Professional Documents

Culture Documents

SIL Review Guideline

Uploaded by

Anonymous U0LPhn6EjAOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIL Review Guideline

Uploaded by

Anonymous U0LPhn6EjACopyright:

Available Formats

STANDARDS PUBLICATION

QP GUIDELINE FOR

SAFETY INTEGRITY LEVEL REVIEW

DOC NO: QP-GDL-S-030

REVISION 1

CORPORATE HSE SUPPORT DEPARTMENT

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

TABLE OF CONTENT

Page No

FOREWORD

1.0

INTRODUCTION..

2.0

SCOPE .

3.0

APPLICATION .

4.0

POLICY ..

5.0

5.1

5.2

TERMINOLOGY

DEFINITIONS ..

ABBREVIATIONS

5

5

7

6.0

REFERENCE STANDARDS........................

7.0

METHODOLOGY/APPROACH ...................................

8.0

8.1

8.2

TEAM STRUCTURE AND RESPONSIBILITIES...........................................

TEAM STRUCTURE.........................................................................................

ROLES AND RESPONSIBILITIES...................................................................

9

9

10

9.0

9.1

9.2

9.3

9.4

9.5

9.6

9.7

REQUIREMENTS.............................................................................................

PREPARATION OF THE REVIEW...................................................................

SIL REVIEW.....................................................................................................

VALIDATION OF SIF........................................................................................

CAUSE DEMAND SCENARIO.........................................................................

CONSEQUENCES OF FAILURE ON DEMAND (CoFD)................................

INDEPENDENT SAFEGUARDS......................................................................

SIL ASSESSMENT CALIBRATED RISK GRAPH METHOD........................

11

11

12

13

13

14

14

14

10.0

10.1

10.2

PLANNING.......................................................................................................

PREPARATION OF THE REVIEW...................................................................

TIMING OF THE REVIEW................................................................................

20

20

20

11.0

11.1

11.2

11.3

DOCUMENTS REQUIRED AND RECORDING.............................................

DOCUMENTS REQUIRED...............................................................................

RECORDING....................................................................................................

REPORTING AND FOLLOW-UP.....................................................................

20

20

20

21

12.0

12.1

APPENDICES.................................................................................................

APPENDIX I: TYPICAL SIL REVIEW WORKSHEET USING RISK GRAPH

METHOD..........................................................................................................

APPENDIX II: TYPICAL SIL ACTION SHEET..................................................

APPENDIX III: TYPICAL SIL REVIEW REPORT TABLE OF CONTENT.......

APPENDIX IV: SIL REVIEW PREPARATION ITEMS CHECKLIST.................

22

12.2

12.3

12.4

Doc File No.: GDL-S-030 R1

Page 2 of 31

22

23

24

25

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

12.5

12.6

12.7

Rev1

APPENDIX V: DESCRIPTION OF PROCESS INDUSTRY RISK GRAPH

PARAMETERS.................................................................................................

APPENDIX VI - DEMAND RATE......................................................................

APPENDIX VII CORPORATE RISK MATRIX...............................................

26

27

28

REVISION HISTORY LOG .

31

Doc File No.: GDL-S-030 R1

Page 3 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

FOREWORD

This document has been developed by Corporate HSE Support Department, reviewed and

edited by Corporate Quality and Management System Department and circulated for review by

user departments before being endorsed by QP Management to provide guideline.

This document is published for QP Departments/ Contractors/ Consultants utilization. It shall

be emphasized that the document to be used for QP operations wherever applicable and

appropriate.

This document is subjected to periodical review to re-affirm its adequacy or to conform to any

changes in the corporate requirements or to include new developments on the subject.

It is recognized that there will be cases where addenda or other clarifications need to be

attached to the standard to suit a specific application or service environment. As such, the

content of the document shall not be changed or re-edited by any user, but any addenda or

clarifications entailing major changes shall be brought to the attention of the Custodian

Department.

The custodian of this document is Corporate HSE Support Department (ST). Therefore, all

comments, views, recommendations, etc. on it shall be forwarded to the same and copied to

Manager, Corporate Quality & Management Systems Department (QA).

Doc File No.: GDL-S-030 R1

Page 4 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

1.0

Rev1

INTRODUCTION

Safety Integrity Level (SIL) review is an analysis which aims at the determination of the

appropriate reliability required from the elements of the Safety Instrumented Functions

(SIF) identified in prior safety reviews (e.g. HAZOP).

The approach of this guideline is to remove the uncertainty regarding the safety

integrity, cost effectiveness and availability requirements, reducing over and under

engineering, in a traceable manner.

SIL study is a method to record all the SIF for a project development and document the

expected reliability level. SIL study provides a basis for future maintenance and

operating strategies. SIL shall be conducted during FEED phase and /or EPIC phase in

accordance with Project HSE Plan or as required by the outcome of Safety Reviews of

a project.

SIL assignment is based on the amount of risk reduction that is necessary to mitigate

the risk associated with the process to a tolerable level. All of the Safety Instrumented

Systems (SIS) design, operation and maintenance choices must then be verified

against the SIL assigned.

2.0

SCOPE

This guideline details the structure, responsibilities and techniques of the Safety

Integrity Level (SIL) review.

3.0

APPLICATION

The SIL review of the project shall cover all Safety Instrumented Systems (SIS) in

process and utility units where there is potential for hazard to human safety,

environment or asset /production loss.

4.0

POLICY

QP is committed to protect the health and safety of its employees and others that may

be affected by its activities and to give proper regard to the conservation of the

environment. QP policy is to conduct its activities such that it strives towards an incident

free, secure, safe and healthy workplace.

Safety studies and reviews shall be performed during the course of a project or

modifications to an existing facility. This is to identify, qualify, quantify and to establish

that design safety measures shall provide adequate protection and mitigate any risk

involved with the proposed project development or the modifications.

5.0

TERMINOLOGY

5.1

DEFINITIONS

Basic Process

Control

System (BPCS)

Doc File No.: GDL-S-030 R1

A combination of Sensors, Logic Solvers and Final

elements which automatically regulate the process

within normal production limits. The BPCS provides

control of a process in the desired manner.

Page 5 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Cause

Factor contributing alone or in combination with others

to the release of a hazard (in this guideline synonymous

to the demand scenario triggering a SIF).

Company

Means QATAR PETROLEUM or QP

Consequence (C)

Number of fatalities and/or serious injuries likely to

result from the occurrence of the hazardous event.

Effect

on

personnel

safety,

economic

loss,

environmental loss.

Consequences of

Failure on Demand

Escalation events that happen after the failure of the SIF

during its solicitation. Effect on personnel safety,

economic loss, environmental effect.

Demand Rate (W)

The number of times per year that the hazardous event

would occur in the absence of the safety instrumented

function under consideration.

Demand Scenario

The set of conditions

(synonymous Cause).

Design Intent

The reason why a SIF is set. Its purpose.

Final Element

A device which manipulates a process variable to

achieve control. e.g. Control Valve, Emergency Block

Valve, motor starter.

Layers of Protection

Analysis

A process of evaluating the effectiveness of

Independent Protection Layers in reducing the

likelihood or severity of an undesirable event to meet

organizational needs.

Logic Solver

The element of the BPCS or SIS that implements one or

more logic functions.

Hazard

A source of potential harm or damage, or a situation

with potential for harm or damage.

Licensor

triggering

SIF

action

LICENSOR or PROCESS LICENSOR means each of

the Companies which have granted (or will grant) to QP

a Process License and have provided (or will provide)

the corresponding Licensor Basic Engineering Package

(BEP) during the FEED project.

Occupancy (F)

Probability that the exposed area is occupied at the time

of the hazardous event .Determined by calculating the

fraction of time the area is occupied at the time of the

hazardous event.

Probability of

Avoiding the Hazard

(P)

The probability that exposed persons is able to avoid

the hazardous situation which exists if the SIF fails on

demand.

Probability of

Failure on Demand

The probability that a system fail to perform a specified

function on demand.

Doc File No.: GDL-S-030 R1

Page 6 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Recovery Measures

All technical, operational and organizational measures

that limit the chain of consequences arising from a top

event and assist return to normal operation.

Safety Integrity

Level

Defined as a relative level of risk-reduction provided by

a safety function, or to specify a target level of risk

reduction. In simple terms, SIL is a measurement of

performance required for a Safety Instrumented

Function (SIF).Four level of SILs are defined, SIL 4 has

the highest level of safety integrity and SIL 1 has the

lowest.

Safety Instrumented

Function

It is a safety function with a specified safety integrity

level which is necessary to achieve functional safety. A

safety instrumented function can be either a safety

instrumented protection function or a safety

instrumented control function.

Safety Instrumented

System

Instrumented system used to implement one or more

safety instrumented functions. A Safety Instrumented

System is composed of any combination of sensor (s),

logic solver (s), and final elements(s).

It performs specified safety instrumented functions to

achieve or maintain a safe state of the process when

unacceptable or dangerous process conditions are

detected. Safety instrumented systems are separate

and independent from regular control systems but are

composed of similar elements, including sensors, logic

solvers, and final elements.

5.2

ABBREVIATIONS

CoFD

Consequence of Failure on Demand

F&G

HAZOP

Hazard and Operability Study

LOPA

Layer of Protection Analysis

LP

Loss Prevention

P&ID

Piping & Instrumentation Diagram

PFD

Process Flow Diagram

PSD

Process Shut Down

QP

Qatar Petroleum.

SIL

Safety Integrity Level

EPIC

ESD

FEED

Doc File No.: GDL-S-030 R1

Engineering, Procurement, Installation and Commissioning

Emergency Shut Down

Front End Engineering Design

Fire & Gas System

Page 7 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

6.0

Rev1

SIF

Safety Instrumented Function

SIS

Safety Instrumented System

REFERENCE STANDARDS

IEC-61508

Functional Safety of Electrical/Electronic/Programmable Electronic

Safety-Related Systems Part 1: General requirements;

Part 2: Requirements for electrical/electronic/programmable electronic

safety-related systems;

Part 3: Software requirements;

Part 4: Definitions and abbreviations;

Part 5: Examples of methods for the determination of safety integrity

levels (supporting Information);

Part 6: Guidelines for the application of IEC 61508-2 and IEC 61508-3;

Part 7: Overview of techniques and measures.

IEC-61511 Functional safety Safety instrumented systems for the process industry

sector

Part 1: Framework, definitions, system, hardware and software

requirements;

Part 2: Guidelines for the application of IEC 61511-1;

Part 3: Guidelines for the determination of the required safety integrity

levels.

7.0

METHODOLOGY/ APPROACH

The technical standard IEC 61511 sets out a good practice for engineering of safety

instrumented systems that ensure the safety of process industries. This standard

defines the functional safety requirements established by IEC 61508 in process industry

sector terminology.

It also focuses attention on one type of instrumented safety system used within the

process sector, the safety instrumented system (SIS).

IEC 61511 covers the design and management requirements for SISs. Its scope

includes initial concept, design, implementation, operation, and maintenance through

decommissioning. The standard starts in the earliest phase of a project and continues

through start up. It contains sections that cover modifications that come along later,

along with maintenance activities and the eventual decommissioning activities.

The standard consists of three parts as detailed under Clause 6.0.

The SIL review session is a guided team brainstorming activity that benefits from a

structured method and from the broad experience of a multidisciplinary team led by a

SIL facilitator.

The methodology that will be employed for the SIL determination is a technique uses a

semi qualitative method: calibrated risk graph, as defined in IEC 61511-3 Annex D.

Doc File No.: GDL-S-030 R1

Page 8 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Essentially the SIL derived rating is a measure of risk reduction that is required to be

achieved by the safety instrumented system in order that the residual risk is acceptable

or is as low as reasonably acceptable (ALARP)

There are four levels of Safety Integrity for Safety Instrumented Functions, SIL1 to SIL

4. SIL 4 has the highest level of safety integrity and SIL 1 has the lowest. For SIF which

are assigned SIL 1 or SIL 2 no further studies or action shall be required. However, for

SIF which are assigned SIL 3 or 4, the SIL classification shall be considered in detail

using a Quantitative method: Layer of Protection Analysis (LOPA) as defined in IEC

61511-3 Annex F.

SIL classification study shall be carried out for all the elements of SIS; i.e. PSD, ESD

and F&G as identified in the Cause & Effect matrix.

The outcome of the SIL assessment is followed by a SIL verification study, where the

reliability of the SIS is verified.

Dedicated computer spreadsheet or dedicated SIL software shall be used for recording

SIL proceedings. The software tool used for determining SIL shall be in accordance

with IEC 61508/61511 and shall have a provision to calibrate the Risk Graph based on

QP SIL review guideline.

Note: Contractor shall develop project specific SIL procedure and terms of reference

consistent with QP SIL guideline and shall submit to QP for prior approval.

8.0

TEAM STRUCTURE AND RESPONSIBILITIES

8.1

TEAM STRUCTURE

In performing a SIL review, the proper selection of team participants is very important.

The review team shall consist of personnel who are knowledgeable in the process

technology and experienced in the operations of the process. The team shall have the

necessary SIL review experience and obtained formal SIL training techniques. The

chairman will be independent of the CONTRACTOR. QP will review and approve the

Chairmans resume prior to the SIL review.

The planned multidisciplinary core team necessary for the realisation of the SIL review

shall include the following disciplines and maximum number to be limited to 10 persons

excluding chairman and scribe.

a) Qatar Petroleum

Loss Prevention Engineer Corporate HSE support

Process Engineer

Instrumentation Engineer

Operation Engineer

Loss Prevention Engineer

Maintenance Engineer

b) Independent Third Party

Chairman

Doc File No.: GDL-S-030 R1

Page 9 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

c) Project Independent

Contractors LP Engineer

Scribe

d) Contractor

Process Engineer

Instrumentation Engineer

Loss Prevention Engineer

e) LICENSOR (for LICENSOR units)

Process Engineer (knowledgeable of processes involved in project)

Instrumentation Engineer

Additional specialists of other disciplines may be called to participate upon request

according to the needs identified by the other permanent members of the team.

8.2

ROLES AND RESPONSIBILITIES

The quality of the review highly results from the contribution of all team members and

from their global expertise.

In order to achieve a quality result, members of the team shall adhere to:

adopt a positive attitude toward other team members contribution,

provide their expertise on the project specifics and from similar experience

elsewhere,

be logical, open minded and creative,

focus on the objective of the SIL study.

8.2.1 Chairman

The Chairman shall require a high level of technical and managerial skills. He shall

require expertise and experience in conducting SIL reviews and SIL verification studies.

He needs to remain independent of the discussion and shall not associate with the

project. The Chairmans resume shall be reviewed and approved by QP prior to a SIL

session.

The role of the Chairman is critical to the success of the meeting.

He shall:

Prepare, and make a presentation prior to the review on SIL techniques, rules

and assumptions to be used by the team during the review,

Lead the team through the SIL Determination technique,

Prompt the brainstorming effort, and manage the discussion,

Identify the key issues as they are raised by the team,

Facilitate the evaluation of demand rates and consequences and ensure

consistency of rating,

Manage the recording of the findings by the scribe,

Ensure that the minutes fully reflect the points identified,

Generate the report of the review.

Doc File No.: GDL-S-030 R1

Page 10 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

8.2.2 Scribe

The role of scribe shall be skilled to record accurately outcome of the discussions.

Without being highly experienced the scribe needs to be familiar with engineering

terminology.

He / She shall:

Be familiar with the computer software used to record the review findings

before the start of the review,

Follow the Chairmans instruction in recording the team findings.

8.2.3 Instrumentation/ LP Engineer ( Contractor)

Prior to the review, the instrumentation engineer/specialist is in charge to complete the

following elements for each SIF, based on the Cause & Effect Matrix /P&ID/

HAZOP/Safe Charts.

For each SIF to be reviewed, SIL review work sheet to be provided with:

Listing the initiators,

Listing the final elements,

Defining the success criteria for initiators and final elements, and

Indicating the associated actions.

An example of SIL Review Worksheet is provided in Appendix I.

8.2.4 Process Engineer( Contractor)

Prior to the review, the process engineer is in charge of the description of the Design

intent of the SIF and to provide this information to Instrumentation Engineer for

implementation in the SIL review worksheet.

An example of how this is documented is provided in Appendix I (1 st column on left of

the table).

9.0

REQUIREMENTS

9.1

PREPARATION OF THE REVIEW

Prior to the review, the chairman shall collect the SIF description (SIF name,

initiator(s), final elements, success criteria, associated actions and design

Intent from the instrumentation specialist/ LP engineer

The chairman shall make a presentation to the team about the purpose and

scope of the SIL review and to focus the efforts of the team members.

The chairman shall make a presentation to the team about the methodology to

be used in the SIL review. This establishes a common starting basis for the

team that is necessary to conduct an effective SIL review.

The parameters of the Project Risk Matrix shall be presented to the team for

subsequent use in the evaluation of SIL assessment (Ref Appendix VII).

The process engineer shall present an overall explanation of the plants

process so that all team members have a clear understanding of the basic

operations of the plant. This also acquaints the team members with typical

scenarios that may lead to a hazardous condition.

Doc File No.: GDL-S-030 R1

Page 11 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

9.2

Rev1

Dedicated SIL software or spreadsheets shall be introduced to the team to log

the SIL review session (Contractor shall specify the software /spreadsheet

proposed while submitting SIL methodology document for QP approval prior to

a SIL review session).

SIL REVIEW

The SIL review sequence process shall be divided into steps as follows:

Select the Safety Instrumented Function,

Validation of the SIF description (already documented in the SIL review

worksheet by instrumentation/ LP engineer),

Validation of the design intent (already documented in the SIL review

worksheet by process engineer,

Determine (by brainstorming) all the potential causes/ demand scenario which

trigger the SIF action,

Agree the credibility of each cause,

Identify potential hazard in terms of:

i. Consequences of SIS failure on Demand (C )

- Personnel Safety (S)

- Environmental Effect (E)

- Economic loss (A)

ii. Occupancy (F)

iii.

Probability of avoiding the hazardous situation (P)

iv.

Demand Rate (W)

Assess the preventive, protective and mitigation safety features,

Assign SIL based on C,F,P&W parameters,

Agree a recommendation for action or further consideration of the problem (if

applicable),

Apply the next cause (relevant to the selected SIF),

Move onto the next SIF of the system until the whole study has been examined.

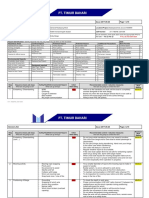

Figure 1 given below is a pictorial description of the review procedure.

Doc File No.: GDL-S-030 R1

Page 12 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

ASSESS

CLASSIFICATION

Figure 1: SIL Review Process Schematic

9.3

VALIDATION OF SIF

Instrumentation or LP engineer shall present each SIF to the review team to have the

same understanding of its purpose (design intend) among the team members.

9.4

CAUSE DEMAND SCENARIO

The team shall brainstorm to identify possible causes for the conditions that trigger the

SIF. The demand could be caused by any of a number of reasons, e.g., control

instrument malfunction, operator error, loss of feed, etc. Each cause shall be clearly

documented in the SIL review worksheet.

The team shall focus on all possible causes of the hazard against which the SIF is

designed (design intend) and ensure all of them are indeed source of demand on the

SIF.

Doc File No.: GDL-S-030 R1

Page 13 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

9.5

Rev1

CONSEQUENCES OF FAILURE ON DEMAND (CoFD)

The team shall identify all the consequences of the identified demand scenario(s). The

location of the plant and of the relative positions of installations can have a significant

influence in the consequences.

The correct appreciation of these consequences is critical to the appropriate

classification of the SIF.

9.6

INDEPENDENT SAFEGUARDS

Where applicable, the team may list of Independent safeguards (independent from SIF)

which can reduce the event probability.

9.7

SIL ASSESSMENT CALIBRATED RISK GRAPH METHOD

After the evaluation of the Consequences of Failure on Demand, each SIF is assigned

with a Safety Integrity Level (SIL).

The SIL determination shall be based on calibrated risk graphs from IEC 61511-3. This

Risk Graphs are based on the following:

The consequences of the hazardous situation for Personnel Safety,

Environment and Economic/ Asset loss (parameters S, E and A respectively),

The Occupancy (parameter F),

The probability of avoiding the hazardous situation (parameter P),

The Demand Rate (W).

9.7.1 Consequence (Parameters S, E and A)

The consequences of the hazardous situation for personnel safety, environment and

economic/ asset loss (parameters S, E and A respectively) are further defined for

various risk levels. These definitions are consistent with QP Risk Assessment Matrix.

Table 1 - Consequence Risk Parameter for Personnel Safety(S)

Consequence Risk

Parameter

Definition

S1(CA)

Minor injury or health effects

S2 (CB)

Major injury or health effects

S3 (CC)

Single fatality or Permanent total disability

S4(CD)

Multiple fatalities

Notes:

The classification system has been developed to deal with injury and

death to people.

For the interpretation of S1, S2, S3 and S4 parameters, the

consequences of the accident and normal healing shall be taken into

account.

Doc File No.: GDL-S-030 R1

Page 14 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Table 2 - Environmental Consequence Parameter (E)

Level of

Environmental

Consequences

E1(CA)

E2(CB)

E3(CC)

E4(CD)

Definition

Minor effect: Contamination; damage sufficiently large to

impact the environment; single exceeding of statutory or

prescribed limits; single complaint; no permanent effect on

the environment.

Localized effect: Limited loss of discharges of unknown

toxicity; repeated exceeding of statutory or prescribed limits

and beyond fence/ neighborhood.

Major effect: Severe environmental damage; the company is

required to take extensive measures to restore the

contaminated environment to its original state. Extended

exceeding of statutory or prescribed limits.

Massive effect: Persistent severe environmental damage or

severe nuisance extending over a large area. In terms of

commercial or recreational use or nature conservancy, a

major economic loss for the company. Constant high

exceeding of statutory or prescribed limits.

Table 3- Economic/Asset Consequence Parameter (A)

Level of Economic

Consequences

Definition

A1(CA)

Minor damage: Brief disruption to operation with

estimated costs less than QR 350,000.

A2(CB)

Local Damage: Partial shutdown of operation; can be

restarted but with estimated costs up to QR 3,500,000.

A3(CC)

Major Damage: Partial loss of operation; 2 weeks

shutdown with estimated costs up to QR 35,000,000.

A4(CD)

Extensive Damage: Substantial or total loss of operation;

with estimated costs in excess of QR 35,000,000.

Doc File No.: GDL-S-030 R1

Page 15 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

9.7.2 Exposure time (Parameter F)

The exposure time of an individual in a hazardous situation are further defined for two

occupancy conditions.

Table 4- Occupancy Exposure Time Parameter (F)

Exposure time in the

hazardous zone

Definition

Rare to more often exposure in the hazardous zone (normally

unmanned operation of the relevant part of the plant).

Occupancy less than 10%.

F1

Frequent to permanent exposure in the hazardous zone

(relevant part of plant is attended locally on a regular basis,

e.g. every shift, or during the specific time of demand, e.g.

start-up or shut-down, or relevant part of the plant is located

near a continuously occupied road)

F2

9.7.3 Probability of avoiding the Hazard (Parameter P)

This parameter represents the probability of avoiding the hazardous event if the

protection system fails. Two scenarios are defined for SIL review.

Table 5- Probability of avoiding the Hazard Parameter (P)

Probability of

avoiding the

hazardous event

Definition

P1

Possible under certain conditions some warning available.

(Operator is capable of getting away from the hazard or

hazard is mitigated by other measures).

P2

Almost impossible No warning available. (Operator may not

be aware of hazard or may not be able to get away sufficiently

quick).

Notes: This parameter takes into account:

Operation of a process (supervised i.e. operated by skilled or unskilled

persons or unsupervised).

Rate of development of the hazardous event (suddenly, quickly and

slowly).

Ease of recognition of danger (seen immediately, detected by technical

measures or detected without technical measures).

Doc File No.: GDL-S-030 R1

Page 16 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Avoidance of hazardous event (escape possible, not possible or

possible under certain conditions; independent facilities are provided to

shutdown).

Facilities are provided to alert the operator that the SIS has failed.

The time between the operator being alerted and a hazardous event

occurring exceeds 15 minutes or is definitely sufficient for the necessary

actions.

Actual safety experience (such experience may exist with an identical

unit or a similar unit or may not exist).

9.7.4 Demand Rate (W)

The purpose of the demand rate (W factor) is to estimate the frequency of the

unwanted occurrence in the absence of the SIF under consideration. This can be

determined by considering all failures which can lead to the hazardous event and

estimating the overall rate of occurrence. Other protection layers should be included in

the consideration. Three conditions are defined for SIL review.

Table 6- Demand Rate Parameter (W)

Likelihood of the

unwanted occurrence

W1

W2

W3

Definition

A very slight probability that the unwanted occurrences will happen

and only a few unwanted occurrences are likely: Once in every 30

to 100 years.

A slight probability that the unwanted occurrences will happen and

few unwanted occurrences are likely: Once in every three to 30

years.

A relatively high probability that the unwanted occurrences will

happen and frequent unwanted occurrences are likely: more than

once in every one to three years.

9.7.5 Risk Graph Personnel Safety, (Ref. IEC 61511-3 fig D.1)

Risk graph as referred in Figure 2 shall be used to determine SIL for personnel safety.

The consequences of the hazardous situation for personnel safety are determined as SIL

levels using risk graph.

Doc File No.: GDL-S-030 R1

Page 17 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Fig 2- Risk Graph: Personnel Safety

9.7.6 Risk Graph Environmental Loss, (Ref. IEC 61511-3 fig D.2)

Risk graph as referred in Figure 3 shall be used to determine SIL for environmental loss.

The consequences of the hazardous situation for environmental loss are determined as

SIL levels using risk graph.

Fig 3- Risk Graph: Environmental Loss

Doc File No.: GDL-S-030 R1

Page 18 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

9.7.7 Risk Graph Economical Loss

The risk graph approach may also be used to determine the integrity level requirements

where the consequences of failure include asset loss. Asset loss is the total economic

loss associated with failure to function on demand.

A similar risk graph to that used for environmental protection can be used for asset

loss. It should be noted that the F parameter should not be used the concept of

occupancy does not apply. Other parameter P and W apply and definitions can be

identical to those applied above to safety consequences.

Fig 4- Risk graph: Economic loss

For each SIF operating in demand mode, the required SIL shall be specified in

accordance with either Figs 2, 3 or 4. SIL assigned against various probability of failure

demand is given in table 7 for reference.

.

Table 7 - Safety Integrity Levels: Demand mode of operation

Safety Integrity

Level

Target average probability of failure on demand

10-5 to < 10-4

10-4 to < 10-3

10-3 to < 10-2

10-2 to < 10-1

Doc File No.: GDL-S-030 R1

Page 19 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

The selected SIL level for a safety interlock function is the highest of the three individual

SILs (Safety, Economical and Environmental) and defines a minimum SIL. It is always

possible to select a higher SIL level than the required SIL, if the project team thinks this

is preferred.

10.0 PLANNING

10.1

PREPARATION OF THE REVIEW

Once the dates and duration of the review(s) are known necessary logistical

arrangement shall be made.

Appendix IV provides a checklist of the SIL review preparation items.

10.2

TIMING OF THE REVIEW

The SIL review of Project shall take place after associated HAZOP review.

Dedicated session shall be performed for each unit.

11.0 DOCUMENTS REQUIRED AND RECORDING

11.1

DOCUMENTS REQUIRED

Before the start of the SIL review exercise the following documents shall be available to

serve as input information for the discussion:

11.2

Process Flow Diagrams (PFD).

Piping and Instrument Diagrams (P&ID). The P&IDs used for the SIL

review will show all instruments, check valves, safety valves, controllers,

pressure and level switches that are included in the limits of supply.

Cause & Effect matrix.

Safe Charts.

Previous Hazard Analysis (HAZOP) review findings.

Control and Safeguarding philosophy.

Interlocks description.

Layout/ plot plan (if available).

For LICENSOR units, where applicable, LICENSOR recommendation for SIL

based on their design knowledge and operating experience.

Material balance information (information on request).

RECORDING

The findings of the application of the methodology presented above shall be recorded

during the session by the scribe with the computer spreadsheet or dedicated SIL

software.

The scribe records the results of this identification activity in a table type file (see

appendix I) using a computer and a video projector.

Use of a video projector shall allow the team to visualise the record. A SIL review

worksheet used for the report of the findings is presented in appendix I.

Doc File No.: GDL-S-030 R1

Page 20 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Upon completion of the review the chairman will produce a report, which discusses the

findings of the review and details the critical findings.

11.3

REPORTING AND FOLLOW-UP

Subsequent to SIL study, SIL chairman shall issue the study report and shall document

the following as minimum (See appendix III for full list of Table of Content of the report).

The scope of the study;

Study Methodology;

The study team;

The SIFs reviewed and the reference used;

Summarise and present the SIL review proceeding, all the recommendations

and actions raised with proper reference for close out actions to be carried out;

Identify/List those responsible for preparing responses to the actions and

recommendations;

Schedule, monitor and record the execution of necessary close out actions.

Recommendation (Action /query items) shall be recorded and the corresponding SIL

ACTION SHEET (see Appendix II) shall be generated for subsequent follow-up by the

project.

The Project Engineer shall have the responsibility to ensure appropriate project followup of the action recommendations generated during the review are implemented (see

Appendix II).

A Formal SIL Close out Report with SIL verification study shall be submitted to QP for

approval.

Doc File No.: GDL-S-030 R1

Page 21 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.0 APPENDICES

12.1

APPENDIX I: TYPICAL SIL REVIEW WORKSHEET USING RISK GRAPH

METHOD

Project Name /No :

SIF No:

Date Reviewed: DD MMM YYYY

SIF: Reference / name of the selected SIF

Initiators:

Final Elements:

Initiator Success Criteria:

Final Element Success Criteria:

Associated Operating Actions:

Drawings and Documents:

Documents used :

DESIGN INTENT

Purpose of the SIF

CAUSE / DEMAND

CONSEQUENCES

INDEPENDENT

RECOMMENDA

SCENARIO

of FAILURE on

DEMAND (CoFD)

SAFEGUARDS

TIONS

List here causes

that will trigger the

SIF to operate.

List here all the

consequences that

will occur in case

list here all the

independent

safeguards

recommendation

of the team (if

any)

of Failure on

demand of the SIF

Consequence

Parameter

Occupancy

Parameter

Probability of

Avoiding the

hazard Parameter

Demand Rate

Parameter

SIL Level

Safety

Environment

Economic

Required SIL level

SIF Action Number:

Assigned to:

Doc File No.: GDL-S-030 R1

Name of person

Page 22 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.2 APPENDIX II: TYPICAL SIL ACTION SHEET

SIF STUDY ACTION AND RESPONSE SHEET

SIF ACTION ON:

SIF ACTION NO:

RESPOND BY:

MEETING DATES: DD MMM YYYY

DRAWINGS AND DOCUMENTS:

documents used (from the front page list of documents studied)

SIF :

Reference / name of the selected SIF

(SIF Table 1)

DESIGN INTENT:

purpose of the SIF

CAUSE / DEMAND SCENARIO:

list here causes that will trigger the SIF to operate

CONSEQUENCES of FAILURE on DEMAND (CoFD):

list here all the consequences that will occur in case of Failure on demand of the SIF

.

INDEPENDENT SAFEGUARDS:

list here all the independent safeguards

RECOMMENDATIONS:

recommendation of the team (if any)

RESPONSE: (Action )

DATED:

SIGNED:

ENTER YOUR RESPONSE IN THE BOX ABOVE, THEN SIGN AND RETURN TO:

NOTES (for use of Scribe only)

Doc File No.: GDL-S-030 R1

Page 23 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.3 APPENDIX III: TYPICAL SIL REVIEW REPORT TABLE OF CONTENT

TABLE OF CONTENT

1.0 SUMMARY

2.0 INTRODUCTION

3.0 SCOPE

4.0 TEAM COMPOSITION

5.0 DOCUMENTS REFERENCES

(Including to the present procedure)

6.0 GENERAL DESCRIPTION

7.0 FINDINGS OF THE REVIEW (if any)

8.0 CONCLUSION (as required)

In attachment:

9.0 COPY OF REFERENCE DOCUMENTS MARQUED DURING

REVIEW

10.0 SIF CLASSIFICATION RISK MATRIX

11.0 SIL WORKSHEET TABLES

12.0 SIF CLASSIFICATION REVIEW ACTION SHEETS (if any)

Doc File No.: GDL-S-030 R1

Page 24 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.4 APPENDIX IV: SIL REVIEW PREPARATION ITEMS CHECKLIST

Check-list up-dated by: Name: _ _ _ _ _ _ _ _ _ _

Date: _ _/ _ _/ _ _

Logistics:

Dates defined: start date: _ _/ _ _/ _ _

Chairman selected:

Scribe selected:

End date: _ _/ _ _/ _ _

Name: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Name: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Room booked for the period: Yes/No Room # _ _ _ _ _ _ _ _ _ _

Computer booked for the period: Yes/No

Data Projector booked for the period: Yes/No

Coffee/biscuits ordered for the period: Yes/No

Documents available:

Methodology, SIL Procedure: Yes/No

PFD:

Yes/No

PID:

Yes/No

Cause & Effect Matrix: Yes/No

Safe Charts: Yes/No

Process description, balance, layout, etc Yes/No

Previous hazard analysis Yes/No

Participants:

List of participants identified: Yes/No

Participants have been informed of review session dates: Yes/No

when ?

Date: _ _/ _ _/ _ _

Documentation made available to participants: Yes/No

Doc File No.: GDL-S-030 R1

Page 25 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.5 APPENDIX V: DESCRIPTION OF PROCESS INDUSTRY RISK GRAPH

PARAMETERS

(REF.: IEC 61511-3)

Descriptions of Process Industry Risk Graph Parameters

Parameter

Description

Consequence

Occupancy

Probability of

avoiding the

hazard

Demand rate

Number of fatalities and/or serious injuries likely to result from the

occurrence of the hazardous event. Determined by calculating the

numbers in the exposed area when the area is occupied taking in to

account the vulnerability to the hazardous event.

Probability that the exposed area is occupied at the time of the

hazardous event. Determined by calculating the fraction of time the

area is occupied at the time of the hazardous event. This should take

in to account the possibility of an increased likelihood of persons

being in the exposed area in order to investigate abnormal situations

which may exist during the build-up to the hazardous event ( consider

also if this changes the C parameter)

The probability that exposed persons are able to avoid the hazardous

situation which exists if the safety instrumented function fails on

demand. This depends on there being independent methods of

alerting the exposed persons to the hazard prior to the hazard

occurring and there being methods of escape.

The number of times per year that the hazardous event would occur

in the absence of the safety instrumented function under

consideration. This can be determined by considering all failures

which can lead to the hazardous event and estimating the overall rate

of occurrence. Other protection layers should be included in the

consideration.

Doc File No.: GDL-S-030 R1

Page 26 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.6 APPENDIX VI - DEMAND RATE

The demand rate will be determined using the teams collective experience, along with

reference from data bases from OREDA or USRMP or other accepted data bases. QP data

base for failure rates shall be primarily considered when available. Failure rates for typical

equipment items, as shown below for example.

Typical Failure Rate Date (from OREDA Offshore Reliability Database)

Item:

Mean Failure

Rate per 106

hours

Per Year

(Continuous

Operation)

1 Failure

per

(years)

Pressure Switch (Pneumatic)

Level Switch (Pneumatic)

Level Switch (Electric)

Level Transducer

PCV / LCV (Ball)

0.05

0.024

0.084

0.096

0.086 to 0.14

21

40

12

10

7 to 11

0.053 to 0.21

5 to 19

0.19

0.227

0.21 to 0.39

5.25

4.4

2.5 to 5

Electric Relay (logic solver)

Pilot Valve (in SDP)

5.3

2.8

9.6

11

10 to 16 (1 to

20)

19 to 24 (1 to

10)

22

25.94

24 to 44 (1 to

10)

4.1

6.5

0.036

0.0575

27.8

17

Fusible Plug

H2S Gas Detector

IR HC Gas Detector

0.27

11.46

36.5

0.00237

0.1004

0.320

423

9.96

3.13

PCV / LCV (Globe)

PSV

XSDV (Globe Valve)

XBDV (Ball Valve)

Item Leak Frequency (Offshore Hydrocarbon Release Statistics and Analysis, 2002, HID

Statistics Report HSR 2002 002, UK Health and Safety Executive, February 2003.)

Item:

Leak Frequency

(per year)

Flange

Valve

Instrument Connections

Pressure Vessel

Centrifugal pump

Shell & Tube Heat Exchanger

Launcher / Receiver

Centrifugal Compressor

Reciprocating Compressor

5.2 x 10

-4

4 x 10

-4

6 x 10

-3

2 x 10

-3

5 x 10

-3

3.5 x 10

-2

1 x 10

-3

8 x 10

-2

7 x 10

-5

1 leak per

(years)

19230

2500

1700

500

200

290

100

125

15

Overall Leak Frequencies for a Platform:

Large Integrated Offshore Platform approx 1 leak per year

Minimum facilities wellhead platform approx 1 leak per 10 years

Riser Failure frequency approx. 1 x 10-3 per year or 1 in 1000 riser years

Doc File No.: GDL-S-030 R1

Page 27 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.7 APPENDIX VII QP CORPORATE RISK MATRIX

(Ref: Corporate Procedure for Incident management Doc# QPR-STM- 001)

Risk Assessment Matrix

Potential

Severity

SEVERITY

INCREASING SEVERITY

CONSEQUENCES

People

Asset/

Production

No injury

No damage

INCREASING PROBABILITY

A

B

C

Environment Reputation

No Effect

No Impact

Slight injury Slight damage

or health

No disruption Slight Effect

effect

to operation

Slight

Impact

Minor injury

Minor damage

or health

Minor effect

( < QR 350,000)

effect

Limited

Impact

Major injury Local damage

or health

( < QR

effect

3,500,000)

National

Impact

Single

Fatality or

permanent

total

disability

Multiple

fatalities

Localised

Effect

Major damage

( < QR

Major Effect

35,000,000)

Extensive

damage ( > QR

35,000,000)

Massive

Effect

E

Occurres

Has

Occurres

Never

Has

several

Occurred

several

heard in

Occurred

times a

in

times a

Industry

in QP

year this

Industry

year in QP

site

No Risk

Low Risk

Regional

Impact

Medium Risk

High Risk

Internation

al impact

FIGURE A- QP RISK ASSESSMENT MATRIX

Doc File No.: GDL-S-030 R1

Page 28 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

12.7 APPENDIX VII Cont., QP CORPORATE RISK MATRIX

Risk Matrix (Explanation Sheet)

Consequence Category Definitions

1.0 PEOPLE

Harm to people is further explained for:

Slight injury or Health effects:

This includes first aid and medical treatment that does not affect work performance or

cause disability.

Minor injury or Health effects: A lost time injury that restricts a person's work

performance where the injury results in a work assignment after the day of the incident

that does not include al of the normal duties of that person's regular job. It may take a few

days off from work to fully recover (Lost Time Incident). Limited health effects that are

reversible, e.g. skin irritation, food poisoning.

Major injury or Health effects (Including permanent partial disability): Work performance

is affected in the long term, such as prolonged absence from work, irreversible damage to

health without loss of life. For example, noise induced hearing loss, chronic back injuries.

Single fatality or permanent total disability: This is either from a work - related incident

or an occupational illness such as poisoning or cancer.

Multiple fatalities: More than one fatality either from a work - related incident

or

an

occupational illness such as poisoning or cancer.

2.0 ENVIRONMENT

Harm to the Environment is further explained for:

Slight effect: Negligible financial consequences and local environmental risk within the

fence and within the system.

Minor effect: Contamination; damage sufficiently large to impact to impact the

environment; single exceeding of statutory or prescribed limits; single complaint; no

permanent effect on the environment.

Local effect: Limited loss of discharges of unknown toxicity; repeated exceeding of

statutory or prescribed limits and beyond fence or neighbourhood.

Doc File No.: GDL-S-030 R1

Page 29 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

Major effect: Severe environmental damage; the company is required to take extensive

measures to restore the contaminated environment to its original state; Extended

exceeding of statutory or prescribed limits.

Massive effect: Persistent severe environmental damage or severe nuisance extending

over a large area; In terms of commercial or recreational use or nature conservancy, a

major economic loss for the company; Constant high exceeding of statutory or prescribed

limits.

3.0 ASSET DAMAGE/ LOSS OF PRODUCTION

Asset damage and loss of production is further explained for:

Slight damage: No disruption to operation with estimated cost less than QR 25,000.

Minor damage: Brief disruption to operation with estimated cost less than QR 350,000.

Local damage: Partial shutdown of operation; can be restarted with estimated cost up to

QR 3,500,000.

Major damage: Partial loss of operation; 2 weeks shutdown with estimated cost up to QR

35,000,000.

Massive damage: Substantial or total loss of operation with estimated cost in excess of

QR 35,000,000.

4.0 REPUTATION

Damage or loss of reputation is further explained for:

Slight impact: Public awareness may exist but there is no public concern.

Limited impact: Some local public concern; some local media and /or local political attention

with potentially adverse aspects for QP operations.

National impact: National public concern; extensive adverse attention in the national media.

Regional impact: Extensive adverse attention in the regional media; regional public and

political concern.

International impact: Extensive adverse attention in international media; international public

attention.

Doc File No.: GDL-S-030 R1

Page 30 of 31

Custodian Dept: ST

QP GUIDELINE FOR SAFETY INTEGRITY LEVEL REVIEW

DOC. No. QP-GDL-S-030

Rev1

REVISION HISTORY LOG

Revision: 1

Date: 24/03/2010

Reason for Change/Amendment

Item Revised:

Changes/Amendment:

This new guideline is developed to cover

requirements for safety integrity level review.

the

corporate

Note:

The revision history log shall be updated with each revision of the document. It shall

contain a written audit trail of the reason(s) why the changes/amendments have occurred,

what the changes/amendments were and the date at which the changes/amendments

were made.

Doc File No.: GDL-S-030 R1

Page 31 of 31

Custodian Dept: ST

You might also like

- JSA-017 Lifting With ForkliftDocument3 pagesJSA-017 Lifting With ForkliftMoaatazz Nouisri67% (6)

- 03B. Pre-Mobilisation Checklist For Civil & DistributionDocument2 pages03B. Pre-Mobilisation Checklist For Civil & DistributionTwin Bulls83% (6)

- Guide For Process Safety in DesignDocument35 pagesGuide For Process Safety in DesignpoundingNo ratings yet

- LOPA and Human ReliabilityDocument26 pagesLOPA and Human ReliabilityAyoun Ul Haque100% (1)

- Petroleum Development Oman L.L.C.: Specification For Lift Planning and ExecutionDocument31 pagesPetroleum Development Oman L.L.C.: Specification For Lift Planning and ExecutionbhaskarNo ratings yet

- CDOIF Guideline Demonstrating Prior Use v7 FinalDocument34 pagesCDOIF Guideline Demonstrating Prior Use v7 Finaldwi rakhmatullahNo ratings yet

- Sabp Z 076Document29 pagesSabp Z 076Hassan Mokhtar100% (1)

- CCAD - Project HSE PlanDocument187 pagesCCAD - Project HSE Plansergio1234567890100% (7)

- Dangerous Goods Emergency Response ChartDocument1 pageDangerous Goods Emergency Response ChartAyman64100% (1)

- PR-1159 - Commissioning and Start-UpDocument116 pagesPR-1159 - Commissioning and Start-UpDeepak Goyal100% (1)

- SP 2062 HSE Specification Specifications For HSE CasesDocument84 pagesSP 2062 HSE Specification Specifications For HSE CasesDaniel Martinez0% (1)

- Project Handover GuidelinesDocument17 pagesProject Handover GuidelinesRoshaan100% (1)

- Safety Plan For Chemical PlantDocument7 pagesSafety Plan For Chemical PlantM Amir Haris100% (1)

- Pre-Startup Safety Review (PSSR)Document4 pagesPre-Startup Safety Review (PSSR)EcoNo ratings yet

- Bow TieDocument2 pagesBow TieAnonymous ocCa18RNo ratings yet

- Implementation of PSM in Capital Projects DuPont 11 1Document11 pagesImplementation of PSM in Capital Projects DuPont 11 1rodrigo_domNo ratings yet

- AI-PS Element Guide No 9Document8 pagesAI-PS Element Guide No 9rahul kavirajNo ratings yet

- Pre Safety ReviewDocument27 pagesPre Safety ReviewMagesh KumarNo ratings yet

- Proof Testing Safety Instrumented Systems: Prasad Goteti May 10, 2018Document33 pagesProof Testing Safety Instrumented Systems: Prasad Goteti May 10, 2018Rujisak MuangsongNo ratings yet

- OGP-Human Factors Engineering For ProjectsDocument84 pagesOGP-Human Factors Engineering For Projectsevarol100% (2)

- GU-648 - Guide For Applying Process Safety in ProjectsDocument35 pagesGU-648 - Guide For Applying Process Safety in ProjectsSiva100% (1)

- Module 9 - ALARP 20150305Document32 pagesModule 9 - ALARP 20150305Muhammad.SaimNo ratings yet

- A New Approach to HAZOP of Complex Chemical ProcessesFrom EverandA New Approach to HAZOP of Complex Chemical ProcessesNo ratings yet

- EGPC PSM GL 001 Hazard Identfication HAZID GuidelineDocument56 pagesEGPC PSM GL 001 Hazard Identfication HAZID Guidelinekhaled farag100% (2)

- Saep 250Document32 pagesSaep 250brecht198075% (4)

- Introduction To HAZID and ENVID Reviews 2022Document32 pagesIntroduction To HAZID and ENVID Reviews 2022elmabroukiNo ratings yet

- Functional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Document32 pagesFunctional Safety: Sil Assessment & Verification: Do Proof Test Practices Affect P&Ids?Muhammad.SaimNo ratings yet

- RAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREDocument57 pagesRAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREKhan Wasim100% (1)

- HPCL QraDocument104 pagesHPCL Qrapmnasim100% (1)

- Managing Change SafelyDocument10 pagesManaging Change SafelyrwerwerwNo ratings yet

- Nebosh: Management of Health and Safety Unit Ig1Document6 pagesNebosh: Management of Health and Safety Unit Ig1zeeshanNo ratings yet

- QP Guideline For Safety Integrity Level ReviewDocument32 pagesQP Guideline For Safety Integrity Level Reviewjeeva438475% (4)

- Sis PDFDocument2 pagesSis PDFsteam100deg1658No ratings yet

- LOPA Enabling ConditionsDocument22 pagesLOPA Enabling Conditionsuserscribd2011No ratings yet

- QP - phl.S.001 R1 - Corporate Philosophy For Fire & SafetyDocument17 pagesQP - phl.S.001 R1 - Corporate Philosophy For Fire & Safetyprabha haranNo ratings yet

- ESD Valve SILDocument8 pagesESD Valve SILmgkvprNo ratings yet

- SIL ObjectivesDocument29 pagesSIL ObjectivesrkoncNo ratings yet

- HAZOP Study Terms of Reference for Rehman Production FacilityDocument30 pagesHAZOP Study Terms of Reference for Rehman Production FacilityMuhammad.SaimNo ratings yet

- FSA Guidance Document - As Published 08.03.2019 1.0Document31 pagesFSA Guidance Document - As Published 08.03.2019 1.0KevinXavierNo ratings yet

- PSM 6 - Element 1 - Process Safety Culture (v3)Document29 pagesPSM 6 - Element 1 - Process Safety Culture (v3)Ahmed HamadNo ratings yet

- SIL Verification of Legacy System V3Document12 pagesSIL Verification of Legacy System V3Anonymous H0xnVVXypgNo ratings yet

- Safety Studies Functional SpecsDocument21 pagesSafety Studies Functional Specsbtmohamed7084No ratings yet

- Chastainw Advancesinlayerofprotectionanalysis PDFDocument37 pagesChastainw Advancesinlayerofprotectionanalysis PDFanon_770350620100% (1)

- How to perform LOPA analysis for process safetyDocument5 pagesHow to perform LOPA analysis for process safetykumar_chemical100% (1)

- Understanding Oil and Gas HSE Management (37Document34 pagesUnderstanding Oil and Gas HSE Management (37Madhur ChopraNo ratings yet

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Document15 pagesPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- Determining The Required Safety Integrity Level For Your Process PDFDocument8 pagesDetermining The Required Safety Integrity Level For Your Process PDFfitasmounirNo ratings yet

- 17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1Document7 pages17 CASS TOES For FSM Assessment From IEC 61511-1 2016 v1didikpramujiNo ratings yet

- SIL Exercises 1Document3 pagesSIL Exercises 1santosh mishraNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: H Sandso Management Engineering DesignDocument71 pagesPetroleum Development Oman L.L.C.: Document Title: H Sandso Management Engineering DesignSARFRAZ ALINo ratings yet

- Best Practices: Consider These Safety-Instrumented SystemDocument18 pagesBest Practices: Consider These Safety-Instrumented SystemardiyantoNo ratings yet

- Hazid Hazop Sil TorDocument24 pagesHazid Hazop Sil TorravisankarNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- 1 What Is Functional Safety, SIF, SISDocument17 pages1 What Is Functional Safety, SIF, SISAlice LinNo ratings yet

- 7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDocument65 pages7s92 06011 0000 SHR 004a r3 - Sil Classification ReportDucViking100% (1)

- FAA SAFO 13002 Manual Flight OperationsDocument1 pageFAA SAFO 13002 Manual Flight OperationsAvtips100% (1)

- Basics of SISDocument4 pagesBasics of SISJagath PrasangaNo ratings yet

- Comparison of Pha Methods PDFDocument10 pagesComparison of Pha Methods PDFQayyum KhanNo ratings yet

- Process Safety Seminar SummaryDocument5 pagesProcess Safety Seminar SummaryBrijesh100% (1)

- 011.TBSHE JSA 005 Pipelaying WorkDocument8 pages011.TBSHE JSA 005 Pipelaying Worknellaika puspa dewi100% (1)

- SRS Safety Requirements SpecDocument7 pagesSRS Safety Requirements SpechiyeonNo ratings yet

- Guidelines for Determining the Probability of Ignition of a Released Flammable MassFrom EverandGuidelines for Determining the Probability of Ignition of a Released Flammable MassNo ratings yet

- Essentials On Safety Instrumented SystemsDocument9 pagesEssentials On Safety Instrumented Systemstibi1000No ratings yet

- Achieved SILDocument4 pagesAchieved SILAkoKhaledi50% (2)

- I&E Systems Pty LTD FS Engineer (TÜV Rheinland) Training and CertificationDocument4 pagesI&E Systems Pty LTD FS Engineer (TÜV Rheinland) Training and Certificationfaisal84inNo ratings yet

- TSE FrameworkDocument3 pagesTSE FrameworkyeNo ratings yet

- GU-611 - 23a - PDO Guide To Engineering Standards and ProceduresDocument1 pageGU-611 - 23a - PDO Guide To Engineering Standards and ProceduresSiva baalanNo ratings yet

- Alarp Exercise Cba Uk HseDocument2 pagesAlarp Exercise Cba Uk HseMuhammad.SaimNo ratings yet

- Brochure SIL CapabilityDocument4 pagesBrochure SIL CapabilityToto_Titi_4584No ratings yet

- CV 2023110722004938Document3 pagesCV 2023110722004938Saqib JavedNo ratings yet

- GEGN8643 Iss 1Document14 pagesGEGN8643 Iss 1Vasudev SangareddyNo ratings yet

- Risk Matrix for HSE Manual ProcessDocument1 pageRisk Matrix for HSE Manual ProcessFrankNo ratings yet

- TUVFSDocument3 pagesTUVFSspkaliNo ratings yet

- Sanisol RC-A SDS SummaryDocument6 pagesSanisol RC-A SDS SummaryMohamad Arta100% (1)

- NEBOSH HSE Certificate in Process Safety ManagementDocument2 pagesNEBOSH HSE Certificate in Process Safety ManagementKannan JaganNo ratings yet

- Sullube American Chemical MSDS - EnglishDocument6 pagesSullube American Chemical MSDS - EnglishMod Kaewdaeng100% (2)

- Safety Data Sheet NALCO® 8140: Section 1. Product and Company IdentificationDocument9 pagesSafety Data Sheet NALCO® 8140: Section 1. Product and Company IdentificationU.s. Ezhil ArivudainambiNo ratings yet

- SDS PLA V3.004-EnDocument5 pagesSDS PLA V3.004-Endesign jyotihydrotech.comNo ratings yet

- 2 Amp Charge Rate Automatic Battery Maintainer Instruction ManualDocument9 pages2 Amp Charge Rate Automatic Battery Maintainer Instruction ManualMarcel PiersonNo ratings yet

- Job Description - Potholing SupervisorDocument6 pagesJob Description - Potholing SupervisorAlbert Jn BaptisteNo ratings yet

- Horizonatal Life Line DesignDocument9 pagesHorizonatal Life Line DesigntriodnsNo ratings yet

- ChecklistDocument8 pagesChecklistainul sufiahNo ratings yet

- Chapter 7 - DIMENSION OF DEVELOPMENT: FIRST AID EDUCATIONDocument23 pagesChapter 7 - DIMENSION OF DEVELOPMENT: FIRST AID EDUCATIONCassandradra MendezNo ratings yet

- Msds Lagd 60-125 Version 01 GBRDocument7 pagesMsds Lagd 60-125 Version 01 GBRThibaut LeconteNo ratings yet

- g7 Safety Regulations Household ServicesDocument36 pagesg7 Safety Regulations Household ServicesTalim Pt NhsNo ratings yet

- 15.1 Safety Management: Contractor Management System: 15.1.1 PurposeDocument13 pages15.1 Safety Management: Contractor Management System: 15.1.1 Purposesyedahmad39No ratings yet

- Exodus Case Study - Ohio Department of Public Safety August 2012Document18 pagesExodus Case Study - Ohio Department of Public Safety August 2012Jon Ortiz100% (1)

- INB Order WorkshopDocument45 pagesINB Order WorkshopRAJARETHINAM PNo ratings yet

- Asbestos Surveying - Mdhs100Document44 pagesAsbestos Surveying - Mdhs100Adam EdwardsNo ratings yet