Professional Documents

Culture Documents

MSDS - Robond L-330 - ISS130910

Uploaded by

Anonymous pXU4tefJCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MSDS - Robond L-330 - ISS130910

Uploaded by

Anonymous pXU4tefJCopyright:

Available Formats

Material Safety Data Sheet

1. PRODUCT AND COMPANY IDENTIFICATION

ROBOND L-330 EMULSION

Revision Date:

Supplier

01/15/2013

THE DOW CHEMICAL COMPANY*

Agent for Rohm and Haas Chemicals LLC

100 INDEPENDENCE MALL WEST

PHILADELPHIA, PA 19106-2399 United States

For non-emergency information contact:

215-592-3000

Emergency telephone number

1 800 424 9300

Local emergency telephone number

989-636-4400

*Trademark of The Dow Chemical Company (Dow)or an affiliated company of Dow

2. COMPOSITION/INFORMATION ON INGREDIENTS

Component

CAS-No.

Concentration

Acrylic/styrene copolymer

Not Hazardous

Residual monomers

Not Required

Aqua ammonia

1336-21-6

0.1 %

Water

7732-18-5

54.0 - 56.0 %

44.0 - 46.0 %

< 0.03 %

3. HAZARDS IDENTIFICATION

Emergency Overview

Appearance

Form

liquid milky

Colour

white

Page 1 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

CAUTION!

INHALATION OF VAPOR OR MIST CAN CAUSE HEADACHE,

NAUSEA AND IRRITATION OF THE NOSE, THROAT AND

LUNGS.

MAY CAUSE EYE AND SKIN IRRITATION.

Hazard Summary

Potential Health Effects

Primary Routes of Entry:

Inhalation

Eye contact

Skin contact

Eyes: Direct contact with material can cause the following:

slight irritation

Skin: Prolonged or repeated skin contact can cause the following:

slight irritation

Inhalation: Inhalation of vapor or mist can cause the following:

irritation of nose, throat, and lungs

Headache

Nausea

4. FIRST AID MEASURES

Inhalation: Move to fresh air.

Skin contact: Wash with water and soap as a precaution. If skin irritation persists, call a physician.

Eye contact: Rinse with plenty of water. If eye irritation persists, consult a specialist.

Ingestion: Drink 1 or 2 glasses of water. Consult a physician if necessary. Never give anything by

mouth to an unconscious person.

Notes to physician: Treatment of exposure should be directed at the control of symptoms and the

clinical condition of the patient.

5. FIREFIGHTING MEASURES

Flash point

Ignition temperature

Lower explosion limit

Upper explosion limit

Noncombustible

not applicable

not applicable

not applicable

Suitable extinguishing media:Use extinguishing media appropriate for surrounding fire.

Thermal decomposition Thermal decomposition may yield styrene and acrylic monomers.

Specific hazards during firefighting: Material can splatter above 100C/212F. Dried product can

burn.

Page 2 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

Special protective equipment for firefighters: Wear self-contained breathing apparatus and

protective suit.

6. ACCIDENTAL RELEASE MEASURES

Personal precautions

Use personal protective equipment.

Keep people away from and upwind of spill/leak.

Material can create slippery conditions.

Environmental precautions

CAUTION: Keep spills and cleaning runoff out of municipal sewers and open bodies of water.

Methods for cleaning up

Contain spills immediately with inert materials (e.g., sand, earth).

Transfer liquids and solid diking material to separate suitable containers for recovery or disposal.

7. HANDLING AND STORAGE

Handling

Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. Keep container tightly

closed. Do not breathe vapors, mist or gas.

Other data: Monomer vapors can be evolved when material is heated during processing operations.

See SECTION 8, for types of ventilation required. NOTE: Formaldehyde will be generated under

acidic conditions. Maintain adequate ventilation under these conditions to prevent exposure to

formaldehyde above the Rohm and Haas Co. recommended ceiling of 0.3 ppm.

Storage

Further information on storage conditions: Store in a cool, dry, well ventilated place. Keep away

from direct sunlight. Keep from freezing. STIR WELL BEFORE USE.

Storage temperature: 3 - 35 C (37 - 95 F)

8. EXPOSURE CONTROLS/PERSONAL PROTECTION

Exposure limit(s)

Exposure limits are listed below, if they exist.

Component

Aqua ammonia

Aqua ammonia

Aqua ammonia

Aqua ammonia

Aqua ammonia

Aqua ammonia

Aqua ammonia

Regulation

Rohm and Haas

ACGIH

ACGIH

OSHA P1

OSHA P0

NIOSH REL

NIOSH REL

Type of listing

TWA

TWA

STEL

TWA

STEL

TWA

ST

Value

10 ppm, As Ammonia

25 ppm

35 ppm

35 mg/m3 50 ppm

27 mg/m3 35 ppm

18 mg/m3 25 ppm

27 mg/m3 35 ppm

Exposure controls

Engineering measures: Use local exhaust ventilation with a minimum capture velocity of 100 ft/min.

(0.5 m/sec.) at the point of vapor evolution. Refer to the current edition of Industrial Ventilation: A

Page 3 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

Manual of Recommended Practice published by the American Conference of Governmental Industrial

Hygienists for information on the design, installation, use, and maintenance of exhaust systems.

Protective measures: Facilities storing or utilizing this material should be equipped with an eyewash

facility.

Individual protection measures

Eye/face protection: Safety glasses with side-shields Eye protection worn must be

compatible with respiratory protection system employed.

Skin protection

Hand protection: The glove(s) listed below may provide protection against

permeation. (Gloves of other chemically resistant materials may not provide adequate

protection): Neoprene gloves

Respiratory protection: A respiratory protection program meeting OSHA 1910.134 and ANSI

Z88.2 requirements or equivalent must be followed whenever workplace conditions warrant a

respirators use. None required if airborne concentrations are maintained below the exposure

limit listed in Exposure Limit Information. For airborne concentrations up to 10 times the

exposure limit, wear a properly fitted NIOSH approved (or equivalent) half-mask, air-purifying

respirator. Air-purifying respirators should be equipped with NIOSH approved (or equivalent)

ammonia/methylamine cartridges and N95 filters. If oil mist is present, use R95 or P95 filters.

9. PHYSICAL AND CHEMICAL PROPERTIES

Appearance

Form

Colour

pH

Boiling point/boiling range

Flash point

Evaporation rate

Lower explosion limit

Upper explosion limit

Vapour pressure

Relative vapor density

Water solubility

Auto-ignition temperature

Viscosity, dynamic

Percent volatility

liquid milky

white

7.4 - 8

100 C ( 212 F) Water

Noncombustible

<1 Water

not applicable

not applicable

17.0 mmHg at 20 C (68 F) Water

<1.0Water

Dilutable

not applicable

1 - 100 mPa.s

54 - 56 %

NOTE: The physical data presented above are typical values and should not be construed as a

specification.

10. STABILITY AND REACTIVITY

Page 4 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

Hazardous reactions

None known.

Stable

Materials to avoid

There are no known materials which are incompatible with this product.

polymerisation

Product will not undergo polymerization.

11. TOXICOLOGICAL INFORMATION

Toxicological information on this product or its components appear in this section when such data is

available.

No data are available for this material. The information shown is based on profiles of compositionally

similar materials.

LD50 rat > 5,000 mg/kg

Acute oral toxicity

Acute dermal toxicity

LD50 rabbit > 5,000 mg/kg

Skin irritation

rabbit May cause transient irritation.

Eye irritation

rabbit No eye irritation

Component: Residual monomers

The LC50 has not been determined.

Acute inhalation

toxicity

Component: Aqua ammonia

LC50 rat male 1 Hour 9.850 mg/l

Acute inhalation

toxicity

12. ECOLOGICAL INFORMATION

Ecotoxicological information on this product or its components appear in this section when such data

is available.

There is no data available for this product.

Residual monomers

Elimination information (persistence and degradability)

Biodegradability

No relevant data found.

Ecotoxicity effects

Toxicity to fish

No relevant data found.

Water

Ecotoxicity effects

Toxicity to fish

not applicable

Page 5 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

13. DISPOSAL CONSIDERATIONS

Environmental precautions: CAUTION: Keep spills and cleaning runoff out of municipal sewers and

open bodies of water.

Disposal

Waste Classification: When a decision is made to discard this material as supplied, it does not meet

RCRAs characteristic definition of ignitability, corrosivity, or reactivity, and is not listed in 40 CFR

261.33. The toxicity characteristic (TC), however, has not been evaluated by the Toxicity

Characteristic Leaching Procedure (TCLP).

Coagulate the emulsion by the stepwise addition of ferric chloride and lime. Remove the clear

supernatant and flush to a chemical sewer. For disposal, incinerate or landfill at a permitted facility in

accordance with local, state, and federal regulations.

14. TRANSPORT INFORMATION

DOT

Not regulated for transport

Classification for SEA transport (IMO-IMDG):

Not regulated for transport

Transportation classifications may vary by container volume and may be influenced by regional or

country variations in regulations.

15. REGULATORY INFORMATION

Workplace Classification

OSHA:

This product is considered non-hazardous under the OSHA Hazard Communication

Standard (29CFR1910.1200).

WHMIS:

This product is not a controlled product under the Canadian Workplace Hazardous

Materials Information System (WHMIS).

SARA TITLE III: Section 313 Information (40CFR372)

SARA 313: This material does not contain any chemical components with known CAS numbers that

exceed the threshold (De Minimis) reporting levels established by SARA Title III, Section 313.

United States TSCA Inventory (US.TSCA): All components of this product are in compliance with the

inventory listing requirements of the U.S. Toxic Substances Control Act (TSCA) Chemical Substance

Inventory.

Pennsylvania

Any material listed as Not Hazardous in the CAS REG NO. column of SECTION 2,

Composition/Information On Ingredients, of this MSDS is a trade secret under the provisions of the

Pennsylvania Worker and Community Right-to-Know Act.

Page 6 of 7

Revision Date

01/15/2013

ROBOND L-330 EMULSION

16. OTHER INFORMATION

HMIS Hazard Rating

Health

Flammability

Physical

Hazard

0

Legend

ACGIH

American Conference of Governmental Industrial Hygienists

BAc

Butyl acetate

OSHA

Occupational Safety and Health Administration

PEL

Permissible Exposure Limit

STEL

Short Term Exposure Limit (STEL):

TLV

Threshold Limit Value

TWA

Time Weighted Average (TWA):

Bar denotes a revision from prior MSDS.

The information provided in this Safety Data Sheet is correct to the best of our knowledge, information

and belief at the date of its publication. The information given is designed only as a guidance for safe

handling, use, processing, storage, transportation, disposal and release and is not to be considered a

warranty or quality specification. The information relates only to the specific material designated and

may not be valid for such material used in combination with any other materials or in any process,

unless specified in the text.

Version: 1.6

Print Date: 09/10/2013

Layout 101123104

Page 7 of 7

Revision Date

01/15/2013

You might also like

- Oil Well Drilling Fluid Additive MSDSDocument6 pagesOil Well Drilling Fluid Additive MSDSjelaapeNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- GRP Piping ManualDocument73 pagesGRP Piping ManualFaruk Atalar100% (2)

- Cleaning Procedures For MoldDocument10 pagesCleaning Procedures For MoldOlaolu SaeedNo ratings yet

- Nfpa 58 Español 2013 PDFDocument280 pagesNfpa 58 Español 2013 PDFAnonymous pXU4tefJNo ratings yet

- Fulton, George P Diatomaceous Earth Filtration For Safe Drinking WaterDocument225 pagesFulton, George P Diatomaceous Earth Filtration For Safe Drinking WaterHarry Yucra100% (1)

- Simops Risk AssessmentDocument3 pagesSimops Risk Assessmentzineddinmakram100% (1)

- Water Resources Planning and Management PDFDocument2 pagesWater Resources Planning and Management PDFSivaShankarNo ratings yet

- TM 3350r Copper Replenisher-EnglishDocument5 pagesTM 3350r Copper Replenisher-EnglishManson FongNo ratings yet

- Butyl OctanolDocument7 pagesButyl Octanolanpuselvi125No ratings yet

- Dow 1111Document7 pagesDow 1111Jorge PerezNo ratings yet

- Acetaldol MsdsDocument6 pagesAcetaldol Msdsdlr1233No ratings yet

- MSDS Styrene Acrylic LatexDocument9 pagesMSDS Styrene Acrylic LatexLailyNo ratings yet

- HTV Sh5070u MSDS (E) PDFDocument5 pagesHTV Sh5070u MSDS (E) PDFAnie WajidNo ratings yet

- MSDS - SiliconeFluid200 350Document7 pagesMSDS - SiliconeFluid200 350Rafael Saldanha LopesNo ratings yet

- ExxonMobil Chalmette Refining LLC MSDS RFCCU Equilibrium CatalystDocument11 pagesExxonMobil Chalmette Refining LLC MSDS RFCCU Equilibrium CatalystGeauxGreenNo ratings yet

- Majestic Mountain Sage, Inc.: Material Safety Data SheetDocument6 pagesMajestic Mountain Sage, Inc.: Material Safety Data SheetCarere TeiNo ratings yet

- Safety Data Sheet for Sulfuric AcidDocument4 pagesSafety Data Sheet for Sulfuric AcidphyphoNo ratings yet

- PDMS MSDSDocument6 pagesPDMS MSDSRazleen RashidiNo ratings yet

- Omala MSDSDocument4 pagesOmala MSDSmevansmetreelNo ratings yet

- 702 Dow CorningDocument7 pages702 Dow Corningaa444444No ratings yet

- 00019023Document4 pages00019023Dgek LondonNo ratings yet

- All Surface Enamel Safety Red 6403-25734Document4 pagesAll Surface Enamel Safety Red 6403-25734ashadeofdarknessNo ratings yet

- Spray Paint MsdsDocument4 pagesSpray Paint MsdsHillary RyanNo ratings yet

- Asidufoam MSDSDocument3 pagesAsidufoam MSDSVictor LopezNo ratings yet

- Zeromist - 01 U - MSDSDocument6 pagesZeromist - 01 U - MSDSLuuThiThuyDuongNo ratings yet

- Safety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingDocument11 pagesSafety Data Sheet: SECTION 1. Identification of The Substance/mixture and of The Company/undertakingBalaji NamachivayamNo ratings yet

- Polymer MSDSDocument6 pagesPolymer MSDSZhen SinNo ratings yet

- Liang Chi Industry Philippines, Inc. Hydralchem Material Safety Data SheetDocument6 pagesLiang Chi Industry Philippines, Inc. Hydralchem Material Safety Data SheetCNo ratings yet

- Siltech E50Document4 pagesSiltech E50Rajesh ChowdhuryNo ratings yet

- Anabond 202 MSDSDocument4 pagesAnabond 202 MSDSPoovannan Prakash0% (1)

- DCP MSDSDocument4 pagesDCP MSDSAsima AtharNo ratings yet

- Aquaseal Gel A-Epoxy Resin & B-AmineDocument9 pagesAquaseal Gel A-Epoxy Resin & B-AmineJodyNo ratings yet

- DAP Aquarium Silicone Sealant Safety Data SheetDocument7 pagesDAP Aquarium Silicone Sealant Safety Data Sheetmerc2No ratings yet

- Msds Cocoa Beans - HsihhugsDocument3 pagesMsds Cocoa Beans - Hsihhugsjean_cynthiaNo ratings yet

- Dow Corning Corporation Material Safety Data SheetDocument8 pagesDow Corning Corporation Material Safety Data SheetbhauqueNo ratings yet

- 175 PacDocument7 pages175 PacRACHMAD ARIFUDDINNo ratings yet

- CBS Material Safety Data SheetDocument3 pagesCBS Material Safety Data SheetHerdianNo ratings yet

- MSDS Sodium ChlorideDocument6 pagesMSDS Sodium ChlorideEndang SupriyatnaNo ratings yet

- MSDS Yellow No 010 Aluminum Lake-7Document8 pagesMSDS Yellow No 010 Aluminum Lake-7Vanti_805100% (1)

- MSDS Tawas PrillDocument5 pagesMSDS Tawas PrillAreIf Cron BmxStreetNo ratings yet

- RTV GasDocument5 pagesRTV GasNathan De Los SantosNo ratings yet

- Msds Dow 732 Sealant PDFDocument7 pagesMsds Dow 732 Sealant PDFJake WestlakeNo ratings yet

- Scalebreak-SS MAR 13Document2 pagesScalebreak-SS MAR 13dalton2004No ratings yet

- Oil Eater Degreaser Cleaner Kafko InternationalDocument3 pagesOil Eater Degreaser Cleaner Kafko InternationalstevgonNo ratings yet

- Asia Wd40 Aerosol Msds 2012Document4 pagesAsia Wd40 Aerosol Msds 2012Sarliza JafarNo ratings yet

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationRudy SkaffNo ratings yet

- Insulating Cement MSDS SummaryDocument6 pagesInsulating Cement MSDS SummaryNazirAhmadBashiriNo ratings yet

- Proven Citrus Degreaser MSDS 56536Document3 pagesProven Citrus Degreaser MSDS 56536Andika WidriantamaNo ratings yet

- Dow Tamol SN MsdsDocument6 pagesDow Tamol SN MsdsbudwilliamsNo ratings yet

- Molykote L0122 Oil MSDSDocument6 pagesMolykote L0122 Oil MSDSRaghavendra MurthyNo ratings yet

- Silicone Mold MsdsDocument6 pagesSilicone Mold MsdsAbraham HumphreysNo ratings yet

- ENG - Prime-Coat-Primer-WP038 - SDSDocument9 pagesENG - Prime-Coat-Primer-WP038 - SDSPedro PaulinoNo ratings yet

- MSDS-PSF-600,000cSt Silicone Damping FluidDocument5 pagesMSDS-PSF-600,000cSt Silicone Damping Fluidvictor.ciprianiNo ratings yet

- MSDS Molykote G-N Metal Assembly PasteDocument9 pagesMSDS Molykote G-N Metal Assembly PasteNikola PolimenovNo ratings yet

- Polypropelen GlycolDocument3 pagesPolypropelen GlycolDedi MulyadiNo ratings yet

- Sodium Aluminate SDS USALCODocument4 pagesSodium Aluminate SDS USALCOMichelle ErasmusNo ratings yet

- Material Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationDocument5 pagesMaterial Safety Data Sheet: Section 1 - Chemical Product and Company IdentificationSafqur RahmanNo ratings yet

- Rocor NBDocument5 pagesRocor NBDenis StepanovNo ratings yet

- Modelo de Ficha de SegurançaDocument8 pagesModelo de Ficha de SegurançaGUSTAVONo ratings yet

- Yd128 MsdsDocument3 pagesYd128 Msdsapi-263411629No ratings yet

- 1201 Alodine, AKA DX 503Document7 pages1201 Alodine, AKA DX 503Mark Evan SalutinNo ratings yet

- Alcohol 80 IngDocument5 pagesAlcohol 80 IngAnonymous pXU4tefJNo ratings yet

- Msds Ing Tubos FluorescentesDocument1 pageMsds Ing Tubos FluorescentesAnonymous pXU4tefJNo ratings yet

- Lamal Cr-1-80 - Iss130905Document9 pagesLamal Cr-1-80 - Iss130905Anonymous pXU4tefJNo ratings yet

- MSDSDocument5 pagesMSDSAnonymous pXU4tefJNo ratings yet

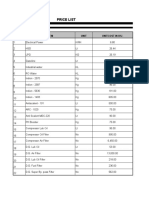

- Price List: S.No Item Unit Unitcost in RSDocument7 pagesPrice List: S.No Item Unit Unitcost in RSamitans2003No ratings yet

- By Mohamad Shahrizal Bin Alias: Cold Water SupplyDocument18 pagesBy Mohamad Shahrizal Bin Alias: Cold Water Supplynurul atiqahNo ratings yet

- GM 2016Document213 pagesGM 2016justusfr4ntzNo ratings yet

- PDS Hadex Dosing Unit HDU S en 01Document2 pagesPDS Hadex Dosing Unit HDU S en 01vikrant911No ratings yet

- Chapter 12-Legislative EnvironmentDocument16 pagesChapter 12-Legislative EnvironmentMULLAINo ratings yet

- Magnafloc 5250 TI EVH 0033Document2 pagesMagnafloc 5250 TI EVH 0033JCL ROmanos100% (1)

- Debit Banjir Rancangan Situ SidomuktiDocument11 pagesDebit Banjir Rancangan Situ SidomuktiTickson TanNo ratings yet

- DBSFWO5 SRB-BART Field Tester For WaterDocument5 pagesDBSFWO5 SRB-BART Field Tester For WaterSaras Unggul UtamiNo ratings yet

- Carbon Cycle DiagramDocument3 pagesCarbon Cycle DiagramRommel Villaroman EstevesNo ratings yet

- Wastewater Treatment Process of Maynilad Water ServicesDocument9 pagesWastewater Treatment Process of Maynilad Water ServicesEjay AbanteNo ratings yet

- Tourism Guidebook For LGUs Consolidated PDFDocument395 pagesTourism Guidebook For LGUs Consolidated PDFMichael BuanaobraNo ratings yet

- SLS 614Document16 pagesSLS 614K S Kumara100% (8)

- Chapter 3: Tamil Nadu: of Eris and OoranisDocument19 pagesChapter 3: Tamil Nadu: of Eris and Ooranisanusha shinyNo ratings yet

- 1950 SQFT RESIDENCE ESTIMATEDocument10 pages1950 SQFT RESIDENCE ESTIMATEsijinNo ratings yet

- GEC97/CGWB/IndiaDocument113 pagesGEC97/CGWB/Indiafk.zaidiNo ratings yet

- Masterseal ADocument6 pagesMasterseal Aapi-283891975No ratings yet

- Indian Railways: 1 1 January, 2005 AllDocument11 pagesIndian Railways: 1 1 January, 2005 Allsourabhsdn76No ratings yet

- Environmental Management NotesDocument23 pagesEnvironmental Management Notesropafadzonyika6No ratings yet

- Natural Resources & Their ConservationDocument3 pagesNatural Resources & Their ConservationMitali GuptaNo ratings yet

- RAIN WATER HARVESTING GUIDEDocument63 pagesRAIN WATER HARVESTING GUIDEThiyagarajan kNo ratings yet

- Final Work 1Document43 pagesFinal Work 1mike djopoNo ratings yet

- Morel CultivationDocument1 pageMorel Cultivationvas2000No ratings yet

- Coagulant WT-SR460 SDSDocument6 pagesCoagulant WT-SR460 SDSnitroxx7No ratings yet

- 2020 - EXPLORER - Manual 8 - FINAL - Cover PDFDocument83 pages2020 - EXPLORER - Manual 8 - FINAL - Cover PDFAna Sofia MirandaNo ratings yet

- Sandy Shores: Sink or FloatDocument5 pagesSandy Shores: Sink or FloatElla Mae PabitonNo ratings yet