetop 3 Argo HytosMartín UrrereNo ratings yet

- Service Manual Okidata ML395 PDFDocument29 pagesService Manual Okidata ML395 PDFPramote RodbonNo ratings yet

- Gigabyte Motherboard GA-M565-S3 Rev 1.0Document96 pagesGigabyte Motherboard GA-M565-S3 Rev 1.0DiNo ratings yet

- Acoustat Model 1 Owners ManualDocument14 pagesAcoustat Model 1 Owners Manualmike davis0% (1)

- 5 XXX Software ManDocument87 pages5 XXX Software ManAnonymous V9fdC6No ratings yet

- Cylinder Head in Vehicle Repair PDFDocument14 pagesCylinder Head in Vehicle Repair PDFMichael HernandezNo ratings yet

- Product Review: Kyosho SeaWindDocument17 pagesProduct Review: Kyosho SeaWindXperarnauNo ratings yet

- Volvo BL 71 8 Machinery House, Cab, Exterior Trim Parts AnywhereDocument55 pagesVolvo BL 71 8 Machinery House, Cab, Exterior Trim Parts AnywhereVygintas Balcius100% (1)

- Colorflex Ez Citrus User ManualDocument64 pagesColorflex Ez Citrus User ManualIvanaColinNo ratings yet

- A Meren Electric Service ManualDocument155 pagesA Meren Electric Service ManualfioricoziucNo ratings yet

- Low Cost 50W-300W Single Output Power SuppliesDocument7 pagesLow Cost 50W-300W Single Output Power SuppliesMarco BonillaNo ratings yet

- Proportional Pressure Relief Valve Type DBE/DBEM: Huade América 1Document9 pagesProportional Pressure Relief Valve Type DBE/DBEM: Huade América 1Joaquin CardenasNo ratings yet

- Harting News 2011Document128 pagesHarting News 2011nadab01No ratings yet

- Robus RB600 - 1000 PDocument26 pagesRobus RB600 - 1000 Pjohn florosNo ratings yet

- (Ebook - PDF - Hack) Advanced Hardware HackingDocument20 pages(Ebook - PDF - Hack) Advanced Hardware HackingogmpsqjuNo ratings yet

- Opps Operating Manual UsDocument88 pagesOpps Operating Manual UsTdr JrbNo ratings yet

- Avr-X3600h Eng SM V01 20190809074057246Document193 pagesAvr-X3600h Eng SM V01 20190809074057246Vicente Fernandez100% (1)

- DTV MD 0058 DIRECTVSet TopInformationforInstallers V2.2Document42 pagesDTV MD 0058 DIRECTVSet TopInformationforInstallers V2.2Kritika RanaNo ratings yet

- GP2401 2501 2601Document139 pagesGP2401 2501 2601Sergio GarciaNo ratings yet

- Ms 27488Document9 pagesMs 27488echobravo1No ratings yet

- Mygps: A Diy Project - Portable and Astronomy Gps Based On Arduino NanoDocument9 pagesMygps: A Diy Project - Portable and Astronomy Gps Based On Arduino NanoadiasmesquitaNo ratings yet

- 2000A ManualDocument37 pages2000A ManualAkinbode Sunday OluwagbengaNo ratings yet

- POE31004P DatasheetDocument4 pagesPOE31004P DatasheetonvcomNo ratings yet