Professional Documents

Culture Documents

Drilling Out Cement Operation

Uploaded by

mohanad0 ratings0% found this document useful (0 votes)

120 views5 pagesDrilling Out Cement Operation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDrilling Out Cement Operation

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

120 views5 pagesDrilling Out Cement Operation

Uploaded by

mohanadDrilling Out Cement Operation

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 5

Drilling out Cement Operation

comes after Squeezing Cement

Operation Job:

Preparation :

1.

2.

3.

4.

5.

6.

Pack off.

Pack off Rubber.

Slips.

Power swivel.

Casing gauge.

Weight indicator.

Pack off Rubber:

To prevent the water comes out of BOP through DP (2 7/8)

meanwhile circulation because BOP pipe Ram has been already closed,

this Rubber hold pressure until 700-800 psi, if the pressure of pump

more than 1000 psi, the assistant driller in pump should decrease the

Rate of pump & closed the pump and must tell the Rig Engineer.

R/U the Rig Floor.

N/U BOP & Tubing head (Spool) for Gas Well ( hold pressure until

3000 psi):

Tubing head (Spool), 3000 psi for Gas well

N/D & M/U Tubing head (spool) hold pressure until 3000 psi & ESP

Spool for Oil Well hold pressure until 5000 psi, R/D the Rig Floor.

BOP, 5000 psi

X-over, adapter or flange

ESP Spool for Oil Well

3000 psi

Tubing head (spool) 5000 psi

oil well with double stud

Casing head

Rig Engineer should Prepare Drilling String Design (BHA Design)&

he must Measure drill-pipe (tally) and check thread, greased &

must be clean, by using drift with crew:

Bottom Hole Assembly (BHA) Design:

Consist of:

1.

2.

3.

4.

Bit (6 3 1/2" Reg Pin).

Bit sub (3 IF Box* 3 Reg Box).

Drill collar (4 , 3 IF Box).

Drilling Jar (4 , 3 IF Box).

5. X-over (2 7/8 IF Box * 3 IF Pin)

6. Drill pipe (2 7/8).

The crew must RIH w/ Drill string to Total Depth (tagged TOC),

Driller must go up 5m above TOC and the crew should circulate

the well(down casing ,up tubing) to check the cement is wet or

dry, if cement is wet & observed in settling tank (shaker), the

crew should circulate until the water comes clean in shaker.

R/U & N/D Pack off w/ BOP (by 4 pail) & R/U power swivel with

special elevator (4 ) & connect power swivel w/ x-over in bob

joint & enter pack off Rubber in bob joint and go down by Rubber

to Pack off until enter in Pack off successfully.

slips

Pack off Rubber

Pack off

The Rig Engineer should ask the crew to make Pressure test after

M/U back off rubber (500-750 psi), meanwhile circulation.

The driller & floor-men connect power swivel with first joint of

drill-pipe, then Start drilling after the mention from derrick-man

in shaker that return is observed, and the pressure is below 500

psi in casing pressure gauge &weight indicator (WOB 1-2 ton).

meanwhile drilling if the assistant driller noticed increase in

pressure the driller must stop drilling (this means bit plugged) and

go up w/ drilling string, then circulate down casing (never reverse

the circulation) until pressure drop to normal (bit nozzle opened),

then continue drilling.

When the joint has been drilled ,the driller go and closed the pipe

Ram & he will mention to assistant driller that to start circulation

meanwhile the shaker-man observed return in shaker, if the

cutting is fine or big size.

Meanwhile the assistant driller circulate the well (down casing, up

tubing) ,he should observed that the pressure in the pump (700800) psi, if the pressure increase more than 1000 psi ,he must

decrease the speed Rate in the pump and closed the pump until

pressure decrease.

Continue drilling to TD, the speed of drilling depend on type of

cement dry or wet, if the cement dry (one joint take 2 hrs enough

with circulation), the cement wet (one joint take 3 hrs enough

with circulation).

POOH W/ BHA assembly after R/D power swivel & Rig Engineer

should ask the crew to RIH W/scraper 7csg to design depth to

clean the well-bore from the cutting when the driller arrived to TD

(tagged), go up 1 joint to Ream & Wash the well-bore.

Rig Engineer must check bit condition form and storage it for next

job according to dull grading, also check power swivel.

Then TCP job is taken place.

Power swivel Engine:

Consist of:

1. Sensor for oil hydraulic line.

2. Tanks for oil (diesel).

3. Pump.

Prepared by:

Ala-eldin Saad Awadallah.

Trainee Engineer.

Supervised by:

Eng. Ahmed Adil.

You might also like

- Drilling With Casing 04Document15 pagesDrilling With Casing 04Dian Sikumbang100% (2)

- Best Practices Drilling 26 inDocument6 pagesBest Practices Drilling 26 inmanuelperdomotNo ratings yet

- The Tripping ProcessDocument3 pagesThe Tripping ProcessFabrizioLaVitaNo ratings yet

- TCP Perforating ProgrammeDocument3 pagesTCP Perforating ProgrammeYougchu LuanNo ratings yet

- Tripping Operations - Best PracticesDocument3 pagesTripping Operations - Best PracticesYougchu Luan100% (1)

- Santos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3Document13 pagesSantos 7'' HPC and TAMCAP Assembly - Running Procedure - Rev.3TonyNo ratings yet

- Drilling EquipmentDocument63 pagesDrilling EquipmentYudha negaraNo ratings yet

- STUCK PIPE SOLUTIONSDocument80 pagesSTUCK PIPE SOLUTIONSwisnu nugrohoNo ratings yet

- AccumulatorDocument12 pagesAccumulatorNaser Khan100% (1)

- Iwcf NotesDocument81 pagesIwcf NotesShraddhanand More100% (1)

- Running Procedure 5Document2 pagesRunning Procedure 5Pesireron RoberthNo ratings yet

- Example 7in Liner 2 Stage Cementing ProcedureDocument2 pagesExample 7in Liner 2 Stage Cementing ProcedureYougchu LuanNo ratings yet

- Operating Manual for Double Acting Hydraulic Drilling JarDocument11 pagesOperating Manual for Double Acting Hydraulic Drilling JarChristian Matteo100% (1)

- 18.625 CSG & CMT PlanDocument2 pages18.625 CSG & CMT PlanMohamed AbozeimaNo ratings yet

- Fishing Tools ListDocument6 pagesFishing Tools Listกัญญารัตน์ พูลทองNo ratings yet

- How to Handle a Pack Off SituationDocument2 pagesHow to Handle a Pack Off SituationMohammad RizwanNo ratings yet

- Tg-374 18.625in Cement Rev No. 1Document3 pagesTg-374 18.625in Cement Rev No. 1Lessly Lorena Apala RamirezNo ratings yet

- RTTS Packer: Technical Data SheetDocument5 pagesRTTS Packer: Technical Data SheetHamid Reza Babaei100% (1)

- 39 - Buckling & Wellhead Load After CementingDocument2 pages39 - Buckling & Wellhead Load After CementingAbdul Hameed OmarNo ratings yet

- TCP-DST-01 String Diagram Rajian-07 PDFDocument1 pageTCP-DST-01 String Diagram Rajian-07 PDFRizwan FaridNo ratings yet

- Re Entry Work: Setting WhipstocksDocument3 pagesRe Entry Work: Setting WhipstocksAnilNo ratings yet

- Pressure Control CalculationsDocument4 pagesPressure Control Calculationsfisco4rilNo ratings yet

- Remedial Cementing TechniquesDocument4 pagesRemedial Cementing TechniquesColor RougeNo ratings yet

- Hard Shut-In Procedure - Drilling Fixed RigDocument6 pagesHard Shut-In Procedure - Drilling Fixed RigLetterio MammolitiNo ratings yet

- Off-Bottom Drilling PracticesDocument3 pagesOff-Bottom Drilling PracticesAdel Ahmed AlkhaligyNo ratings yet

- Circulation Junk Baskets ManualDocument22 pagesCirculation Junk Baskets ManualAnonymous R4VU5fxINo ratings yet

- Diverter Drilling System For Well Control Full GuideDocument19 pagesDiverter Drilling System For Well Control Full GuiderahulNo ratings yet

- 13 3-8" Cementing Program ChecklistDocument2 pages13 3-8" Cementing Program ChecklistYougchu LuanNo ratings yet

- Drilling BHA - General AssemblyDocument3 pagesDrilling BHA - General AssemblyAdel Ahmed AlkhaligyNo ratings yet

- STUCK PIPE RESOLUTION WORKSHEETDocument1 pageSTUCK PIPE RESOLUTION WORKSHEETPashaakapaulNo ratings yet

- Squeeze Cementing JobDocument1 pageSqueeze Cementing JobstevebeardsleyNo ratings yet

- Tutorial Sheet No - 4Document23 pagesTutorial Sheet No - 4ali jabbarNo ratings yet

- Drilling Jar and Accelerator Positioning GuideDocument10 pagesDrilling Jar and Accelerator Positioning GuidegaddasalimNo ratings yet

- Well Control For Directional Wells, WT & WT Method, PsiDocument1 pageWell Control For Directional Wells, WT & WT Method, PsiscrbdgharaviNo ratings yet

- Halliburton: VR Safety JointDocument2 pagesHalliburton: VR Safety Jointsaeed65No ratings yet

- Implementing Drilling Practices in Cased Hole - B. CantrellDocument23 pagesImplementing Drilling Practices in Cased Hole - B. Cantrellsmithyry2014No ratings yet

- Cementing Squeeze Program Example PDFDocument10 pagesCementing Squeeze Program Example PDFfauzanhaq1602No ratings yet

- Houston Engineers Drilling Jar Operation ManualDocument3 pagesHouston Engineers Drilling Jar Operation ManualVincetine AlmazanNo ratings yet

- Primary Cementing CalculationsDocument40 pagesPrimary Cementing CalculationsMostafa ElghifaryNo ratings yet

- Section 05 Tripping Backreaming PracticesDocument68 pagesSection 05 Tripping Backreaming PracticesSpeculeNo ratings yet

- SPE Rig SelectionDocument8 pagesSPE Rig SelectionEyoma EtimNo ratings yet

- Spe 196232 MSDocument18 pagesSpe 196232 MShijoetigreNo ratings yet

- Chap 4Document43 pagesChap 4adrien_ducaillouNo ratings yet

- Tom Mile Calculation PDFDocument6 pagesTom Mile Calculation PDFBeni N SoloNo ratings yet

- DRILPLEX - Casing MillingDocument5 pagesDRILPLEX - Casing MillingPablo Martínez BerenguerNo ratings yet

- AirComp Air Drilling ManualDocument36 pagesAirComp Air Drilling ManualWilliamNo ratings yet

- Fishing Tools For 17 and Half Inch HoleDocument2 pagesFishing Tools For 17 and Half Inch Holehamid0% (1)

- Rig Stuck Pipe Assessment FormDocument13 pagesRig Stuck Pipe Assessment FormBalkis FatihaNo ratings yet

- 20 in Surf - 94 PPFDocument12 pages20 in Surf - 94 PPFAnonymous XbmoAFtINo ratings yet

- Drill LineDocument16 pagesDrill Linemech133No ratings yet

- Stuck Pipe Prevention and SolutionsDocument14 pagesStuck Pipe Prevention and SolutionsLazhar100% (1)

- Optimizing ROP with Schlumberger TechniquesDocument14 pagesOptimizing ROP with Schlumberger TechniquesMaría MarquinaNo ratings yet

- Rules of Thumb To Improve High-Angle Hole CleaningDocument29 pagesRules of Thumb To Improve High-Angle Hole CleaningjalalNo ratings yet

- 12 Casing Running Speed - QuartzDocument1 page12 Casing Running Speed - QuartzRebarNo ratings yet

- PDF Halliburton Cementing 1 Book CompressDocument238 pagesPDF Halliburton Cementing 1 Book CompressRoque muñoz lopezNo ratings yet

- IADC Formula Sheet: X X X + + ÷ X + X - ÷ XDocument5 pagesIADC Formula Sheet: X X X + + ÷ X + X - ÷ XMarwa ElghifaryNo ratings yet

- Squeeze ProcedureDocument4 pagesSqueeze Proceduresaa6383No ratings yet

- Specs ZJ 30 2Document1 pageSpecs ZJ 30 2fatehul alamNo ratings yet

- Drill String Design 4.11Document23 pagesDrill String Design 4.11Ryan Tan Ping YiNo ratings yet

- Bridging The Industry-Academia Gap and Knowledge Management: Need of HourDocument6 pagesBridging The Industry-Academia Gap and Knowledge Management: Need of HourmohanadNo ratings yet

- Well Killing OperationDocument3 pagesWell Killing OperationmohanadNo ratings yet

- Unu GTP 1995 04Document24 pagesUnu GTP 1995 04mohanadNo ratings yet

- 893484Document45 pages893484mohanadNo ratings yet

- Morning & Afternoon Report FromDocument1 pageMorning & Afternoon Report FrommohanadNo ratings yet

- Morning & Afternoon Report FromDocument1 pageMorning & Afternoon Report FrommohanadNo ratings yet

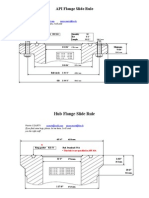

- API Flange and Clamp Slide RulesDocument3 pagesAPI Flange and Clamp Slide RulesmohanadNo ratings yet

- Briana SmithDocument3 pagesBriana SmithAbdul Rafay Ali KhanNo ratings yet

- Column Array Loudspeaker: Product HighlightsDocument2 pagesColumn Array Loudspeaker: Product HighlightsTricolor GameplayNo ratings yet

- Pre Job Hazard Analysis (PJHADocument2 pagesPre Job Hazard Analysis (PJHAjumaliNo ratings yet

- IDocument2 pagesIsometoiajeNo ratings yet

- Olympics Notes by Yousuf Jalal - PDF Version 1Document13 pagesOlympics Notes by Yousuf Jalal - PDF Version 1saad jahangirNo ratings yet

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilNo ratings yet

- (23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion SpringsDocument6 pages(23005319 - Acta Mechanica Et Automatica) A Study of The Preload Force in Metal-Elastomer Torsion Springsstefan.vince536No ratings yet

- ISO 9001:2015 Explained, Fourth Edition GuideDocument3 pagesISO 9001:2015 Explained, Fourth Edition GuideiresendizNo ratings yet

- JurnalDocument9 pagesJurnalClarisa Noveria Erika PutriNo ratings yet

- Ensayo Bim - Jaime Alejandro Martinez Uribe PDFDocument3 pagesEnsayo Bim - Jaime Alejandro Martinez Uribe PDFAlejandro MartinezNo ratings yet

- IGCSE Chemistry Section 5 Lesson 3Document43 pagesIGCSE Chemistry Section 5 Lesson 3Bhawana SinghNo ratings yet

- Energy AnalysisDocument30 pagesEnergy Analysisca275000No ratings yet

- Resume Template & Cover Letter Bu YoDocument4 pagesResume Template & Cover Letter Bu YoRifqi MuttaqinNo ratings yet

- EIN CP 575 - 2Document2 pagesEIN CP 575 - 2minhdang03062017No ratings yet

- Artist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheDocument2 pagesArtist Biography: Igor Stravinsky Was One of Music's Truly Epochal Innovators No Other Composer of TheUy YuiNo ratings yet

- Analytical Approach To Estimate Feeder AccommodatiDocument16 pagesAnalytical Approach To Estimate Feeder AccommodatiCleberton ReizNo ratings yet

- #3011 Luindor PDFDocument38 pages#3011 Luindor PDFcdouglasmartins100% (1)

- Multiple Choice: CH142 Sample Exam 2 QuestionsDocument12 pagesMultiple Choice: CH142 Sample Exam 2 QuestionsRiky GunawanNo ratings yet

- Maj. Terry McBurney IndictedDocument8 pagesMaj. Terry McBurney IndictedUSA TODAY NetworkNo ratings yet

- Quantification of Dell S Competitive AdvantageDocument3 pagesQuantification of Dell S Competitive AdvantageSandeep Yadav50% (2)

- Sentinel 2 Products Specification DocumentDocument510 pagesSentinel 2 Products Specification DocumentSherly BhengeNo ratings yet

- Sanhs Ipcrf TemplateDocument20 pagesSanhs Ipcrf TemplateStephen GimoteaNo ratings yet

- Log File Records Startup Sequence and Rendering CallsDocument334 pagesLog File Records Startup Sequence and Rendering CallsKossay BelkhammarNo ratings yet

- Take This LoveDocument2 pagesTake This LoveRicardo Saul LaRosaNo ratings yet

- Mission Ac Saad Test - 01 QP FinalDocument12 pagesMission Ac Saad Test - 01 QP FinalarunNo ratings yet

- Chem 102 Week 5Document65 pagesChem 102 Week 5CAILA CACHERONo ratings yet

- Service and Maintenance Manual: Models 600A 600AJDocument342 pagesService and Maintenance Manual: Models 600A 600AJHari Hara SuthanNo ratings yet

- TWP10Document100 pagesTWP10ed9481No ratings yet

- Trading As A BusinessDocument169 pagesTrading As A Businesspetefader100% (1)

- Java development user guide eclipse tutorialDocument322 pagesJava development user guide eclipse tutorialVivek ParmarNo ratings yet

- The Grid: The Fraying Wires Between Americans and Our Energy FutureFrom EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureRating: 3.5 out of 5 stars3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Renewable Energy: A Very Short IntroductionFrom EverandRenewable Energy: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Handbook on Battery Energy Storage SystemFrom EverandHandbook on Battery Energy Storage SystemRating: 4.5 out of 5 stars4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successFrom EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successRating: 4.5 out of 5 stars4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsFrom EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNo ratings yet

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesFrom EverandThe Rare Metals War: the dark side of clean energy and digital technologiesRating: 5 out of 5 stars5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualFrom EverandTransmission Pipeline Calculations and Simulations ManualRating: 4.5 out of 5 stars4.5/5 (10)

- Implementing an Integrated Management System (IMS): The strategic approachFrom EverandImplementing an Integrated Management System (IMS): The strategic approachRating: 5 out of 5 stars5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemFrom EverandISO 50001: A strategic guide to establishing an energy management systemNo ratings yet

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksFrom EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNo ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- The Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeFrom EverandThe Boy Who Harnessed the Wind: Creating Currents of Electricity and HopeRating: 4 out of 5 stars4/5 (130)

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AFrom EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&ARating: 5 out of 5 stars5/5 (1)