Professional Documents

Culture Documents

S Weatherf

Uploaded by

Hany AhmedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S Weatherf

Uploaded by

Hany AhmedCopyright:

Available Formats

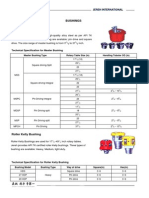

Stabberless casing handling gear is safe, efficient

SAFETY AND EFFICIENCY objectives were behind the development of a

casing stabbing system that has now

proved itself in commercial use on both

land and offshore conventional rigs.

Weatherford International Inc first

installed a mechanized casing modem

design in 1994 that incorporated remote

controlled casing tongs mounted on a

hydraulic roughneck. That system used a

programmable logic controller to link five

mechanized component groupsmechanized power tongs, tong positioning system, remote control systems, stabberless

positioning system and a circulating

head. This technology evolved into more

sophisticated systems in the past 6 years.

One result of this evolution is the StabMasterTM, which now has been operated

on a land rig in the US and on a floating

rig in the US Gulf of Mexico.

In Wyoming, the system was used to run

almost 15,000 ft of 14-in. heavy wall casing and install other casing strings and

tubing in a deep gas well.

On its first job on a floating rig in the Gulf

of Mexico, StabMaster ran 3,100 ft of 16in. casing in 4 hours, a job that takes 6-12

hours when run conventionally.

G O A L S : E F F I C I E N C Y, S A F E T Y

Weatherford now offers the stabberless

system as an efficient, safe method of

running casing and tubing.

Casing and tubing operations can represent a large investment in drilling and

completing a well.

According to Weatherford, more than

30% of the time a rig is on location is

spent tripping drill pipe

or running casing and

tubing.

The first step in the using the Stabberless

System is to perform a thorough analysis

of the rig. Because adequate preparation

will help ensure the safety and success of

And stabbing operations are the hardest

and most dangerous

tasks to perform while

casing is being run.

Working in an awkward

position high above the

rig floor, the stabber is

exposed to weather and

works under extremely

demanding

physical

conditions.

Because of these conditions it is difficult to

achieve 100% repeatability.

In developing the stabberless system, Weatherford set some simple

objectives. Goals were

to increase safety,

improve cycle time,

reduce rig personnel

and decrease costs.

CAPABILITIES

Weatherfords rig mechanization system can reduce the risks involved

in manhandling casing in the derrick and in handling tongs.

The StabMaster is a

remote-controlled hydraulic stabbing arm

that:

Allows the operator to control the StabMaster from the rig floor;

Reduces the risk of rig-floor and stabbing-board accidents and eliminates the

need for a stabber;

Allows the pipe to be moved horizontally to find the well center;

Stores the exact center position of the

well bore in memory and with the Stabset feature can move each joint to this

well center automatically;

Retracts to a vertical parked position

once connection makeup has begun;

Allows pipe makeup to be repeatable.

24

THE PROCEDURE

D R I L L I N G

the operation, a training and communication session with the rig crew should be

held before the job begins.

When the job does begin, the system

works in the following sequence.

The Stabberless Single-Joint Elevator

(SSJE) is attached to the joint of tubing or

casing in the V-door and the joint lifted

into the derrick.

The StabMaster arm is lowered with the

head opened.

After the thread protector on the pin end

of the joint is removed, the operator

presses the stab set switch.

The StabMaster head closes around the

joint of casing or tubing and the head

extends in the horizontal plane to the well

centerline position that has been stored in

C O N T R A C T O R

September/October 2000

the systems memory. This stored well

centerline position can be changed manually during operation from the remotecontrol panel.

The ISIS system:

Detects correct slip engagement on the

casing or tubing joint;

Ensures that the elevator slips are over

the casing collar and are locked into place

below the coupling;

During final makeup of the joint, the

home switch is pressed on the control

panel, the head is released and the arm

retracts to the vertical (parked) position.

Enables the spider and elevator to be

run in an interlocking mode, which prevents the accidental simultaneous opening of the spider and elevator;

The casing elevator is lowered over the

box end of the casing or tubing joint until

the flagging device indicator illuminates

on the drillers console.

Allows the operator to control the spiders and elevators from a safe position on

the rig floor or from the driller's cabin.

The driller closes the elevator with the

ISIS remote-controlled system. The ISIS

also opens the spider once the elevator

slips are properly set.

Finally, the casing elevator is lowered and

the SSJE is pulled to the V-door side of

the rig by the positioning straps attached

to the slings of the swivel and the casing

elevator.

ISIS SYSTEM

The Weatherford Integrated Safety Interlock System remote-controlled spider/

September/October 2000

The elevator position-flagging device signals the driller when the casing elevator is

in the correct position to be closed.

Stabberless system was used to run a long

string of heavy wall casing in Wyoming well.

elevator system (ISISTM) system prevents

inadvertent opening or closing of the spider and elevator.

D R I L L I N G

A sensor located on top of the elevator is

connected to a pneumatically operated

lamp on the drillers console.

When the casing elevator is in the correct

closed position, the lamp changes from

red to green.

The Stabberless Single-Joint Elevator

C O N T R A C T O R

25

(SSJE) has two hinges, enabling it to be

opened or closed from either side. The

positioning straps are connected between

the single-joint elevator slings and casing

elevator to guide the swivel to the V-door

side of the rig floor.

The SSJE stays on the pipe when the

main elevator is being lowered.

WYOMING JOB

Weatherford has considerable success

with the StabMaster stabberless system

both on land and offshore.

In Wyoming, the system set an installation record running 14,814 ft of 14-in.

heavy wall casing using the power tong

positioning and stabberless systems. It

was the first time a major string of pipe

has been run without the use of a stabber,

according to Weatherford.

Burlington Resources Inc drilled the

ultradeep gas well in the Wind River

Basin.

As the size of the pipe increases, the safety risks of running and handling that pipe

26

also rise. Thats why Weatherford recommended that its power tong positioning

and stabberless systems be used to run the

heavy wall casing in this Wyoming well.

These systems allow one person to operate the large, heavy power tongs and eliminate the need for a stabber in the derrick.

In a typical, non-automated rig casing

operation, the two most dangerous running situations include manhandling the

casing in the derrick and handling the

power tongs, says Weatherford. Weatherfords mechanized systems at Wind River

included:

The Stabberless System that eliminates

the need for the stabber and remotely

aligns the casing for makeup;

The Integrated Safety Interlock System

that allows remote control of the spider

and elevator, guides the swivel and signals

the driller;

The PushMaster tong positioning

system that moves the power tong into the

proper position for makeup;

Hydraulically operated doors on the

D R I L L I N G

tong and backup allow the large casing

tongs to be operated without any assistance from other rig floor personnel.

After running the 14-in. heavy wall string

to almost 15,000 ft, a 12 1/4-in. hole was

drilled to 20,700 ft.

Weatherford Tubular Services then ran

6,400 ft of 10 3/4-in. oversized OD liner

from 14,300 ft to 20,700 ft. The liner

weighed 330,000 lb.

Then a tapered (10,000 ft of 7 3/4-in. by

13,500 ft of 10 3/4-in.) casing string was

run using the Stabberless and PushMaster

Systems.

Finally, a corrosion-resistant alloy liner

that required the special handling tools to

prevent damage to this very expensive

pipe was installed. And the same equipment was used to run 23,000 ft of 4-by-4

1/2-in. corrosion-resistant alloy tubing.

A key to the success of these operations,

said a Burlington spokesman, is Weatherfords post-job reviews. These reviews

help further improve performance and

n

coordination.

C O N T R A C T O R

September/October 2000

You might also like

- Formation Testing: Supercharge, Pressure Testing, and Contamination ModelsFrom EverandFormation Testing: Supercharge, Pressure Testing, and Contamination ModelsNo ratings yet

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- Reservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsFrom EverandReservoir Engineering in Modern Oilfields: Vertical, Deviated, Horizontal and Multilateral Well SystemsNo ratings yet

- Measurement While Drilling: Signal Analysis, Optimization and DesignFrom EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNo ratings yet

- Baker Hughes Caisson ESP (2010)Document2 pagesBaker Hughes Caisson ESP (2010)hermit44535No ratings yet

- Ensco Ds-10: General InformationDocument1 pageEnsco Ds-10: General Informationmsm.ele2009No ratings yet

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsFrom EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsNo ratings yet

- Laser DrillingDocument19 pagesLaser Drillingmts1234100% (1)

- Young Tech Showcase - Reelwell Drilling MethodDocument2 pagesYoung Tech Showcase - Reelwell Drilling Methodlulalala8888100% (1)

- MHD55148 BOP Catalog 052008Document20 pagesMHD55148 BOP Catalog 052008jlmunozv100% (4)

- Hydrocarbon Fluid Inclusions in Petroliferous BasinsFrom EverandHydrocarbon Fluid Inclusions in Petroliferous BasinsNo ratings yet

- Rod Pump CatalogueDocument17 pagesRod Pump CataloguePedro Antonio Mejia SuarezNo ratings yet

- Heavy Duty Jackup Rigs Are Versatile and Capable: Application RangeDocument2 pagesHeavy Duty Jackup Rigs Are Versatile and Capable: Application RangeMILADNo ratings yet

- DepthStar® Tubing-RetrievableDocument9 pagesDepthStar® Tubing-RetrievableJohnHynesNo ratings yet

- SafeVision Standalone v.2.0 GuideDocument55 pagesSafeVision Standalone v.2.0 GuideermaiezNo ratings yet

- Microbial Enhancement of Oil Recovery - Recent AdvancesFrom EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesNo ratings yet

- Perforating Catalog: ISSUE 5 - March 2020Document218 pagesPerforating Catalog: ISSUE 5 - March 2020Aboozar Fathinejad100% (1)

- Cable Centriline CELR 76426Document2 pagesCable Centriline CELR 76426Melvin CastroNo ratings yet

- E&P Magazine. Feb 2020Document92 pagesE&P Magazine. Feb 2020Alberto Mora PereaNo ratings yet

- SAOGE 2008 - Paper - Full Scale Verification of The Reelwell Drilling MethodDocument10 pagesSAOGE 2008 - Paper - Full Scale Verification of The Reelwell Drilling MethodBep De JongNo ratings yet

- Deepstim: Advanced, Versatile Stimulation VesselsDocument4 pagesDeepstim: Advanced, Versatile Stimulation VesselsKenneth Tan100% (1)

- SPE-108284-Sucker RodDocument14 pagesSPE-108284-Sucker RodRuben ChirinosNo ratings yet

- Offshore Jack UpsDocument5 pagesOffshore Jack Upsfle92100% (1)

- 003 - Presentation From Nabors Drilling PDFDocument16 pages003 - Presentation From Nabors Drilling PDFVi Et100% (1)

- Ficha Tecnica Centrifuga WFT1656Document2 pagesFicha Tecnica Centrifuga WFT1656Ricardo VillarNo ratings yet

- Laminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisFrom EverandLaminar Flow and Convective Transport Processes: Scaling Principles and Asymptotic AnalysisNo ratings yet

- Chapter Five Jet Pumping System (JP)Document33 pagesChapter Five Jet Pumping System (JP)mghareebNo ratings yet

- Permian Basin Development WellsDocument8 pagesPermian Basin Development WellsPesireron RoberthNo ratings yet

- MWD Troubleshooting GuideDocument13 pagesMWD Troubleshooting GuidefedericoNo ratings yet

- Fundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyFrom EverandFundamentals of Horizontal Wellbore Cleanout: Theory and Applications of Rotary Jetting TechnologyNo ratings yet

- Cwor-Brochure WebDocument8 pagesCwor-Brochure WebMartin McCaffreyNo ratings yet

- Hydraulic Power Units ExplainedDocument4 pagesHydraulic Power Units ExplainedJay JayNo ratings yet

- Fracking Powerpoint Presentation May 8 2014Document15 pagesFracking Powerpoint Presentation May 8 2014zendarazakNo ratings yet

- PET 314 - Drilling Engrg IDocument88 pagesPET 314 - Drilling Engrg Iifiok100% (1)

- How the dual activity drill floor is expected to operateDocument8 pagesHow the dual activity drill floor is expected to operateWILLIANS HERNANDEZNo ratings yet

- VetcoGray S-Series SVXTDocument2 pagesVetcoGray S-Series SVXTarchitectintxNo ratings yet

- Rig SelectionDocument3 pagesRig SelectionMegat RitzhanNo ratings yet

- MPD LIBRA PROJECT ADVANCE TRAINING: FINGERPRINTING FOR MPD OPERATIONSDocument187 pagesMPD LIBRA PROJECT ADVANCE TRAINING: FINGERPRINTING FOR MPD OPERATIONSGabrielNo ratings yet

- Tendeka Swell ChartDocument1 pageTendeka Swell ChartodscamNo ratings yet

- Top Drive Systems 1Document5 pagesTop Drive Systems 1Akashdeep HazarikaNo ratings yet

- Part 1 Introduction New PDFDocument12 pagesPart 1 Introduction New PDFRanim HishamNo ratings yet

- Amphion Standard Operator GuideDocument362 pagesAmphion Standard Operator Guidemohamed mohsenNo ratings yet

- 5 Mixer FlygtDocument8 pages5 Mixer FlygtHugo Miño Carrasco100% (1)

- Innovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentFrom EverandInnovative Exploration Methods for Minerals, Oil, Gas, and Groundwater for Sustainable DevelopmentA. K. MoitraNo ratings yet

- Packer HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFDocument16 pagesPacker HPHT Downhole Completion Equipment Bsee May 2015 Hilts PDFfredyNo ratings yet

- SPE Casing Design For Dual Gradient WellsDocument18 pagesSPE Casing Design For Dual Gradient WellsAntonio HernándezNo ratings yet

- Comparison of Under-Balanced and Managed-Pressure Drilling TechniquesDocument10 pagesComparison of Under-Balanced and Managed-Pressure Drilling TechniquesJessica Cecilia Silva Angulo100% (1)

- Working Out A Tight SpotDocument8 pagesWorking Out A Tight SpotMustafa NaithelNo ratings yet

- Well Integrity Course Summary in Nov-2023Document50 pagesWell Integrity Course Summary in Nov-2023Yovaraj KarunakaranNo ratings yet

- Wo Esp DevelopmentsDocument6 pagesWo Esp DevelopmentsHamed GeramiNo ratings yet

- Sucker Rods Brochure 851 06Document12 pagesSucker Rods Brochure 851 06Ronald LlerenaNo ratings yet

- Rig 12 Inventory SummaryDocument3 pagesRig 12 Inventory Summaryherysyam1980100% (1)

- 2mm Vs 8mm Charpy Striker Edge RadiusDocument26 pages2mm Vs 8mm Charpy Striker Edge RadiusErick EaxNo ratings yet

- Reservoir SimulationDocument3 pagesReservoir SimulationEuler MendozaNo ratings yet

- Skid Off DrillingDocument2 pagesSkid Off DrillingKeithbNo ratings yet

- CDS Crown Mounted Compensator SpecDocument1 pageCDS Crown Mounted Compensator SpecMarcos SobreiroNo ratings yet

- SPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionDocument13 pagesSPE 167698 Imbibition and Water Blockage in Unconventional Reservoirs: Well Management Implications During Flowback and Early ProductionsouthliNo ratings yet

- PRS - Diverless Connection System - HorizontalDocument2 pagesPRS - Diverless Connection System - HorizontalPedro DutraNo ratings yet

- GrantPrideco Drill Pipe Data TablesDocument24 pagesGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezNo ratings yet

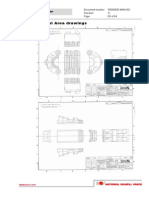

- Critical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Document2 pagesCritical Area Drawings: Document Number 50000805-MAN-001 Revision A 64 of 66Hany AhmedNo ratings yet

- Critical AreaDocument2 pagesCritical AreaHany AhmedNo ratings yet

- Safety Alert: Stabbing Board Related IncidentsDocument1 pageSafety Alert: Stabbing Board Related IncidentsHany AhmedNo ratings yet

- Stabbing Board Accident Panel Report 2006-002Document48 pagesStabbing Board Accident Panel Report 2006-002Hany AhmedNo ratings yet

- Bushings Master BushingDocument2 pagesBushings Master BushingHany AhmedNo ratings yet

- Fishbone RevisedDocument3 pagesFishbone RevisedHany AhmedNo ratings yet

- Guidance For RcaDocument12 pagesGuidance For RcaHany AhmedNo ratings yet

- API Tubing Table SpecificationsDocument6 pagesAPI Tubing Table SpecificationsDavid KusumaNo ratings yet

- 758 42000e Testork Revd LoresDocument4 pages758 42000e Testork Revd LoresHany AhmedNo ratings yet

- Oilfield JetlubeDocument24 pagesOilfield JetlubeHany AhmedNo ratings yet

- Радиус-Сервис - Products - Shock ToolsDocument2 pagesРадиус-Сервис - Products - Shock ToolsHany AhmedNo ratings yet

- Радиус-Сервис - Products - JarsDocument4 pagesРадиус-Сервис - Products - JarsHany AhmedNo ratings yet

- Jereh ElevatorDocument4 pagesJereh ElevatorHany AhmedNo ratings yet

- Jet Lube Jet Lok IIDocument2 pagesJet Lube Jet Lok IIHany Ahmed0% (1)

- Stabbing BoardsDocument2 pagesStabbing BoardsHany AhmedNo ratings yet

- Spider Varco 375Document1 pageSpider Varco 375Hany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf4Hany AhmedNo ratings yet

- Shock Tool - Downhole Drilling ToolsDocument4 pagesShock Tool - Downhole Drilling ToolsHany AhmedNo ratings yet

- High Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling ToolsDocument4 pagesHigh Output Hydraulic - Mechanical Drilling Jar - (HO-HMJ) - Downhole Drilling ToolsHany AhmedNo ratings yet

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocument4 pagesHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNo ratings yet

- Hydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsDocument4 pagesHydraulic - Mechanical Drilling Jar (HMJ) - Downhole Drilling ToolsHany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf2Hany AhmedNo ratings yet

- Challenger Bumper Jar - Downhole Drilling ToolsDocument3 pagesChallenger Bumper Jar - Downhole Drilling ToolsHany AhmedNo ratings yet

- Drill String DesignDocument12 pagesDrill String DesignAsaadgz100% (1)

- Tianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Document3 pagesTianhe Oil Group Huifeng Petroleum Equipment Co - pdf1Hany AhmedNo ratings yet

- Tianhe Oil Group Huifeng Petroleum Equipment CoDocument3 pagesTianhe Oil Group Huifeng Petroleum Equipment CoHany AhmedNo ratings yet

- Jar Pro Drillstring Jarring Analysis SoftwareDocument5 pagesJar Pro Drillstring Jarring Analysis SoftwareHany AhmedNo ratings yet

- Pumps Motors AssDocument57 pagesPumps Motors AssHany AhmedNo ratings yet

- Turbo ShaftDocument10 pagesTurbo ShaftMarco MendezNo ratings yet

- Pulp PaperDocument104 pagesPulp Paperabu141No ratings yet

- 95 TOP Refrigeration and Air Conditioning MCQsDocument19 pages95 TOP Refrigeration and Air Conditioning MCQsNagaraj Muniyandi80% (5)

- AC Generator and Motor ProtectionDocument76 pagesAC Generator and Motor ProtectionAtif Husayn100% (1)

- Project Report by Manish YadavDocument53 pagesProject Report by Manish Yadavmanish yaduvanshiNo ratings yet

- Future of GTDocument28 pagesFuture of GTfaustino_guillen2465No ratings yet

- Total Automation Solution in Super Critical Thermal Power Plant PDFDocument28 pagesTotal Automation Solution in Super Critical Thermal Power Plant PDFpredic1No ratings yet

- Ee ThesisDocument28 pagesEe ThesisEarl Jay UayanNo ratings yet

- International Civil Aviation OrganizationDocument17 pagesInternational Civil Aviation OrganizationAditya Rahman HalimNo ratings yet

- Linear PM Generator for Wave Energy Conversion Design and AnalysisDocument131 pagesLinear PM Generator for Wave Energy Conversion Design and AnalysisEzaTejaKusumaNo ratings yet

- L1 BEKG2433 Power SystemDocument40 pagesL1 BEKG2433 Power SystemAmeer KhanNo ratings yet

- Akai Apiflo File - 461c9a72a4fa6APIFLO M Series BrochureDocument6 pagesAkai Apiflo File - 461c9a72a4fa6APIFLO M Series Brochure2009tamerNo ratings yet

- Saving EnergyDocument11 pagesSaving EnergyNicoleta MariaNo ratings yet

- Control Valves PDFDocument2 pagesControl Valves PDFmacholdingsNo ratings yet

- Amit Kumar Tata Power SolarDocument38 pagesAmit Kumar Tata Power SolarEka BNo ratings yet

- 07factsheet Mini GridDocument6 pages07factsheet Mini GridSarthak ShuklaNo ratings yet

- Designing of HV Power Substation and Layout - EEPDocument13 pagesDesigning of HV Power Substation and Layout - EEPSuresh Umadi100% (1)

- Catalogue PV Grid Connected Inverters 2010 2011Document120 pagesCatalogue PV Grid Connected Inverters 2010 2011Sunil ParikhNo ratings yet

- Economic Assessment of Grid-Connected Residential Solar Photovoltaic Systems Introduced Under Romania's New RegulationDocument17 pagesEconomic Assessment of Grid-Connected Residential Solar Photovoltaic Systems Introduced Under Romania's New RegulationMinh Pháp VũNo ratings yet

- MV network design & devices selection guideDocument31 pagesMV network design & devices selection guideAnonymous kdFzbQ4jfNo ratings yet

- 66kV Substation Presentation SummaryDocument11 pages66kV Substation Presentation SummaryHimanshu KhandelwalNo ratings yet

- PDFDocument199 pagesPDFEdsel PedernalNo ratings yet

- Deludge System CHECKLISTDocument15 pagesDeludge System CHECKLISTjiks_i4uNo ratings yet

- Ju BurnhamDocument7 pagesJu BurnhamART'S PLACENo ratings yet

- Motor Protection Training CourseDocument439 pagesMotor Protection Training CourseAlireza Farsani100% (1)

- Improve boiler efficiency with regular maintenanceDocument5 pagesImprove boiler efficiency with regular maintenanceAnonymous Q9i062VNo ratings yet

- Embedded Generation Connection Guide PDFDocument43 pagesEmbedded Generation Connection Guide PDFSunrider2014No ratings yet

- CBSE Class 9 Physics Worksheet - Work & EnergyDocument2 pagesCBSE Class 9 Physics Worksheet - Work & EnergyAtharva VarshneyNo ratings yet

- Alternate Energy Sources EVsDocument28 pagesAlternate Energy Sources EVsirfan_nitNo ratings yet

- Mitra 2016Document6 pagesMitra 2016Mani AshouriNo ratings yet