Professional Documents

Culture Documents

Boq For Road Works

Uploaded by

Faisal KhanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boq For Road Works

Uploaded by

Faisal KhanCopyright:

Available Formats

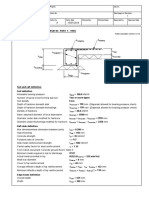

s.no.

sor no

item description

Granular Sub-base with Close Graded Material (Table:- 400-1)

Plant Mix Method (Construction of granular sub-base by providing

close graded Material, mixing in a mechanical mix plant at OMC,

carriage of mixed Material to work site, spreading in uniform

layers with motor grader on prepared surface and compacting

with vibratory power roller to achieve the desired density,

complete as per clause 401)

(i) for grading- I Material

1

Dry Lean Cement Concrete Sub- base (Construction of dry lean

cement concrete Sub base over a prepared sub-grade with

coarse and fine aggregate conforming to IS: 383, the size of

coarse aggregate not exceeding 25 mm, aggregate cement ratio

not to exceed 15:1, aggregate gradation after blending to be as

per table 600-1, cement content not to be less than 150 kg/ cum,

optimum moisture content to be determined during trial length

construction,

concrete strength not to be less than 10 Mpa at 7 days, mixed in

a batching plant, transported to site, laid with a paver with

electronic sensor, compacting with 8-10 tonnes vibratory roller,

finishing and curing.)

2

Cement Concrete Pavement (Construction of un-reinforced,

dowel jointed, plain cement concrete pavement M-40 grade

concrete over a prepared sub base with cement , coarse and fine

aggregate conforming to IS 383, maximum size of coarse

aggregate not exceeding 25 mm, mixed in a batching and mixing

plant as per approved mix design, transported to site,

laid with a fixed form or slip form paver, spread, compacted and

finished in a continuous operation including provision of

contraction, expansion, construction and longitudinal joints, joint

filler, separation membrane, sealant primer, joint sealant,

debonding strip, admixtures as approved, curing compound,

finishing to lines and grades as per drawing as per IRC 15 2011

and as per relevant clauses of section 602 of specifications

complete but excluding cost of steel in dowel bar and tie rods

etc.)

3

Add extra in item no.3 for the cost of steel in dowel bar including

cradle, laps etc, complete required as per design for Mild Steel

Add extra in item no.3 for the cost of steel in tie rod including

cradle, laps etc, complete required as per design for TOR Steel

Construction of Shoulders with approved material/selected soil i/c

excavation all lifts & leads i/c grading to required slope & camber

of 4% and compacting using vibratory roller of 80 to 100 kN

static weight to meet requirement as per relevant clause of 400.

Hard Shoulders (CBR value > 12)

Retro- reflectorised Traffic signs (Providing and fixing of retroreflectorised cautionary, mandatory and informatory sign as per

IRC :67 made of encapsulated lens type reflective sheeting vide

clause 801.3, fixed over aluminium sheeting, 1.5 mm thick

supported on a mild steel angle iron post 75 mm x 75 mm x 6

mm firmly fixed to the ground by means of properly designed

foundation with M15 grade cement concrete 45 cm x 45 cm x 60

cm, 60 cm below ground level as per approved drawing) (ii) 60

cm equilateral triangle

Direction and Place Identification signs up to 0.9 sqm size board.

(Providing and erecting direction and place identification retroreflectorised sign as per IRC:67 made of encapsulated lens type

reflective sheeting vide clause 801.3, fixed over aluminium

sheeting, 2 mm thick with area not exceeding 0.9 sqm supported

on a mild steel single angle iron post 75 x 75 x 6 mm firmly fixed

to the ground by means of properly designed foundation with

M15 grade cement concrete 45 x 45 x 60 cm, 60 cm below

ground level as per approved drawing)

Cable Duct Across the Road (Providing and laying of a reinforced

cement concrete pipe duct, 300 mm dia, across the road (new

construction), extending from drain to drain in cuts and toe of

slope to toe of slope in fills, constructing head walls at both ends,

providing a minimum fill of granular material over top and sides

of RCC pipe as per IRC:98-1997, bedded on a 0.3 m thick layer of

granular material free of rock pieces, outer to outer distance of

pipe at least half dia of pipe subject to minimum 450 mm in case

of double and triple row ducts, joints to be made leak proof,

invert level of duct to be above higher than ground level to

prevent entry of water and dirt, all as per IRC: 98 - 1997 and

approved drawings.) for single row

Cable Duct Across the Road (Providing and laying of a reinforced

cement concrete pipe duct, 300 mm dia, across the road (new

construction), extending from drain to drain in cuts and toe of

slope to toe of slope in fills, constructing head walls at both ends,

providing a minimum fill of granular material over top and sides

of RCC pipe as per IRC:98-1997, bedded on a 0.3 m thick layer of

granular material free of rock pieces, outer to outer distance of

pipe at least half dia of pipe subject to minimum 450 mm in case

of double and triple row ducts, joints to be made leak proof,

invert level of duct to be above higher than ground level to

prevent entry of water and dirt, all as per IRC: 98 - 1997 and

approved drawings.)

Double Row for two utility services

unit

qty

rate

You might also like

- Is 13849 PDFDocument517 pagesIs 13849 PDFsauravNo ratings yet

- Sand Asphalt Base Course 2260Document4 pagesSand Asphalt Base Course 2260Tinh HuynhNo ratings yet

- Design Calc Sheet - Septic Tank Rev1 15-03-09 - 200Document12 pagesDesign Calc Sheet - Septic Tank Rev1 15-03-09 - 200Bok MortegaNo ratings yet

- ANCHORED PILE JETTY DESIGN CALCULATIONSDocument2 pagesANCHORED PILE JETTY DESIGN CALCULATIONSWilfredoEnghoyNo ratings yet

- Cable Trench Installation GuideDocument12 pagesCable Trench Installation GuideTimothy LeonardNo ratings yet

- How To Calculate Materials For Different-Ratio Concrete - Online CivilDocument6 pagesHow To Calculate Materials For Different-Ratio Concrete - Online CivilGriddati Chaitanyakumar100% (1)

- Energy Crisis in NigeriaDocument9 pagesEnergy Crisis in NigeriaCharles Romeo Duru100% (1)

- Schedule of Rates For ROAD WORKS With New ItemsDocument161 pagesSchedule of Rates For ROAD WORKS With New ItemsShabbir1989No ratings yet

- Design Report For Water Works Roads and DrainageDocument6 pagesDesign Report For Water Works Roads and DrainageTayyabah ZafarNo ratings yet

- Analysis of Geopolymer Concrete ColumnsDocument10 pagesAnalysis of Geopolymer Concrete ColumnsRodick AndyNo ratings yet

- Analysis of Jetty Platform Due To Earthquake and Storm Wave (Batam Sea, Indonesia)Document6 pagesAnalysis of Jetty Platform Due To Earthquake and Storm Wave (Batam Sea, Indonesia)RulyIrawanNo ratings yet

- Kerala State Pollution Control BoardDocument34 pagesKerala State Pollution Control Boardprofessionalservices_infoNo ratings yet

- Concrete Slabs On GradeDocument4 pagesConcrete Slabs On Grademr.KramNo ratings yet

- Case Studies in Geotechnical Engineering ConstructionsDocument34 pagesCase Studies in Geotechnical Engineering ConstructionsTHULASI MNo ratings yet

- Design of RC Pad With Single Column Footing: Dead Imposed WindDocument22 pagesDesign of RC Pad With Single Column Footing: Dead Imposed Windsvrao4u100% (2)

- Footing Calculation Rev1Document17 pagesFooting Calculation Rev1RobbyTeresaNo ratings yet

- Cable Trench Design Calculation for 50 MW Solar PlantDocument4 pagesCable Trench Design Calculation for 50 MW Solar PlantAmol ChavanNo ratings yet

- Modifications of Conventional Rigid and Flexible Methods For Mat Foundation DesignDocument156 pagesModifications of Conventional Rigid and Flexible Methods For Mat Foundation Designapirakq100% (1)

- Drainage NotesDocument23 pagesDrainage NotesSandhya EgaNo ratings yet

- Pier FootingDocument2 pagesPier FootingMathurathipan Rajendraseelan100% (1)

- Pile Fixity-38Document3 pagesPile Fixity-38Bilal MuhammadNo ratings yet

- Slab Foundation Design 1Document6 pagesSlab Foundation Design 1Renato ZanescoNo ratings yet

- Checking Bearing CapacityDocument1 pageChecking Bearing CapacityAmir SyamNo ratings yet

- Geosynthetics Product Brochure 2Document32 pagesGeosynthetics Product Brochure 2Mulsa KTGNo ratings yet

- Estimate For Road WorkDocument9 pagesEstimate For Road WorkRajesh KumarNo ratings yet

- Design of ring foundation for clariflacculatorDocument22 pagesDesign of ring foundation for clariflacculatorVarad Sonawadekar100% (1)

- WLG2445 - Chain Link FenceDocument38 pagesWLG2445 - Chain Link FenceIho1No ratings yet

- Lintel DesignDocument7 pagesLintel DesignMuhammad Irfan KhanNo ratings yet

- Stabilization of Black Cotton Soil by Using Fly AshDocument52 pagesStabilization of Black Cotton Soil by Using Fly AshManohar ManuNo ratings yet

- Load Combination For Steel Design Per BS en 1990 EditionDocument2 pagesLoad Combination For Steel Design Per BS en 1990 EditionAsaru Deen100% (1)

- Paper For Bearing Capacity PDFDocument4 pagesPaper For Bearing Capacity PDFernestnsabimana74No ratings yet

- ASD Specification (Volumn 1 Corrigendum)Document0 pagesASD Specification (Volumn 1 Corrigendum)Agnon FungNo ratings yet

- Summary of Cost EstimateDocument18 pagesSummary of Cost EstimatehitcvlNo ratings yet

- Mechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATDocument9 pagesMechanical Force of Short Circuit On Steel Structure For Terminator Inside EGATApichartj JusuayNo ratings yet

- 6 X 8 1M ShadeDocument11 pages6 X 8 1M ShadeamachmouchiNo ratings yet

- Mojkovac Substation EMP ProjectDocument18 pagesMojkovac Substation EMP ProjectVeenoyNo ratings yet

- ALPAXL pile analysis toolDocument12 pagesALPAXL pile analysis toolleodegarioporralNo ratings yet

- Concrete Topping Reinforcement DesignDocument3 pagesConcrete Topping Reinforcement DesignGermar PorquerinoNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- RECTANGULAR SPREAD FOOTING ANALYSISDocument8 pagesRECTANGULAR SPREAD FOOTING ANALYSISdicktracy11No ratings yet

- Settlement Estimation Using Schmertmann MethodDocument20 pagesSettlement Estimation Using Schmertmann MethodpnNo ratings yet

- Differential Settlement Bh7Document9 pagesDifferential Settlement Bh7Zhi Ming CheahNo ratings yet

- Rhomboidal Steel Wire Rope Net Panels SpecificationDocument5 pagesRhomboidal Steel Wire Rope Net Panels SpecificationSOMNATH JANANo ratings yet

- RENEWABLE 2015 Global Status ReportDocument251 pagesRENEWABLE 2015 Global Status Reportpdf2000No ratings yet

- Analysis & Design of Combined Footing: Condition:1Document3 pagesAnalysis & Design of Combined Footing: Condition:1Nikhil PoriyaNo ratings yet

- Circular Footing Design Based On ACI 318-14: Input Data & Design SummaryDocument3 pagesCircular Footing Design Based On ACI 318-14: Input Data & Design SummaryinnovativekarthiNo ratings yet

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 pagesModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioNo ratings yet

- Construction Site Wash Bays GuideDocument0 pagesConstruction Site Wash Bays GuideWan MahiramNo ratings yet

- Topo Survey QuotationDocument3 pagesTopo Survey QuotationAnkur Chauhan50% (2)

- Structural AnalysisDocument13 pagesStructural AnalysisAzaina1No ratings yet

- Design of Concrete Ring Beam For Storage TankDocument5 pagesDesign of Concrete Ring Beam For Storage TanknsutharNo ratings yet

- Concrete Joints GuideDocument4 pagesConcrete Joints GuideVSMS8678No ratings yet

- Requirements of Tower/AntennasDocument8 pagesRequirements of Tower/Antennasvaram1No ratings yet

- ROAD BILL TITLEDocument18 pagesROAD BILL TITLEgsNo ratings yet

- Boq of BridgeDocument6 pagesBoq of BridgeMuzamil Rather100% (1)

- Estimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriDocument15 pagesEstimate For Construction of R.C.C. Bridge Over River Buribalason, at Jalasnijamtara, Phansidewa, SiliguriRio HandokoNo ratings yet

- Chhattishgarh Rural Road Devlopment Agency, Kanker BOQ of Balance WorkDocument12 pagesChhattishgarh Rural Road Devlopment Agency, Kanker BOQ of Balance Workshakil8No ratings yet

- Construction Bill of Quantities for 9.7 km Road ProjectDocument18 pagesConstruction Bill of Quantities for 9.7 km Road ProjectUyavie ObonnaNo ratings yet

- DSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)Document2 pagesDSR Rates For Additional Cost Calculation: Page Code No Description Unit Rate Rate (61% Above DSR)vijayakapoorNo ratings yet

- Sector 7 Infrastructure Cost AnalysisDocument129 pagesSector 7 Infrastructure Cost AnalysisSunil Kumar GeraNo ratings yet

- Icntad Full Paper 2020Document5 pagesIcntad Full Paper 2020Faisal KhanNo ratings yet

- Cover Note Estimate-R4Document6 pagesCover Note Estimate-R4Faisal KhanNo ratings yet

- Detailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaDocument44 pagesDetailed Project Report Development of Industrial Area,: at Piparsewa, Dist - MorenaVIKASNo ratings yet

- List of DocumentsDocument1 pageList of DocumentsFaisal KhanNo ratings yet

- MangalDocument1 pageMangalFaisal KhanNo ratings yet

- Precast Concrete Technology OverviewDocument17 pagesPrecast Concrete Technology OverviewSamuel RochaNo ratings yet

- TextDocument1 pageTextFaisal KhanNo ratings yet

- Management Consultant For Infrastructure Development Work For Plastic Park, Bilaua, Dist-Gwalior (MP) "Document1 pageManagement Consultant For Infrastructure Development Work For Plastic Park, Bilaua, Dist-Gwalior (MP) "Faisal KhanNo ratings yet

- Design Problem 2Document2 pagesDesign Problem 2Faisal KhanNo ratings yet

- Piparsewa DPR (Part 1 and Part 2) PDFDocument175 pagesPiparsewa DPR (Part 1 and Part 2) PDFFaisal KhanNo ratings yet

- PCI Designing With PrecastDocument318 pagesPCI Designing With PrecastCynthia Hasang100% (1)

- Hcs IntroDocument24 pagesHcs IntroPavan PatchigollaNo ratings yet

- E-ticket details for travel from Gwalior to DelhiDocument2 pagesE-ticket details for travel from Gwalior to DelhiFaisal KhanNo ratings yet

- Precast Concrete Pavement SystemDocument65 pagesPrecast Concrete Pavement SystemFaisal KhanNo ratings yet

- 1298DrawingNIT2Document16 pages1298DrawingNIT2Faisal KhanNo ratings yet

- Section BBDocument1 pageSection BBFaisal KhanNo ratings yet

- Haryana Government Invites Proposals for Health University ProjectDocument4 pagesHaryana Government Invites Proposals for Health University ProjectFaisal KhanNo ratings yet

- M7L7 PDFDocument8 pagesM7L7 PDFRANJINI02VNo ratings yet

- Hydr Desi Sewer M7L7Document85 pagesHydr Desi Sewer M7L7Faisal KhanNo ratings yet

- License Agreement ComDocument4 pagesLicense Agreement ComafffsdfNo ratings yet

- Standard DWG For Box Cell CulvertDocument58 pagesStandard DWG For Box Cell CulvertFaisal KhanNo ratings yet

- 678 PDFDocument1 page678 PDFFaisal KhanNo ratings yet

- Illustration 1: Slab Foundation and Drum FoundationDocument8 pagesIllustration 1: Slab Foundation and Drum FoundationHafiz KamalNo ratings yet

- Sum Est MPPKVV PDFDocument1 pageSum Est MPPKVV PDFFaisal KhanNo ratings yet

- Standard DWG For Box Cell Culvert PDFDocument62 pagesStandard DWG For Box Cell Culvert PDFFaisal KhanNo ratings yet

- NITNEWDocument110 pagesNITNEWFaisal KhanNo ratings yet

- M7L7 PDFDocument8 pagesM7L7 PDFRANJINI02VNo ratings yet

- Detailed Project Report Approach for STPDocument66 pagesDetailed Project Report Approach for STPFaisal KhanNo ratings yet

- WindDocument2 pagesWindFaisal KhanNo ratings yet

- 678Document1 page678Faisal KhanNo ratings yet

- Peka SC Year 3Document11 pagesPeka SC Year 3joepcw1578No ratings yet

- TIN InformationDocument14 pagesTIN InformationAin FarhanNo ratings yet

- Scaffolding and Solution in Iron Blast FurnaceDocument142 pagesScaffolding and Solution in Iron Blast Furnacesatya7960100% (2)

- Flame Straightening S355Document9 pagesFlame Straightening S355Anonymous oI04sS100% (1)

- AccumulatorsDocument9 pagesAccumulatorsBaldo CastilloNo ratings yet

- Cored Wires for Iron Foundry TreatmentDocument6 pagesCored Wires for Iron Foundry TreatmentamitkkambleNo ratings yet

- BS en 10020 Definition and Classification of Grades of SteelDocument12 pagesBS en 10020 Definition and Classification of Grades of SteelRishi Oberai100% (5)

- 6 Different Types of Electrical ConduitsDocument2 pages6 Different Types of Electrical Conduitskash30No ratings yet

- Thermophysical PropertiesDocument14 pagesThermophysical PropertiesKalinga BalNo ratings yet

- ISCAR Industries BrochureDocument92 pagesISCAR Industries BrochureAnonymous CYdagINo ratings yet

- Weldlok Grating ManualDocument32 pagesWeldlok Grating ManualtylerlhsmithNo ratings yet

- Defect in Casting For Amie Manufacturing Technology and Manufacturing ScienceDocument33 pagesDefect in Casting For Amie Manufacturing Technology and Manufacturing ScienceparameshwaranpraveenNo ratings yet

- TMT RebarsDocument15 pagesTMT RebarsMohan Dakshina0% (1)

- Imcc - EtsDocument7 pagesImcc - EtssutanuprojectsNo ratings yet

- Hardfacing Wires: For The Cement IndustryDocument20 pagesHardfacing Wires: For The Cement Industrymarlon peña romero100% (1)

- Ball Valve Catalouge - ParkarDocument60 pagesBall Valve Catalouge - Parkardevesh@inboxNo ratings yet

- Heat Resistant Alloy HN Data SheetDocument2 pagesHeat Resistant Alloy HN Data SheetAzize RazamNo ratings yet

- Civil - Ele SpecificationDocument283 pagesCivil - Ele SpecificationTATATAHERNo ratings yet

- Colour ChartDocument1 pageColour ChartgawaNo ratings yet

- Non Ferrous MetalsDocument30 pagesNon Ferrous MetalsjemahbabesNo ratings yet

- Bending (Metalworking)Document7 pagesBending (Metalworking)semizxxxNo ratings yet

- Practical Guidelines For The Fabrication of High Performance Austenitic SSDocument72 pagesPractical Guidelines For The Fabrication of High Performance Austenitic SSlram70No ratings yet

- Die CastingDocument9 pagesDie CastingBhushan SalunkeNo ratings yet

- Name: ANEEZ Wri 3 Batch: PDO Interview QuestiansDocument9 pagesName: ANEEZ Wri 3 Batch: PDO Interview QuestiansMohammed Raje100% (1)

- Grease 2Document4 pagesGrease 2arunNo ratings yet

- Qcs 2010 Section 16 Part 10 Protective TreatmentDocument5 pagesQcs 2010 Section 16 Part 10 Protective Treatmentbryanpastor106No ratings yet

- 15419Document29 pages15419Sadashiva SahooNo ratings yet

- Phase Diagrams 3Document5 pagesPhase Diagrams 3SukhamMichaelNo ratings yet

- Arc Welding Electrodes (Product Catalogue)Document28 pagesArc Welding Electrodes (Product Catalogue)ddprt123No ratings yet