Professional Documents

Culture Documents

Control Motor Ac-Dc

Uploaded by

Luis Ramos PumaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control Motor Ac-Dc

Uploaded by

Luis Ramos PumaCopyright:

Available Formats

1

Brian Bouma

Overview and Control of DC and AC Motors

Abstract an overview of the differences in form and

function between DC and AC motors. An in-depth analysis of

the general differential equations and transfer functions of DC

and AC motors. Strategies for controlling DC and AC motors

using gain and PID control are discussed and analyzed in depth.

Methods for determining the time constants of DC and AC

motors are discussed and analyzed.

Index Terms AC motors, Control systems, DC motors,

Motor drives.

PID

I. NOMENCLATURE

Proportional Integral Derivative

II. INTRODUCTION

Motors are an integral part of engineering in todays

society. They are used in a wide variety of applications, from

running fans to driving belts to turning wheels. Yet, despite

their prevalence in the designs of undergraduate engineering

students, most such students have very little idea of how

motors actually work, or of how to control them safely and

dependably. This paper describes both DC and AC motors,

analyzes them from a control standpoint, and determines

adequate strategies for controlling them in a manner which is

both safe and reliable. Stepper and servo motors will not be

discussed here, as their form, function, and application are

considerably different from that of DC and AC motors, and

the analysis of those four motor types would be too much

information to cover in this setting.

III. MOTOR OVERVIEW

To the uninformed observer, DC and AC motors appear to

be basically identical. Even though they seem to operate in

essentially the same way, their physical structures, and thus

their range of applications, vary significantly.

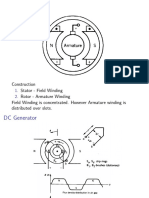

The brush DC motor is arguably the simplest variablespeed DC motor design, in addition to being the most

common. For these reasons, the brush design is the one being

described and analyzed here. The brush DC motor (or all DC

motors, for that matter) is made up of a stator and a rotor

(refer to Fig. 1 for all descriptions relating to the brush DC

motor). As the names suggest, the rotor (the circular portion

of Fig. 1 made up of eight T-shaped parts) is the part of the

motor that rotates during operation, while the stator (the dark

blue block and light blue fingers around the rotor in Fig. 1)

remains stationary during operation, relative to the motors

casing and mounting [3]. The stator is made up of either a

This work was done for Engineering 315 at Calvin College in Grand Rapids,

Michigan, in the fall of 2004. All software used in this paper was supplied by

Calvin College. This project was supported financially by Calvin College and

Smiths Aerospace LLC.

Brian Bouma works for Smiths Aerospace LLC and attends Calvin College

in Grand Rapids, MI 49546 USA (e-mail: bbouma83@calvin.edu).

winding or a magnet, which creates magnetic flux in the

magnetic field formed between the stator and the rotor [3].

For the simple analytical purposes herein, it makes no

difference whether a winding or a magnet is used in the

stator, so the use of a magnet will be assumed. The rotor has

a winding on its surface, termed the armature, in which

electromotive forces are induced by the magnetic field formed

between the stator and the rotor [3]. The armature winding is

supplied current through the collector (the yellow cylinder

attached to the rotor in Fig. 1), on which the brushes (the two

brown tabs touching the collector) apply pressure [3]. The

collector is mounted on the same shaft as the armature, and

the fixed brushes are connected to the armature terminals [3].

Thus, the power to the motor runs through the brushes, into

the collector, and through the armature winding to produce

the electromotive forces between the stator and the rotor (the

power cables are the red lines attached to the brushes in Fig.

1). The brush-collector assembly provides current to the

armature windings in such a way that the current flows in one

direction when the windings are under a magnetic North pole

(from the stator magnet), and in the other direction when the

windings are under a magnetic South pole [3]. The rotor

windings are made up of coils, called sections, all sections

being of an equal number of turns (in Fig. 1, the eight colored

sets of line segments, two segments per set, on the front of

the T-shaped parts of the rotor are the ends of the coils; the

coils run through the length of the rotor and wrap around the

opposite end of the T-shaped parts of the rotor) [3]. Each

section has two sides, which are inserted into two slots spaced

apart a distance equal to the distance between the two field

poles [3]. This way, when the conductors of one side of a

section are under the North pole, the conductors of the other

side of the same section are under the South pole [3]. The

sections of armature winding are all connected together, in

series, with the end of the last section being connected to the

beginning of the first section, so that the winding as a whole

is continuous, having no particular start or finish [3]. For

this to work, each slot must contain two sides of sections (half

each of two different sections) [3]. As the rotor rotates, when

a section changes from being under the North pole to being

under the South pole (and hence the current in that section

reverses direction), that section commutates. Commutation

of a section of the winding is the changing of the section from

being under one pole to being under the other pole [3]. Two

sections (two sections that are opposite each other on the

rotor) commutate at a time, one switching from North to

South pole, the other switching from South to North pole.

Because the two poles swap sections simultaneously, half of

the windings are under each pole at all times. The North and

South poles are an effect of the flux in the armature created

by the current flowing through the two sets of windings (each

pole containing one set). When a section commutates, the

brushes, applying pressure on the collector, short-circuit the

two ends of that section together, to release the energy stored

in the coils of the section before the direction of current flow

in the section is reversed [3]. Despite this ingenious design,

sparks are still produced between the brushes and the

collector [3].

grooves, depending on the exact design, but that distinction

makes no difference for this analysis), through which the

windings run (the red arrow in Fig. 3 indicates one such slot)

[3].

Fig. 1. Brush DC Motor

Fig. 3. Winding Slot in AC Motor Stator

The primary advantage of a DC motor is that the

magnitude of the torque produced by the output shaft never

changes [3].

This makes the DC motor perfect for

applications that have large startup loads, particularly

automotive applications (like the drive wheels in electric

vehicles, for instance), where DC power is readily available

under most circumstances.

Today, the asynchronous (or induction) motor is the most

commonly used electric motor in industry and in household

devices [3]. For this reason, the asynchronous motor is the

AC motor design being described and analyzed here.

Electromagnetic induction is the creation of a current through

a conductor that that is within a magnetic field [3]. The

magnetic field is capable of generating a large current in the

conductor without requiring any physical contact whatsoever

[3]. It is this principle that allows the induction motor to

function without having any sliding electrical contacts (such

as the brushes in the brush DC motor) [3]. The stator (the

hollow cylinder in Fig. 2) is essentially a hollow cylinder with

no ends, and may be constructed out of either cast iron or

aluminum [3].

The motors number of poles is determined by the layout of

the windings within the stator (the number of poles will

always be a multiple of two, but, again, that has no impact

here) [3].

The rotor is also cylindrical, though this cylinder does have

a core. The rotor is made of steel disks (the long black

segments in Fig. 4) slotted around the exterior of the cylinder

[3]. A short-circuited winding is placed in the slots between

the steel disks, preventing the need for a supply to be

connected to the rotor [3]. The currents in the rotor are

induced by the interaction between the magnetic fields of the

stator and the rotor, leading to the name for this type of motor

[3]. A copper or aluminum bar (in the case of Fig. 4,

aluminum, judging by the color) is also placed in each slot

between the steel disks [3]. A circular conducting ring is

placed on the end of the cylinder (refer to Fig. 4), to connect

the ends of the bars together (because the conducting ring and

bars resemble a circular cage, this rotor design is called

squirrel cage) [3].

Fig. 4. Squirrel Cage and Steel Disks in AC Rotor

Fig. 2. AC Motor Stator and Rotor

The inner face of the stator is made up of deep slots (or

The interaction between the stator magnetic field and the

rotor magnetic field forces the rotor to spin, relative to the

stator, resulting in a functioning AC motor [3].

There are two varieties of asynchronous motors: three

phase and single phase. Three phase motors are used mainly

in industry, while single phase motors are more common

household appliances [3].

The primary advantage of an induction motor is that it

contains no sliding electrical contacts, resulting in a simple

robust design that is easy to manufacture and maintain [3]. A

secondary advantage is that the available range of induction

motors is from only a few watts to several megawatts, making

the use of induction motors in a wide variety of applications

physically feasible [3].

IV. TRANSFER FUNCTIONS

The differential equations and transfer functions of DC and

AC motors are crucial to the analysis of the control of these

machines. The transfer functions are derived from the

differential equations using Laplace transforms, a method all

too familiar to most engineers.

The differential equations and transfer functions for DC

motors are more complicated than those of AC motors, due to

the fact that DC motors have time lags because of both the

armature inductance and the winding, while AC motors have

only a single time constant. DC motors are described by

three differential equations: The developed torque (T(t)) is

described by

T( t ) K2 if( t )

,

(1)

where if(t) is the current through the field and K 2 is constant

[2]. The field voltage (vf(t)) is described by

d

v f( t ) Rf if( t ) Lf if( t )

dt

,

(2)

where Rf is the field resistance and Lf is the field inductance

[2]. Lastly, the mechanical torque (T(t)) is described by

I

d

( t) B ( t)

dt

dt

,

(3)

where I is the motors moment of inertia, B is the motors

viscous damping, and (t) is the motors angular position [2].

By assuming zero initial conditions and then Laplace

transforming each of these equations, s-domain equations are

reached. The developed torque is now

T( s ) K2 If( s )

,

(4)

the field voltage is now

Vf( s )

Lf s Rf If( s )

,

(5)

and the mechanical torque is now

T( t )

Is 2 Bs (s ),

T( s )

(6)

where all of the constants have the same meaning as in the

time-domain differential equations, I f is used in place of i f and

is used in place of [2]. By substituting and solving, the

transfer function of the motor is found to be

Km

( s )

Vf( s )

s m s 1 e s 1

(7)

where

m

B

is the mechanical time constant of the motor,

(8)

Lf

Rf

(9)

is the electrical time constant of the motor, and

K2

Km

B Rf

(10)

is another constant [2]. This is the transfer function that will

be used for the control analysis of the DC motor in the next

section.

The differential equations and transfer functions for AC

motors are considerably less complicated than those for DC

motors, owing to the fact that AC motors only have a single

time constant while DC motors have two. AC motors are

described by two differential equations: The torque (T(t)) is

described by

d

T( t) K v ( t) m ( t)

dt

,

(11)

where K is a constant, v(t) is the voltage provided to the

motor, (t) is the angular position of the motor, and m is

described by

"stall torque (at rated voltage)"

m

"no-load speed (at rated voltage)" ,

(12)

where stall torque (at rated voltage) and no-load speed (at

rated voltage) are characteristics of any specific AC motor

[2]. The torque is also described by

d

d

( t) B ( t)

dt

dt

,

(13)

which is identical to the third differential equation that

describes DC motors, and has the same meaning [2]. By

equating the two AC motor equations, assuming zero initial

conditions, and then taking the Laplace transform of the

resultant equation, the transfer function of an AC motor is

found to be

Km

( s )

T( t )

V( s )

s s 1 ,

(14)

where

Km

K

m B

(15)

is a constant, and

I

m B

(16)

is the time constant of the motor [2]. This is the transfer

function that will be used for the control analysis of the AC

motor in the next section.

V. CONTROL

Precise control of motors is vital to the use of motors in

any application. Without a system in place to prevent the

motor from operating unchecked, a step increase to the inputs

of a motor would result in the motor accelerating until it

literally broke apart, costing untold amounts of money to

repair and replace damaged equipment, and undoubtedly

ruining someones day.

The first step to safe control is the use of negative

feedback, a concept so common that it warrants no

explanation here, which has been employed in all of the

simulations whose results are shown here.

A control method which is popular because of its

robustness, its simplicity, and its reusability is PID control. A

PID controller contains a proportional gain, an integrator,

and a differentiator (hence its name), all of which are

summed together to produce the output of the controller. The

transfer function of a PID controller has the form

KI

KD s KP s KI

KP

KD s

s

s

,(17)

where KP is the proportional gain coefficient, K I is the

integrator coefficient, and KD is the differentiator coefficient.

The proportional gain is used to amplify the input signal.

The integrator is used to improve the accuracy of the control

system, that is, to minimize the steady-state error (the

difference between the input value and the final output value)

as much as possible. The differentiator is used to increase the

damping in the system, which will decrease both the peak

time and the settling time of the system.

As can be recalled from above, the transfer function of the

DC motor is third order in the denominator, so it has three

poles (roots of the polynomial in the denominator). Likewise,

the transfer function of the PID controller is second order in

the numerator, so it has two zeros (roots of the polynomial in

the numerator). Thus, the PID values may be set so that the

zeros of the PID controller eliminate the poles of the DC

motor. However, since the DC motor has three poles and the

PID controller only has two zeros, only two of the poles may

be eliminated. This raises the obvious question: Which poles

should be eliminated and which one should be left alone?

That depends on which pole, as the only pole in the system,

results in a system with the shortest rise time, the shortest

settling time, and the least overshoot. This system was

modeled and simulated in MATLAB/Simulink (see Fig. 5),

using a unit step input as a standard input.

PID

Fig. 5. Simulink Model of DC Motor Control System with

PID Control

The gain block in this system is used to dramatically speed up

the response of the system, although it does not effect the

location of any of the poles or zeros, so it does not impact the

control aspect of this analysis (even though it decreases the

peak and settlings times for the system). The electrical time

constant of the motor ( e) was assumed to be 1 ms, the

mechanical time constant of the motor ( m) was assumed to be

100 ms, and the motor constant (K m) was assumed to be 0.050

N*m/A, all of which are typical constants for a DC motor [1].

The first two poles to be eliminated were the poles that result

from the electrical and mechanical time constants, leaving

the third pole (at s = 0) alone. This was done by setting the

differentiator coefficient to the product of the electrical and

mechanical time constants, the proportional gain coefficient

to the sum of the electrical and mechanical time constants,

and the integrator coefficient to one. The result of this

simulation is so worthless that it will not be shown here. By

eliminating those two particular poles (hand calculations

would confirm this, but are not necessary here), the overshoot

of the system became 100% (the output was 2 while the

input step was only 1), the peak time became 0.44 seconds

(not terrible, but not great either), and the settling time

became infinite. The system never settled. The output of the

system was sinusoidal and continued for all of eternity (until

the simulation time of ten seconds was reached). This is no

good. In the next simulation run, the two poles eliminated

were the pole at s = 0 and the pole created by the electrical

time constant. This was done by setting the differentiator

coefficient to the value of the electrical time constant, the

proportional gain coefficient to one, and the integrator

coefficient to zero. The output of this simulation is shown in

Fig. 6.

Fig. 6. Time Response of System with Mechanical Time

Constant Pole

Fig. 6 shows the time response of the system when the

mechanical time constant and s = 0 poles were eliminated by

the settings of the PID controller. The horizontal axis shows

time, in seconds, and the vertical axis is the output of the

system, normalized to the magnitude of the input step.

Closer analysis of this simulation output shows a settling time

(using 2% criterion) of approximately 0.76 seconds, a peak

time of approximately 0.14 seconds, and an overshoot of

approximately 49%. This simulation shows a better peak

time (0.14 seconds as opposed to 0.44 seconds), a better

overshoot (49% as opposed to 100%), and a much better

settling time (0.76 seconds as opposed to not settling at all).

However, the peak time could still improve (a little), the peak

time could improve quite a bit, and the overshoot has the

most room for improvement. The simulation was run a third

time, this time eliminating the pole at s = 0 and the pole

created by the mechanical time constant. This was done by

setting the differentiator coefficient to the value of the

mechanical time constant, the proportional gain coefficient to

one, and the integrator coefficient to zero. This simulation

output is shown in Fig. 7.

settling time will change if the time constant is changed. For

comparison purposes, the model of Fig. 8 was simulated (see

Fig. 9), using a gain of 135, as that value is roughly midway

between the two gain values discussed earlier which denote

the two endpoints of the range in which optimum output

values are produced.

Fig. 7. Time Response of System with Electrical Time

Constant Pole

The simulation output in Fig. 7 shows that the elimination of

the s = 0 and mechanical time constant poles produces the

best system performance yet. Since the output does not

oscillate, the peak time cannot be characterized as having a

unique value, so the peak time will be considered to be the

same as the settling time. The settling time is approximately

0.073 seconds (73 ms), and there is no overshoot. Note also

that while the system corresponding to Fig. 6 was simulated

for 1 second (with the step input occurring at time t = 0

seconds), the system corresponding to Fig. 7 was simulated

for only 0.25 seconds, because its time response was so fast

that it could scarcely be seen on a 1-second time plot.

From these findings, it appears as though the best way to

use a PID controller in conjunction with a DC motor is to set

the PID values so that the s = 0 pole and the pole created by

the larger of the two time constants (typically the mechanical

time constant) are eliminated.

The transfer function of an AC motor is simple enough

that, even though PID control may be implemented for an AC

motor (as it will be later), acceptable time response values

may be attained by simply adjusting the gain in the system

(see Fig. 8). For all of the AC motor control system

simulations, a time constant () of 0.1 seconds (100 ms) and a

motor constant of 0.050 N*m/A have been assumed.

Fig. 8. Simulink Model of AC Motor Control System

By running this simulation many times, and adjusting the

gain value each time, it can be found that, between the gain

values of approximately 128.957 and 143.076, the overshoot

is less than (or equal to) 10% and the peak time is less than

(or equal to) 0.5 seconds. At a gain of 128.957, the overshoot

is 8.21% while the peak time is exactly 0.5 seconds. At a

gain of 143.076, the peak time is 0.461 seconds while the

overshoot is exactly 10.0%. For gain values between the two

just given, the overshoot and peak time are between the two

extremes given above for overshoot and peak time. It just so

happens that the settling time, regardless of the gain value, is

always 0.8 seconds (two opposing values, both functions of

the gain, cancel out in the calculation of the settling time).

These values are, of course, also dependent on the value of

the motors time constant, so the overshoot, peak time, and

Fig. 9. AC Motor System Time Response with Gain of 135

This simulation output shows a peak time of approximately

0.48 seconds, a settling time of approximately 0.73 seconds,

and an overshoot of approximately 9.0%.

Since the AC motor transfer function is only second order

(as opposed to the third order DC motor transfer function),

those values may be easily changed by adjusting the gain

value. However, better system response may be attained by

placing a PID controller in the control system with the motor

(see Fig. 10), and setting the PID values accordingly.

Fig. 10. Simulink Model of AC Motor Control System

with PID Control

Because the denominator of the AC motor transfer function is

second order, both poles may be eliminated by setting the PID

values strategically.

This was done by setting the

differentiator coefficient to the value of the time constant, the

proportional gain coefficient to one, and the integrator

coefficient to zero. The output of that simulation is shown in

Fig. 11.

Fig. 11. Time Response of System with Both Motor Poles

Eliminated

Closer inspection of Fig. 11 reveals a peak time of 0.14

seconds, a settling time of 0.065 seconds, and an overshoot of

0.4%. The settling time is less than the peak time because the

peak value is less than 2% greater than the final value. In

comparison to the simulation (of Figs. 8 and 9) which was

optimized by adjusting nothing other than the gain, this

simulation exhibited considerable improvement, decreasing

the peak time by approximately 0.34 seconds (from 0.48 to

0.14 seconds), decreasing the settling time by approximately

0.665 seconds (from 0.73 to 0.065 seconds), and decreasing

the overshoot by approximately 8.6% (from 9.0 to 0.4%). A

simpler way to compare the two responses by inspection is to

note the time scale in Figs. 9 and 11. The simulation

represented in Fig. 9 was run for 1.5 seconds, while the

response of the system whose simulation is represented in

Fig. 11 was so much faster that a time scale of only 0.5

seconds had to be used to attain a high enough resolution in

the output graph that the response could be seen without

difficulty.

From these findings, it appears as though the best way to

control an AC motor is the use a PID controller and to set the

PID values so that the poles of the motor are eliminated.

When such equipment is not available, the gain can be

adjusted to optimize the response, although that approach

produces much less favorable results than those ensuing from

the use of a PID controller.

those values must be obtained experimentally.

In the case of a DC motor, this is easier said than done.

First, a system resembling that of Fig. 5 must be constructed,

where the output being measured is the rotational speed of the

output shaft of the motor. Keep in mind that, in this case, the

transfer function of the motor is really a black box; all that is

known about is for certain is that it has three poles, one of

them at s = 0, and the other two created by the two time

constants. Unfortunately, there is no cut and dried, step by

step process by which to determine the time constants of the

DC motor. As such, the system must be run many times,

adjusting the PID values each time. The integrator coefficient

should be set to zero, and the proportional gain coefficient

should be set to one, and both values should left there for all

of the system runs. Only the value of the differentiator

coefficient should be changed between runs. The electrical

time constant will likely be around 1 ms, and the mechanical

time constant will be greater than the electrical. Recall from

earlier that the best system response will be attained when the

differentiator coefficient is equal to the mechanical time

constant. The mechanical time constant may range anywhere

from only a few milliseconds to hundreds of milliseconds, so

that full range should be tested. Thus, when a system

response closely resembling Fig. 7 (no oscillations, no

overshoot, and a very short settling time) is achieved, the

value of the differentiator coefficient for that run is the value

of the mechanical time constant.

To determine the time constants of an AC motor, a system

resembling that of Fig. 8 must be constructed, where the

output being measured is the rotational speed of the output

shaft of the motor. Choose an arbitrary gain value (it should

be somewhat high, to get a relatively fast time response, so a

run will take no more than a couple seconds, but not so high

that separate oscillations are indistinguishable), and then do

not change the gain value again. Keep in mind, again, that

the transfer function of the motor is really a black box, and

the only thing that is known about it for certain is that it has

two poles, one at s = 0 and the other created by the time

constant. The system must be run a single time (after

running it several times to determine a good gain value), and

the peak time, settling time, and percent overshoot all need to

be observed. Fig. 12 shows the output of the model of Fig. 8,

using a gain of 1000 instead of the gain of 135 shown in Fig.

8.

VI. TIME CONSTANTS

A method to control both DC and AC motors with PID

control has been determined. This method is heavily reliant

on the time constants of the motor, and assumes that anyone

trying to implement PID control for a motor knows the values

of the motors time constants. Since the nameplate on most

motors only provides the name of the manufacturer, the

motors serial number, the motors input voltage, the

maximum rotational speed of the motors output shaft (in

RPM), the power of the motor (in horsepower), and the

weight of the motor, another questions arises: How can the

time constants be determined for a motor that one already has

in hand? This is a very good question.

While the data sheets for some motors do contain the

values of the time constants, this is not true in every case, so

Fig. 12. AC Motor System Response with Gain of 1000

Fig. 12 shows a peak time of approximately 0.14 seconds, a

settling time of approximately 0.76 seconds, and an overshoot

of approximately 49%. Next, several calculations must be

made, using the following equations:

PO 100 exp

1 ,

(18)

where PO is the percent overshoot of the response and is the

damping ratio of the system,

Tp

2

n 1

,

(19)

where Tp is the peak time of the response and n is the natural

frequency of system,

4

Ts

n

,

(20)

where Ts is the settling time of the response, and

1

2 n

,

(21)

where is the time constant of the motor. Using the percent

overshoot (in this case, 49%) in conjunction with (18), solve

for the damping ratio, which in this case turns out to be

approximately 0.22. Next, use the value of the damping ratio

and the peak time (in this case, 0.14 seconds) in conjunction

with (19), and solve for the natural frequency, which in this

case turns out to be approximately 23.0 radians/second. If,

for some reason, the value of the peak time is not available or

cannot be gleaned from the time response graph, the damping

ratio and the settling time may be used in conjunction with

(20) to find the value of the natural frequency, but since the

peak time may generally be observed with greater accuracy

than the settling time, (20) should only be used as a last

resort. Similarly, if there is some problem with the value of

the peak time or percent overshoot, any two of (18), (19), and

(20) may be used to solve for the values of the damping ratio

and natural frequency, but since the percent overshoot and

peak time are the two that may be measured the most easily

and with the most accuracy, (18) and (19) should be used

whenever possible. Finally, using the values of the damping

ratio and natural frequency in conjunction with (21), the time

constant may be solved for, in this case turning out to be

approximately 0.10 seconds. Considering that the value used

for the time constant in the simulation was 0.1 seconds, it

appears as though this method works with some degree of

accuracy.

When attempting to determine the time constants of a DC

motor, the best method available is adjust the values of the

coefficients of a PID controller until the result of a run bears

resemblance to that of Fig. 7, and then to use those coefficient

settings from then on. When attempting to determine the

time constant of an AC motor, the system should be run, and

the peak time, settling time, and overshoot observed and used

to calculate the value of the time constant.

2

VII. ACKNOWLEDGMENTS

The author gratefully acknowledges the contribution of

Paulo Ribeiro, for his help in writing this paper. Without his

support, this process would have been much more difficult.

The author also acknowledges the contributions of John

Washburn, Frank Saggio, Paul Bakker, Matt Husson, and

Nate Studer for their help in the research process.

VIII. REFERENCES

[1]

[2]

[3]

Robert H. Bishop, Richard C. Dorf, Modern Control Systems, 9th ed.

Upper Saddle River, NJ: Prentice-Hall, 2001, p. 52-56, 227-231.

D.K. Anand, Introduction to Control Systems. New York: Pergamon Press

Inc., 1974, p. 34-37.

The ST Microcontroller Support Site Motor Control Tutorial,

http://mcu.st.com/contentid-7.html.

IX. BIOGRAPHY

2001.

Brian Bouma was born in Grand Rapids, Michigan

in the United States of America, on September 30,

1982. He graduated from Grand Rapids Christian

High School in 2001, and is currently pursuing his

undergraduate degree at Calvin College. He is

majoring in engineering, with a concentration in

electrical and computer engineering, and currently

holds a minor in mathematics.

His work experience includes Smiths Aerospace

LLC where he works in Digital Design.

He has been a student member of IEEE since

You might also like

- Hilux PDFDocument6 pagesHilux PDFEuler De Souza Silva CarvalhoNo ratings yet

- Hilux PDFDocument6 pagesHilux PDFEuler De Souza Silva CarvalhoNo ratings yet

- Hilux PDFDocument6 pagesHilux PDFEuler De Souza Silva CarvalhoNo ratings yet

- IC L293 and Its Avr Interface v1.0Document9 pagesIC L293 and Its Avr Interface v1.0Tapas DasNo ratings yet

- Light Emitting Diodes (Leds) : Ele 432 Assignment # 3 Vijay Kumar PeddintiDocument14 pagesLight Emitting Diodes (Leds) : Ele 432 Assignment # 3 Vijay Kumar Peddintimhf394No ratings yet

- Raspberry Pi B+Document1 pageRaspberry Pi B+nobugmanNo ratings yet

- PWM: How Pulse-Width Modulation WorksDocument1 pagePWM: How Pulse-Width Modulation Worksraj3323No ratings yet

- T-1 3/4 (5mm) SOLID STATE LAMPDocument6 pagesT-1 3/4 (5mm) SOLID STATE LAMPLuis Ramos PumaNo ratings yet

- L293DDocument7 pagesL293Dapi-370080950% (2)

- Tutorial Motor Basics Lecture PDFDocument23 pagesTutorial Motor Basics Lecture PDFBenjaminas OrlovasNo ratings yet

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoNo ratings yet

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoNo ratings yet

- Road-marking analysis for autonomous vehiclesDocument6 pagesRoad-marking analysis for autonomous vehiclesLuis Ramos PumaNo ratings yet

- Baldor MotorsDocument124 pagesBaldor Motorsangel_basualdoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Physics O Level Electromagnetic EffectsDocument76 pagesPhysics O Level Electromagnetic EffectsSaad AhmedNo ratings yet

- DC MachinesDocument46 pagesDC MachinesAung NetflixNo ratings yet

- Work and Power 1 QPDocument13 pagesWork and Power 1 QPIMJ JNo ratings yet

- Implementing Embedded Speed Control For Brushless DC Motors Part1Document8 pagesImplementing Embedded Speed Control For Brushless DC Motors Part1charliesteven100% (2)

- Electric MotorsDocument30 pagesElectric MotorsAmanpreet SinghNo ratings yet

- Kerala SSLC Physics CH 1-7 Easy Note (Eng Med)Document32 pagesKerala SSLC Physics CH 1-7 Easy Note (Eng Med)Asish Thampi100% (3)

- Iind Ed Alternators (8) - MaintenanceDocument8 pagesIind Ed Alternators (8) - MaintenancetesfuNo ratings yet

- SPPU All Course MCQ - Electrical Circuits MCQDocument141 pagesSPPU All Course MCQ - Electrical Circuits MCQSanket KarandeNo ratings yet

- Diesellocomotivetechnology 120815130704 Phpapp02Document89 pagesDiesellocomotivetechnology 120815130704 Phpapp02AnshulJainNo ratings yet

- Sem QuestionsDocument11 pagesSem QuestionsRojaNo ratings yet

- Modeling and Control of BLDC Motor using PI and FLCDocument66 pagesModeling and Control of BLDC Motor using PI and FLCBalajiKRamNo ratings yet

- Torqmotor™ Service Procedure: TC, TS, TB, Te and TJ Series Low Speed, High Torque Hydraulic Torqmotors™Document52 pagesTorqmotor™ Service Procedure: TC, TS, TB, Te and TJ Series Low Speed, High Torque Hydraulic Torqmotors™Jose SanchezNo ratings yet

- CH-2-DC MachineDocument83 pagesCH-2-DC MachineÙm ØrthøbøyNo ratings yet

- Lecture 5: DC Motors: Instructor: Dr. Gleb V. Tcheslavski Contact: Office HoursDocument105 pagesLecture 5: DC Motors: Instructor: Dr. Gleb V. Tcheslavski Contact: Office HoursAnonymous m8oCtJBNo ratings yet

- J 4 Wheels 10 50T Service Manual CEDocument68 pagesJ 4 Wheels 10 50T Service Manual CEbenjamin100% (1)

- KG390 Engine Service Manual: The Coast Distribution System, Ver. 2, October 1, 2007Document32 pagesKG390 Engine Service Manual: The Coast Distribution System, Ver. 2, October 1, 2007АлексейNo ratings yet

- Armature Winding - Pole Pitch Coil Span Commutator Pitch - Electrical4uDocument8 pagesArmature Winding - Pole Pitch Coil Span Commutator Pitch - Electrical4uM Kumar MarimuthuNo ratings yet

- DC Motors ApplicationsDocument4 pagesDC Motors ApplicationsidealparrotNo ratings yet

- Endeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationDocument8 pagesEndeavor - 20210519 - Nexperia - Understanding and Solving Thermal Design Issues in MOSFET ApplicationJNarigonNo ratings yet

- 3.basic Concept of Rotating Electrical Machine PDFDocument126 pages3.basic Concept of Rotating Electrical Machine PDFStadpyrkhat lyngkhoiNo ratings yet

- Kawaski Service ManualDocument101 pagesKawaski Service ManualJonathan StephensNo ratings yet

- Actuators and Motion Control DevicesDocument84 pagesActuators and Motion Control Devicesjohanna shaanyenengeNo ratings yet

- Blower Motor 4 Poles 2 Brushes With 14 Slots Armature For Automotive Heating, Ventilating, and Air Conditioning (HVAC) ApplicationsDocument5 pagesBlower Motor 4 Poles 2 Brushes With 14 Slots Armature For Automotive Heating, Ventilating, and Air Conditioning (HVAC) ApplicationsSophia GraceNo ratings yet

- Lecture 3.1.4Document26 pagesLecture 3.1.4simranjotkaur735No ratings yet

- Scilab ManualDocument44 pagesScilab ManualMeer Mustafa AliNo ratings yet

- 1477640681681-Locomotive Troubleshooting ALCODocument16 pages1477640681681-Locomotive Troubleshooting ALCOankur bhatnagarNo ratings yet

- Mobile Robotics: 3. ActuatorsDocument44 pagesMobile Robotics: 3. ActuatorsLe Dinh PhongNo ratings yet

- Arduino Based Bluetooth Controlled Robot Report 1Document27 pagesArduino Based Bluetooth Controlled Robot Report 1RakeshNo ratings yet

- Section 16.5 Simple D.C. MotorDocument13 pagesSection 16.5 Simple D.C. Motortwy113No ratings yet

- Catalog Switchboard InstrumentsDocument42 pagesCatalog Switchboard InstrumentsFlo MircaNo ratings yet