Professional Documents

Culture Documents

Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560

Uploaded by

Shah GrungeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2013/MEM560

Uploaded by

Shah GrungeCopyright:

Available Formats

CONFIDENTIAL

EM/JAN 2013/MEM560

UNIVERSITI TEKNOLOGI MARA

FINAL EXAMINATION

COURSE

MANUFACTURING PROCESSES

COURSE CODE

MEM560

EXAMINATION

JANUARY 2013

TIME

3 HOURS

INSTRUCTIONS TO CANDIDATES

1.

This question paper consists of seven (7) questions.

2.

Answer six (6) questions in the Answer Booklet. Start each answer on a new page.

3.

Do not bring any material into the examination room unless permission is given by the

invigilator.

Please check to make sure that this examination pack consists of:

i)

ii)

the Question Paper

an Answer Booklet - provided by the Faculty

DO NOT TURN THIS PAGE UNTIL YOU ARE TOLD TO DO SO

This examination paper consists of 5 printed pages

Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

CONFIDENTIAL

EM/JAN 2013/MEM560

QUESTION 1

a)

b)

Answer the following questions briefly:

i)

What is metrology and why it is important in mechanical engineering practices?

ii)

How is measurement distinguished from inspection?

iii)

Explain briefly the two (2) major universal systems of units in recording the

measurement.

(6 marks)

Lalila is a project engineer in a car manufacturing company and the company had

decided to introduce a new model and the new model must be produced at a

competitive price for global distribution. Discuss four (4) possible ways that she should

take in order to achieve that objective.

(4 marks)

QUESTION 2

a)

Hot working for metal involves plastic deformation above the recrystallization

temperature of the work material. Define the recrystallization temperature for the metal.

(2 marks)

b)

Propose the most suitable metal forming process to manufacture the following

engineering products:

i)

Crane hook

ii)

Spanner

iii)

Aluminium curtain railing for domestic application

iv)

Electric power cable

v)

Copper tube for air conditioning duct

vi)

Steel T-section for building

(2 marks)

c)

Crankshaft is an important automotive component. There are at least two (2)

manufacturing processes that can be used to manufacture a crankshaft. Suggest the

two (2) processes and which of these processes preferred and why?

(2 marks)

d)

One of the common metal forming processes is extrusion process. Define extrusion

process and briefly describe the types or methods of extrusion.

(4 marks)

Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

CONFIDENTIAL

EM/JAN 2013/MEM560

QUESTION 3

a)

Varieties of materials can be used for casting components and there are number of

different casting techniques involved. Explain the advantages and limitation of these

casting techniques.

(3 marks)

b)

Generally there are two (2) types of casting; expendable and permanent mould

casting. Describe the differences between expendable and permanent mould casting.

(3 marks)

c)

Briefly explain Die casting process and name two (2) common products that can be

produced by this process.

(4 marks)

QUESTION 4

Many methods can be used for joining materials and every joining method has particular

design requirements.

a)

Soldering is a joining process and various metals can be soldered together. Explain

briefly about soldering process.

(2 marks)

b)

Brazing joins two pieces of metal when a melted metallic filler called brass flows across

the joint and cools to form a solid bond. Briefly explain the principle of brazing process.

(2 marks)

c)

Explain the principle underlying resistance welding process. Give examples of products

produced by the following resistance welding processes:

i)

Spot welding

ii)

Seam welding

iii)

Upset butt welding

(6 marks)

Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

CONFIDENTIAL

EM/JAN 2013/MEM560

QUESTION 5

a)

There are many traditional machine tools available in FKM machine shop. Answer

briefly the following questions with regards to machine tools:

i)

Name at least six (6) machine tools available in FKM machine shop.

(2 marks)

b)

ii)

Describe briefly one (1) of the machines that you had named in part (i) above.

(2 marks)

iii)

When the machine tool is used for metal cutting, chips are produced as waste

materials. Name three (3) basic categories of chips in metal cutting. Discuss

briefly one (1) of them.

(2 marks)

Two experiments for turning process using HSS cutting tool were carried out based on

different cutting speeds and the tool lifes were recorded as follows:

Experiment

Cutting speed; V

(m/min)

Tool life; T

(min)

478

10

321

25

Determine:

i)

the constant in the Taylor's equation,

ii)

the tool life T, at V = 319 m/min, and

iii)

the cutting speed for tool life of 20 min.

(4 marks)

Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

CONFIDENTIAL

EM/JAN 2013/MEM560

QUESTION 6

a)

As a manufacturing engineer, you are required to make a mould for a new design of

mobile-phone-casing using a non-traditional machining (NTM) process. What is the

most suitable NTM process that you will recommend? Explain why you select that NTM

process.

(4 marks)

b)

In NTM process, Electron Beam Machining (EBM) and Electrical Discharge Machining

(EDM) fall under the category of thermal process.

i)

Sketch the schematic illustration for both machining methods to show the

differences in the operational principles.

(4 marks)

ii)

Determine two (2) design guidelines for each type of the processes.

(2 marks)

QUESTION 7

a)

Name four (4) plastic processing methods available currently in industries. Describe

two (2) of the methods that you have named and list at least two (2) advantages and

disadvantages of the methods described.

(6 marks)

b)

Powder metallurgy (P/M) application enables the manufacturing of small, intricate parts

of high precision resulting in high density, net-shape and the elimination of scrap

during the process. Describe some of the characteristics of the metal powders to be

considered in P/M.

(4 marks)

END OF QUESTION PAPER

Hak Cipta Universiti Teknologi MARA

CONFIDENTIAL

You might also like

- Universiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JUN2012/MEM560Muhammad FirdawsNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Document4 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM561/KJP516/470Nasri JamaludinNo ratings yet

- Universiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Document5 pagesUniversiti Teknologi Mara Final Examination: Confidential EM/JAN 2012/MEM560Muhammad FirdawsNo ratings yet

- BDD 40103Document3 pagesBDD 40103zinilNo ratings yet

- Techno-Environmental Feature-Based Sun Tracking Model Fabrication & Optimal Analyses by Precise Position AlgorithmDocument9 pagesTechno-Environmental Feature-Based Sun Tracking Model Fabrication & Optimal Analyses by Precise Position AlgorithmInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Real-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkDocument12 pagesReal-Time Monitoring Security System Integrated With Raspberry Pi and E-Mail Communication LinkIJRASETPublicationsNo ratings yet

- Bank Token Display SystemDocument22 pagesBank Token Display Systemsandy_18_sn5879No ratings yet

- Chapter 3 - Choppers - PDFDocument75 pagesChapter 3 - Choppers - PDFZahidullah100% (1)

- Window Function ComparisonsDocument7 pagesWindow Function ComparisonsHaripriya RadhakrishnanNo ratings yet

- FIR Using Window MethodDocument24 pagesFIR Using Window MethodModyKing99No ratings yet

- Chapter 2 - FIR Filters - Digital Filter DesignDocument100 pagesChapter 2 - FIR Filters - Digital Filter DesignSanjay BalwaniNo ratings yet

- Design and Fabrication of Stair Climbing Hand Cart: Government Engineering CollegeDocument28 pagesDesign and Fabrication of Stair Climbing Hand Cart: Government Engineering CollegeFayyaz NadeemNo ratings yet

- Addressing The Causes That Hinder Effective English Language Teaching in Saudi Universities: A Case StudyDocument36 pagesAddressing The Causes That Hinder Effective English Language Teaching in Saudi Universities: A Case StudyChoudhary Zahid JavidNo ratings yet

- Lab 9 TransistorDocument8 pagesLab 9 TransistorChing Wai YongNo ratings yet

- Monitoring and Control of Solar Power System Using Reliance SCADADocument4 pagesMonitoring and Control of Solar Power System Using Reliance SCADAEditor IJTSRDNo ratings yet

- C++ Tokens, Literals, and Short ProgramsDocument17 pagesC++ Tokens, Literals, and Short Programsmehak2106No ratings yet

- Malaysian Studies Exam Tips Tri 1 1011Document45 pagesMalaysian Studies Exam Tips Tri 1 1011Karthik100% (1)

- EMG 2505 - Measurement and Instrumentation PDFDocument159 pagesEMG 2505 - Measurement and Instrumentation PDFVasda VinciNo ratings yet

- LED flasher using UJT oscillatorDocument5 pagesLED flasher using UJT oscillatorBharathNo ratings yet

- Solar Powered Mobile Operated Smart Multifunction Agriculture RobotDocument4 pagesSolar Powered Mobile Operated Smart Multifunction Agriculture RobotVIVA-TECH IJRINo ratings yet

- Function of Law ReportDocument3 pagesFunction of Law ReportzurainaNo ratings yet

- Design & Implementation of Mamdani Fuzzy Inference System On An Automatic Train Braking SystemDocument5 pagesDesign & Implementation of Mamdani Fuzzy Inference System On An Automatic Train Braking SystemijsretNo ratings yet

- PLC Based Automatic Car Washing System-18849Document6 pagesPLC Based Automatic Car Washing System-18849Jok ZamNo ratings yet

- Steady State ErrorsDocument13 pagesSteady State ErrorsChetan KotwalNo ratings yet

- Chapter No. Description Page No.: 1.1 Block Diagram 3Document69 pagesChapter No. Description Page No.: 1.1 Block Diagram 3Deekshith Ram50% (2)

- Lab Sheet: Faculty of Engineering & TechnologyDocument12 pagesLab Sheet: Faculty of Engineering & TechnologyMun Kit ChokNo ratings yet

- EE658A Assignment 6Document14 pagesEE658A Assignment 6sai kNo ratings yet

- Adaptive Lighting for Automobiles Seminar PresentationDocument18 pagesAdaptive Lighting for Automobiles Seminar Presentationkavitha mNo ratings yet

- How Does A PID Controller Work - Structure & Tuning MethodsDocument12 pagesHow Does A PID Controller Work - Structure & Tuning Methodsmurugan1984No ratings yet

- 16 Unit15Document45 pages16 Unit15ZULUNo ratings yet

- Design of Adders, Subtractors, BCD Adders Week6 and 7 - Lecture 2Document60 pagesDesign of Adders, Subtractors, BCD Adders Week6 and 7 - Lecture 2Gursheel SinghNo ratings yet

- Mechanical Work Shop Lab ReportDocument9 pagesMechanical Work Shop Lab ReportOG HackNo ratings yet

- FIR Filters ExplainedDocument22 pagesFIR Filters ExplainedShivMeenaNo ratings yet

- Robotics and AutomationDocument4 pagesRobotics and AutomationTemitayo Olutimi EjidokunNo ratings yet

- The Use of Non Linear Metal Oxide Resistors in Transformer PDFDocument3 pagesThe Use of Non Linear Metal Oxide Resistors in Transformer PDFtalaporriNo ratings yet

- EE6504 Electrical Machines-II PDFDocument233 pagesEE6504 Electrical Machines-II PDFkumar m100% (1)

- ZNC Varistor Switching SurgeDocument39 pagesZNC Varistor Switching Surgeth3g4m3No ratings yet

- Pe Final Ex SS 2010-2011Document8 pagesPe Final Ex SS 2010-2011Saif Uddin100% (1)

- (Experiment 3) BJT - Common Emiter Amplifier PDFDocument9 pages(Experiment 3) BJT - Common Emiter Amplifier PDFArik JuniarNo ratings yet

- 4b Digital System - Logic Gates & Boolean ExpressionDocument52 pages4b Digital System - Logic Gates & Boolean ExpressionAhmad IzzuddinNo ratings yet

- SRM Valliammai Engineering College (An Autonomous Institution)Document12 pagesSRM Valliammai Engineering College (An Autonomous Institution)vijayalakshmiNo ratings yet

- Staircase Climbing TrollyDocument47 pagesStaircase Climbing TrollySathish Royalraja75% (4)

- Homemade Vacuum Cleaner Mini Project ReportDocument20 pagesHomemade Vacuum Cleaner Mini Project ReportVijaya WamanNo ratings yet

- MECH-151 TEXT BOOK TEVTA - 3 DesktopDocument244 pagesMECH-151 TEXT BOOK TEVTA - 3 DesktopWasif Ali Sindhu100% (1)

- Design of Fully Differential Operational Amplifier With High Gain, Large Bandwidth and Large Dynamic RangeDocument93 pagesDesign of Fully Differential Operational Amplifier With High Gain, Large Bandwidth and Large Dynamic RangeAhmed EdrisNo ratings yet

- Design and Fabrication of Mini DC VacuumDocument7 pagesDesign and Fabrication of Mini DC VacuumArhyel IshakuNo ratings yet

- Applications of 8051 MicrocontrollersDocument23 pagesApplications of 8051 MicrocontrollersUsama Spiffy100% (1)

- Integrated Mobile Surveillance and Wireless Sensor SystemDocument10 pagesIntegrated Mobile Surveillance and Wireless Sensor SystemARVIND100% (1)

- Microcontroller Based Automatic Solar Power Tracking SystemDocument6 pagesMicrocontroller Based Automatic Solar Power Tracking SystemIAEME Publication50% (2)

- Clippers and Clampers Circuits GuideDocument25 pagesClippers and Clampers Circuits GuideUsman BabarNo ratings yet

- Scilab ProgramsDocument47 pagesScilab ProgramsNatraj Anita Prabhurao HulsureNo ratings yet

- ME 1305 - Applied Hydraulics and PneumaticsDocument7 pagesME 1305 - Applied Hydraulics and PneumaticsUva ShruthikaNo ratings yet

- LTspice Lecture326Document37 pagesLTspice Lecture326adadnnnnn100% (1)

- Dr. Ayman A. El-Badawy Control Engineering Assignment MATLAB CodeDocument10 pagesDr. Ayman A. El-Badawy Control Engineering Assignment MATLAB CodeSeifeldin T. AbdelghanyNo ratings yet

- P, PI, PD & PID Controllers ApproachesDocument77 pagesP, PI, PD & PID Controllers ApproachesTushit ThakkarNo ratings yet

- Porosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering ADocument7 pagesPorosity Reduction and Mechanical Properties Improvement in Die Cast Engine Blocks (Pub Year) Materials Science and Engineering AgiokniessNo ratings yet

- Solar Power PlantDocument65 pagesSolar Power PlantHil GloriosoNo ratings yet

- Assignment 2Document5 pagesAssignment 2aiao90No ratings yet

- C Programming Lab ManualDocument45 pagesC Programming Lab ManualSiva Kiran100% (3)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Chapter 7 Ohsas 18001 Edit Ba 29 Nov 2015 PDFDocument112 pagesChapter 7 Ohsas 18001 Edit Ba 29 Nov 2015 PDFShah GrungeNo ratings yet

- Mec551 PDFDocument10 pagesMec551 PDFShah GrungeNo ratings yet

- Chapter 7 Ohsas 18001 Edit Ba 29 Nov 2015 PDFDocument112 pagesChapter 7 Ohsas 18001 Edit Ba 29 Nov 2015 PDFShah GrungeNo ratings yet

- Power Train DepartmentDocument26 pagesPower Train DepartmentShah GrungeNo ratings yet

- MEM564 Manufacturing Processes Lab ReportDocument4 pagesMEM564 Manufacturing Processes Lab ReportPutera AshrafNo ratings yet

- 1.0-Lab Sheet Foundry - 1Document2 pages1.0-Lab Sheet Foundry - 1atheerahfarahNo ratings yet

- History of Printing Press: First Stage: Woodblock PrintingDocument7 pagesHistory of Printing Press: First Stage: Woodblock PrintingAnjali GuptaNo ratings yet

- Lecture 7 Reforming and IsomerizationDocument5 pagesLecture 7 Reforming and IsomerizationMadhuri Gupta100% (1)

- TypingDocument2 pagesTypinglakpatNo ratings yet

- OAW SMAW Flat WeldingDocument12 pagesOAW SMAW Flat WeldingHaikal SubriNo ratings yet

- WORKSHOPDocument9 pagesWORKSHOPManjunatha EikilaNo ratings yet

- Plugin-Exhibitorlist 2Document12 pagesPlugin-Exhibitorlist 2bbharaniprasad0% (1)

- Heat Treating Music Wire for Model Aircraft PartsDocument2 pagesHeat Treating Music Wire for Model Aircraft PartsCiprian MaiorNo ratings yet

- Force Recon WorkoutDocument1 pageForce Recon WorkoutMatthew CittaNo ratings yet

- DURFERRIT2Document22 pagesDURFERRIT2Kyle BennettNo ratings yet

- SCX-6345N XET SM EN 20070130090204078 07-Exploded Views XET PDFDocument85 pagesSCX-6345N XET SM EN 20070130090204078 07-Exploded Views XET PDFSoraphong NaknoppakoonNo ratings yet

- RFCCDocument6 pagesRFCCMejdi Sylas Toudji100% (1)

- Tratamente Termice F4Document6 pagesTratamente Termice F4andreeaoana45No ratings yet

- Lam 2013Document4 pagesLam 2013usha pawanNo ratings yet

- Me6302 Manufacturing Technology-I Big Questions Unit-IDocument5 pagesMe6302 Manufacturing Technology-I Big Questions Unit-IElumalai PcNo ratings yet

- Hardening and TemperingDocument3 pagesHardening and TemperingwtfnoneoNo ratings yet

- PWPS 013 PRDocument2 pagesPWPS 013 PRRenjith Gopan100% (1)

- Pavel 5 Week WorkoutDocument1 pagePavel 5 Week Workoutkris-340437No ratings yet

- Main EB Transformer - 33KV/11KV (8000KVA) ReadingsDocument30 pagesMain EB Transformer - 33KV/11KV (8000KVA) Readingsiotaathi tNo ratings yet

- Types of AnnealingDocument2 pagesTypes of AnnealingAshwani Kansara50% (2)

- All Outokumpu SS GradesDocument1 pageAll Outokumpu SS Gradespipedown456No ratings yet

- en 10052 PDFDocument29 pagesen 10052 PDFmojgfdNo ratings yet

- Industry: Member IMC GroupDocument12 pagesIndustry: Member IMC GroupM. AguiarNo ratings yet

- Pulp and Paper IndustryDocument6 pagesPulp and Paper IndustrySaad AhmedNo ratings yet

- LONG Telephone DirectoryDocument7 pagesLONG Telephone DirectoryBHAWANI SINGH TANWARNo ratings yet

- Afd 091005 064Document444 pagesAfd 091005 064phaninittNo ratings yet

- Maintenance KitsDocument11 pagesMaintenance KitsJohn HinkleNo ratings yet

- Weld Joint PreparationDocument2 pagesWeld Joint PreparationMurali Krishna DNo ratings yet

- Unit # 5 Dynamic Cmos and ClockingDocument15 pagesUnit # 5 Dynamic Cmos and ClockingKiran KumariNo ratings yet

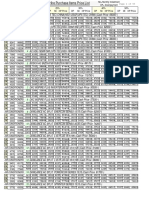

- PriceListHirePurchase Normal 1Document55 pagesPriceListHirePurchase Normal 1Muhammad HajiNo ratings yet

- Pec Ifica Tion .PW: Surface Vehicle InformationDocument11 pagesPec Ifica Tion .PW: Surface Vehicle InformationCelso100% (1)