Professional Documents

Culture Documents

Bs 6485 1999 PVC Insulated Conductors For Overhead Power Lines

Uploaded by

AnamulKabirOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bs 6485 1999 PVC Insulated Conductors For Overhead Power Lines

Uploaded by

AnamulKabirCopyright:

Available Formats

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c)

BSI

BRITISH STANDARD

PVC-covered conductors

for overhead power

lines

ICS 29.060.20; 29.240.20

NO COPYING WITHOUT BSI PERMISSION EXCEPT AS PERMITTED BY COPYRIGHT LAW

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BS 6485:1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Committees responsible for this

British Standard

The preparation of this British Standard was entrusted by Technical Committee

GEL/20, Electric cables, to Subcommittee GEL/20/2, Mains cables 1 kV and above,

upon which the following bodies were represented:

Association of Consulting Engineers

British Approvals Service for Cables

British Cable Makers Confederation

British Plastics Federation

ERA Technology Ltd.

Electricity Association

London Underground Ltd.

UK Steel Association

This British Standard, having

been prepared under the

direction of the Electrotechnical

Sector Committee, was published

under the authority of the

Standards Committee and comes

into effect on 15 February 1999

BSI 02-1999

First published April 1971

Second edition May 1990

Third edition February 1999

The following BSI references

relate to the work on this

standard:

Committee reference GEL/20/2

Draft for comment 97/262300 DC

ISBN 0 580 28254 6

Amendments issued since publication

Amd. No.

Date

Text affected

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Contents

Page

Committees responsible

Inside front cover

Foreword

ii

1 Scope

1

2 Normative references

1

3 Terms and definitions

1

4 Conductor

2

5 PVC covering

2

6 Schedule of tests

2

7 Test conditions

2

8 Routine tests

2

9 Sample tests

3

10 Type test

3

Annex A (normative) Test methods

4

Annex B (normative) Particulars of PVC-covered conductors

5

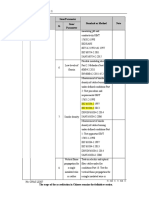

Table 1 Schedule of tests

2

Table 2 Spark test voltage values

2

Table B.1 PVC-covered stranded hard-drawn copper conductors

(Based on BS 7884)

5

Table B.2 PVC-covered stranded hard-drawn copper alloy conductors

(Based on BS 7884)

5

Table B.3 PVC-covered aluminium stranded conductors (Based on BS 215-1)

6

Table B.4 PVC-covered aluminium conductors, steel reinforced

(Based on BS 215-2)

6

Table B.5 PVC-covered aluminium alloy stranded conductors

(Based on BS 3242)

7

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Foreword

This new edition of BS 6485 has been prepared by Subcommittee GEL/20/2 and

supersedes BS 6485:1990 which is withdrawn.

This edition has updated references mainly due to the withdrawal of BS 125:1970 and

BS 2755:1970 which have been replaced by BS 7884:1997.

This new edition incorporates technical changes. It does not represent a full review or

revision of the standard, which will be undertaken in due course.

Annexes A and B are normative.

It has been assumed in the preparation of this British Standard that the execution of its

provisions will be entrusted to appropriately qualified and experienced people, for

whose use it has been produced.

This British Standard calls for the use of substances and/or procedures that may be

injurious to health if adequate precautions are not taken. It refers only to technical

suitability and does not absolve the user from legal obligations relating to health and

safety at any stage.

A British Standard does not purport to include all the necessary provisions of a

contract. Users of British Standards are responsible for their correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

Summary of pages

This document comprises a front cover, an inside front cover, pages i and ii, pages 1

to 7 and a back cover.

ii

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

1 Scope

This British Standard specifies requirements for

PVC-covered conductors for overhead power lines.

Two types of PVC-covered conductor have been

standardized by the designation of minimum

thickness of covering as follows:

a) Type 8: 0.8 mm;

b) Type 16: 1.6 mm.

Type 8 is intended for use only where the operating

voltage of the power lines does not exceed 650 V r.m.s.

between any two conductors or 250 V r.m.s. between

any conductor and earth. Under these operating

conditions, it is suitable for:

a) crossings of telecommunication lines to guard

against contact;

b) proximities to telecommunication lines to guard

against contact;

c) lines (particularly service lines) accessible from

buildings.

Type 16 is intended for use only where the operating

voltage of the power line exceeds 650 V r.m.s

between any two conductors or 250 V r.m.s.

between any conductor and earth, but does not

normally exceed 11 kV r.m.s. between conductors

or 6.6 kV r.m.s. between any conductor and earth.

The earthing of the neutral point of the system

through an arc-suppression coil is not precluded, if

arrangements exist for clearing earth faults without

undue delay. Under these operating conditions,

type 16 is suitable for crossings of

telecommunication lines and proximities to them.

2 Normative references

The following normative documents contain

provisions which, through reference in this text,

constitute provisions of this British Standard. For

dated references, subsequent amendments to, or

revisions of, any of these publications do not apply.

For undated references, the latest edition of the

publication referred to applies.

BS 215-1, Specification for aluminium conductors

and aluminium conductors, steel-reinforced for

overhead power transmission Part 1: Aluminium

stranded conductors.

BS 215-2, Specification for aluminium conductors

and aluminium conductors, steel-reinforced for

overhead power transmission Part 2: Aluminium

conductors, steel-reinforced.

BSI 02-1999

BS 3242, Specification for aluminium alloy

stranded conductors for overhead power

transmission.

BS 4727-2, Glossary of electrotechnical, power,

telecommunication, electronics, lighting and colour

terms Part 2: Terms particular to power

engineering Group 08: Electric cables.

BS 5099, Specification for spark testing of electric

cables.

BS 7655-3.1, Specification for insulating and

sheathing materials for cables Part 3: PVC

insulating compounds Section 3.1: Harmonized

types.

BS 7884, Specification for copper and

copper-cadmium stranded conductors for overhead

electric traction and power transmission systems.

BS EN 60811-1-1:1995, Insulating and sheathing

materials of electric cables Common test

methods Part 1: General application

Section 1: Measurement of thickness and overall

dimensions.

3 Terms and definitions

For the purposes of this British Standard, the

definitions given in BS 4727-2:Group 08 apply,

together with the following.

3.1

nominal value

value by which a quantity is designated and which is

often used in tables

NOTE Usually, in this standard, nominal values give rise to

values to be checked by measurements taking into account

specified tolerances.

3.2

approximate value

value which is only indicative

NOTE Usually, in this standard, values described as

approximate do not constitute requirements to be checked by

measurements.

3.3

routine tests

tests made by the manufacturer on each

manufactured length of covered conductor to check

that the whole of each length meets the specified

requirements

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

3.4

sample tests

tests made by the manufacturer on samples of

completed product or components taken from a

completed product, at a specified frequency, so as to

verify that the finished product meets the specified

requirements

3.5

type tests

tests made before supplying on a general commercial

basis a type of product covered by this standard in

order to demonstrate satisfactory performance

characteristics to meet the intended application

NOTE 1 These tests are of such a nature that, after they have

been made, they need not be repeated unless changes are made in

the materials or design or manufacturing process which might

change the performance characteristics.

NOTE 2 Tests classified as routine or sample may be required as

part of any type approval schemes.

4 Conductor

The material, construction and physical properties of

the conductor shall, after covering, conform to either

BS 215, BS 3242, or BS 7884 for the bare conductor.

The conductor sizes are specified in annex B.

5 PVC covering

5.1 Material

The PVC covering shall conform to the type

TI 1 compound requirements of BS 7655-3.1.

5.2 Colour

The colour of the covering shall be as follows:

a) Type 8: Black;

b) Type 16: Green.

NOTE The purchaser should consult the manufacturer when

ordering green material for use in tropical countries.

5.3 Thickness of covering

When tested in accordance with A.3 the thickness of

the PVC covering at any point shall be not less than

the appropriate value given below:

a) Type 8: 0.8 mm;

b) Type 16: 1.6 mm.

6 Schedule of tests

Testing shall be carried out in accordance with the

schedule of tests given in Table 1.

Table 1 Schedule of tests

Test

Clause

reference

Routine tests

Spark test

High voltage test (Type 16 only)

Conductor resistance

Insulation resistance test

(Type 16 only)

8.2

8.3

8.4

8.5

Sample tests

Thickness of PVC covering

Conductor examination and test

5.3

9.2

Type test

PVC material

5.1

7 Test conditions

7.1 Ambient temperature

Tests shall be made at ambient temperature within

the range 5 8C to 35 8C unless otherwise specified in

the details of the particular test.

7.2 Frequency and waveform of power

frequency test voltages

Unless otherwise specified, alternating test voltages

shall have a frequency between 49 Hz and 61 Hz. The

waveform shall be substantially sinusoidal.

8 Routine tests

8.1 General

Routine tests shall be as given in Table 1.

8.2 Spark test

When the PVC covering is tested in accordance with

BS 5099, applying the voltage given in Table 2, no

breakdown shall occur.

Table 2 Spark test voltage values

Designation

Test voltage

kV

a.c. (r.m.s.)

d.c.

Type 8

Type 16

12

18

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

8.3 High voltage test (Type 16 only)

When tested in accordance with A.1 no breakdown

of the PVC covering shall occur.

8.4 Conductor resistance

The d.c. resistance of hard-drawn copper and

hard-drawn copper-cadmium conductors shall be

measured in accordance with BS 7884 and corrected

to 20 8C in accordance with that standard. The

results shall not exceed the appropriate maximum

values given in Tables B.1 and B.2.

8.5 Insulation resistance test (Type 16 only)

When tested in accordance with A.2 the insulation

resistance shall be greater than 0.5 MV/km.

BSI 02-1999

9 Sample tests

9.1 General

Sample tests shall be as given in Table 1.

9.2 Conductor examination and test

When examined and tested in accordance with the

appropriate British Standard from those listed in

clause 4, the conductor shall conform to the

requirements of that standard.

10 Type test

The type test shall be as given in Table 1.

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Annex A (normative)

Test methods

A.1 High voltage test (type 16 only)

Cut a sample of PVC-covered conductor not less

than 1 m long from each manufactured drum length.

Immerse the sample in water for at least 24 h, and

whilst it is still immersed apply 25 kV (r.m.s.) between

the conductor and the water, the latter being earthed.

Raise the voltage gradually and maintain at the full

value for 5 min.

A.3 Thickness of PVC coating

Take a representative sample of the PVC-covered

conductor, approximately 300 mm long, not less

than 300 mm from the end of the selected drum

lengths. At three different sections not less

than 100 mm apart measure the thickness of the

covering in accordance with BS EN 60811-1-1:1995, 8.1.

A.2 Insulation resistance test (type 16 only)

Cut a sample of PVC-covered conductor not less

than 10 m long from each manufactured drum length.

Immerse the sample in water at ambient temperature

for at least 4 h. Measure the insulation resistance

between the conductor and the water after steady

electrification for 1 min using a voltage of between 80 V

and 500 V d.c.

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Annex B (normative)

Particulars of PVC-covered conductors

NOTE Additional information may be obtained by direct reference to the British Standard designated in each table.

Table B.1 PVC-covered stranded hard-drawn copper conductors (Based on BS 7884)

1

Nominal

cross-sectional

area

Stranding

and wire

diameter

mm2

mm

Approximate

Maximum

Approximate

Approximate

overall

resistance

breaking load overall diameter of

diameter of per kilometre

covered conductor

bare

at 20 8C

Type 8

Type 16

conductor

mm

kN

mm

mm

Approximate mass

per kilometre of

covered conductor

Type 8

Type 16

kg

kg

14

7/1.60

4.80

1.303

5.744

6.8

8.4

160

190

16

3/2.65

5.70

1.106

6.590

7.7

9.3

180

220

32

3/3.75

8.06

0.5520

12.71

10.5

12.1

350

390

35

7/2.50

7.50

0.5337

14.097

9.9

11.5

360

400

70

7/3.55

10.65

0.2646

26.88

13.5

14.7

690

750

100

7/4.30

12.90

0.1810

37.64

15.7

16.9

990

1 060

Table B.2 PVC-covered stranded hard-drawn copper alloy conductors (Based on BS 7884)

1

Nominal

cross-sectional

area

Stranding

and wire

diameter

Approximate

overall

diameter of

bare

conductor

Maximum

resistance

per

kilometre

at 20 8C

Approximate

breaking

load

Approximate

overall diameter

of covered

conductor

Approximate mass

per kilometre of

covered conductor

Type 16

Type 16

mm2

mm

mm

kN

mm

kg

12

3/2.30

4.95

1.780

7.20

8.2

170

22

7/2.00

6.00

1.011

12.94

9.6

270

38

7/2.60

7.80

0.5983

21.69

11.8

430

75

7/3.70

11.10

0.2954

40.23

15.1

810

125

19/2.90

14.50

0.1784

68.75

18.5

1 310

150

19/3.20

16.00

0.1465

82.16

20.0

1 570

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Table B.3 PVC-covered aluminium stranded conductors (Based on BS 215-1)

1

Nominal

cross-sectional

area

Stranding and

wire diameter

Approximate

overall

diameter of

bare conductor

Calculated

resistance per

kilometre

at 20 8C

Approximate

breaking load

Approximate

overall

diameter of

covered

conductor

Approximate

mass per

kilometre of

covered

conductor

Type 8

Type 8

mm2

mm

mm

kN

mm

kg

22

7/2.06

6.18

1.227

3.99

8.2

100

50

7/3.10

9.30

0.5419

8.28

11.7

200

100

7/4.39

13.17

0.2702

16.00

16.0

360

200

19/3.78

18.90

0.1349

32.40

21.7

690

Table B.4 PVC-covered aluminium conductors, steel reinforced (Based on BS 215-2)

1

Nominal

cross-sectional

area

mm2

Stranding and wire

diameter

Aluminium

Steel

mm

mm

Approximate

overall

diameter of

bare

conductor

Calculated

resistance

per

kilometre

at 20 8C

mm

Approximate Approximate Approximate

breaking

overall

mass per

load

diameter of kilometre of

covered

covered

conductor

conductor

Type 16

Type 16

mm

kg

kN

25

6/2.36

1/2.36

7.08

1.093

9.61

10.7

190

50

6/3.35

1/3.35

10.05

0.5426

18.35

14.1

330

100

6/4.72

7/1.57

14.15

0.2733

32.70

18.2

550

150

30/2.59

7/2.59

18.13

0.1828

69.20

22.2

920

150

18/3.35

1/3.35

16.75

0.1815

35.70

20.8

680

175

30/2.79

7/2.79

19.53

0.1576

79.80

23.6

1 050

175

18/3.61

1/3.61

18.05

0.1563

41.10

22.1

780

200

30/3.00

7/3.00

21.00

0.1363

92.25

25.0

1 190

200

18/3.86

1/3.86

19.30

0.1367

46.55

23.3

870

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BS 6485:1999

Table B.5 PVC-covered aluminium alloy stranded conductors (Based on BS 3242)

1

Nominal

cross-sectional

area

Stranding

and wire

diameter

Approximate

overall

diameter of

bare

conductor

Calculated

resistance

per

kilometre

at 20 8C

Approximate

breaking load

Approximate

overall diameter

of covered

conductor

Approximate mass

per kilometre of

covered conductor

Type 16

Type 16

mm2

mm

mm

kN

mm

kg

25

7/2.34

7.02

1.094

8.44

10.6

170

50

7/3.30

9.90

0.5498

16.80

13.9

280

100

7/4.65

13.95

0.2769

33.30

18.0

470

150

19/3.48

17.40

0.1830

50.65

21.4

680

175

19/3.76

18.80

0.1568

59.10

22.8

780

BSI 02-1999

Licensed Copy: Institute Of Technology Tallaght, Institute of Technology, Mon Jul 31 00:20:14 BST 2006, Uncontrolled Copy, (c) BSI

BSI

389 Chiswick High Road

London

W4 4AL

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

BSI British Standards Institution

BSI is the independent national body responsible for preparing British Standards. It

presents the UK view on standards in Europe and at the international level. It is

incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of British Standards

should make sure that they possess the latest amendments or editions.

It is the constant aim of BSI to improve the quality of our products and services. We

would be grateful if anyone finding an inaccuracy or ambiguity while using this

British Standard would inform the Secretary of the technical committee responsible,

the identity of which can be found on the inside front cover. Tel: 020 8996 9000.

Fax: 020 8996 7400.

BSI offers members an individual updating service called PLUS which ensures that

subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: 020 8996 9001. Fax: 020 8996 7001.

In response to orders for international standards, it is BSI policy to supply the BSI

implementation of those that have been published as British Standards, unless

otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and international

standards through its Library and its Technical Help to Exporters Service. Various

BSI electronic information services are also available which give details on all its

products and services. Contact the Information Centre. Tel: 020 8996 7111.

Fax: 020 8996 7048.

Subscribing members of BSI are kept up to date with standards developments and

receive substantial discounts on the purchase price of standards. For details of

these and other benefits contact Membership Administration. Tel: 020 8996 7002.

Fax: 020 8996 7001.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the UK, of

the publications of the international standardization bodies. Except as permitted

under the Copyright, Designs and Patents Act 1988 no extract may be reproduced,

stored in a retrieval system or transmitted in any form or by any means electronic,

photocopying, recording or otherwise without prior written permission from BSI.

This does not preclude the free use, in the course of implementing the standard, of

necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

If permission is granted, the terms may include royalty payments or a licensing

agreement. Details and advice can be obtained from the Copyright Manager.

Tel: 020 8996 7070.

You might also like

- BS 07655-1.1-2000Document9 pagesBS 07655-1.1-2000Reda ElawadyNo ratings yet

- BS 5099-2004 Electric Cables - Voltage Levels For Spark TestingDocument7 pagesBS 5099-2004 Electric Cables - Voltage Levels For Spark TestingAnamulKabirNo ratings yet

- BS 6622-2007Document60 pagesBS 6622-2007oadipphone7031100% (7)

- PGCIL Power & Control Cable Rev-5Document14 pagesPGCIL Power & Control Cable Rev-5uttam100% (1)

- Product Quality Plan: Customer Manufacturer Conductor Type SizesDocument7 pagesProduct Quality Plan: Customer Manufacturer Conductor Type SizesAvinash LalNo ratings yet

- BS 6622 XLPE CablesDocument57 pagesBS 6622 XLPE Cablesdanferreiro8318No ratings yet

- NF C 33-209 cable specsDocument2 pagesNF C 33-209 cable specsshivam dwivedi0% (1)

- BS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireDocument12 pagesBS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireThanh Dang67% (3)

- En 50397-2 PDFDocument43 pagesEn 50397-2 PDFJCuchapin100% (1)

- BS 07870-5-2011 (2012)Document22 pagesBS 07870-5-2011 (2012)bean bean50% (2)

- As 1222.2-1992 Steel Conductors and Stays - Bare Overhead Aluminium Clad (SC AC)Document7 pagesAs 1222.2-1992 Steel Conductors and Stays - Bare Overhead Aluminium Clad (SC AC)SAI Global - APACNo ratings yet

- Insulating and Sheathing Materials For CablesDocument8 pagesInsulating and Sheathing Materials For CablesHanh-Trang DangNo ratings yet

- ( - Ekgo: TandcfrciDocument23 pages( - Ekgo: TandcfrciRajesh Arora100% (4)

- Onshore Power & Control Cables Flame Retardant DatasheetDocument2 pagesOnshore Power & Control Cables Flame Retardant DatasheetBajjaliNo ratings yet

- Is 5484 1997Document9 pagesIs 5484 1997Cristian Walker100% (2)

- COMESA Standard for Hard-drawn Aluminium WireDocument18 pagesCOMESA Standard for Hard-drawn Aluminium WiremartinpellsNo ratings yet

- BS 7629-1Document20 pagesBS 7629-1floyd hope prieto100% (1)

- Astm B 233Document4 pagesAstm B 233Ryan LasacaNo ratings yet

- BS 7655-0-2006Document13 pagesBS 7655-0-2006Surendra Mishra100% (2)

- B 231 - B 231M - 99 - Qjizms05oqDocument11 pagesB 231 - B 231M - 99 - Qjizms05oqAifam RawNo ratings yet

- BS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDocument16 pagesBS 215-2-1970-Aluminium Conductors and Aluminium Conductors Steel-Reinforced For Overhead Power TransmissionDayan Yasaranga100% (2)

- IEC 61238-1 Compression and Mechanical Connectors For Power CablesDocument12 pagesIEC 61238-1 Compression and Mechanical Connectors For Power Cablesquarktop123456100% (3)

- Bs 6387 Catc-950deg Cel-HighlightedDocument1 pageBs 6387 Catc-950deg Cel-HighlightedAshik M RasheedNo ratings yet

- IEC 61238 1 Compression and Mechanical Connectors For Power Cables PDFDocument12 pagesIEC 61238 1 Compression and Mechanical Connectors For Power Cables PDFkarviz100% (1)

- Tabla IEC 62219Document5 pagesTabla IEC 62219ManuelNo ratings yet

- Opgw - 2S 1 - 24B1 (59 - 30 - 57.9) PDFDocument8 pagesOpgw - 2S 1 - 24B1 (59 - 30 - 57.9) PDFTriyanto SoewawiNo ratings yet

- ISO/IEC 17025认可证书标题Document1 pageISO/IEC 17025认可证书标题Renzo Romero ArenasNo ratings yet

- Icea S-121-733-2016Document38 pagesIcea S-121-733-2016TrầnHữuHòa100% (1)

- Bsi BS en 60371-0-1 - 2014Document38 pagesBsi BS en 60371-0-1 - 2014alferedNo ratings yet

- Cover Conductor ReportDocument73 pagesCover Conductor ReportCarlosNo ratings yet

- Technical Specification For Low-Frequency Cables and Wires - Fo PDFDocument40 pagesTechnical Specification For Low-Frequency Cables and Wires - Fo PDFking_electricalNo ratings yet

- Extra-High-Strength and Ultra-High-Strength Zinc-Coated (Galvanized) Steel Core Wire For Overhead Electrical ConductorsDocument4 pagesExtra-High-Strength and Ultra-High-Strength Zinc-Coated (Galvanized) Steel Core Wire For Overhead Electrical ConductorsSofia YuliNo ratings yet

- BS 07870-3.12-2011 (2012)Document22 pagesBS 07870-3.12-2011 (2012)Fernando Sánchez RomeroNo ratings yet

- Astm B 263Document3 pagesAstm B 263Ryan Lasaca100% (1)

- Cross sectional drawing and technical data sheet for MV cableDocument4 pagesCross sectional drawing and technical data sheet for MV cableGhiles AOUICHENo ratings yet

- En 60889Document3 pagesEn 60889Pankaj Goyal0% (1)

- Cable MT NFC 33 226 18 30 36 KV PDFDocument2 pagesCable MT NFC 33 226 18 30 36 KV PDFSourav BhattacharyaNo ratings yet

- Iec 209Document14 pagesIec 209AnamulKabir100% (2)

- IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded ConductorsDocument74 pagesIEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded ConductorsManuel Novo50% (2)

- BS en 1715 1 2008Document18 pagesBS en 1715 1 2008Ирина МихайловаNo ratings yet

- BS 6231Document15 pagesBS 6231keyurNo ratings yet

- Iec 62219Document31 pagesIec 62219boopathy1705No ratings yet

- Aluminium Conductor PropertiesDocument16 pagesAluminium Conductor PropertiesHemantha Balasuriya100% (1)

- B49-20 Copper RodDocument8 pagesB49-20 Copper RodAmit Mishra100% (1)

- Acss TWDocument5 pagesAcss TWharoldc4No ratings yet

- As 1746-1991Document15 pagesAs 1746-1991Quantudogon DangNo ratings yet

- B115 PDFDocument9 pagesB115 PDFSanth v SaksenaNo ratings yet

- Specs ZTT OPGW 24 Fibers PDFDocument9 pagesSpecs ZTT OPGW 24 Fibers PDFVictor DoyoganNo ratings yet

- Vol-II (B) EditedDocument125 pagesVol-II (B) EditedtanujaayerNo ratings yet

- Icea Nema S-61-402 Parte 4Document23 pagesIcea Nema S-61-402 Parte 4DamiánNo ratings yet

- BS 03288 3 1989 1999Document30 pagesBS 03288 3 1989 1999André FerreiraNo ratings yet

- BS 6007 - (0101001)Document26 pagesBS 6007 - (0101001)rommel duranNo ratings yet

- As 60372-2010 Locking Devices For Ball and Socket Couplings of String Insulator Units - Dimensions and TestsDocument6 pagesAs 60372-2010 Locking Devices For Ball and Socket Couplings of String Insulator Units - Dimensions and TestsSAI Global - APACNo ratings yet

- PVC Insulated Underground Railway Signalling Cable SpecificationDocument45 pagesPVC Insulated Underground Railway Signalling Cable SpecificationAshish GuptaNo ratings yet

- 111 - Spec. No. 45 of AL-59 PantherDocument17 pages111 - Spec. No. 45 of AL-59 Pantherdeepthik27No ratings yet

- SANS 1411-1:2008: Materials of Insulated Electric Cables and Flexible Cords Part 1: ConductorsDocument23 pagesSANS 1411-1:2008: Materials of Insulated Electric Cables and Flexible Cords Part 1: ConductorsShadi Abd Alazim100% (1)

- BS 6724 1997Document42 pagesBS 6724 1997Simon Law100% (1)

- BS 6231 PDFDocument18 pagesBS 6231 PDFThomas Or100% (1)

- BS 06622-2007Document60 pagesBS 06622-2007Thanh DangNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Cable Datasheet Provides Key SpecsDocument4 pagesCable Datasheet Provides Key SpecsAnamulKabirNo ratings yet

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirNo ratings yet

- Iec 209Document14 pagesIec 209AnamulKabir100% (2)

- BS 215 Part 1 1970Document11 pagesBS 215 Part 1 1970AnamulKabirNo ratings yet

- 012 1998 Galvanized Steel WireDocument12 pages012 1998 Galvanized Steel WireChandana KumaraNo ratings yet

- 012 1998 Galvanized Steel WireDocument12 pages012 1998 Galvanized Steel WireChandana KumaraNo ratings yet

- Bs 5308 - Part - 1-1986 Instrumentation CablesDocument20 pagesBs 5308 - Part - 1-1986 Instrumentation CablesAnamulKabir100% (2)

- BS 5345 P1 PDFDocument48 pagesBS 5345 P1 PDFAnamulKabir100% (3)

- ASTM A475 Standard Specification For Zinc-Coated Steel Wire StrandDocument5 pagesASTM A475 Standard Specification For Zinc-Coated Steel Wire StrandAdam JonesNo ratings yet

- Astm D 3999 - 91 R03Document15 pagesAstm D 3999 - 91 R03AnamulKabirNo ratings yet

- Fire Resistance CablesDocument5 pagesFire Resistance CablesdhandapaniamzaNo ratings yet

- YMVK-mb ss Powerflex Cable for Energy DistributionDocument2 pagesYMVK-mb ss Powerflex Cable for Energy DistributionAnamulKabirNo ratings yet

- Astm A 178 A 178M 2002Document4 pagesAstm A 178 A 178M 2002AnamulKabir0% (1)

- PCM Cables: What Is PCM Cable? Why PCM Cables? Application?Document14 pagesPCM Cables: What Is PCM Cable? Why PCM Cables? Application?sidd_mgrNo ratings yet

- 17th Amd 1 Corrigendum June 2013 V2Document10 pages17th Amd 1 Corrigendum June 2013 V2shaktikumarjhaNo ratings yet

- Cable and WireDocument6 pagesCable and Wiresteam100deg1658No ratings yet

- Bs 5308 - Part - 1-1986 Instrumentation CablesDocument20 pagesBs 5308 - Part - 1-1986 Instrumentation CablesAnamulKabir100% (2)

- FP200 FR Gold Flex Cable - PDF - Prysmian FP200 Gold&FlexDocument4 pagesFP200 FR Gold Flex Cable - PDF - Prysmian FP200 Gold&FlexAnamulKabirNo ratings yet

- ICEA-S 96-659 5kVDocument2 pagesICEA-S 96-659 5kVAnamulKabirNo ratings yet

- Ansi Icea T 27-581-2008Document43 pagesAnsi Icea T 27-581-2008AnamulKabir67% (3)

- Ansi Icea P 32 382 1999Document14 pagesAnsi Icea P 32 382 1999AnamulKabirNo ratings yet

- HPC 5DC 07 0005 2012 Distribution Design Manual Vol 5v1Document139 pagesHPC 5DC 07 0005 2012 Distribution Design Manual Vol 5v1AnamulKabirNo ratings yet

- Partial Discharge Detection For Condition Monitoring of An 11-kV XLPE CableDocument4 pagesPartial Discharge Detection For Condition Monitoring of An 11-kV XLPE CableAnamulKabirNo ratings yet

- Shore HardnessDocument12 pagesShore HardnessAnamulKabirNo ratings yet

- Astm B23 00Document4 pagesAstm B23 00e_dnei901950% (2)

- NS220Document267 pagesNS220Victor IkeNo ratings yet

- Mechanical Properties For Steel FastenersDocument7 pagesMechanical Properties For Steel FastenersepriyonoNo ratings yet

- PVC XLPE Insulated Cables Up To 33kVDocument6 pagesPVC XLPE Insulated Cables Up To 33kVmashan98No ratings yet

- VPE WorkbenchDocument27 pagesVPE Workbenchmajor_duanNo ratings yet

- U.V. Flame Detectors HoneywellDocument12 pagesU.V. Flame Detectors HoneywellgabNo ratings yet

- FaultDocument9 pagesFaultđức lêNo ratings yet

- MAK 3002 SA 971113 eDocument255 pagesMAK 3002 SA 971113 eIrimia Matei AlexNo ratings yet

- AC-115 Hardware Instruction Manual 10-02Document58 pagesAC-115 Hardware Instruction Manual 10-02Carmen MihaelaNo ratings yet

- Manual de Usuario Aire Acondicionado Sp121cmDocument35 pagesManual de Usuario Aire Acondicionado Sp121cmcardan128No ratings yet

- Genesis 3.8L Section 1Document23 pagesGenesis 3.8L Section 1Nacho MowjiNo ratings yet

- Volex Accessories PDFDocument1 pageVolex Accessories PDFNithin M NambiarNo ratings yet

- Service Manual: Split TypeDocument112 pagesService Manual: Split TypeVăn NamNo ratings yet

- Cobas 6000 Series - PreSite Canadian Nov 2008Document17 pagesCobas 6000 Series - PreSite Canadian Nov 2008Luis Guillermo GuaniloNo ratings yet

- iSTAR UltraSE QSG 8200 1761 01 B0 enDocument32 pagesiSTAR UltraSE QSG 8200 1761 01 B0 enJan Andre RøeNo ratings yet

- NetAXS123 Access Control Unit Installation Guide 800-05779-ADocument76 pagesNetAXS123 Access Control Unit Installation Guide 800-05779-AASTROLAB4208No ratings yet

- Specification For Electrical InstallationsDocument54 pagesSpecification For Electrical InstallationsMohamed987100% (1)

- Dynapac Ca250 Manual ElectricoDocument42 pagesDynapac Ca250 Manual ElectricoDino Martin Mercado Quispe80% (15)

- Generator Set Installation Checklist: Enclosed or Containerized Generator Cooling SystemDocument3 pagesGenerator Set Installation Checklist: Enclosed or Containerized Generator Cooling SystemMohamed H. ShedidNo ratings yet

- TL4100 Top 5 Build Tips for Calibration and AssemblyDocument15 pagesTL4100 Top 5 Build Tips for Calibration and AssemblyRheneir MoraNo ratings yet

- Site Preparation SelfServ 27Document34 pagesSite Preparation SelfServ 27Oleg IzvoreanuNo ratings yet

- Akai Dv-p4785kdsm DVD PlayerDocument50 pagesAkai Dv-p4785kdsm DVD PlayerhussainArifNo ratings yet

- TFB 180en102 PDFDocument8 pagesTFB 180en102 PDFJoseph BoshehNo ratings yet

- ZALUX Protected LED Luminaires WEB PDFDocument64 pagesZALUX Protected LED Luminaires WEB PDFopplusNo ratings yet

- Recommended Practices For Overfill Prevention For Shop-Fabricated Aboveground TanksDocument3 pagesRecommended Practices For Overfill Prevention For Shop-Fabricated Aboveground TanksHugo0% (1)

- PSP - Slides CH # 1 (Introdution To Protective Relaying)Document47 pagesPSP - Slides CH # 1 (Introdution To Protective Relaying)ejazabdurrehmanNo ratings yet

- Alexor Pc9155 InstallDocument88 pagesAlexor Pc9155 Installaoramos1506No ratings yet

- ABB-Fireman Switch PDFDocument4 pagesABB-Fireman Switch PDFhandaomeNo ratings yet

- M6 - Design Implementation: Prepared byDocument89 pagesM6 - Design Implementation: Prepared byNam ĐỗNo ratings yet

- 65 Series Lubricated OmDocument12 pages65 Series Lubricated Omalex_alfonso9407No ratings yet

- BWXDS 0-2.5 Bar PTB121 English Instalation ManualDocument6 pagesBWXDS 0-2.5 Bar PTB121 English Instalation ManualMaría VieiraNo ratings yet

- Power and Control Cable SpecificationDocument23 pagesPower and Control Cable SpecificationJithuRajNo ratings yet

- Fire Alarm Systems 2017NECDocument14 pagesFire Alarm Systems 2017NECDomingo Ruiz100% (1)

- 29352d1282876866 Wash File Cat Ecm Adem4 Adem2 Flash FileDocument237 pages29352d1282876866 Wash File Cat Ecm Adem4 Adem2 Flash FileDuy Kha100% (12)