Professional Documents

Culture Documents

PTW-Hot Work 2-Checklist 35 - Well Entry Operations

Uploaded by

alizareiforoushCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PTW-Hot Work 2-Checklist 35 - Well Entry Operations

Uploaded by

alizareiforoushCopyright:

Available Formats

PTW CHECKLIST - NO.

35

Owner:

Title: Well Services Offshore / Onshore Operations

Capability Coordinator

Approver: Capability Coordinator

Document No:

PTW-01.35

Max Validity Period: 5 yrs

Permit No.:

Date:

Latest Rev

Date

Details

12.0

01/03/13

Full revision

M Gilmour

12.1

30/01/14

No. 22 added and changes to No. 31.

M. Gilmour

Other Checklists That May Be Relevant:

Authorised By

24, 25, 29, 30, 51

HRA Checklists:

PRIOR TO PERMIT ISSUE:

Tick when done

Y

N

NA

1.

Agree location of equipment with PI.

NOTE: Equipment should always be placed as far away from process

equipment as practical

Specify Location:_________________________________________________

Have all required parties signed off the WE Dept work programme?

The PIC and AT have been informed of the actual task to be carried out

including potential for Complex and Non-Routine crane lifts, vehicle entry and gas

venting?

Confirm if gas and flame detectors require isolation in the vicinity of work area.

5.

Onshore: If explosives are being used, has Section 36.0.0, Perforating Operations,

in document A-73.04.03.002 General Well Services Procedures been reviewed

and Checklist 36.1.0 Kapuni Wellsites been completed?

6.

Offshore: If explosives are being used, has Section 37.0.0 Safe Firing Systems

Offshore in document A-73.04.03.002 General Well Services Procedures been

reviewed and Checklist 37.01.0 Platform Safety Checklist Prior to Perforating been

completed?

Is this system one that may contain Mercury contamination? (Refer to

Site Mercury Register) If the answer is yes, refer to Standard Operating Procedure

(SOP) STA-01.43 and PTW Checklist 25

Printed on: 11 February 2015

Page 1 of 4

PRIOR TO WORK COMMENCING:

8

Well Handover Sheet completed (isolation of subsurface safety valve and

actuated OMV is handled under CMI).

The Under Well Services Control signs been placed on the UMV 3-way valve

and the SCSSSV hydraulic supplies.

10

Conduct a gas test immediately prior to and continuous whilst working.

11

A portable dry powder extinguisher is present at the engine site.

12

Barriers and warning signs are erected to exclude persons not involved.

13

Has the xmas tree / well head been bled prior to tree cap removal.

14

Make sure there is adequate lighting in and around work area.

15

The windsock or equivalent device is visible.

16

Consideration has been given to the restraining of the handrails, grating,

hatches and fixed ladders to prevent the falling, slipping and sliding.

17

Physical barriers are erected around open hatches and removed gratings.

SET UP EQUIPMENT:

Tick when done

Y

N

NA

18

All work shall be carried out as per Well services procedures.

19

All personnel are competent with the equipment to be used, including

procedures for any hazardous substances.

20

Whip checks and R clips are installed where applicable.

21

Bond equipment to earth where necessary.

22

Measure resistance between well entry equipment and plant earth using

Multimeter. Readings must be below 10 ohms. Record reading on continuity

Section of HW2 permit.

CARRY OUT OPERATION:

Tick when done

Y

N

NA

23

Function test Emergency Shut Down Systems and ensure personnel are

competent and willing to operate them in an emergency. (Well Control

Panel winch panel and site ESD)

24

The winch is not left unattended in gear or with the power pack running.

25

The pump relief valves are set and direction of relief flow is checked.

26

Pressure testing barriers & Pressure Test signs are in place and pressure

control equipment is secured correctly and certified.

27

List the substance to be used for the test medium, ie (50/50 Water/Glycol).

.

28

Prior to bleeding down well to atmosphere check wind direction and inform AT.

29

Hydrocarbons cannot be drained into waste water line.

Printed on: 11 February 2015

Page 2 of 4

ON COMPLETION OF THE JOB:

Tick when done

Y

N

NA

30

Function / inflow test SCSSSV after well entry and reinstate control panels.

31

The Well Handover Sheet been completed. (NB: This can only be done after /

during completion of the deisolation process).

32

Remove all the Under Well Services Control signs.

33

Ensure the worksite been left clean and tidy and have all tools, hoses, portable

equipment, extinguishers and barriers been returned to storage.

34

Ensure all chemicals and hazardous materials been disposed of appropriately.

35

Gas and flame detectors inhibited for the work have been reinstated.

36

Incidents or potential incidents have been brought to the attention of the PI.

NOTE: Any member of the Well Services Team is to notify the Control Room immediately an

abnormal situation occurs.

Printed on: 11 February 2015

Page 3 of 4

WELL HANDOVER SHEET

STOS Well Services Operations

WELL:

Permit #(s):..

Date/Time Well Closed In:

Operations to Well Services

THP & Time/Date recorded

A/B/C Annulus Pressures

Pres

Well Services to Operations

Time/Date

Pres

Time/Date

Lower Master Valve

OPEN/CLOSED

OPEN/CLOSED

Upper Master Valve (SSV)

OPEN/CLOSED

OPEN/CLOSED

Flow Wing Valve

OPEN/CLOSED

OPEN/CLOSED

Outer Flow Wing Valve

(where installed)

OPEN/CLOSED*

OPEN/CLOSED*

Kill Wing Valve

OPEN/CLOSED

OPEN/CLOSED

Outer Kill Wing Valve

(where installed)

OPEN/CLOSED*

OPEN/CLOSED*

Swab Valve

OPEN/CLOSED

OPEN/CLOSED

SCSSV (WR or TR)

OPEN/CLOSED

OPEN/CLOSED

YES/NO

YES/NO

YES/NO

YES/NO

OPEN/CLOSED

OPEN/CLOSED

SCSSV On facility supply

and locked open

SSV On facility supply and

locked open

Control line Pressure

Annulus valve checks

offshore only

Chemical injection system

A Annulus Valve (to

sensor/gauge)

A Annulus Valve (opposite

side to sensor/gauge)

B Annulus Valve (to

sensor/gauge)

B Annulus Valve (opposite

side to sensor/gauge)

C Annulus Valve (to

sensor/gauge)

C Annulus Valve (opposite

side to sensor/gauge)

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Inner valve

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

Outer valve*

OPEN/CLOSED

OPEN/CLOSED

OPEN/CLOSED

OPEN/CLOSED

OPEN/CLOSED

Notes - NORM readings,

hydrates, other issues, etc.

*If no valve fitted then write N/A

WELL HANDED OVER TO WELL SERVICING TEAM BY/DATE

: ..

WELL ACCEPTED BY WELL SERVICING TEAM BY/DATE

: ..

WELL HANDED BACK TO OPERATIONS BY/DATE

: ..

WELL ACCEPTED BACK BY OPERATIONS BY/DATE

Printed on: 11 February 2015

: ..

Page 4 of 4

You might also like

- SWP Plasma Cutter AS532Document2 pagesSWP Plasma Cutter AS532Adet WildanNo ratings yet

- SOR Tracker 2.14Document75 pagesSOR Tracker 2.14faisal nadeemNo ratings yet

- Rigging JSA SafetyDocument5 pagesRigging JSA SafetyaQiLGunawanNo ratings yet

- Abrasive CutDocument1 pageAbrasive CutWahyu Haidar PratamaNo ratings yet

- HSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesDocument1 pageHSE Incident Lesson Learnt Eye Injury Charging Lifeboat Air BottlesKyaw MinNo ratings yet

- Safety Observation Card TemplateDocument1 pageSafety Observation Card TemplatePermana Eka SatriaNo ratings yet

- LOLER Inspection Checklist GuideDocument25 pagesLOLER Inspection Checklist GuideTatak Bay AhmedNo ratings yet

- XSteam Excel v2.6Document9 pagesXSteam Excel v2.6Yos Cornel TariganNo ratings yet

- Excavator Daily Inspection Check List Rev 0Document1 pageExcavator Daily Inspection Check List Rev 0Zhafran diniyNo ratings yet

- How To Read A Centrifugal Pump CurveDocument15 pagesHow To Read A Centrifugal Pump Curvearunima04No ratings yet

- Precision Drilling International Task Risk Assessment WorksheetDocument2 pagesPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Safe Work Procedure: Overhead CraneDocument2 pagesSafe Work Procedure: Overhead CraneNos GoteNo ratings yet

- Manual bending rolls safetyDocument1 pageManual bending rolls safetyvasu_suvaNo ratings yet

- Safety Hot Work ProgramDocument10 pagesSafety Hot Work ProgramkevinNo ratings yet

- GP 10 10 11 June 2008 Well Control PRT 2Document22 pagesGP 10 10 11 June 2008 Well Control PRT 2alizareiforoushNo ratings yet

- Introduction to the Dynamic Three-Phase Flow Simulator OLGADocument56 pagesIntroduction to the Dynamic Three-Phase Flow Simulator OLGAi786zzyNo ratings yet

- Nail Gun Pnuematic Work Method Statement SWMS V8Document5 pagesNail Gun Pnuematic Work Method Statement SWMS V8ferny.51No ratings yet

- GP 10-20 26 August 2008Document41 pagesGP 10-20 26 August 2008alizareiforoushNo ratings yet

- ESC Are You in The Line of Fire Case For ChangeDocument19 pagesESC Are You in The Line of Fire Case For ChangeAli NasseriNo ratings yet

- Drilling Rig Audits and Rig Acceptance: Group PracticeDocument14 pagesDrilling Rig Audits and Rig Acceptance: Group PracticealizareiforoushNo ratings yet

- GP 10-15 9 July 2008Document19 pagesGP 10-15 9 July 2008alizareiforoushNo ratings yet

- JSA EnglishDocument33 pagesJSA EnglishSavu DanielNo ratings yet

- Check Hard Hat Expiry Dates Before UseDocument1 pageCheck Hard Hat Expiry Dates Before UsetimbulNo ratings yet

- Heat ConductionDocument25 pagesHeat ConductionAnonymous z4Fe39jNo ratings yet

- Safe Work Practice: Title General Application Protective MechanismsDocument1 pageSafe Work Practice: Title General Application Protective MechanismseankiboNo ratings yet

- Introduction To ME-GI Engines (Dual Fuel)Document23 pagesIntroduction To ME-GI Engines (Dual Fuel)Lucinio PittiNo ratings yet

- Change Out Rig Tong DiesDocument1 pageChange Out Rig Tong DiesAbdul Hameed OmarNo ratings yet

- Rescue Confined WorkersDocument5 pagesRescue Confined WorkersOlaniyi AdewaleNo ratings yet

- GP 10-16 9 July 2008Document17 pagesGP 10-16 9 July 2008alizareiforoushNo ratings yet

- List of Safety Forms: S. No. Title Rev. No. Rev. DateDocument1 pageList of Safety Forms: S. No. Title Rev. No. Rev. Dateadil khanNo ratings yet

- Hand Trolley PDFDocument1 pageHand Trolley PDFcityofdarwingisNo ratings yet

- Python Programming Tutorial for BeginnersDocument68 pagesPython Programming Tutorial for BeginnersFiktoriusKevinNo ratings yet

- GP 10 10 11 June 2008 Well Control PRT 1Document23 pagesGP 10 10 11 June 2008 Well Control PRT 1alizareiforoushNo ratings yet

- LifeSavingRules NotepadDocument2 pagesLifeSavingRules NotepadInternational Association of Oil and Gas ProducersNo ratings yet

- Visible Safety and Induction: Hse Management Visit ChecklistDocument6 pagesVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNo ratings yet

- Cummins Hystat 70 SpecsheetDocument2 pagesCummins Hystat 70 SpecsheetamsukdNo ratings yet

- Determination of Optimum N2 Rate For Unloading Gas Wells With Coiled Tubing 2011Document12 pagesDetermination of Optimum N2 Rate For Unloading Gas Wells With Coiled Tubing 2011alizareiforoushNo ratings yet

- Process Design of Liquid & Gas TransferDocument19 pagesProcess Design of Liquid & Gas Transferhawk1821No ratings yet

- Safe Working PracticesDocument7 pagesSafe Working PracticesDiana ParkerNo ratings yet

- Completion-Workover Riser Systems: Group PracticeDocument13 pagesCompletion-Workover Riser Systems: Group PracticealizareiforoushNo ratings yet

- LifeSavingRules - Supplementary Rules PostersDocument11 pagesLifeSavingRules - Supplementary Rules PostersInternational Association of Oil and Gas ProducersNo ratings yet

- Simultaneous Operations: Group PracticeDocument11 pagesSimultaneous Operations: Group PracticealizareiforoushNo ratings yet

- 10 Questions For Line of FireDocument2 pages10 Questions For Line of FireGary Moses100% (1)

- Fork Lift Daily Check: (Only For FL Operated by Batery)Document1 pageFork Lift Daily Check: (Only For FL Operated by Batery)Martin CabelloNo ratings yet

- Guidelines For Step Rate TestingDocument18 pagesGuidelines For Step Rate TestingweldsvNo ratings yet

- Secondary Well Control - Well Control EquipmentDocument43 pagesSecondary Well Control - Well Control EquipmentalizareiforoushNo ratings yet

- Brake HidraulicsDocument40 pagesBrake HidraulicsSERGIO CARDENAS CASTILLONo ratings yet

- 01-Ppe Eng PDFDocument17 pages01-Ppe Eng PDFZaki AdamouNo ratings yet

- PSI PumpsDocument12 pagesPSI PumpsagiacomuzoNo ratings yet

- Brochure B1500 All Fire PumpsDocument4 pagesBrochure B1500 All Fire Pumpseng_elbarbaryNo ratings yet

- Ficha TecnicaDocument2 pagesFicha TecnicaAllende Fretel CarhuasNo ratings yet

- Moving and Securing of Mobile Offshore Drilling Units: Group PracticeDocument17 pagesMoving and Securing of Mobile Offshore Drilling Units: Group PracticealizareiforoushNo ratings yet

- GP 10-50 11 June 2008 Drilling EquipDocument26 pagesGP 10-50 11 June 2008 Drilling EquipalizareiforoushNo ratings yet

- Precision Drilling International Task Risk Assessment WorksheetDocument2 pagesPrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- JSA CT Cement (Example)Document2 pagesJSA CT Cement (Example)aneshseNo ratings yet

- Casing Design PreliminaryDocument29 pagesCasing Design Preliminaryalizareiforoush100% (2)

- Climate Change Impact On Occupational Health and SafetyDocument31 pagesClimate Change Impact On Occupational Health and Safetyarslan MaqboolNo ratings yet

- Plant Experience - Molecular Sieve Dehydration of Gas Containing OxygenDocument23 pagesPlant Experience - Molecular Sieve Dehydration of Gas Containing OxygenHoang-Vu BuiNo ratings yet

- Good Catch Safety Program ConstructionDocument3 pagesGood Catch Safety Program ConstructionStephanie0% (1)

- FINAL Shivani Confined Space PermitDocument1 pageFINAL Shivani Confined Space PermitVimal SinghNo ratings yet

- Process and Risk Assessment Template All Faculty January 2015Document6 pagesProcess and Risk Assessment Template All Faculty January 2015hungonline07No ratings yet

- Job StudyDocument3 pagesJob StudyVictor PhiriNo ratings yet

- Job Safety Observation Report RecommendationsDocument1 pageJob Safety Observation Report RecommendationsFrancis Enriquez TanNo ratings yet

- JsaDocument10 pagesJsaTanzeel LiaqatNo ratings yet

- Index: Cv. Dira Utama SejahteraDocument12 pagesIndex: Cv. Dira Utama SejahteraFreshop SurabayaNo ratings yet

- CHECKLIST FOR LIFTING PLANDocument1 pageCHECKLIST FOR LIFTING PLANAndrianoNo ratings yet

- Preventing Heat Stress at WorkDocument66 pagesPreventing Heat Stress at WorkEldhose VargheseNo ratings yet

- Pera JackhammerDocument7 pagesPera Jackhammerjumansyahamid1988No ratings yet

- BP Safety AlertDocument2 pagesBP Safety AlertRikza AhmadNo ratings yet

- RRC Risk Assessment Dec 2010Document14 pagesRRC Risk Assessment Dec 2010Li ChenNo ratings yet

- CL-07-02 Crane Lift Study ChecklistDocument7 pagesCL-07-02 Crane Lift Study Checklisthanes0% (1)

- SWMS Bored PilingDocument17 pagesSWMS Bored PilingnaraNo ratings yet

- HSSE Statistics For The Past 5 YearsDocument4 pagesHSSE Statistics For The Past 5 YearsNikhil VermaNo ratings yet

- Safety Induction: Presented By: Rizky RamadhanDocument10 pagesSafety Induction: Presented By: Rizky RamadhanMuhammad Rizky RamadhanNo ratings yet

- Halliburton: Job Safety AnalysisDocument2 pagesHalliburton: Job Safety Analysisaneshse100% (1)

- Surface Exploration Drilling ChecklistDocument5 pagesSurface Exploration Drilling ChecklistZulfiqar HyderNo ratings yet

- Ladder Safety Tips <40Document2 pagesLadder Safety Tips <40Ange JuanNo ratings yet

- HSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Document1 pageHSE Alert - Property Damage - Drill Pipe Fell - JDE # 747806Edwin M. MolinaNo ratings yet

- HSE Manual Unlimited EnergyDocument74 pagesHSE Manual Unlimited Energysangar sabirNo ratings yet

- 07.03.09 Rig Move (Working at Height)Document1 page07.03.09 Rig Move (Working at Height)Hamdi RafiekNo ratings yet

- Risk AssesmentDocument2 pagesRisk Assesmentsabu1995No ratings yet

- Dr. Nirali Patel Pediatric Emergency MedicineDocument31 pagesDr. Nirali Patel Pediatric Emergency Medicinemarsan12No ratings yet

- Hand - Protection Safety TrainingDocument2 pagesHand - Protection Safety TrainingEmmaprinceNo ratings yet

- Safety & Health ProgramDocument2 pagesSafety & Health ProgramD.k. PathakNo ratings yet

- Health and Safety Rules and Regulations 2012 PDFDocument54 pagesHealth and Safety Rules and Regulations 2012 PDFBranislavVorgic100% (1)

- GP 10-20 26 August 2008 222Document41 pagesGP 10-20 26 August 2008 222alizareiforoushNo ratings yet

- GP 10 80 11 June 2008Document29 pagesGP 10 80 11 June 2008Yasmine ياسمينNo ratings yet

- Basic Cement CalculationsDocument1 pageBasic Cement Calculationsابوالحروف العربي ابوالحروفNo ratings yet

- An Expert System For Casing String Design SPE 20328 1990Document8 pagesAn Expert System For Casing String Design SPE 20328 1990alizareiforoushNo ratings yet

- Insulation Resistance Monitoring Prevents ESP FailureDocument1 pageInsulation Resistance Monitoring Prevents ESP FailurealizareiforoushNo ratings yet

- Evaluate Gas Condensate Blockage with Reservoir Simulation and Lab ExperimentsDocument5 pagesEvaluate Gas Condensate Blockage with Reservoir Simulation and Lab ExperimentsMod Hah GhasdcNo ratings yet

- How To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesDocument9 pagesHow To Improve Poor System Efficiencies of ESP Installations Controlled by Surface ChokesjoreliNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- Coiled Tubing Running SpeedsDocument1 pageCoiled Tubing Running SpeedsalizareiforoushNo ratings yet

- SLB Enhanced Dominator Motor - Product BulletinDocument15 pagesSLB Enhanced Dominator Motor - Product BulletinalizareiforoushNo ratings yet

- Well Integrity Management System - Leak Rate CriteriaDocument1 pageWell Integrity Management System - Leak Rate CriteriaalizareiforoushNo ratings yet

- Insulation Resistance Monitoring Prevents ESP Failure - 1Document1 pageInsulation Resistance Monitoring Prevents ESP Failure - 1alizareiforoushNo ratings yet

- TWPCEDocument1 pageTWPCEalizareiforoushNo ratings yet

- TWPCEDocument1 pageTWPCEalizareiforoushNo ratings yet

- 14A - E12 PADocument4 pages14A - E12 PAbeyNo ratings yet

- 3 - Introduction To Nodal AnalysisDocument24 pages3 - Introduction To Nodal AnalysisLuis Marcio AvendañoNo ratings yet

- A Complete Line of Efficient Heat ExchangersDocument4 pagesA Complete Line of Efficient Heat Exchangersmember1000No ratings yet

- 5 - Choke Performance, Pages 59-67Document9 pages5 - Choke Performance, Pages 59-67ehsanNo ratings yet

- Fluid Mechanics Assignment: Continuity, Bernoulli and Energy EquationsDocument4 pagesFluid Mechanics Assignment: Continuity, Bernoulli and Energy EquationsAbhinandan RamkrishnanNo ratings yet

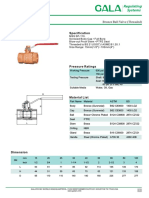

- 1gala - 1251 - Bronze Ball ValveDocument1 page1gala - 1251 - Bronze Ball ValveAbadimetal UtamaNo ratings yet

- Full Bore Ball Valve With Red Lever Handle - PB100Document2 pagesFull Bore Ball Valve With Red Lever Handle - PB100dinukaeeNo ratings yet

- TestDocument9 pagesTestArgielJohn LlagasNo ratings yet

- Chittagong University of Engineering & Technology Chittagong - 4349, BangladeshDocument8 pagesChittagong University of Engineering & Technology Chittagong - 4349, BangladeshAL-AMIN AHMED MOBIN 1801015No ratings yet

- Underbalance Drilling SeminarDocument4 pagesUnderbalance Drilling Seminarmin thantNo ratings yet

- Module 2 - Pumps: Engr. P.C. Ramos - Mechanical Engineering Department - 1Document6 pagesModule 2 - Pumps: Engr. P.C. Ramos - Mechanical Engineering Department - 1Цедіе РамосNo ratings yet

- SC Ims10.sc01.00 Ultraceco - SC - Bro - enDocument4 pagesSC Ims10.sc01.00 Ultraceco - SC - Bro - enHEINER_PNo ratings yet

- ScrubberDocument3 pagesScrubberriz2010No ratings yet

- Breathing Apparatus-List-SCBA-06072020-GR PDFDocument1 pageBreathing Apparatus-List-SCBA-06072020-GR PDFwarikhNo ratings yet

- Troubleshooting For Relief Valves Used in Hydraulic SystemsDocument3 pagesTroubleshooting For Relief Valves Used in Hydraulic SystemspradipNo ratings yet

- Fluid Power Systems - Sheet 2Document4 pagesFluid Power Systems - Sheet 2Mohamed Maher100% (1)

- FM GPSCDocument13 pagesFM GPSCVishal DhandhukiyaNo ratings yet

- HM225.Xx Flow Around Bodies EnglishDocument1 pageHM225.Xx Flow Around Bodies EnglishsaintanddevilNo ratings yet

- Hydrogen Production and DeliveryDocument2 pagesHydrogen Production and DeliveryAnkitPatel90No ratings yet