Professional Documents

Culture Documents

Bulbflat Specification

Uploaded by

Toia ValentinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulbflat Specification

Uploaded by

Toia ValentinCopyright:

Available Formats

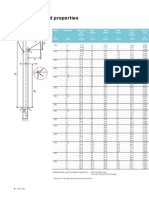

Dimensions and properties

Dimensions and properties

Width

Thickness

b

[mm]

t

[mm]

120

140

160

180

200

220

240

260

280

300

320

340

370

400

430

6

7

8

6.5

7

8

10

7

8

9

11.5

8

9

10

11.5

8.5

9

10

11

12

9

10

11

12

9.5

10

11

12

10

11

12

10.5

11

12

13

11

12

13

11.5

12

13

14

12

13

14

15

12.5

13

14

15

16

13

14

15

16

14

15

17

20

Mass per

Unit

Length

G

[kg/m]

Bulb

Height

Bulb

Width

Bulb

Radius

c

[mm]

d

[mm]

7.31

8.25

9.19

9.21

9.74

10.8

13.0

11.4

12.7

14.0

17.3

14.8

16.2

17.6

19.7

17.8

18.5

20.1

21.7

23.2

21.0

22.8

24.5

26.2

24.4

25.4

27.4

29.3

28.3

30.3

32.4

32.4

33.5

35.7

37.9

36.7

39.0

41.5

41.2

42.5

45.0

47.5

46.1

48.8

51.5

54.2

53.1

54.6

57.5

60.5

63.5

60.8

63.9

67.0

70.2

70.6

73.9

80.6

90.8

17

17

17

19

19

19

19

22

22

22

22

25

25

25

25

28

28

28

28

28

31

31

31

31

34

34

34

34

37

37

37

40

40

40

40

43

43

43

46

46

46

46

49

49

49

49

53.5

53.5

53.5

53.5

53.5

58

58

58

58

62.5

62.5

62.5

62.5

17.7

17.7

17.7

19.7

19.7

19.7

19.7

22.2

22.2

22.2

22.2

25.5

25.5

25.5

25.5

28.8

28.8

28.8

28.8

28.8

32.1

32.1

32.1

32.1

35.4

35.4

35.4

35.4

38.7

38.7

38.7

42.0

42.0

42.0

42.0

45.3

45.3

45.3

48.6

48.6

48.6

48.6

52.0

52.0

52.0

52.0

56.9

56.9

56.9

56.9

56.9

61.9

61.9

61.9

61.9

66.8

66.8

66.8

66.8

Additional sizes may be available by agreement:

80 & 100 DIN range

180, 200, 230 and 250 JIS range

* Values for H are taken about the line of attachment.

8 Bulb flats

Surface

Area

r

[mm]

Area of

crosssection

F

[cm2]

5

5

5

5.5

5.5

5.5

5.5

6

6

6

6

7

7

7

7

8

8

8

8

8

9

9

9

9

10

10

10

10

11

11

11

12

12

12

12

13

13

13

14

14

14

14

15

15

15

15

16.5

16.5

16.5

16.5

16.5

18

18

18

18

19.5

19.5

19.5

19.5

9.31

10.5

11.7

11.7

12.4

13.8

16.6

14.6

16.2

17.8

21.8

18.9

20.7

22.5

25.2

22.6

23.6

25.6

27.6

29.6

26.8

29.0

31.2

33.4

31.2

32.4

34.9

37.3

36.1

38.7

41.3

41.2

42.6

45.5

48.4

46.7

49.7

52.8

52.6

54.2

57.4

60.6

58.8

62.2

65.5

69.0

67.8

69.6

73.3

77.0

80.7

77.4

81.4

85.4

89.4

89.7

94.1

103.0

115.0

0.276

0.278

0.280

0.319

0.320

0.322

0.326

0.365

0.367

0.369

0.374

0.411

0.413

0.415

0.418

0.456

0.457

0.459

0.461

0.463

0.501

0.503

0.505

0.507

0.546

0.547

0.549

0.551

0.593

0.593

0.595

0.636

0.637

0.639

0.641

0.681

0.683

0.685

0.727

0.728

0.730

0.732

0.772

0.774

0.776

0.778

0.839

0.840

0.842

0.844

0.846

0.907

0.908

0.910

0.912

0.975

0.976

0.980

0.986

U

[m2/m]

Dimensions and properties

Distance of

Centre of Gravity

dx

[mm]

72.0

70.7

69.6

83.7

83.1

81.8

79.2

96.6

94.9

93.6

91.1

109

107

106

104

122

121

119

118

117

136

134

132

130

148

147

146

144

162

160

158

175

174

172

170

189

187

185

202

201

199

197

215

213

211

209

236

235

232

230

228

258

255

252

250

277

274

269

263

dy

[mm]

5.3

5.6

6.0

5.8

5.9

6.3

7.0

6.4

6.8

7.1

8.1

7.4

7.7

8.1

8.6

8.2

8.4

8.7

9.0

9.4

9.1

9.3

9.6

10.0

9.9

10.0

10.3

10.6

10.7

11.0

11.3

11.6

11.7

11.9

12.2

12.4

12.6

12.9

13.3

13.4

13.6

13.9

14.1

14.3

14.6

14.8

15.4

15.4

15.6

15.9

16.1

16.6

16.8

17.0

17.2

17.9

18.1

18.5

19.3

Second Moment

of Area

Axis

x-x

[cm4]

133

148

164

228

241

266

316

373

411

448

544

609

665

717

799

902

941

1020

1090

1160

1296

1400

1500

1590

1800

1860

2000

2130

2477

2610

2770

3223

3330

3550

3760

4190

4460

4720

5370

5530

5850

6170

6760

7160

7540

7920

9213

9470

9980

10490

10980

12280

12930

13580

14220

16460

17260

18860

21180

Axis

y-y

[cm4]

2.34

2.70

3.10

3.57

3.80

4.32

5.56

5.86

6.55

7.32

9.62

9.90

10.93

12.05

13.93

15.07

15.76

17.21

18.77

20.46

22.03

23.89

25.86

27.98

31.15

32.34

34.81

37.43

42.84

45.90

49.11

57.55

59.44

63.34

67.42

75.74

80.44

85.33

97.92

100.8

106.6

112.6

124.6

131.5

138.6

145.9

172.3

176.7

185.7

194.8

204.3

232.4

243.6

255.0

266.6

313.9

327.9

356.7

402.6

Elastic Modulus

Axis

x-x

[cm3]

18.4

21.0

23.6

27.3

29.0

32.5

39.9

38.6

43.3

47.9

59.8

55.9

62.1

67.8

76.8

74.0

77.7

85.0

92.3

99.6

95.3

105

113

122

123

126

137

148

153

162

175

184

191

206

221

222

239

256

266

274

294

313

313

335

357

379

390

402

428

455

481

476

507

537

568

594

628

700

804

Radius of Gyration

Axis

y-y

[cm3]

Axis

x-x

[cm]

4.42

4.82

5.17

6.16

6.44

6.86

7.94

9.16

9.63

10.3

11.9

13.4

14.2

14.9

16.2

18.4

18.8

19.8

20.9

21.8

24.2

25.7

26.9

28.0

31.5

32.3

33.8

35.3

40.0

41.7

43.5

49.6

50.8

53.2

55.3

61.1

63.8

66.1

73.6

75.2

78.6

81.0

88.4

92.0

94.9

98.6

112

115

119

123

127

140

145

150

155

175

181

193

209

3.78

3.75

3.74

4.41

4.41

4.39

4.36

5.05

5.04

5.02

5.00

5.68

5.67

5.65

5.63

6.32

6.31

6.31

6.28

6.26

6.95

6.95

6.93

6.90

7.60

7.58

7.57

7.56

8.28

8.21

8.19

8.84

8.84

8.83

8.81

9.47

9.47

9.45

10.10

10.10

10.10

10.09

10.72

10.73

10.73

10.71

11.66

11.66

11.67

11.67

11.66

12.60

12.60

12.61

12.61

13.55

13.54

13.53

13.57

Axis

y-y

[cm]

0.50

0.51

0.51

0.55

0.55

0.56

0.58

0.63

0.64

0.64

0.66

0.72

0.73

0.73

0.74

0.82

0.82

0.82

0.82

0.83

0.91

0.91

0.91

0.92

1.00

1.00

1.00

1.00

1.09

1.09

1.09

1.18

1.18

1.18

1.18

1.27

1.27

1.27

1.36

1.36

1.36

1.36

1.46

1.45

1.45

1.45

1.59

1.59

1.59

1.59

1.59

1.73

1.73

1.73

1.73

1.87

1.87

1.86

1.87

Warping

Constant

Torsional

Constant

H*

[cm6(x103)]

J

[cm4]

0.242

0.251

0.263

0.504

0.508

0.528

0.575

1.12

1.16

1.20

1.31

2.45

2.51

2.58

2.71

4.67

4.72

4.83

4.93

5.09

8.64

8.80

8.98

9.18

14.8

14.9

15.3

15.6

24.7

25.0

25.4

39.0

39.2

40.1

41.0

59.9

60.5

61.8

89.9

90.3

91.2

92.3

131

132

133

135

221

221

223

225

227

357

359

362

364

557

562

576

570

1.595

2.100

2.773

2.383

2.708

3.501

5.752

3.681

4.600

5.763

9.936

6.352

7.686

9.328

12.44

9.129

9.924

11.70

14.00

16.65

13.24

15.31

17.81

20.76

18.16

19.37

22.46

25.73

25.03

28.09

31.68

33.05

34.80

39.19

44.25

43.25

47.55

53.06

56.02

58.45

63.86

70.06

71.17

77.02

83.00

91.30

97.66

100.7

108.1

116.6

126.0

131.0

139.3

148.7

159.6

176.6

187.9

215.6

252.6

Bulb flats

Technical data

Tolerances & Steel Specifications

Tolerances (In accordance with BS EN 10067:1997)

1. Dimensional Variation - All Dimensions in mm

Width b

Thickness t

Over

Up to

Permitted Variation

From

Up to

Permitted Variation

120

1.5

+ 0.7 - 0.3

120

180

2.0

11

+ 1.0 - 0.3

180

300

3.0

13

+ 1.0 - 0.4

300

430

4.0

12

20

+ 1.2 - 0.4

Improved tolerances may be available by agreement

Radius of curvature of corners

r1 for thicknesses

Over

Up to

Max.

-

1.5

2.0

13

3.0

13

20

4.0

2. Weight Variation

The weights shown in the tables have been calculated from the cross section with a density of 0.785

kilogram per square centimetre per metre run.

Permitted weight variations:

+6.0% - 2.0% of the total weight for consignments of 5 tonnes and over.

+8.0% - 2.7% of the total weight for consignments under 5 tonnes.

3. Straightness Variation in Accordance with BS EN 10067: 1997

Straightness tolerance q shall be 0.0035 L (the entire length of the bar)

Improved straightness tolerances may be available by agreement

Steel specifications

1. Shipbuilding

Classification Society

A32/36*

D32/36*

Lloyds

DNV

ABS

BV

GL

Class NK

RINA

D40

F**

F = Full approval O = Approval obtained on an order by order basis

* = Equivalent to AH32/36 and DH 32/36 for Lloyds Register.

Equivalent to KA 32/36 and KD 32/36 for class NK.

**

up to 12mm thickness

2. Construction

Bulb flats are available in a range of steel grades suitable for bridge construction in accordance with BS

EN 10025: 1993 and BS EN 10113-3 S420M (upto 12mm thickness)

10 Bulb flats

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Sipn Toia ValentinDocument27 pagesSipn Toia ValentinToia ValentinNo ratings yet

- CV-Toia Valentin PDFDocument3 pagesCV-Toia Valentin PDFToia ValentinNo ratings yet

- CV-Toia Valentin PDFDocument3 pagesCV-Toia Valentin PDFToia ValentinNo ratings yet

- Necula Petrica CFDDocument60 pagesNecula Petrica CFDToia ValentinNo ratings yet

- Necula Petrica CFDDocument60 pagesNecula Petrica CFDToia ValentinNo ratings yet

- Necula Petrica CFDDocument60 pagesNecula Petrica CFDToia ValentinNo ratings yet

- D230 XML 2019 28012020try PDFDocument1 pageD230 XML 2019 28012020try PDFToia ValentinNo ratings yet

- In Valea UmbreiDocument2 pagesIn Valea UmbreiToia ValentinNo ratings yet

- Bulbflat SpecificationDocument3 pagesBulbflat SpecificationToia ValentinNo ratings yet

- Tabel Studenti An 1 Master 2018-2019Document2 pagesTabel Studenti An 1 Master 2018-2019Toia ValentinNo ratings yet

- TM 2102 AVEVA Marine 12 1 Hull Detailed Design Planar Hull Modelling Rev 4 1 PDFDocument186 pagesTM 2102 AVEVA Marine 12 1 Hull Detailed Design Planar Hull Modelling Rev 4 1 PDFToia ValentinNo ratings yet

- TM 2102 AVEVA Marine 12 1 Hull Detailed Design Planar Hull Modelling Rev 4 1Document21 pagesTM 2102 AVEVA Marine 12 1 Hull Detailed Design Planar Hull Modelling Rev 4 1Toia ValentinNo ratings yet

- Vibration Measurement Report: Vibration Measurements For Soc (Statement of Compliance) On Board Vessels According ToDocument7 pagesVibration Measurement Report: Vibration Measurements For Soc (Statement of Compliance) On Board Vessels According ToToia ValentinNo ratings yet

- Produced by An Autodesk Educational Product: KitchenDocument1 pageProduced by An Autodesk Educational Product: KitchenToia ValentinNo ratings yet

- Diargame RezistentaDocument17 pagesDiargame RezistentaToia ValentinNo ratings yet

- Ibp ProectDocument2 pagesIbp ProectToia ValentinNo ratings yet

- Pharmacy Letter of Intent InternshipDocument2 pagesPharmacy Letter of Intent InternshipToia ValentinNo ratings yet

- Probleme Rezolvate AlgadDocument3 pagesProbleme Rezolvate AlgadCristian Giorgian LovinNo ratings yet

- Preliminary Estimation Codes of Propeller Performances: Prof. M.G. Parsons, University of Michigan, USADocument6 pagesPreliminary Estimation Codes of Propeller Performances: Prof. M.G. Parsons, University of Michigan, USAToia ValentinNo ratings yet

- Vasa Museum: How Vasa Was BuiltDocument5 pagesVasa Museum: How Vasa Was BuiltToia ValentinNo ratings yet

- D100 XML v122 2013Document1 pageD100 XML v122 2013Toia ValentinNo ratings yet

- New Document Microsoft WordDocument1 pageNew Document Microsoft WordToia ValentinNo ratings yet