Professional Documents

Culture Documents

Smith Fibercast CENTRICAST CL-1520 Piping

Uploaded by

DGWCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smith Fibercast CENTRICAST CL-1520 Piping

Uploaded by

DGWCopyright:

Available Formats

Bulletin No.

A1480

October 15, 2003

CENTRICAST

CL-1520

Piping Systems

CENTRICAST CL-1520 Pipe

PRODUCT

CENTRICAST CL-1520 pipe is

manufactured with high-strength glass

fabrics and a highly resilient formulation of corrosion resistant vinyl ester

resin. An inner liner of 50 mils of 100%

pure resin provides excellent corrosion

resistance. It is recommended for most

highly chlorinated or acidic mixtures up

to 175F and many other chemicals

up to 200F. Pipe and fittings are available in 112" through 14" diameters with

static pressure ratings up to 150 psig, with

higher pressure ratings in smaller sizes.

CENTRICAST CL-1520 pipe comes in 20

nominal or exact lengths.

EXTERNAL BARRIER

CL-1520 has a resin-rich corrosion barrier on the outside surface

which provides superior resistance

to exterior corrosion. CL-1520 also contains a UV inhibitor for protection

against fiber blooming caused by

ultraviolet radiation. Smith Fibercast

warrants CENTRICAST CL-1520 pipe and

fittings against reduction of physical and

corrosion ratings due to ultraviolet

exposure for a period of 15 years.

Refer to Chemical Resistance Guide,

Manual No. E5615 for proper application.

BENEFITS

A socket joining system connection is available for easy field assembly.

Fittings are equipped with consistent,

predetermined socket dimensions and

positive landing areas for the mating pipe

ends. Only thorough sanding of the pipe

O.D. and the mating fittings socket is

required prior to applying adhesive.

Adhesive joints are assembled using a

patented, high strength adhesive with

the same chemical and temperature

capabilities as the pipe and fittings.

The excellent chemical resistance

of CL-1520 fiberglass reinforced pipe

means a longer service life than pipe

made of traditional materials, especially

in acids and mixtures of chemicals.

The longer life means a reduction in

maintenance and replacement costs.

Compared to metallic piping systems, CL-1520 pipe can be installed

easier and faster, and heavy equipment

is seldom required. A considerable

savings on total installed cost may be

achieved because less labor and auxiliary equipment is required.

CL-1520 pipe offers the advantage

of light weight. For example, 4" CL1520 pipe weighs 1.70 lbs. per ft.

compared to 10.79 lbs. per ft. for 4"

Schedule 40 stainless. Therefore, a

20 ft. length of CL-1520 pipe weighs

only 34 lbs. while the same length of

Schedule 40 weighs 216 lbs. or six

times the weight of CL-1520 pipe.

FIELD JOINING

DISTRIBUTION

CL-1520 pipes easy-to-fabricate

joining system provides user friendly field fabrication with standard

contractor hand tools. The positive

stops in the fittings allow easy fabrication of complex pipe spools where

close tolerances are required. See

Manual No. F6080, Pipe Installation

Handbook, for installation instructions

and proper fabrication for your particular application.

Smith Fibercast has a network of

stocking distributors across the U.S.

as well as representatives and distributors in many other parts of the

world. These distributors are supported by a staff of experienced technical personnel at the home offices and

by highly trained, strategically located field personnel.

FITTINGS

Compatible vinyl ester fittings are

manufactured with the same chemical/

temperature capabilities as the pipe.

Depending on the particular part and size,

fittings will be compression molded,

contact molded, filament wound, or

hand fabricated.

JOINING METHODS

RECOMMENDED SERVICES

CENTRICAST CL-1520 vinyl ester

resin pipe is excellent for many chemical and slurry applications including

strong acids, chlorine and oxidizing

agents that corrode traditional metal pipe.

CENTRICAST CL-1520 Pipe

PIPE PROPERTIES

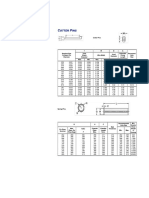

General Specifications and Dimensional Data*

Nominal

Pipe

Size

(In.)

1 12

2

3

4

6

8

10

12

14

*

Nominal

I.D.

(In.)

(mm)

1.52

2.00

3.12

4.12

6.21

8.15

10.3

12.3

13.5

Nominal

O.D.

(In.)

(mm)

38.6 1.90

50.7 2.38

79.2 3.50

105.0 4.50

158.0 6.63

207.0 8.63

261.0 10.75

312.0 12.75

343.0 14.00

48.3

60.3

88.9

114.0

168.0

219.0

273.0

324.0

356.0

Nominal

Wall

Thickness

(In.)

(mm)

0.19

0.19

0.19

0.19

0.21

0.24

0.24

0.24

0.24

4.8

4.8

4.8

4.8

5.3

6.1

6.1

6.1

6.1

Reinforcement

Thickness

(In.)

(mm)

0.13

0.13

0.13

0.13

0.15

0.18

0.18

0.18

0.18

3.3

3.3

3.3

3.3

3.8

4.6

4.6

4.6

4.6

Nominal

Weight

(Lbs./Ft.) (kg/m)

0.67

1.00

0.86

1.28

1.30

1.94

1.70

2.53

2.79

4.16

4.17

6.21

5.23

7.78

6.23

9.26

6.85 10.19

Capacity

(Gal./Ft.) (Cu. Ft./Ft.)

0.09

0.16

0.40

0.69

1.57

2.71

4.30

6.14

7.46

0.013

0.022

0.053

0.093

0.210

0.362

0.575

0.821

0.997

All values are nominal. Tolerances or maximum/minimum limits can be obtained from Smith Fibercast.

ASTM D2997 Designation Codes:

112 - 4

RTRP-22BT-4556

RTRP-22BT-4555

RTRP-22BT-4554

10 - 12

RTRP-22BT-4553

14

RTRP-22BT-4552

Pipe Lengths Available

Size

(In.)

Mechanical properties cell

classifications shown are

minimum. Actual classifications may be higher for some

sizes.

112 - 14

Length (Ft.)

20*

* Pipe is offered in random or

exact lengths. Random lengths

are from 15.0 to 20.4 feet long.

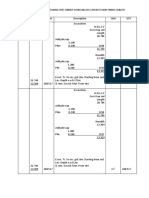

Pressure Ratings for Uninsulated Piping Systems (1)(2)

Nominal

Maximum External Pressure(6)

Max. Internal Pressure @ 175F (psig)

Pipe

Socket

Flanged

Other

Size

Pressure

Pressure

Pressure

(In.)

Fittings(3)

Fittings(4)

Fittings(5)

112

2

3

4

6

8

10

12

14

300

275

200

150

150

150

150

150

125

300

200

150

150

150

150

150

150

150

NA

125

125

100

100

100

75

75

NA

(1) Static pressure ratings, typically created with use of a gear pump, turbine pump, centrifugal pump, or multiplex pump having 4 or more

pistons, or elevation head.

(2) Reduce pressure ratings by 30% for 175 to 200F operating temperatures. For compressible gasses, insulated and/or heat traced piping systems, consult the factory for pressure ratings. CENTRICAST CL-1520

pipe and vinyl ester fittings can be used in drainage and vent systems

up to 200F. Heat cured adhesive joints are highly recommended for

all piping systems carrying fluids at temperatures above 120F.

@ 75F

@150F

650

380

130

50

30

25

16

10

7

579

268

74

33

21

17

13

8

5

@ 175F

491

227

63

28

17

14

11

7

4

(3) Socket elbows, tees, reducers, couplings, flanges and nipples joined

with WELDFAST CL-200 adhesive.

(4) Flanged elbows, tees, reducers, couplings and nipples assembled at factory.

(5) Laterals, crosses, saddles and grooved nipples.

(6) Ratings shown are 50% of ultimate. 14.7 psi external pressure is equal

to full vacuum.

NA = Not available at time of printing.

CENTRICAST CL-1520 Pipe

Average Physical Properties(1)

Property

Nominal Size

@ 75 F/ @ 24 C

psi

MPa

Nominal Size

@ 150 F/ @ 66 C

psi

MPa

Nominal Size

@ 175 F/ @ 80 C

psi

MPa

30,000

7,500

210

52

26,000

6,500

180

45

25,000

6,250

170

43

2.6E+06

17900

2.3E+06

15900

2..2E+06

15200

Axial Tensile ASTM D2105

Ultimate Stress

Design Stress

Modulus of Elasticity

Poissons Ratio

0.15

0.15

0.15

Axial Compression ASTM D695

Ultimate Stress

Design Stress

Modulus of Elasticity

32,000

8,000

220

55

30,000

7,500

200

52

22,000

5,500

150

38

3.1E+06

21400

2.7E+06

18600

2.6E+06

17900

40,000

5,000

280

34

35,000

4,375

240

30

33,000

4,125

230

28

3.3E+06

22800

2.9E+06

20000

2.8E+06

19300

Beam Bending ASTM D2925

Ultimate Stress

Design Stress

Modulus of Elasticity (long term)

Hydrostatic Burst ASTM D1599

Ultimate Hoop Tensile Stress

Hoop Tensile Modulus of Elasticity

30,000

200

26,000

180

25,000

170

2.4E+06

17000

2.1E+06

14500

2.0E+06

13800

11,690

81

Hydrostatic Design ASTM D2992,

Procedure B Hoop Tensile Stress

Static 50 Year @ 175F

Coefficient of Linear Thermal Expansion

ASTM D696

Non-Insulated Pipe:

Insulated Pipe:

8.4 x 10-6 in./in./F

9.2 x 10-6 in./in./F

15.2x10-6 mm/mmC

16.6x10-6 mm/mmC

Thermal Conductivity

0.07 BTU/(ft)(hr)(F)

0.04 W/(m)(C)

Specific Gravity (Density)

152 (0.055 Lb/in.3)

(1.52 g/cm3)

Hazen-Williams Flow Factor

C-150

1.7 x 10-5 Feet

Surface Roughness

Mannings n

0.009

(1) Stress and modulus values can be interpolated between temperatures shown. Consult the factory for Modulus of Elasticity values between 175F and 200F.

Properties of Pipe Sections Based on

Minimum Reinforced Walls

Size

(In.)

Reinforcement

End Area (In.2)

Reinforcement

Moment of Inertia (In.4)

112

2

3

4

6

8

10

12

14

0.72

0.92

1.38

1.79

3.05

4.78

5.98

7.11

7.82

0.29

0.58

1.96

4.26

16.00

42.60

83.50

140.00

187.00

Reinforcement

Total Wall

Section Modulus (In.3) End Area (In.2)

0.30

0.49

1.12

1.90

4.83

9.88

15.50

22.00

26.70

1.02

1.30

1.98

2.57

4.23

6.32

7.92

9.43

10.40

CENTRICAST CL-1520 Pipe

Recommended Operating Ratings(1)

Axial

Tensile Loads

Max. (Lbs.)

Size

(In.)

Axial Compressive

Loads

Bending

Radius

Max. (Lbs.)(2)

Min. (Ft.)

Entire

@

@

Temp.

75 F 175F(1)(2) Range

Torque

Max.

(Ft.Lbs.)

Entire

Temp.

Range

Parallel Plate Loading(3)

@ 5% Deflection & 75F

ASTM D2412

Stiffness

Pipe

Hoop

Factor

Stiffness Modulus

In.3Lbs./In.2 (psi)

x 106 (psi)

@

75 F

@

175F(1)

112

5,400

4,500

5,800

4,000

52

125

366

3,545

2.0

6,900

5,700

7,300

5,000

65

203

366

1,738

2.0

10,300

8,600

11,000

7,600

96

466

458

642

2.5

13,400

11,200

14,300

9,800

124

790

458

294

2.5

22,900

19,100

24,400

16,800

182

2,013

788

156

2.8

35,800

29,800

38,200

26,300

237

4,115

1,264

113

2.6

10

44,800

37,400

47,800

32,900

296

6,473

1,458

66

3.0

12

53,300

44,400

56,900

39,100

351

9,178

1,652

45

3.4

14

58,600

48,800

62,500

43,000

385

11,108

1,652

34

3.4

(1) Consult the factory for design recommendations above 175F.

(2) Compressive loads are for short columns only. Buckling loads

must be calculated when applicable.

(3) Burial calculations must be based on 5% deflection as shown in

table above.

SUPPORTS

4 Avoid point contact loads.

5 Avoid excessive bending. This applies to handling, transporting, initial layout, and final installed position.

6 Avoid excessive vertical run loading. Vertical loads

should be supported sufficiently to minimize bending

stresses at outlets or changes in direction.

The following engineering analysis must be performed to

determine the maximum support spacing for the piping system. Proper pipe support spacing depends on the temperature and weight of the fluid carried in the pipe. The support

spacing is calculated using continuous beam equations and

the pipe bending modulus derived from long-term beam

bending tests. The following tables were developed to ensure

a design that limits beam mid-span deflection to 12 inch and

bending stresses to less than or equal to 1/8 of the ultimate

bending stress. Any additional weight on the piping system

such as insulation or heat tracing requires further consideration. Restrained (anchored) piping systems operating at elevated temperatures often result in guide spacing requirements that are more stringent than simple unrestrained piping systems. In this case, the maximum guide spacing will

dictate the support/guide spacing requirements for the system. Pipe support spans at changes in direction require special attention. Supported and unsupported fittings at

changes in direction are considered in the following tables

and must be followed to properly design the piping system.

Maximum Support Spacing

for Uninsulated Pipe*

Continuous Spans of Pipe (Ft.)

Specific Gravity=1.0, Deflection=12

There are six basic rules to follow when designing piping

system supports, anchors, and guides:

1 Do not exceed the recommended support span.

2 Support valves and heavy in-line equipment independently . This applies to both vertical and horizontal piping.

3 Protect pipe from external abrasion.

Nom.

Pipe Size

(In.)

Temperature

75F

150F

175F

112

2

3

4

6

8

10

12

14

16.4

17.6

19.9

21.4

24.7

27.7

29.4

30.8

31.6

15.8

17.0

19.2

20.7

23.9

26.8

28.5

29.8

30.6

15.7

16.9

19.1

20.5

23.7

26.5

28.2

29.5

30.3

Consult factory for spans above 175F or for insulated pipe

support spacing.

CENTRICAST CL-1520 Pipe

Support Spacing vs. Specific Gravity

Specific

Gravity

3.00

2.00

1.50

1.25

1.00

0.75

Gas/Air

Multiplier

0.76

0.84

0.90

0.95

1.00

1.07

1.40

Example: 6 pipe @ 150F with 1.5 specific gravity fluid, maximum support spacing = 22.5 x 0.9 = 20.2 ft.

Piping Span Adjustment Factors

With Supported Fitting at Change in

Direction

Piping Span Adjustment Factors

With Unsupported Fitting at

Change in Direction

Span Type

Type of Span

Factor

Adjustment Factor

Continuous interior or fixed end spans

1.00

Continuous interior or fixed end spans

1.00

Second span from simple supported

end or unsupported fitting

0.80

Span at supported fitting or span adjacent

to a simple supported end

0.80

c+d

Sum of unsupported spans at fitting

< 0.75*

Simple supported end span

0.67

Simple supported end span

0.67

*For example: If continuous support span is 10 ft., c + d must not

exceed 7.5 ft. (c = 3 ft. and d = 4.5 ft. would satisfy this condition).

THERMAL EXPANSION

Four methods are as follows:

To determine the effects of expansion and contraction

within a piping system, it is necessary to know the following:

1. Direction Changes

2. Restrained End

Installation

1. The design temperature conditions,

2. The type and size of pipe,

3. The layout of the system, including dimensions and the

thermal movements, if any, of the terminal points.

4. The limitations on end reactions at terminal points as

established by equipment manufacturers.

5. The temperature changes for expansion are calculated by

subtracting the installation temperature (temperature at

time of final tie in) from the maximum design temperature. Temperature changes for contraction are calculated

by subtracting the minimum design temperature from

the installation temperature.

3. Mechanical Expansion Joints

4. Expansion Loops

Guides, mechanical expansion joints, and expansion

loops are installed in straight pipe lines that are anchored at

both ends.

The experience of users of Smith Fibercast piping systems

has shown that if direction changes cannot be used to

accommodate thermal expansion and contraction, then

guide spacing is usually the most economical method.

Expansion and contraction of above ground fiberglass

pipe may be handled by several different methods.

CENTRICAST CL-1520 Pipe

Unrestrained

Thermal Expansion

Uninsulated Pipe(1)

Change in

Temperature

(F)

Restrained Thermal Expansion

Pipe Compressive End Loads

Uninsulated Pipe(1)

Pipe Change

in Length

(In./100 Ft.)

25

50

75

100

125

150

175

200

Allowable

Bending Moment

90 Elbow

Nominal

End

Nominal

End

Pipe Size Loads Pipe Size Loads

(in)

(Lbs./F)

(in)

(Lbs./F)

0.25

0.50

0.76

1.01

1.26

1.51

1.76

2.02

Nominal Allowable Nominal Allowable

Pipe Size Moment Pipe Size Moment

(in)

(FtLbs.)

(in)

(FtLbs.)

112

18.8

124.4

112

150

2,850

23.9

10

155.6

225

10

4,500

35.8

12

185.1

475

12

6,500

46.5

14

203.5

650

14

10,000

79.5

1,650

(1) Consult the factory for thermal expansion and

compressive end loads of insulated pipe.

Maximum Guide Spacing for Restrained Thermal End Loads (Feet)

Nominal

Pipe Size

(In.)

25

50

75

Temperature Change F*

100

125

150

175

200

1 2

10.8

7.6

6.2

5.4

4.8

4.4

4.1

3.8

13.7

9.7

7.9

6.8

6.1

5.6

5.2

4.8

20.5

14.5

11.8

10.2

9.2

8.4

7.7

7.2

26.5

18.8

15.3

13.3

11.9

10.8

10.0

9.4

39.3

27.8

22.7

19.7

17.6

16.1

14.9

13.9

51.3

36.3

29.6

25.6

22.9

20.9

19.4

18.1

10

64.2

45.4

37.1

32.1

28.7

26.2

24.3

22.7

12

76.3

54.0

44.1

38.2

34.1

31.2

28.8

27.0

14

83.9

59.3

48.4

41.9

37.5

34.3

31.7

29.7

*Note: Temperature Change = Maximum Fluid Temperature - Installation Temperature.

Expansion Loop Minimum Leg Length (Feet)

Total Deflection to be Absorbed (inches)

Size (In.)

1/2

112

2

3

4

6

8

10

12

14

2.6

2.9

3.5

4.3

5.3

6.5

7.3

7.9

7.3

3.6

4.0

4.9

6.1

7.5

9.3

10.3

11.1

10.3

2

5.1

5.7

6.9

8.7

10.5

13.1

14.6

15.7

14.6

3

6.3

7.0

8.5

10.6

12.9

16.0

17.9

19.3

17.9

4

7.2

8.1

9.8

12.3

14.9

18.5

20.6

22.3

20.7

8.1

9.0

11.0

13.7

16.7

20.7

23.1

24.9

23.1

8.9

9.9

12.0

15.0

18.3

22.7

25.3

27.3

25.3

9.6

10.7

13.0

16.2

19.7

24.5

27.3

29.4

27.4

Note: Multiply expansion loop minimum leg length by 1.414 for directional change contilever leg length.

8

10.2

11.4

13.9

17.3

21.1

26.2

29.2

31.5

29.2

10

10.8

12.1

14.7

18.4

22.4

27.8

30.9

33.4

31.0

11.4

12.8

15.5

19.4

23.6

29.3

32.6

35.2

32.7

CENTRICAST CL-1520 Pipe

TESTING

See Section 3 of Smith Fibercast Manual No. F6080, Pipe

Installation Handbook: Hydrostatic Testing and System Start

Up.

Whenever possible, Smith Fibercast piping systems

should be hydrostatically tested prior to being put into

service. Care should be taken when testing, as in actual

installation, to avoid water hammer. All anchors, guides

and supports must be in place prior to testing the line.

Test pressure should not be more than 112 times the

working pressure of the piping system and never exceed 112

times the rated operating pressure of the lowest rated component in the system.

OTHER CONSIDERATIONS

Fluid (Water) Hammer

When flow suddenly starts or stops, by pump startup or by

a quick closing valve, a high pressure surge can be created.

The maximum pressure surge in psig caused by water hammer can be calculated by multiplying the fluid velocity in

ft./sec. times the constant listed in this table. The instantaneous

peak pressure for the system will equal the water hammer surge

plus the pressure in the system at the time the water hammer

occurred.

Fluid hammer high pressure surge can be significantly

reduced by controlling pump startup and valve closure

rates.

Fluid (Water) Hammer

Constants(1)

Nominal

Nominal

Pipe Size

Pipe Size

(in)

Constants

(in)

Constants

112

40.5

24.6

37.2

10

22.3

31.8

12

20.6

28.5

14

19.7

25.6

(1) Constants

are valid for

water at 75F.

It is the policy of Smith Fibercast to improve its products continually. In accordance with that policy, the right is

reserved to make changes in specifications, descriptions, and illustrative material contained in this bulletin as conditions warrant. The information contained herein is general in nature and is not intended to express any warranty of

any type whatsoever, nor shall any be implied.

P.O. Box 968 25 South Main Sand Springs, OK 74063

(800) 331-4406 or (918) 245-6651 Fax: (Local/International) (918) 245-7566 Fax: (800) 365-7473

2700 West 65th Street Little Rock, AR 72209

(501) 568-4010 Fax: (501) 568-4465

http://www.smithfibercast.com

and Trademarks of Varco I/P Inc.

Copyright 2003, Varco L.P.

PRINTED IN USA, 5M, 1003

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- What Is Sealcoating - Asphalt Sealcoating - Seal CoatDocument2 pagesWhat Is Sealcoating - Asphalt Sealcoating - Seal CoatDGWNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Overkote Asphalt Pavement Coating: DescriptionDocument1 pageOverkote Asphalt Pavement Coating: DescriptionDGWNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Masonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)Document2 pagesMasonry, Stucco & Brick Paints: Z - Xghiiify06991Tz)DGWNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- He130 - Driveway Asphalt Coating: Physical PropertiesDocument2 pagesHe130 - Driveway Asphalt Coating: Physical PropertiesDGWNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Wood Finishing Basics: Application Techniques & Product SelectionDocument13 pagesWood Finishing Basics: Application Techniques & Product SelectionDGWNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- Nord-Lock Washers: The Original Wedge-Locking SolutionDocument16 pagesNord-Lock Washers: The Original Wedge-Locking SolutionDGWNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 01 04tocDocument428 pages01 04tocFaltooNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Schedule 80 Pipe Dimensions & Pressure RatingsDocument1 pageSchedule 80 Pipe Dimensions & Pressure RatingsDGWNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Lee Spring CatalogDocument391 pagesLee Spring CatalogDGWNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Standard Pipe Sizes ME303-4.1.1Document5 pagesStandard Pipe Sizes ME303-4.1.1manashbdNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Flat Washer and FastenersDocument49 pagesFlat Washer and FastenersDGWNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- D-01 7041 Flange-ANSI 125,150-RevlDocument4 pagesD-01 7041 Flange-ANSI 125,150-RevlJohanna RojasNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- CAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDocument1 pageCAD-012854 - ROMAC 612 PIPE RESTRAINT FOR C905 PVCDGWNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Pipe Chart PDFDocument2 pagesPipe Chart PDFCarlos Rivera0% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- PVC Gravity Sewer PipeDocument1 pagePVC Gravity Sewer PipeDGWNo ratings yet

- Bolt - Astm A449Document2 pagesBolt - Astm A449DGWNo ratings yet

- Technical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDocument2 pagesTechnical Note 812 - : MJ Adapter Connections Performance Pipe MJ AdaptersDGWNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Thrust Restraint For Expansion JointDocument2 pagesThrust Restraint For Expansion JointDGWNo ratings yet

- The First Hillside Washer That Eliminated Back-Up Plates!Document1 pageThe First Hillside Washer That Eliminated Back-Up Plates!DGWNo ratings yet

- Rubber Expansion JointsDocument9 pagesRubber Expansion JointsDGWNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tap Drill ChartDocument2 pagesTap Drill ChartDGWNo ratings yet

- Steel Rebar SizesDocument1 pageSteel Rebar SizesDGWNo ratings yet

- Threaded Rod AccessoriesDocument1 pageThreaded Rod AccessoriesDGWNo ratings yet

- Countersinking Drill Bit ReamerDocument1 pageCountersinking Drill Bit ReamerDGWNo ratings yet

- Tap Drill DataDocument1 pageTap Drill DataDGWNo ratings yet

- JLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDocument2 pagesJLRQQB JLRQQ - JLRQJRLL JLRQQK JLRQQC JLRQMQ JLRQMM JLRQMJ JLRQMRDGWNo ratings yet

- Cotter Pins and Spring PinsDocument1 pageCotter Pins and Spring PinsDGWNo ratings yet

- Screw Threads DesignDocument1 pageScrew Threads DesignDGWNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Standard Pipe Schedules and Sizes ChartDocument1 pageStandard Pipe Schedules and Sizes ChartDGWNo ratings yet

- Introduction to Civil EngineeringDocument157 pagesIntroduction to Civil EngineeringXaviorOuseph100% (4)

- Instrumentation in TunnelsDocument14 pagesInstrumentation in Tunnelssravan_ruby100% (2)

- Granular PilesDocument16 pagesGranular Pilessgaluf5No ratings yet

- BS 743 Specification For Materials For Damp-Proof CoursesDocument12 pagesBS 743 Specification For Materials For Damp-Proof CoursesTranタオNo ratings yet

- School of Electrical Engineering and Computer Science Time TableDocument5 pagesSchool of Electrical Engineering and Computer Science Time TableJunaidZafarNo ratings yet

- EIT Adv Dip Mechanical Engineering TechnologyDocument33 pagesEIT Adv Dip Mechanical Engineering TechnologyAnsar Ali100% (1)

- Tutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklDocument11 pagesTutorial 2 (Basic) : Pin/Lug Assembly: 5Dplq5LdklIbnu RiswanNo ratings yet

- Mechanisation and Automation Evolution of Automation Goals and Applications of AutomationDocument7 pagesMechanisation and Automation Evolution of Automation Goals and Applications of AutomationRifat RashidNo ratings yet

- Earthquake Resistant BuildingsDocument16 pagesEarthquake Resistant BuildingsArnold TunduliNo ratings yet

- Ansi Asabe S366.2 May2004 (Iso 5675-1992) (R2009)Document3 pagesAnsi Asabe S366.2 May2004 (Iso 5675-1992) (R2009)StephanNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Department of Architecture Urban Planning 1 Assignment 2: by Bethelhem Getnet To Yirsaw ZegeyeDocument8 pagesDepartment of Architecture Urban Planning 1 Assignment 2: by Bethelhem Getnet To Yirsaw Zegeyefitsum tesfayeNo ratings yet

- Elements of Civil EngineeringDocument62 pagesElements of Civil EngineeringShubhamNo ratings yet

- Standard Welded Beams Dimensions and PropertiesDocument35 pagesStandard Welded Beams Dimensions and PropertiesKmt_Ae100% (2)

- Ramyasri Email BrochureDocument6 pagesRamyasri Email BrochureADITYA RAMADUGULANo ratings yet

- MADE EASY GATE 2019 Rank Predictor - Rank Calculator and EstimatorDocument40 pagesMADE EASY GATE 2019 Rank Predictor - Rank Calculator and EstimatorGiridhari ChandrabansiNo ratings yet

- Geometry and Dimensional Tolerances of Engine BearingsDocument8 pagesGeometry and Dimensional Tolerances of Engine BearingsAnonymous K3FaYFlNo ratings yet

- WileyCMOS Circuit Design, Layout, and Simulation, 3rd EditionDocument2 pagesWileyCMOS Circuit Design, Layout, and Simulation, 3rd EditionRoshdy AbdelRassoulNo ratings yet

- Christian's Declassified RIT Survival GuideDocument17 pagesChristian's Declassified RIT Survival Guideapi-341474413No ratings yet

- Outcome 1: Define, Investigate and Analyse Complex Engineering ProblemsDocument3 pagesOutcome 1: Define, Investigate and Analyse Complex Engineering ProblemsThobadingoe PhokaneNo ratings yet

- DrillCAP AnnouncementDocument4 pagesDrillCAP AnnouncementremoNo ratings yet

- Tugas 1Document2 pagesTugas 1Laisa HusrainiNo ratings yet

- Mining EquipmentDocument11 pagesMining EquipmentKaushalendra Kumar Singh100% (1)

- ContractDocument12 pagesContractNor Syazwani SharudinNo ratings yet

- BEng EEDocument12 pagesBEng EEJimmy NeoNo ratings yet

- Binu George CVDocument5 pagesBinu George CVUmed UnnikrishnanNo ratings yet

- Basic Engineering Circuit Analysis 10thDocument185 pagesBasic Engineering Circuit Analysis 10thGustavoNo ratings yet

- Curriculum Vitae: Bio DataDocument3 pagesCurriculum Vitae: Bio DataMwesigye Batatwenda Peterson100% (1)

- Carter Variator CatDocument40 pagesCarter Variator CatMatias MancillaNo ratings yet

- Resume Electrical Engineer HR-Ref#EE-SSM-1602 GLPT April 28 2016Document2 pagesResume Electrical Engineer HR-Ref#EE-SSM-1602 GLPT April 28 2016Bishwa Pokharel0% (1)

- Bachelor of Civil Engineering - An Official Site of Pokhara UniversityDocument1 pageBachelor of Civil Engineering - An Official Site of Pokhara UniversityaayushNo ratings yet

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)