Professional Documents

Culture Documents

31 14544 2

Uploaded by

plasmapeteOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

31 14544 2

Uploaded by

plasmapeteCopyright:

Available Formats

30" FREE-STANDING ELECTRIC RANGE

IMPORTANT SAFETY NOTICE: This information is intended for use by

individuals possessing adequate backgrounds of electrical, electronic

and mechanical experience. Any attempt to repair a major appliance

may result in personal injury and property damage. The manufacturer

or seller cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

NOTE: Installation information for reference

only. See Installation Instructions shipped

with product for complete details and before

attempting to install.

Brackets should be attached to the floor or wall

to hold either right or left rear leg leveler. Make

sure leg leveler re-engages

the bracket when

range is moved for any reason.

Adjacent Cabinet

Or Final Location

Of Range Side Panel

Wall

Floor-Wood

Bracket

Side

Rear

Leveling

Leg

WARNING

All ranges can tip

Injury to persons could result

Install anti-tip bracket

packed with range

See Installation Instructions

Attachment to Wall

and Floor

650-16C

Removal Position

Wall Plate

Screw Must Enter

Wood or Metal

650-08P

Hinge Lock

(Unlocked Position)

To Remove:

1. Fully open the door.

2. Push the hinge locks down toward the door frame, to

the unlocked position. This may require a flat blade

screwdriver.

Slot

3. Firmly grasp both sides of the door at

the top.

4. Close door to the door removal position.

5. Lift door up until the hinge arm is clear

of the slot.

650-08U

Gasket

To Service Gasket

A gap must be left in the gasket at bottom of door.

The gap is required to provide air flow in the oven for proper baking results.

CONTROL PANEL REMOVAL

650-02Q

The control panel contains the ERC infinite heat switches.

To Service:

1. Remove 2 screws (from bottom) securing control panel to the backguard.

2. Remove 2 screws at the top, in the back of the range.

3. Pull bottom of panel out while lifting panel up.

4. Lay panel on cooking surface.

CAUTION: Place protective covering (such as towel) between control panel and

cooking surface to avoid damage to control panel.

The Electronic Range Control system consists

of the control,

key panel, oven

sensor, door lock

assembly.

Key Panel Test

Depress each

pad on the Key

panel followed

by the pad. If the Key panel is functioning properly the following

should occur:

Bake, Broil, Clean, Timer, Clock, Stop Time and Cook Time ModesAudible tone

plus display showing mode of operation selected.

657-06H

Clear/OffAudible tone and display shows time of day.

Increase/Decrease padsNo audible tone. Can only be used after another

function has been selected.

SPECIAL FUNCTION ON T09 CONTROL:

Hold Bake and Broil keys simultaneously for 3 seconds until display shows SF

(Special Function). Select the are to change. When change has been made press

start key to return to time of day.

Adjust oven temperature: Press Bake key, Display shows OO. Use Up/Down

keys to change the oven temperature. Oven temperature can be adjusted to a

range of +/-35 degrees in steps of 1 degree.

SAb/ON/OFF: Press Clock key when display showing SF. The display changes

for every clock key press to ON/OFF/SAb. ON stands for 12 Hr shutdown, OFF

stands for no Shut down, SAb stands for SABBATH special feature.

T09 FAULT CODES

FAILURE MEANING

CODE

F0 SHORTED

CANCEL/OFF KEY

Bottom

Edge

of Slot

F3 OPEN OVEN SENSOR

Sensor resistance

>2900 ohms

Disconnect sensor/latch connector from the control.

Measure sensor circuit resistance at sensor/lock switch

connector (should be ~1100 ohms at room temperature).

Ensure each sensor lead to chassis ground resistance is

infinitely high.

If open or short circuit is detected:

1. Look for cut or pinched sensor harness wire.

2. Look for sensor leads shorted to chassis ground.

3. Look for loss of terminal contact in the harness and at

the control.

4. Check sensor resistance directly at sensor harness

connector (away from the control). If reading is abnormalREPLACE OVEN SENSOR.

If sensor circuit appears to be normal:

1. Reinstall sensor/lock switch connector on the control

and measure sensor resistance at solder joints on

the back of the control circuit board. If abnormal

resistance reading is observedRESTORE CONTACT

PRESSURE OR SENSOR/LOCK SWITCH CONNECTOR.

If corrective actions above do not eliminate the

problemREPLACE CONTROL.

F4 SHORTED OVEN

SENSOR

Sensor resistance

<950 ohms

Indentation

650-08R

Cooling Air Flow

Air enters the door assembly through large slots in the bottom and flows

upward between the inner and outer assemblies, exhausting through slots in

the top of the door. DO NOT INSULATE THIS AIR CHANNEL.

650-08Q

To Service Full Glass Door

1. Complete door assembly:

Remove three screws from the bottom door frame

Remove two screws at the top of the door on the liner

The liner assembly and outer glass panel assembly can now be separated.

2. Outer glass panel assembly:

Remove four screws from the side posts at the bottom

Remove four screws from the side posts at the top near the door vent trim

Slide the bottom trim and top vent trim out to free the outer door glass

Note: On some doors the bottom trim is sealed to the outer door glass and

cannot be separated.

3. Liner assembly:

Remove three screws on each side of the door liner to remove the door

hinge assembly

Remove four screws from the insulation retainer

Remove insulation retainer and then the insulation

The window pack and window gasket are now accessible,

on units with a window door.

NOTE: Mode and temperature selection is necessary for operation of relay

contacts. This model incorporates Double Line Break meaning there is no voltage on the elements when the control is in standby.

Terminals on ERC Voltage, standby Voltage, Broil Voltage, Bake

(element terms (no relays

mode active

mode active

are on tops

energized)

of large relays)

L1-N

120VAC (if not, harness may be bad)

L1-L2

240VAC (if not, harness may be bad)

L1-BAKE

240VAC (mode ~0VAC when

active, bake

bake element

relay off, DLB on (if not,

~0VAC

(if

not,

relay on)*

relay/ERC

relay may be

may be bad)**

L1-BROIL bad)

~0VAC when

240VAC (mode

broil element active, broil

on (if not,

relay off, DLB

relay/ERC may relay on)*

be bad)**

**If not, check indicated element and harnessing.

**Relay is on only when calling for heat. 240VAC when not calling

for heat, else check indicated element and wiring.

Sensor & Lock Circuits

Ohmmeter Test

Disconnect power and make

measurement from side of

connector that has terminals

exposed.

1100

2600

@ RM. TEMP.

@ 865 OVEN

OVEN SENSOR

PINS 1 & 2

3

C

NC

LOCK SWITCH

4

5

DOOR LOCK CIR.

PINS 3 & 5

Power down then power up the range. If the fault

condition reappears within 15 minutesREPLACE

CONTROL.

1. If no overtemperature condition occurredcheck all

contacts and connections in sensor circuit. Eliminate

excessive resistance in sensor circuit due to increased

contact/connector resistance.

2. If overtemperature condition occurredlook for

welded relay contacts on bake, broil, or double-linebreak relays. If relay contact welding is confirmed

REPLACE CONTROL.

3. Ensure Door Latch stays locked for duration of CLEAN

cycle.

CONTROL VOLTAGEERC

650-08S

CORRECTION

F2 OVEN

OVERTEMPERATURE

CONDITION

Door unlockedoven

exceeded ~620F

Door lockedoven

exceeded ~930F

Door latch unlocked

while oven in excess

of ~620F

Hinge

Arm

Hinge Arm

To Replace:

1. Firmly grasp both sides of the door

at the top, with the door at the

same angle as the removal

Locked Position

position, seat the

indentation of the hinge arm into

the bottom edge of the hinge slot.

2. Fully open the door.

3. Push the hinge locks up against

the front frame of the oven cavity,

to the locked position.

4. Close the oven door.

Door panel

T09 CONTROL

Bracket

Floor-Concrete

REMOVABLE OVEN DOOR

Door Gasket

The door gasket is clipped into the liner of the

door panel.

F5 CONTROL

SUPERVISORY

CIRCUIT FAILURE

REPLACE CONTROL.

F7 SHORTED MATRIX

KEY

Power down then power up the range. If the fault

condition reappears within 15 minutesREPLACE

CONTROL.

F8 EEPROM ERROR

Power down then power up the range. If the fault

condition reappears within 5 minutesREPLACE

CONTROL.

DOOR LATCH MECHANISM

The latch mechanism is thermally

operated. When the latch handle is

moved to the clean position the latch

hook engages into a slot in the oven

door. As the clean cycle progresses,

the increase in oven temperature

causes a bi-metal spring on the latch

mechanism to expand. This expansion causes the thermal lock to move

into the path of the latch mechanism

thus locking it into position. The door

locks when the oven has reached a

temperature between 560 and 600

degrees F and will remain locked until

the oven has dropped below these

temperatures (560-600 degrees F).

"L-1"

BLACK

BAKE

Lock

Latch

RY2

BAKE

14.2A

DLB

3410W/16.9

BROIL

BROIL

14.2A

L1-2

16.6A

3410W/16.9

RY11

"L-1"

BLACK

"L-2"

RED

BROIL & CLEAN-UNTIL

FIRST CYCLE OFF

16.7A

L1

RY11

BROIL

DLB

BR

L2

3410W16.9

RY2

650-02DD

Bi-metal

Spring

Assembly

(Thermal

Lock)

Latch Mechanism

"L-2"

RED

BAKE & TIME BAKE/CLEAN

RY12

Lock

Switch

NOTE:

BAKE/TIME BAKE Bake

and broil units cycle during

preheat and balance of

operation, one unit is on at

a time.

CLEAN Broil unit only on

during 1st 30 minutes or

until oven reaches 750F.

During balance of clean

oven will cycle between

bake and broil units.

SCHEMATIC DIAGRAM

Pub. No. 31-14544-2

POWER MUST BE DISCONNECTED BEFORE SERVICING THE APPLIANCE

IMPORTANT

SERVICE INFORMATION

DO NOT DISCARD

WARNING

JBP23

JBP24

JBP25

JBP27

JBP28

JBP35

POWER MUST BE DISCONNECTED BEFORE SERVICING THE APPLIANCE

MODEL NUMBER

WARNING

WIRING DIAGRAM

You might also like

- Tech Sheet for Microwave Oven ServicingDocument8 pagesTech Sheet for Microwave Oven ServicingDouglas A. Joslyn Jr.No ratings yet

- Accona: Product Instruction ManualDocument16 pagesAccona: Product Instruction Manualdeanot63No ratings yet

- Syntec Instructions ManualDocument6 pagesSyntec Instructions ManualLior BenjaminNo ratings yet

- A88JY ManualDocument6 pagesA88JY ManualionmocanuNo ratings yet

- SMEG Oven ENDocument28 pagesSMEG Oven ENManju2303No ratings yet

- DezumidificatorDocument80 pagesDezumidificatormihaisuarasanNo ratings yet

- Ah-Ap5Hml Au-A5Hly Ah-Ap5Hmy Au-A5Hy Ah-Ap7Hmy Au-A7Hy Ah-Ap9Hmy Au-A9Hy Ah-Ap12Hmy Au-A12HyDocument24 pagesAh-Ap5Hml Au-A5Hly Ah-Ap5Hmy Au-A5Hy Ah-Ap7Hmy Au-A7Hy Ah-Ap9Hmy Au-A9Hy Ah-Ap12Hmy Au-A12HyAyodha PramuditaNo ratings yet

- Heat Force 1500 Infrared Heater Owners ManualDocument10 pagesHeat Force 1500 Infrared Heater Owners ManualInfraredHeatStoreNo ratings yet

- ELECTRIC OIL FILLED RADIATOR INSTRUCTIONSDocument8 pagesELECTRIC OIL FILLED RADIATOR INSTRUCTIONSAnonymous 3ca4Sq39No ratings yet

- X300 Furnace Door Adjustment Rev 3 2018 - 06 - 04Document8 pagesX300 Furnace Door Adjustment Rev 3 2018 - 06 - 04AntWonxxxNo ratings yet

- Oil Heater Instuction ManualDocument5 pagesOil Heater Instuction ManualEhsan MohammadiNo ratings yet

- White Rodgers 1F89-211 Non-Programmable Electronic Digital Heat Pump ThermostatDocument6 pagesWhite Rodgers 1F89-211 Non-Programmable Electronic Digital Heat Pump ThermostatJohnny_M412No ratings yet

- AHXP18MVDocument40 pagesAHXP18MVpkscwcNo ratings yet

- Remote InstructionsDocument4 pagesRemote InstructionsdengersincNo ratings yet

- Henkel Inc PO Box oven installation guideDocument7 pagesHenkel Inc PO Box oven installation guideEmerson GarciaNo ratings yet

- Single Pole Humidity Sensor and Fan Controller: Installation InstructionsDocument2 pagesSingle Pole Humidity Sensor and Fan Controller: Installation InstructionsEdmundBlackadderIVNo ratings yet

- Heat Pure 1500 Infrared Heater Owners ManualDocument10 pagesHeat Pure 1500 Infrared Heater Owners ManualInfraredHeatStoreNo ratings yet

- Lux TX1500E Thermostat User GuideDocument2 pagesLux TX1500E Thermostat User GuideBrendan KeithNo ratings yet

- Homebase Air Conditioner 253797 ManualDocument14 pagesHomebase Air Conditioner 253797 Manualbmmanuals75% (16)

- IzuruDocument43 pagesIzuruChris TsiarasNo ratings yet

- Wireless Remote Controller: Owner's & Installation ManualDocument20 pagesWireless Remote Controller: Owner's & Installation ManualMalay K GhoshNo ratings yet

- 1430 Vacoven ManualDocument21 pages1430 Vacoven ManualBill SmithNo ratings yet

- Lux TX9000a Thermostat (ManualDocument1 pageLux TX9000a Thermostat (ManualGreenMentorNo ratings yet

- T7350 Installation InstructionsDocument12 pagesT7350 Installation InstructionsAmy ThompsonNo ratings yet

- HVAC Klimatronic Comfort 70 Eco r290Document24 pagesHVAC Klimatronic Comfort 70 Eco r290Ruben Lopez SaizNo ratings yet

- Manual Vulcan en InglesDocument12 pagesManual Vulcan en InglesingegusNo ratings yet

- Instrument - Tpe3000 Thermal Oil HeateDocument24 pagesInstrument - Tpe3000 Thermal Oil HeatejadetorresNo ratings yet

- Yorfk ZF 180 To 300Document7 pagesYorfk ZF 180 To 300Martin BourgonNo ratings yet

- Generic AIR ShowerDocument39 pagesGeneric AIR Showerhakim fastaNo ratings yet

- User ManualDocument5 pagesUser ManualrafeeqcscsNo ratings yet

- Atlantic - Artisan - Odyssee - Rio - Operating ManualDocument8 pagesAtlantic - Artisan - Odyssee - Rio - Operating ManualRamakrishnan RamachandranNo ratings yet

- Manual Midea Ac MPN1 08CR.10CR EN Version1 PDFDocument24 pagesManual Midea Ac MPN1 08CR.10CR EN Version1 PDFwayne dinhNo ratings yet

- Troubleshooting Common Thermostat Problems: Signature/Star SeriesDocument2 pagesTroubleshooting Common Thermostat Problems: Signature/Star Seriessonare8000No ratings yet

- Sobni Termostat BežičniDocument60 pagesSobni Termostat BežičnizlatkoNo ratings yet

- Zit 64 BVDocument12 pagesZit 64 BVVT86No ratings yet

- Owner's Manual: Gemini Multi Function ThermofanDocument12 pagesOwner's Manual: Gemini Multi Function ThermofanSteven GovenderNo ratings yet

- Split UnitDocument20 pagesSplit Unitsakthi100% (1)

- LG Oven Training Manual Spring 2009Document82 pagesLG Oven Training Manual Spring 2009equus43No ratings yet

- Termostat KotelDocument112 pagesTermostat KotelexaNo ratings yet

- Berg Freezer Chiller ManualDocument12 pagesBerg Freezer Chiller ManualboNo ratings yet

- LRA067AT7 Air Cond Manual 2020211a2133enDocument12 pagesLRA067AT7 Air Cond Manual 2020211a2133enguidonero100% (1)

- Service Manual: Labplant Sd-05 Spray DryerDocument14 pagesService Manual: Labplant Sd-05 Spray Dryerfacu_falaNo ratings yet

- Thermostat Carrier Install ManualDocument12 pagesThermostat Carrier Install ManualSimNo ratings yet

- Aire LG w122cmDocument36 pagesAire LG w122cmGuerra GermanNo ratings yet

- Inventor Manual IDIDocument47 pagesInventor Manual IDIDani100% (1)

- IncuKit XL Advanced InstructionsDocument5 pagesIncuKit XL Advanced Instructionssandro CardosoNo ratings yet

- User Guide AC SharpDocument28 pagesUser Guide AC Sharpcashh_man0% (1)

- Montaje y Conexionado Tipico de Controlador T7350 PDFDocument12 pagesMontaje y Conexionado Tipico de Controlador T7350 PDFMoises Antonio Vasquez VasquezNo ratings yet

- ELECTRIC HEATING CONVECTOR INSTRUCTIONSDocument7 pagesELECTRIC HEATING CONVECTOR INSTRUCTIONSmgcproNo ratings yet

- Integrated Heat Pump Water HeaterDocument13 pagesIntegrated Heat Pump Water HeaterErich AutomatonNo ratings yet

- Melting Point ApparatusDocument24 pagesMelting Point Apparatusrohmen042No ratings yet

- TK-SC6 Installation and Operation ManualDocument17 pagesTK-SC6 Installation and Operation ManualTalpes AureliaNo ratings yet

- User'S: ManualDocument14 pagesUser'S: ManualguerrezNo ratings yet

- BXC-86HL398 ManualDocument19 pagesBXC-86HL398 ManualMAC SUCESORESNo ratings yet

- Instructions Electric Oil Filled RadiatorDocument4 pagesInstructions Electric Oil Filled RadiatorNormos GinisNo ratings yet

- Ahu ManualDocument15 pagesAhu ManualAlan LaundrdayNo ratings yet

- 1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part9Document197 pages1995 - 1998 Acura 2.5TL 3.2TL Service Manual - Part9CandieApple100% (4)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- Delco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationFrom EverandDelco Manuals: Radio Model 633, Delcotron Generator Delco Radio Owner's Manual Model 633, Delcotron Generator InstallationNo ratings yet

- Automatic Washer: Study Course (Direct Drive Models)Document16 pagesAutomatic Washer: Study Course (Direct Drive Models)plasmapeteNo ratings yet

- GE Pgss5pjxss ManualDocument74 pagesGE Pgss5pjxss ManualplasmapeteNo ratings yet

- 2016 Electrolux LuxCare DryerDocument57 pages2016 Electrolux LuxCare DryerplasmapeteNo ratings yet

- Cooktop Downdraft Install ManualDocument24 pagesCooktop Downdraft Install ManualplasmapeteNo ratings yet

- LG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFDocument95 pagesLG LFX31945 Refrigerator Service Manual MFL62188076 - Signature2 Brand DID PDFplasmapete71% (7)

- 1042 EI24ID81SS0A Solaro Dishwasher SM V3.0Document73 pages1042 EI24ID81SS0A Solaro Dishwasher SM V3.0plasmapeteNo ratings yet

- Automatic Washer: Study CourseDocument32 pagesAutomatic Washer: Study CourseplasmapeteNo ratings yet

- Automatic Washer: Study Course (Belt Drive Models)Document24 pagesAutomatic Washer: Study Course (Belt Drive Models)plasmapeteNo ratings yet

- #2 PDFDocument20 pages#2 PDFplasmapeteNo ratings yet

- 1043 Refrigerator EW28BS87SS0 04252017 V2.0Document96 pages1043 Refrigerator EW28BS87SS0 04252017 V2.0plasmapeteNo ratings yet

- MSA VMW PP PresentationDocument65 pagesMSA VMW PP PresentationplasmapeteNo ratings yet

- Ge Laundry Diagnostic ModesDocument128 pagesGe Laundry Diagnostic ModesplasmapeteNo ratings yet

- Ei27mo45gsa Ei30mo45gsa PDFDocument52 pagesEi27mo45gsa Ei30mo45gsa PDFplasmapeteNo ratings yet

- MSA VMW PP PresentationDocument65 pagesMSA VMW PP PresentationplasmapeteNo ratings yet

- Electrolux Technical Service Manual Dishwasher 2015Document30 pagesElectrolux Technical Service Manual Dishwasher 2015dosandosan100% (1)

- WD 8888 22 Service Manual CL11SDWDocument12 pagesWD 8888 22 Service Manual CL11SDWplasmapeteNo ratings yet

- GEMonogramSXSTechManual31 9091 Defrost HeaterDocument1 pageGEMonogramSXSTechManual31 9091 Defrost HeaterplasmapeteNo ratings yet

- GE Fridge DiagnosticsDocument6 pagesGE Fridge DiagnosticsplasmapeteNo ratings yet

- Amana Refrigerator S130 - 3R0Document95 pagesAmana Refrigerator S130 - 3R0plasmapeteNo ratings yet

- WR55X10552 Motherboard Replacement PDFDocument2 pagesWR55X10552 Motherboard Replacement PDFplasmapeteNo ratings yet

- Haier Rwt350aw-Ex (081227)Document3 pagesHaier Rwt350aw-Ex (081227)plasmapeteNo ratings yet

- GE 2012 Washer TrainingDocument106 pagesGE 2012 Washer TrainingplasmapeteNo ratings yet

- 31 9136 1Document50 pages31 9136 1plasmapeteNo ratings yet

- GE JVM1540 OTR MicrowaveDocument56 pagesGE JVM1540 OTR MicrowaveplasmapeteNo ratings yet

- FAV9800AWW Tech Sheets 16023174Document14 pagesFAV9800AWW Tech Sheets 16023174plasmapeteNo ratings yet

- FAV9800AWW Service Manual 16022808Document98 pagesFAV9800AWW Service Manual 16022808plasmapeteNo ratings yet

- v22 v24 v23 - DtoDocument70 pagesv22 v24 v23 - DtoplasmapeteNo ratings yet

- Mitsubishi - Service Manual - Chassis V21Document83 pagesMitsubishi - Service Manual - Chassis V21api-3725622100% (4)

- 809 DW1002 Getting An E01 Error Code On The ControlDocument2 pages809 DW1002 Getting An E01 Error Code On The ControlplasmapeteNo ratings yet

- Excavator Instructors NotesDocument61 pagesExcavator Instructors NotesEd Calhe80% (5)

- 6 77740 Linked PDFDocument178 pages6 77740 Linked PDFroparts clujNo ratings yet

- Permit To Work ProcedureDocument25 pagesPermit To Work ProcedureGordon Watson100% (1)

- Atlas Traction Gearless MRL LiftDocument4 pagesAtlas Traction Gearless MRL LiftKleemmann Hellas SA50% (2)

- How Elevators Move People and Goods VerticallyDocument27 pagesHow Elevators Move People and Goods VerticallyshelmiNo ratings yet

- Rotary Dryer Start UpDocument2 pagesRotary Dryer Start UpherwinNo ratings yet

- Atlas 2:1-Rph: Planning DataDocument12 pagesAtlas 2:1-Rph: Planning DataAdarsh ManoharanNo ratings yet

- 01-Mst For Shifting of Equipment Rev-00Document8 pages01-Mst For Shifting of Equipment Rev-00AbdurRahmanFNo ratings yet

- LF 20 Logistics: Fire Fighting Vehicle LogisticsDocument2 pagesLF 20 Logistics: Fire Fighting Vehicle LogisticsLaurensNLNo ratings yet

- TACB4- TRẮC NGHIỆMDocument24 pagesTACB4- TRẮC NGHIỆMLan Anh TrầnNo ratings yet

- ASTM MNL 2 Manual On Vapor Degreasing 3rd EditionDocument50 pagesASTM MNL 2 Manual On Vapor Degreasing 3rd Edition320338100% (2)

- G12 PHOTOCELLULE-BANDE PHOTO - ëLECTRIQUEDocument3 pagesG12 PHOTOCELLULE-BANDE PHOTO - ëLECTRIQUEtoufikNo ratings yet

- Hotel PicadallyDocument52 pagesHotel Picadallysaikripa121No ratings yet

- RITDOC73Document17 pagesRITDOC73Chandrasekaran NNo ratings yet

- THE NEED FOR ASPIRATING SMOKE DETECTORS IN ELEVATOR SHAFTSDocument11 pagesTHE NEED FOR ASPIRATING SMOKE DETECTORS IN ELEVATOR SHAFTSSamuelJrManatadNo ratings yet

- Load Weighing Devices: Tech Tip 7Document2 pagesLoad Weighing Devices: Tech Tip 7mohammad ghassanNo ratings yet

- gw4 Unit2Document26 pagesgw4 Unit2Cohan Yong100% (1)

- Revelina Vs Wack WackDocument13 pagesRevelina Vs Wack WackLouie Sallador100% (1)

- 2021 INTERNATIONAL BUILDING CODE - Chapter For Elevators and EscalatorsDocument13 pages2021 INTERNATIONAL BUILDING CODE - Chapter For Elevators and EscalatorsAlexander RemachaNo ratings yet

- Project ReportDocument19 pagesProject ReportEr Nandkishor Prajapati86% (7)

- Bobcat S250 Service Repair Manual SN 520711001 and Above PDFDocument621 pagesBobcat S250 Service Repair Manual SN 520711001 and Above PDFFranklin Lewis100% (10)

- Isuzu Engine 4j - SeriesDocument7 pagesIsuzu Engine 4j - SeriesAvaa AmgaaNo ratings yet

- Honda Jazz Fit 2007 To 2014 Workshop Manual PDFDocument4,178 pagesHonda Jazz Fit 2007 To 2014 Workshop Manual PDFmyrmidon164% (11)

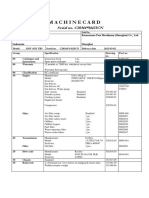

- Machinecard details for SMV 4531 TB5Document3 pagesMachinecard details for SMV 4531 TB5Abas AbasariNo ratings yet

- ICRA Form v08.07Document5 pagesICRA Form v08.07Indra Juang Putra HarefaNo ratings yet

- Elcosmo PDFDocument19 pagesElcosmo PDFLewKarKeongNo ratings yet

- Hydraulic Escalator Project Report FinalDocument31 pagesHydraulic Escalator Project Report FinalMohammed Ali100% (1)

- Gujarat Fire Prevention and Life Safety Measures Regulations, 2023Document73 pagesGujarat Fire Prevention and Life Safety Measures Regulations, 2023BHATTU24No ratings yet

- 2210 Industrial Crane Safety PresentationDocument3 pages2210 Industrial Crane Safety PresentationbangladragosNo ratings yet

- Lifts Part 1Document17 pagesLifts Part 1Divya Vani ReddyNo ratings yet