Professional Documents

Culture Documents

Research On Tensile Testing of Materials

Uploaded by

kenechidukorOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Research On Tensile Testing of Materials

Uploaded by

kenechidukorCopyright:

Available Formats

RESEARCH ON TENSILE TESTING OF MATERIALS

University of Lagos, Akoka

Tensile Testing of Materials (Mild Steel)

Dukor Kenechi Franklin

Mechanical Engineering

120404036

Author Note

The research on tensile testing of materials was performed on the June 13 2014 by

Dukor Kenechi Franklin and other members of Group 6. The research was carried

out at the Federal Institute of Industrial Research (FIIRO), Oshodi, Lagos. Nigeria.

This research project wouldnt be a success without the help of the tensile testing

manager, Engineer Ojo.

Phone number(s): +2348031157806, +2348084717793.

E-mail: kennydukor@gmail.com, 120404036@students.unilag.edu.ng

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

1

RESEARCH ON TENSILE TESTING OF MATERIALS

TABLE OF CONTENT

Abstract

Nomenclature

Introduction

Literature Review

Research Design

12

Industrial Application of Tensile Testing

18

Conclusion

23

Acknowledgment

24

Reference

24

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

2

RESEARCH ON TENSILE TESTING OF MATERIALS

I.

Abstract

The research was performed to study the tensile strength of materials. The material used for the test was mild steel.

The material was subjected to tensile force. Due to the increasing tensile load, the specimen is continuously

stretched until rupture occurred on the material.

Graph and values were obtained from the test and compared with standard value of young modulus, Yield strength,

etc and it was discovered that the mild steel material obeys Hookes law of elasticity

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

3

RESEARCH ON TENSILE TESTING OF MATERIALS

II.

Nomenclature

(Nomenclature entries should have the units identified)

engineering stress

engineering strain

external axial tensile load

original cross-sectional area of the specimen

original length of the specimen

final length of the specimen

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

4

RESEARCH ON TENSILE TESTING OF MATERIALS

III.

Introduction

Tensile testing, also known as tension testing, is a fundamental material science test in which a sample is

subjected to a controlled tension until failure.

These results from the test are commonly used to select a material for an application, for quality control, and to

predict how a material will react under other type of forces.

Properties are that are directly measured via a tensile test are ultimate tensile strength, maximum elongation and

reduction in area.

From these measurements the following properties can also be determined. Youngs modulus, Poissons ratio,

yield strength and strain hardening characteristics

Uniaxial tensile testing is the most commonly used for obtaining the mechanical characteristics of isotropic

materials. For anisotropic materials such as composite materials and textiles, biaxial tensile testing is required

Typical applications of tensile testing are highlighted in the following sections on:

a)

b)

c)

d)

e)

f)

g)

h)

Aerospace Industry

Automotive Industry

Beverage Industry

Construction Industry

Electrical and Electronics Industry

Medical Device Industry

Packaging Industry

Paper and Board Industry

IV.

Literature Review

A. TENSILE TESTING

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

5

RESEARCH ON TENSILE TESTING OF MATERIALS

Uniaxial tensile test is known as a basic and universal engineering test to achieve material parameters such as

ultimate strength, yield strength, % elongation, % area of reduction and Young's modulus. These important

parameters obtained from the standard tensile testing are useful for the selection of engineering materials for any

applications required.

The tensile testing is carried out by applying longitudinal or axial load at a specific extension rate to a standard

tensile specimen with known dimensions (gauge length and cross sectional area perpendicular to the load direction)

till failure. The applied tensile load and extension are recorded during the test for the calculation of stress and strain.

A range of universal standards provided by Professional societies such as American Society of Testing and Materials

(ASTM), British standard, JIS standard and DIN standard provides testing are selected based on preferential uses.

Each standard may contain a variety of test standards suitable for different materials, dimensions and fabrication

history. For instance, ASTM E8: is a standard test method for tension testing of metallic materials and ASTM B557

is standard test methods of tension testing wrought and cast aluminum and magnesium alloy products.

B. STANDARDS IN TENSILE TESTING

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

6

RESEARCH ON TENSILE TESTING OF MATERIALS

Figure 1: Standard tensile specimens

A standard specimen is prepared in a round or a square section along the gauge length as shown in figures 1 a)

and b) respectively, depending on the standard used. Both ends of the specimens should have sufficient length and a

surface condition such that they are firmly gripped during testing.

Type specimen

Sheet (L / A)

Rod (L / D)

United State (ASTM)

4.5

Great Britain

5.65

4.0

5.0

Germany

11.3

10.0

Table 1: Dimensional relationships of tensile specimens used in different countries.

The initial gauge length L is standardized (in several countries) and varies with the diameter (D ) or the crosssectional area (A) of the specimen as listed in table 1. This is because if the gauge length is too long, the %

elongation might be underestimated in this case.

Any heat treatments should be applied on to the specimen prior to machining to produce the final specimen

readily for testing. This has been done to prevent surface oxide scales that might act as stress concentration which

might subsequently affect the final tensile properties due to premature failure.

There might be some exceptions, for examples, surface hardening or surface coating on the materials.

These processes should be employed after specimen machining in order to obtain the tensile properties results which

include the actual specimen surface conditions.

C. STRESS AND STRAIN RELATIONSHIP

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

7

RESEARCH ON TENSILE TESTING OF MATERIALS

When a specimen is subjected to an external tensile loading, the metal will undergo elastic and plastic

deformation. Initially, the metal will elastically deform giving a linear relationship of load and extension. These two

parameters are then used for the calculation of the engineering stress and engineering strain to give a relationship as

illustrated in figure 3 using equations 1 and 2 as follows

P

(1)

A

LL L

=

(2)

L

L

Where:

is the engineering stress

is the engineering strain

is the external axial tensile load

is the original cross-sectional area of the specimen

is the original length of the specimen

Lf

is the final length of the specimen

The unit of the engineering stress is Pascal (Pa) or N/m2 according to the SI Metric Unit whereas the unit of psi

(pound per square inch) can also be used.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

8

RESEARCH ON TENSILE TESTING OF MATERIALS

Figure 3: Stress-strain relationship under uniaxial tensile loading

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

9

RESEARCH ON TENSILE TESTING OF MATERIALS

D. EXPLANTION OF TECHNICAL TERMS IN TENSILE TESTING

i. Elastic modulus (Young's modulus) (E): This is ratio of stress to strain below the elastic limit.

The engineering stress-strain relationship follows the Hook's Law and the slope of the curve indicates the

Young's modulus (E)

E= (3)

Young's modulus is of importance where deflection of materials is critical for the required engineering

applications. This is for examples: deflection in structural beams is considered to be crucial for the design in

engineering components or structures such as bridges, building, ships, etc.

The applications of tennis racket and golf club also require specific values of spring constants or Young's

modulus values.

ii. Yield strength, (y): This occurs when the tensile loading continues, yielding occurs at the beginning of plastic

deformation. The yield stress, y, can be obtained by dividing the load at yielding (P y) by the original crosssectional area of the specimen (Ao) as shown in equation 4.

y=

Py

( 4)

A

iii. Ultimate Tensile Strength, TS: Beyond yielding, continuous loading leads to an increase in the stress required to

permanently deform the specimen as shown in the engineering stress-strain curve. At this stage, the specimen

is strain hardened or work hardened. The degree of strain hardening depends on the nature of the deformed

materials, crystal structure and chemical composition, which affects the dislocation motion.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

10

RESEARCH ON TENSILE TESTING OF MATERIALS

iv. Fracture Strength, f: After necking, plastic deformation is not uniform and the stress decreases accordingly until

fracture. The fracture strength ( fracture) can be calculated from the load at fracture divided by the original

cross-sectional area, Ao, as expressed in equation 5.

fracture=

Pfracture

(5)

A

v. Elongation: The strain at fracture expressed as a percentage; this is a measure of the ductility of the material.

vi. Modulus of resilience: The amount of energy (or work) stored per unit volume at the elastic limit.

vii. Modulus of toughness: The amount of energy stored per unit volume at fracture of the material; this is a measure

of the ductility of the material.

viii. Percent Area Reduction: Reduction in area at fracture in necking region with respect to original cross-section

area; this is a measure of the ductility of the material.

ix. Strain (engineering): the unit deformation of the material under load.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

11

RESEARCH ON TENSILE TESTING OF MATERIALS

V.

Research Design

The Research Design is to Study the tensile strength of materials and to understand its importance

and application in industry today.

The industry where this research was carried out is Federal Institute of Industrial Research located

at, Oshodi, and Lagos, Nigeria (FIIRO). FIIRO is a well-known research institute in Nigeria which

aids to build and equip center for commercial production demonstration of developed technologies

e.g bio-technology unit, material research, technology transfer, development of Agro-based etc.

The research design was carried out on the following machines;

1.

Mild Steel

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

12

RESEARCH ON TENSILE TESTING OF MATERIALS

2.

Universal testing Machine

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

13

RESEARCH ON TENSILE TESTING OF MATERIALS

A The procedure carried out during this research was:

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

14

RESEARCH ON TENSILE TESTING OF MATERIALS

1. The engineer in charge of the machines Engineer Ojo introduced us to the Tensile testing

machine

2. After the introduction and discussion on the importance and application of Tensile testing,

we proceeded to perform a mini experiment on mild steel.

3. We started by fixing the mild steel material into the universal tensile testing machine.

Picture of apparatus with fixed mild before loading

4. We then subjected the mild steel material to tensile test until the material experienced

fracture.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

15

RESEARCH ON TENSILE TESTING OF MATERIALS

5. We then printed the readings and graph generated by the Universal tensile testing machine.

6.

We studied the result obtained and drew some conclusions.

E. Picture of material after fracture

Picture of material after loading

F. Graph of stress against strain

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

16

RESEARCH ON TENSILE TESTING OF MATERIALS

Graph plotted for stress against strain

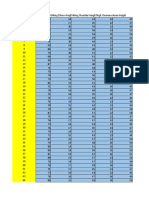

G. Results Obtained From the Test

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

17

RESEARCH ON TENSILE TESTING OF MATERIALS

VI.

Industrial Applications of Tensile Testing

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

18

RESEARCH ON TENSILE TESTING OF MATERIALS

Applications of Tensile Testing:

Tensile testing is used to guarantee the quality of components, materials and finished products within wide range

industries. Typical applications of tensile testing are highlighted in the following sections on:

i)

j)

k)

l)

m)

n)

o)

p)

q)

r)

s)

t)

Aerospace Industry

Automotive Industry

Beverage Industry

Construction Industry

Electrical and Electronics Industry

Medical Device Industry

Packaging Industry

Paper and Board Industry

Pharmaceuticals Industry

Plastics, Rubber and Elastomers Industry

Safety, Health, Fitness and Leisure Industry

Textiles Industry

Aerospace Industry

Applications of tensile testing in the aerospace industry include:

Peel tests on airframe composites

Shear and tensile strength testing of fasteners e.g. bolts, nuts and screws

Tensile & material strength testing of adhesive bonds, aircraft textiles and carpets, cables, hoses and tubing,

gaskets and o-rings, seat belts, welded and crimped joints, wiring looms and harnesses

H.

Automotive Industry

Applications of tensile testing in the automotive industry include:

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

19

RESEARCH ON TENSILE TESTING OF MATERIALS

Quality assessment through tensile testing of interior fittings including: airbags, carpets, dashboards,

electrical harness (incl. crimped terminals pull-off force), handles, laminated trim, mirrors, seals and

seatbelts and handbrake levers.

Quality assessment through tensile testing of exteriors fittings including: bumper mouldings and trims, door

and window seals, emblems and number plates, mirrors and mud flaps

I. Beverage Industry

Applications of tensile testing in the beverage industry include:

J.

Peel strength of induction-sealed foils and labels

Tensile force required to open 'ring-pulls' on bevcans

Testing cork extraction force

Construction Industry

Applications of tensile testing in the construction industry include:

Bond strength testing of adhesives, mastics, sealants and bonds between brick and foam layers

Tensile and material strength testing of geotextiles and safety support netting

K. Electrical and Electronics Industry

Applications of tensile testing in the electrical and electronics industry include:

L.

Connector withdrawal force

Pull-off forces of crimped, welded or soldered electrical contacts

Component-to-PCB pull-off force

PCB material tensile strength.

Medical Device Industry

Applications of tensile testing in the medical device industry include:

Hypodermic needle-to-hub retention force

Tensile strength and elongation at break of medical tubing, bandages, dressings and tapes

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

20

RESEARCH ON TENSILE TESTING OF MATERIALS

M.

Joint strength of IV connector fittings

Suture-to-needle crimps pull out test

Tensile strength of suture material and knotting

Joint strength and material elongation of respiratory masks

Elongation and tensile strength of examination gloves

Mechanical strength of orthopedic implant components

Packaging Industry

Applications of tensile testing in the packaging industry include:

N.

Adhesive/peel testing of adhesive bonds, container seals and labels

Force associated with opening snap-caps, pop-caps and other push pull closures

Elongation of plastic packaging materials

Paper and Board Industry

Applications of tensile testing in the paper and board industry include:

O.

Openability of card and paper based packaging

Folding characteristics of boxes and cartons

Force to separate multi-part documents

Durability of documents

Pharmaceuticals Industry

Applications of tensile testing in the pharmaceuticals industry include:

P.

Pull off force of phial caps

Plastics, Rubber and Elastomers Industry

Applications of tensile testing in the plastics, rubber and elastomers industry include:

Joint strength of interlocking plastic components

Assessment of material tensile properties

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

21

RESEARCH ON TENSILE TESTING OF MATERIALS

Q.

Adhesion / peel testing of plastic labels, ID and credit cards

Safety, Health, Fitness and Leisure Industry

Applications of tensile testing in the safety, health, fitness and leisure industry include:

R.

Tensile testing of safety support netting

Ergonomic risk evaluations

Elastic properties of racquet strings

Textiles Industry

Applications of tensile testing in the textiles industry include:

'Pull-off' characteristics of buttons, stitched-on decorations, press studs, poppers, zip fasteners, hook-and-

loop fasteners

Strength testing of vulnerable seams

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

22

RESEARCH ON TENSILE TESTING OF MATERIALS

VII.

Conclusion

From experiment we performed, we noticed a gradually and slowly increasing tensile load applied on the mild

steel material through the tensile machine. Due to the increasing tensile load, the specimen is continuously stretched

until fracture occurred.

There was an increase in length of the mild steel material compared to it's original length. this increase in length

was used to calculate the stain in the material.

It was confirmed that the material obeys Hookes law. Slope of this line provides information on the Youngs

modulus of the material.

Also, when the values we obtained was compared with standard values similarities were noticed.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

23

RESEARCH ON TENSILE TESTING OF MATERIALS

Acknowledgments

The research was carried out at the Federal Institute of Industrial Research (FIIRO), Oshodi,

Lagos. Nigeria.

This research project wouldnt be a success without the help of the tensile testing manager,

Engineer Ojo.

References

[1] Hashemi, S. Foundations of materials science and engineering, 2006, 4th edition, McGraw-Hill, ISBN 007-1256903.

[2] Norman E. Dowling, Mechanical Behavior of Materials, Prentice-Hall International, 1993.

[3] W.D. Callister, Fundamental of materials science and engineering/an interactive e. text, 2001, John Willey & Sons, Inc.,

New York, ISBN 0-471-39551-x

[4] Dieter, G.E., Mechanical metallurgy, 1988, SI metric edition, McGraw-Hill, ISBN 0-07-100406-8.

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

24

RESEARCH ON TENSILE TESTING OF MATERIALS

[5] Czichos, Horst (2006). Springer Handbook of Material Measurement Method, Berlin:Springer. Pp. 303-304. ISBN 978-3540-20785-6

[6] WIKIPEDIA: http://en.m.wikipedia.org/wiki/Tensile_testing

Dukor Kenechi Franklin, Department of Mechanical Engineering, 120404036, kennydukor@gmail.com, Group 6.

25

You might also like

- Autodesk Inventor Practice Part DrawingsDocument25 pagesAutodesk Inventor Practice Part DrawingsInventorTrenches93% (29)

- Africa and African Trivia Quiz Questions and Answers With Over 40 Questions About African NationsDocument5 pagesAfrica and African Trivia Quiz Questions and Answers With Over 40 Questions About African NationskenechidukorNo ratings yet

- Hardness Testing NotesDocument2 pagesHardness Testing NotesJohnNo ratings yet

- Dislocations and Strengthening Mechanisms ExplainedDocument29 pagesDislocations and Strengthening Mechanisms ExplainedBaskar ManiNo ratings yet

- Deformation & StrengthDocument35 pagesDeformation & StrengthcolorofstoneNo ratings yet

- Mech 285 True or False Quiz ReviewDocument18 pagesMech 285 True or False Quiz ReviewKayleigh RobotnikNo ratings yet

- Deposition RateDocument4 pagesDeposition Rateahmed100% (1)

- Lecture 5 Strengthening Mechanisms LecDocument17 pagesLecture 5 Strengthening Mechanisms LecLeencie SandeNo ratings yet

- 28 Jupyter Notebook Tips, Tricks and ShortcutsDocument35 pages28 Jupyter Notebook Tips, Tricks and ShortcutskenechidukorNo ratings yet

- Properties of Engineering Materials Lesson 3 (I)Document11 pagesProperties of Engineering Materials Lesson 3 (I)Douglas Kufre-Abasi GilbertNo ratings yet

- Example Flexural Member - TimberDocument4 pagesExample Flexural Member - TimberJay Jackman50% (2)

- Harman Kardon AV SMPS PDFDocument11 pagesHarman Kardon AV SMPS PDFbenygiurgiuNo ratings yet

- Komatsu Pc5500 6Document8 pagesKomatsu Pc5500 6matt_alc100% (1)

- 322 F22 Lecture15 Plasticity Vs Defects1Document59 pages322 F22 Lecture15 Plasticity Vs Defects1lokeshNo ratings yet

- Dislocation Mobility and Hydrogen - A Brief ReviewDocument6 pagesDislocation Mobility and Hydrogen - A Brief ReviewIchsan HakimNo ratings yet

- Chapters 1 To 4Document108 pagesChapters 1 To 4Andreu1287100% (1)

- My Home-Made Biomass GasifierDocument18 pagesMy Home-Made Biomass GasifierkenechidukorNo ratings yet

- Numerical Simulations For Reliability Assessment of Lead-Free Solder Interconnections in BGA PackagesDocument55 pagesNumerical Simulations For Reliability Assessment of Lead-Free Solder Interconnections in BGA PackagesEL HADDADNo ratings yet

- Fish Feed Production SystemsDocument22 pagesFish Feed Production SystemsRoman Mujahid RahmanNo ratings yet

- Prayer On Deliverance of The MindDocument10 pagesPrayer On Deliverance of The Mindkenechidukor67% (3)

- Non-Traditional Machining: Electro Chemical Machining (ECM)Document14 pagesNon-Traditional Machining: Electro Chemical Machining (ECM)NimoNo ratings yet

- 2 - Mechanical Properties-StudentDocument119 pages2 - Mechanical Properties-StudentNishant DeyNo ratings yet

- Main Ideas and SupportingDocument5 pagesMain Ideas and Supportingmilitansina100% (1)

- Foundations of Materials Science and Engineering 5th Edition Smith Solutions ManualDocument79 pagesFoundations of Materials Science and Engineering 5th Edition Smith Solutions Manualdextrermachete4amgqgNo ratings yet

- MSE 280: Introduction To Engineering MaterialsDocument44 pagesMSE 280: Introduction To Engineering Materialsjains.boyNo ratings yet

- Introduction to Materials Science for NDTDocument96 pagesIntroduction to Materials Science for NDTMircea Dubenco100% (1)

- CAESAR II Pipe Stress Analysis GuideDocument37 pagesCAESAR II Pipe Stress Analysis GuideEko Idris Hutagaol100% (1)

- Corrosion Cotrol ManualDocument36 pagesCorrosion Cotrol ManualNwosu AugustineNo ratings yet

- Modern Methods of Non-Destructive TestingDocument19 pagesModern Methods of Non-Destructive TestingphanthanhhungNo ratings yet

- Negative Thermal Expansion Materials: Literature ReviewDocument7 pagesNegative Thermal Expansion Materials: Literature ReviewsilentShoeNo ratings yet

- Interpretation of An IndicationDocument2 pagesInterpretation of An IndicationAshfaq Khan100% (1)

- UNILAG Post UTME Past Questions Answers 2 1Document34 pagesUNILAG Post UTME Past Questions Answers 2 1kenechidukor100% (2)

- Chapter11 Mechanical BehaviorDocument31 pagesChapter11 Mechanical BehaviorDheivendranRamiah100% (1)

- Physical Metallurgy M1 PDFDocument21 pagesPhysical Metallurgy M1 PDFAnca ElenaNo ratings yet

- Material Lab Manual Experiments January2016 1Document47 pagesMaterial Lab Manual Experiments January2016 1gosaye desalegn100% (2)

- ME2101E - Design Against Fatigue - BWDocument26 pagesME2101E - Design Against Fatigue - BWZhang DunJieNo ratings yet

- Mechanical Properties of MetalsDocument258 pagesMechanical Properties of MetalsIsza Marie N. SocorinNo ratings yet

- Tunnel Construction Techniques and Their DetailsDocument72 pagesTunnel Construction Techniques and Their DetailsRajesh Khadka100% (1)

- Tutorial Answers - Mechanical Behaviour of MaterialsDocument2 pagesTutorial Answers - Mechanical Behaviour of MaterialsbananaNo ratings yet

- Design For Fracture: Lecture Two Lect. Dr. Hind B. Al-AttraqchiDocument35 pagesDesign For Fracture: Lecture Two Lect. Dr. Hind B. Al-AttraqchiTRNADEWNo ratings yet

- Nano-Mechanics and Thermal Phenomena at the Indian Institute of Technology RoorkeeDocument50 pagesNano-Mechanics and Thermal Phenomena at the Indian Institute of Technology RoorkeeAnkit VermaNo ratings yet

- What Is The Difference Between The Hardness, Toughness, Resilience, and Stiffness of Materials - QuoraDocument5 pagesWhat Is The Difference Between The Hardness, Toughness, Resilience, and Stiffness of Materials - QuoraUdit AgarwalNo ratings yet

- Material Science - Properties of MaterialsDocument13 pagesMaterial Science - Properties of MaterialsBlessings James Bwalya100% (1)

- High Entropy Alloys A Critical Assessment of Their Founding Principles and Future ProspectsDocument21 pagesHigh Entropy Alloys A Critical Assessment of Their Founding Principles and Future ProspectsFeng ZhuNo ratings yet

- Issues To Address... : Chapter 5-1Document58 pagesIssues To Address... : Chapter 5-1Nasser SANo ratings yet

- Defining Nanomaterials and Their PropertiesDocument5 pagesDefining Nanomaterials and Their Propertiesharsha sNo ratings yet

- Introduction To Materials: Prof. H. K. KhairaDocument75 pagesIntroduction To Materials: Prof. H. K. KhairaDhanush NairNo ratings yet

- Current Topics in Amorphous Materials: Physics & TechnologyFrom EverandCurrent Topics in Amorphous Materials: Physics & TechnologyY. SakuraiRating: 5 out of 5 stars5/5 (1)

- Testing and Evaluation of Engineering MaterialsDocument5 pagesTesting and Evaluation of Engineering MaterialsFAHED AYYAD100% (1)

- Elastic/Plastic Deformation (Chapter 6canggaan)Document11 pagesElastic/Plastic Deformation (Chapter 6canggaan)qc12345No ratings yet

- Toughness TestDocument25 pagesToughness TestNehaJainNo ratings yet

- Engineering Lab Report StructureDocument7 pagesEngineering Lab Report StructureSana ButtNo ratings yet

- Corrosion Measurement UNIT-5: CHE-545-172 DR Ime B.ObotDocument48 pagesCorrosion Measurement UNIT-5: CHE-545-172 DR Ime B.ObotArielNo ratings yet

- Chapter2 - AJMDocument13 pagesChapter2 - AJMravish kumarNo ratings yet

- FM (MEE84) Module-1 PresentationDocument29 pagesFM (MEE84) Module-1 Presentationsonic somannaNo ratings yet

- 2019-High Cycle Fatigue Behavior of Hard Turned 300 M Ultra-High Strength SteelDocument12 pages2019-High Cycle Fatigue Behavior of Hard Turned 300 M Ultra-High Strength SteelYoussef Mbarek100% (1)

- Module 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite SealDocument18 pagesModule 1: Introduction Introduction To Tribology: Fig. 1.1: Carbon Graphite Sealbansalmohit01No ratings yet

- Lec5-Yield Phenomenon, Strain Aging, & Bauchinger EffectDocument14 pagesLec5-Yield Phenomenon, Strain Aging, & Bauchinger Effectsamurai7_77No ratings yet

- 15ME103-Materials Tech - Unit IIIDocument79 pages15ME103-Materials Tech - Unit IIIVedanth ArulvelNo ratings yet

- Li Dissertation 2014Document162 pagesLi Dissertation 2014chesspalace2No ratings yet

- Blast Event Simulation For A Structure Subjected To A Landmine ExplosionDocument8 pagesBlast Event Simulation For A Structure Subjected To A Landmine ExplosionaishurenjsNo ratings yet

- Lab ManualDocument62 pagesLab ManualKhalid M. Hafez100% (1)

- 8.2 Final Fracture ToughnessDocument19 pages8.2 Final Fracture ToughnessHenry Theodore DaquinagNo ratings yet

- TEM Lecture CrystallineDocument30 pagesTEM Lecture CrystallineSyed Abdul AhadNo ratings yet

- Yield Point PDFDocument12 pagesYield Point PDFengineer bilal100% (1)

- Scanning Electron MicrosDocument14 pagesScanning Electron Microszhoushengyuanly100% (1)

- Determination of Mixed-Mode Stress Intensity Factors, FractureDocument16 pagesDetermination of Mixed-Mode Stress Intensity Factors, FractureSoupramanien KathirvelouNo ratings yet

- Volumetric DilatometryDocument14 pagesVolumetric DilatometryNasim MalekiNo ratings yet

- Lecture 5 - Crystal Defects-Dislocations - 2 PDFDocument53 pagesLecture 5 - Crystal Defects-Dislocations - 2 PDFArpit Pradhan100% (1)

- Engineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandEngineering Plasticity: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNo ratings yet

- Advances in Plasticity 1989: Proceedings of Plasticity '89, the Second International Symposium on Plasticity and Its Current ApplicationFrom EverandAdvances in Plasticity 1989: Proceedings of Plasticity '89, the Second International Symposium on Plasticity and Its Current ApplicationAkhtar S. KhanNo ratings yet

- Fracture of Nonmetals and CompositesFrom EverandFracture of Nonmetals and CompositesH. LiebowitzNo ratings yet

- Seismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationFrom EverandSeismic Migration: Imaging of Acoustic Energy by Wave Field ExtrapolationNo ratings yet

- Transition Metal ToxicityFrom EverandTransition Metal ToxicityG. W. RichterNo ratings yet

- Toolkit Deck - Empathy MapDocument14 pagesToolkit Deck - Empathy MapkenechidukorNo ratings yet

- Tee UniqueDocument1 pageTee UniquekenechidukorNo ratings yet

- Toolkit Deck As-IsDocument11 pagesToolkit Deck As-IskenechidukorNo ratings yet

- Performance of Neon With MNIST and CIFAR10 PDFDocument52 pagesPerformance of Neon With MNIST and CIFAR10 PDFkenechidukorNo ratings yet

- Performance of Neon With MNIST and CIFAR10 PDFDocument52 pagesPerformance of Neon With MNIST and CIFAR10 PDFkenechidukorNo ratings yet

- The Robots Are ComingDocument16 pagesThe Robots Are ComingkenechidukorNo ratings yet

- LagosDocument10 pagesLagosHowellNo ratings yet

- Anthropometric Data Sheet Edited by DJDocument9 pagesAnthropometric Data Sheet Edited by DJkenechidukorNo ratings yet

- ProjectReport2017 GuidelinesDocument2 pagesProjectReport2017 GuidelineskenechidukorNo ratings yet

- Healthcare Record System2Document5 pagesHealthcare Record System2kenechidukorNo ratings yet

- R&AC Lecture 36Document25 pagesR&AC Lecture 36jadasaripNo ratings yet

- Leadership QuestionnaireDocument4 pagesLeadership QuestionnairekenechidukorNo ratings yet

- BME-020 B-4 (Unit 15)Document33 pagesBME-020 B-4 (Unit 15)kenechidukorNo ratings yet

- GRE Practice Test 1 Evaluating PerformanceDocument12 pagesGRE Practice Test 1 Evaluating PerformanceraviNo ratings yet

- 3 - All Engineering Ranking 2017-US News & World ReportsDocument112 pages3 - All Engineering Ranking 2017-US News & World ReportskenechidukorNo ratings yet

- Top 100 International Scholarships To Watch Out For in 2017 2017-2018 ScholarshipsDocument9 pagesTop 100 International Scholarships To Watch Out For in 2017 2017-2018 ScholarshipskenechidukorNo ratings yet

- U-Values reference table for building materialsDocument3 pagesU-Values reference table for building materialskenechidukor100% (1)

- US Presidents ListDocument2 pagesUS Presidents ListkenechidukorNo ratings yet

- Quiz Questions About Africa For ChildrenDocument4 pagesQuiz Questions About Africa For ChildrenkenechidukorNo ratings yet

- Top 10 Most Luxurious Houses of The WorldDocument10 pagesTop 10 Most Luxurious Houses of The WorldkenechidukorNo ratings yet

- Major6 PDFDocument1 pageMajor6 PDFkenechidukorNo ratings yet

- Nigerian Presidents Since 1960Document10 pagesNigerian Presidents Since 1960kenechidukorNo ratings yet

- C Major 6 B Major 6: Play-By-Ear Music SystemDocument1 pageC Major 6 B Major 6: Play-By-Ear Music SystemkenechidukorNo ratings yet

- Degradation of MaterialsDocument29 pagesDegradation of Materialstanzil10100% (1)

- Fabrication of Counter-Jib Ballast Blocks GuideDocument14 pagesFabrication of Counter-Jib Ballast Blocks GuideNirmalya SenNo ratings yet

- E Cospace: AE Aterial SpecificationDocument5 pagesE Cospace: AE Aterial SpecificationAsraff Abdul RahmanNo ratings yet

- List of Steel TradersDocument2 pagesList of Steel TraderspreanandNo ratings yet

- #2050 PolyhybDocument4 pages#2050 PolyhybmampookuNo ratings yet

- 5600 Series Mechanical Heat DetectorsDocument2 pages5600 Series Mechanical Heat DetectorsHector Cueva LopezNo ratings yet

- Chemical Kinetics +Document22 pagesChemical Kinetics +LaraStrbacNo ratings yet

- Sistema Gaspex Multicamadas EmmetiDocument28 pagesSistema Gaspex Multicamadas EmmetiTec SolNo ratings yet

- Inkjet RefillingDocument5 pagesInkjet RefillingpedroNo ratings yet

- The Secret Is in The Blend: A Whole Menu of BlendsDocument2 pagesThe Secret Is in The Blend: A Whole Menu of BlendsLogist ChinaNo ratings yet

- NEISCO Technical Catalog 2020 Features UPVC Pressure FittingsDocument66 pagesNEISCO Technical Catalog 2020 Features UPVC Pressure FittingsKadiri El MoustaphaNo ratings yet

- TANGRAM KRISIiiiiDocument58 pagesTANGRAM KRISIiiiiSanoj gautamNo ratings yet

- Introduction To Powder Metallurgy A ReviDocument7 pagesIntroduction To Powder Metallurgy A ReviFerry SetiawanNo ratings yet

- DOW FILMTEC™ BW30-400 Element: DescriptionDocument2 pagesDOW FILMTEC™ BW30-400 Element: DescriptionKamal ChokshiNo ratings yet

- GMK4115Document28 pagesGMK4115SeksiNo ratings yet

- Is 694Document30 pagesIs 694nm_rangaNo ratings yet

- Demolition Contractor Guide to Safe Concrete Demolition MethodsDocument20 pagesDemolition Contractor Guide to Safe Concrete Demolition MethodsjayadushNo ratings yet

- Rest House M.nagar Painting EstimateDocument45 pagesRest House M.nagar Painting EstimateMihirNo ratings yet

- Lecture3 CH315 Winter2013 ClassDocument30 pagesLecture3 CH315 Winter2013 ClassRaj PatelNo ratings yet

- Lecture 5 CondenserDocument37 pagesLecture 5 CondenserWalid MohammedNo ratings yet

- Petrolchimico Eng Ita PDFDocument28 pagesPetrolchimico Eng Ita PDFJavier TrujillanoNo ratings yet

- HDP e Drainage Products Brochure 10222114Document20 pagesHDP e Drainage Products Brochure 10222114realchicNo ratings yet

- Premium Water Treatment Solutions ManufacturerDocument6 pagesPremium Water Treatment Solutions ManufacturerUttaraHomesNo ratings yet