Professional Documents

Culture Documents

Eight Things You Should Know About Leak Testing Equipment

Uploaded by

CatalinOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Eight Things You Should Know About Leak Testing Equipment

Uploaded by

CatalinCopyright:

Available Formats

Uson Feature IT Fall 2007:Layout 1

9/21/07

11:28 AM

Page 27

Eight Things You Should Know about

Leak Testing Equipment

The following tips can help you pick the right equipment for your application

ust quality engineers and product managers always be

at odds? The former seeks perfection while the latter

pushes for greater throughput. With the latest

improvements in leak detection devices, both agendas can be

served, as the best examples of this testing equipment help

speed the quality control process without sacrificing accuracy.

Especially when manufacturing for critical applications,

where every product must be tested, the consequences for component failure can come back to haunt the manufacturer in the

form of expensive liability claims. Yet, armed with some

advanced knowledge about what to look for in leak detection

devices, test engineers can increase the odds that all products

will roll off the production line with absolute quality assurance

without acting as an anchor to production schedules.

We had some older manual testers we used in Mexico, but I

can honestly say that our new automated testers have cut the

test time in half, if not a little more, said Brian Yutzy, design

engineer at Marshall Gas Controls in San Marcos, Tex.

Such impressive gains come from a refocused emphasis on

the process of selecting test equipment, one that recognizes the

salient differences between devices. Following are several

important pointers that can help you determine which leak testing equipment you need to help you meet your production

schedules while upholding the highest quality standards.

1) Insist on application specificity.

A one-size-fits-all approach only succeeds at being universally mediocre.

Leak testing equipment demands especially exacting attention to detail, since even very small leaks can mean the difference between product success or failure in critical applications.

Any test equipment must be designed so that it can be adapted

to accurately meet the needs of the quality check at hand.

We used to build all of our test equipment from scratch and,

although doing this worked for us, we needed to shorten our

project time frame, Yutzy said. Since 1979, Marshall Gas

Controls, a division of the S. H. Leggitt Co., has been a highvolume manufacturer of high-pressure and adjustable liquid

propane gas regulators, hose assemblies, and pigtails.

We went looking for an alternative solution, and one of our

reps pointed us to Uson, whom we worked with to develop a system that fit our needs they built-in the necessary I/O cards,

tools, and transducers. Uson, headquartered in Houston, Tex.,

has been in the leak detection and nondestructive testing business for 40 years. The company has developed a range of testers

designed for a wide variety of industrial manufacturing test

applications.

For particularly challenging applications, the experience of

the test equipment vendor accounts for the bulk of successfully

Fig. 1 Todays leak testers, such as this Vector model from Uson,

offer a simple programming process with a high-resolution color

graphic interface. They can provide accurate measurement of

minute pressure and flow changes with high efficiency and are

easy to operate.

channeling a leak testers capabilities for the benefit of a specific product. The vendor should consider each unique case, and

then maximize the potential of the test equipment to fit that

need through a redesign of the tester or by reconfiguring

it with custom-designed pneumatic circuits, for example to

integrate within the manufacturers production system.

2) Look for equipment that automates the testing

process as much as possible.

Ideally, test equipment must feature semiautomatic or fully

automated leak detection systems that streamline product delivery, sealing, clamping, testing, and marking.

Timesaving features such as infills, which reduce volumes

and allow for varying container sizes to be tested in the same

chamber with minimum changeover time and expense, PLC

connectivity, and remote-start input, can greatly speed the testing process.

Additionally, the latest multichannel testers, some of which

can run up to ten channels, automatically cycle through all the

tests at the push of a button.

3) Examine ease of operation.

A leak tester, no matter how capable its performance, is nothing if it isnt easy to use Fig. 1. Programming should be sim-

Based on information from Uson L.P., Houston, Tex., www.uson.com.

FALL 2007 27

Uson Feature IT Fall 2007:Layout 1

9/21/07

11:29 AM

Page 28

plified by software with preformatted test configurations easily

modified to each application.

Leak testers that work within the Windows environment

also lend themselves toward instant, intuitive operation. Added

features to look for include touch screen input, large graphical

displays, selectable engineering units, built-in diagnostics, and

remote troubleshooting.

With the old testers, I was the only one who could support

them, so if anything went down, Id have to jump on a plane

occasionally even to China to reload the software, Yutzy

said. But since our new testers are a standardized piece of

equipment, the staff at our remote plants can program them by

themselves.

4) Check for fixturing that fits your product.

Partly a product of application specificity, the physical

process of affixing the product to the leak tester is extremely

important, as failures here can quickly undo all other attempts

at accuracy and expediency.

At a minimum, leak detection testers should have attributes

like automatic clamping, sealing, and interlocking guards that

perfectly match the dimension orifices of the part under test.

When speed counts, quick connect or auto-coupling pneumatic self-sealing devices can be specified.

Some leak testers have the potential by way of custom volume filling inserts to accommodate industrial components

ranging from lumens measured in millimeters, all the way up to

4.5-in.-diameter orifices.

On the other hand, when complicated products, such as

those with unusual geometry or multiple orifices, require test-

A test has no meaning unless

it can be repeated with the

same results.

ing, then a vendor who manufactures custom couplings must be

located. Find one who will arrange custom CNC work to create

fixtures to handle square and other odd-shaped orifices.

5) Hold out for options in output.

When it comes to certifying a manufacturing process, theres

nothing like a good paper trail. A complete leak detection system must include options for documenting the testing process.

At a minimum, the tester should be able to input leak rates

and other results right into a database such as Access or a

spreadsheet such as Excel, for archival purposes.

Other industry options for data downloading include RJ-45

Ethernet connectors, RS-232 serial ports, PCMCIA card slots,

digital I/O cards, and 24-volt reference outputs. Also helpful are

screens that display results at the control unit, for interrogation

by a supervisor as required. Marking capabilities, whether by

ink, percussion, or laser, also speed and reinforce the documentation process.

6) Consider repeatability.

As any quality control person will tell you, a test has no meaning unless it can be repeated with the same results.

Unlike reliance on the memory of an operator to initiate a

sequence of tests, the automation of leak detection actually

improves repeatability because the testing process becomes

nonsubjective. Innate to some leak detection equipment, the

ability to automatically compensate for temperature and humidity changes also helps ensure consistent product quality.

7) Demand good support from the supplier.

Like most any other sophisticated piece of equipment, a leak

tester is only as good as the support it gets after it leaves the factory. Here again, the number of years a supplier has been in

business counts for a lot, as this adds to its knowledge base in

following up on challenging applications.

Look for a supplier that offers custom system design, installation, and commissioning services. In addition, some suppliers

provide online tools to help test engineers dial in their testing

parameters. One example is online tables that offer quick calculations for hole diameter to flow rate calculation, leak correlation

for one gas relative to another, leak rate to pressure drop relationship, flow rate conversion, conversion for volume, conversion for pressure, and hole/size/flow rate approximation.

8) Seek system flexibility for future upgrades.

Product variations, specification changes, and the introduction of new components all mandate changes in testing parameters. A quality leak tester can accommodate such changes,

saving the expense of having to buy a totally new piece of

equipment.

A modular design suits future needs especially well, as users

can choose only those features that may be needed for initial

requirements, but later expand the same unit to add capabilities

for more complicated applications easily and economically.

For info go to www.aws.org/ad-index

28 INSPECTION TRENDS

You might also like

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationFrom EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationNo ratings yet

- Improve Manufacturing Quality, Yield, and Profi Tability: Advanced Manufacturing Process Analysis SoftwareDocument12 pagesImprove Manufacturing Quality, Yield, and Profi Tability: Advanced Manufacturing Process Analysis SoftwareYue KaiNo ratings yet

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- Guidelines For Automation TestingDocument17 pagesGuidelines For Automation Testingapi-3787635100% (1)

- Factory Acceptance Testing Ensures Equipment Meets SpecsDocument8 pagesFactory Acceptance Testing Ensures Equipment Meets Specspsn_kylm100% (2)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- 10 Factors Impacting Next-Gen Pilot PlantsDocument21 pages10 Factors Impacting Next-Gen Pilot PlantsNathalie Jamett GuillierNo ratings yet

- Dimensional Analysis: Practical Guides in Chemical EngineeringFrom EverandDimensional Analysis: Practical Guides in Chemical EngineeringNo ratings yet

- Enterprise Testing FundamentalsDocument3 pagesEnterprise Testing FundamentalsSrinivas SomanchiNo ratings yet

- d3804b51 sw5Document7 pagesd3804b51 sw5shailesh singhNo ratings yet

- Developments and Experimental Tests On A Laboratory Scale Drilling Automation SystemDocument17 pagesDevelopments and Experimental Tests On A Laboratory Scale Drilling Automation SystemnanlingjigongNo ratings yet

- Controls As Part of The Bigger PictureDocument2 pagesControls As Part of The Bigger PictureRodica TimofteNo ratings yet

- Test AutomationDocument4 pagesTest AutomationkualitatemNo ratings yet

- EEE_1Document5 pagesEEE_1Ogbodo IsraelNo ratings yet

- Ateq Air Leak Testing: Automobile TransmissionDocument12 pagesAteq Air Leak Testing: Automobile Transmissionjack macNo ratings yet

- Flow Meters-SierraDocument5 pagesFlow Meters-SierraRahul ChandrawarNo ratings yet

- Intro and Generalized ConfigurationsDocument37 pagesIntro and Generalized Configurationsset letNo ratings yet

- How Can We Improve The Trust in Process Analzers?Document19 pagesHow Can We Improve The Trust in Process Analzers?Andres FlorezNo ratings yet

- Benefits Parallel ProcessingDocument4 pagesBenefits Parallel ProcessingAnnaKarenina56No ratings yet

- Proper Validation of Filter Test Stands Is Critical For Product Development ProgramsDocument4 pagesProper Validation of Filter Test Stands Is Critical For Product Development ProgramsnannidNo ratings yet

- Considerations For Estimating The Costs of Pilot-Scale FacilitiesDocument9 pagesConsiderations For Estimating The Costs of Pilot-Scale FacilitiesAlexNo ratings yet

- OPTICast Workbook 8-3-0 11-18-14Document51 pagesOPTICast Workbook 8-3-0 11-18-14emilianoNo ratings yet

- Robustness Valdiation Step by StepDocument36 pagesRobustness Valdiation Step by StepGreenheart OussamaNo ratings yet

- Development of Multipurpose Quality Inspection System For Plastic Molding PartsDocument19 pagesDevelopment of Multipurpose Quality Inspection System For Plastic Molding Partssmartxdigital marketNo ratings yet

- Fundamentals of Agv Acceptance TestingDocument8 pagesFundamentals of Agv Acceptance TestingYap Weiloon100% (1)

- At The Heart of Halliburton Is Well TestingDocument9 pagesAt The Heart of Halliburton Is Well TestingYasir Ahmed100% (1)

- Design Verification Testing Methods and TechniquesDocument10 pagesDesign Verification Testing Methods and TechniquesPalaniyappan KailasamNo ratings yet

- Witness Testing of API 610 Centrifugal Pumps and API 611 Steam TurbinesDocument9 pagesWitness Testing of API 610 Centrifugal Pumps and API 611 Steam Turbinessiva242245No ratings yet

- Unit-4 & 5Document21 pagesUnit-4 & 5neemarawat11No ratings yet

- Report ChaptersDocument48 pagesReport ChaptersRaghul ArulNo ratings yet

- Installation of Pharmaceutical Process Piping - Part 1Document5 pagesInstallation of Pharmaceutical Process Piping - Part 1Smith780512No ratings yet

- Introduction FormatDocument31 pagesIntroduction Formatshashikumar_desaiNo ratings yet

- Air Gauging BaiscsDocument36 pagesAir Gauging BaiscsAnil MoreNo ratings yet

- UltraPIPE Software InglesDocument34 pagesUltraPIPE Software InglesJairo ContrerasNo ratings yet

- Checking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCDocument5 pagesChecking Machine Tools: Their Uses Keywords: Machines Tols, Measurements, Mini-Lathe, Accuracy, CNCMihai GhitulescuNo ratings yet

- Prevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsDocument3 pagesPrevalidation Study of A Form-Fill-Seal Packaging Machine - Pharmaceutical & Medical Packaging NewsJanna Hendrix BabsonNo ratings yet

- Top-Co Tech News Volume 1 Issue 4 - Flow LoopDocument8 pagesTop-Co Tech News Volume 1 Issue 4 - Flow LoopsamruggerNo ratings yet

- Leveraging Cloud and Open Source for Performance TestingDocument5 pagesLeveraging Cloud and Open Source for Performance TestingaustinfruNo ratings yet

- Test Compression - DFTDocument8 pagesTest Compression - DFTbalaji ENo ratings yet

- 2019 TUGx Global Seminar Abstracts on Test StrategiesDocument15 pages2019 TUGx Global Seminar Abstracts on Test StrategiesMahesh MahiNo ratings yet

- 3 Prerequisites To Establishing An Environmental Monitoring PlanDocument8 pages3 Prerequisites To Establishing An Environmental Monitoring PlanCatrinescu OanaNo ratings yet

- Witness Testing of Api 610 Centrifugal PumpsDocument6 pagesWitness Testing of Api 610 Centrifugal PumpsHatem ShawkiNo ratings yet

- Extrel Questor GPDocument4 pagesExtrel Questor GPDidit AndiatmokoNo ratings yet

- Translating The Economic Benefits of Parallel Memory Test To Non-Memory DevicesDocument4 pagesTranslating The Economic Benefits of Parallel Memory Test To Non-Memory DevicesKhoo Voon ChingNo ratings yet

- 10 Hakan Karlsson Lorentzen Wettre Standardized PP Quality Testing For Process OptimizationDocument5 pages10 Hakan Karlsson Lorentzen Wettre Standardized PP Quality Testing For Process OptimizationAhmed AsforaNo ratings yet

- How To Get Better Mfi Results: TroubleshootingDocument4 pagesHow To Get Better Mfi Results: TroubleshootingppmasterNo ratings yet

- High Quality Test Solutions For Secure Applications: Silicon Test and Yield Analysis WhitepaperDocument7 pagesHigh Quality Test Solutions For Secure Applications: Silicon Test and Yield Analysis WhitepapersthomasangNo ratings yet

- How To Witness Test A TransformerDocument3 pagesHow To Witness Test A TransformerMind of Beauty100% (1)

- Totally Data Driven Automated TestingDocument17 pagesTotally Data Driven Automated TestingHareen ReddyNo ratings yet

- (TP0A011) High-Capacity Liquid Measurement SystemsDocument5 pages(TP0A011) High-Capacity Liquid Measurement SystemsRoberto Carlos TeixeiraNo ratings yet

- Strategies of Succesful Distillation Equipment Revamps PDFDocument6 pagesStrategies of Succesful Distillation Equipment Revamps PDFJose DavalilloNo ratings yet

- Performance Enhancement of Processor Functional Verification by Script Based ApproachDocument7 pagesPerformance Enhancement of Processor Functional Verification by Script Based ApproachInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- 06 TM Test CompressionDocument7 pages06 TM Test CompressionRathnambiga UnnikrishnanNo ratings yet

- BCA ProjectDocument64 pagesBCA Projectpmcmbharat264No ratings yet

- Efficient Type Testing of Digital Protection RelaysDocument0 pagesEfficient Type Testing of Digital Protection Relaysvasilev_darkoNo ratings yet

- A Comparative Study of Manual and AutomatedDocument6 pagesA Comparative Study of Manual and AutomatedShinoMasters thesisNo ratings yet

- Unit TestingDocument5 pagesUnit TestingDanyal KhanNo ratings yet

- Arc Basics - FA 2009 ISO 14175 Revised StandardDocument10 pagesArc Basics - FA 2009 ISO 14175 Revised StandardCatalinNo ratings yet

- Leak Detection MethodsDocument24 pagesLeak Detection MethodsCatalinNo ratings yet

- Arc Gases - FA 1997 The Shielding Gas HandbookDocument79 pagesArc Gases - FA 1997 The Shielding Gas HandbookCatalinNo ratings yet

- Coming Financial CrashDocument35 pagesComing Financial CrashDykey22No ratings yet

- Arc Metals FE - DuplexDocument8 pagesArc Metals FE - DuplexCatalinNo ratings yet

- Remains of Atlantis DiscoveredDocument6 pagesRemains of Atlantis DiscoveredÊlder Lima0% (1)

- Brochure On Shielding GasesDocument12 pagesBrochure On Shielding GasesCatalinNo ratings yet

- Shielding Gases For Stainless Steel BrochureDocument7 pagesShielding Gases For Stainless Steel BrochureCatalinNo ratings yet

- Leak Detection MethodsDocument24 pagesLeak Detection MethodsCatalinNo ratings yet

- British Legal SystemDocument7 pagesBritish Legal SystemValentin TriponescuNo ratings yet

- 101 Shortcuts in Math Anyone Can DoDocument95 pages101 Shortcuts in Math Anyone Can DoNaveed 205100% (3)

- Expressing Emotions Through Body Llanguage Lectures)Document203 pagesExpressing Emotions Through Body Llanguage Lectures)محمد موسىNo ratings yet

- Helium Leak TestDocument8 pagesHelium Leak TestHiren Panchal50% (2)

- IENCSEPRO0007-2 - General Leak Test Procedure PDFDocument9 pagesIENCSEPRO0007-2 - General Leak Test Procedure PDFCatalinNo ratings yet

- 393 Profile PDFDocument2 pages393 Profile PDFCatalinNo ratings yet

- 321 GeigerDocument25 pages321 GeigerMadson MachadoNo ratings yet

- Acoustic Leak Detection in BoilersDocument7 pagesAcoustic Leak Detection in BoilersRajash Vk100% (1)

- Quality AssuranceDocument210 pagesQuality AssuranceCatalinNo ratings yet

- 11 LeakDetectionDocument66 pages11 LeakDetectionCatalinNo ratings yet

- 11 LeakDetectionDocument66 pages11 LeakDetectionCatalinNo ratings yet

- Helium Leak TestDocument8 pagesHelium Leak TestHiren Panchal50% (2)

- Manual de Servicio Tvs 100 SportDocument2 pagesManual de Servicio Tvs 100 SportJOSE0% (1)

- Cross Reference-Electroswitch To Shallco RevBDocument31 pagesCross Reference-Electroswitch To Shallco RevB4Chat GptNo ratings yet

- 1 - Measurement Assurance TechnologyDocument116 pages1 - Measurement Assurance TechnologyShouzab Abbas0% (1)

- Job AidDocument336 pagesJob AidKishor VishwanatheNo ratings yet

- Materials Testing Equipment For Civil EngineeringDocument308 pagesMaterials Testing Equipment For Civil EngineeringCooper Technology100% (1)

- BOMDocument1 pageBOMHytech Pvt. Ltd.No ratings yet

- ATS 4P 250A Panel and Distribution Boards BOQ ListsDocument6 pagesATS 4P 250A Panel and Distribution Boards BOQ ListsKao SophearakNo ratings yet

- Magazine: The Sound EngineeringDocument52 pagesMagazine: The Sound EngineeringMatthew Walker100% (1)

- CBC Computer Systems ServicingDocument96 pagesCBC Computer Systems ServicingDemy Magaru Calate75% (4)

- MultimeterDocument12 pagesMultimeterallen jann pulmaNo ratings yet

- Rish Xmer Protection CTDocument14 pagesRish Xmer Protection CTAarif PatelNo ratings yet

- Electronic Instruments and Instrumentation TechnologyDocument11 pagesElectronic Instruments and Instrumentation TechnologyAnonymous z3ihT9DJ1vNo ratings yet

- Model Simulink Motor DC Terkendali Jangkar (Daur Tertutup)Document2 pagesModel Simulink Motor DC Terkendali Jangkar (Daur Tertutup)Oktavianus Okec KatiNo ratings yet

- LatihanDocument17 pagesLatihanMohd ShahrilNo ratings yet

- Lecture07 Testing PDFDocument50 pagesLecture07 Testing PDFJavier Valencia MurilloNo ratings yet

- Price List 2018-19: Rishabh Instruments Pvt. LTDDocument77 pagesPrice List 2018-19: Rishabh Instruments Pvt. LTDpranay prakashNo ratings yet

- Transistor Curve TracerDocument8 pagesTransistor Curve TracerCarlos Ramos100% (1)

- MoDOT Route XX Project Quality Management PlanDocument17 pagesMoDOT Route XX Project Quality Management PlanKhaled Abdelbaki100% (1)

- Pengukuran Listrik dan ElektronikaDocument31 pagesPengukuran Listrik dan ElektronikaBagja HendiansyahNo ratings yet

- CHROMA Catalog GC - 2012 - en PDFDocument312 pagesCHROMA Catalog GC - 2012 - en PDFy2k_yah77580% (1)

- Logic Probe - Tester Basics - Radio-Electronics PDFDocument3 pagesLogic Probe - Tester Basics - Radio-Electronics PDFabhishekNo ratings yet

- Gadar Series - Current ElectricityDocument118 pagesGadar Series - Current ElectricitybackuoonluNo ratings yet

- Electronic Test Equipment: Electronic Test Equipment Is Used To Create Signals and Capture Responses FromDocument5 pagesElectronic Test Equipment: Electronic Test Equipment Is Used To Create Signals and Capture Responses FromPrasanthNo ratings yet

- Multi Tester Parts & UsesDocument37 pagesMulti Tester Parts & UsesRonald Baral87% (31)

- Audit Checklist For The Evaluation of Calibration SystemsDocument22 pagesAudit Checklist For The Evaluation of Calibration Systemse2yc100% (2)

- GR 10 - Term 3 Experiment MemoDocument3 pagesGR 10 - Term 3 Experiment Memoantonette kotzeNo ratings yet

- Lab JamDocument10 pagesLab JamIthel LtheiNo ratings yet

- Atrt01s2 021210 108Document4 pagesAtrt01s2 021210 108Rakesh KumarNo ratings yet

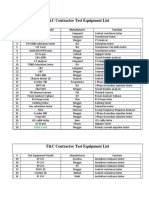

- T&C Contractor Test Equipment ListDocument2 pagesT&C Contractor Test Equipment Listahmed tarekNo ratings yet

- Vintage Electronics Equipment ListingDocument14 pagesVintage Electronics Equipment ListingRuggero RamponeNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)