Professional Documents

Culture Documents

Nearly maintenance-free fly ash handling with Airslide to pump system

Uploaded by

Vikas SuryavanshiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Nearly maintenance-free fly ash handling with Airslide to pump system

Uploaded by

Vikas SuryavanshiCopyright:

Available Formats

A2P : Airslide to Pump

TM TM

Fly Ash Handling System

Nearly maintenance-free

Capital cost reduced by up to 50%

Continuous ash removal from

collection hoppers

Only two moving pieces between

collection hopper and storage

Continuous conveying to storage

Power Plant Dust Collector

TM

Airslide Gathering System

Fly ash continuously discharges from all dust collector hoppers simultaneously. Ash becomes

fluidized within the Airslide conveyor and flows rapidly down the slope via gravity.

Fluidization air is heated to further ensure proper ash flow to the Fuller-KinyonTM pump. The

pump acts as a "line charger," injecting the ash into the pressurized convey pipeline while

acting as an airlock between the conditions in the dust collector / Airslide conveyor and the

conveying system.

The FK Pump conveying system uses carbon steel straight piping and hard iron sweep

fittings. A simple bin vent filter is required at the destination silo to vent the conveying air.

Testimonial regarding Airslide gathering system on

process utility dust collector:

“Since the installation of the system in 1995, we have

replaced one 4-foot long section of the Airslide fabric. Other

than that, the system is nearly maintenance free.“

- Glenn Outland, Plant Engineer,

Roanoke Valley Energy Facility, 2004

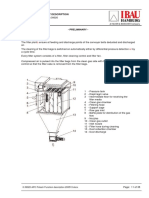

Components of the

Airslide / FK Pump System

TM TM

Airslide Air Gravity Conveyor

• Conveys fluidized product via gravity through

Material

sloping trough. The conveying plenum (top) Plenum

and air plenum (bottom) are separated by a

proprietary 5-ply porous membrane.

• Air supply is low pressure fan or blower

package.

• No moving parts within material flow stream

• As an example of Airslide capabilities, Airslide

conveyor gathering networks are installed in

power plants on circulating dry scrubbers (both

baghouses and electrostatic precipitators) with

circulating ash/lime flows over 400 STPH.

• Ten to twenty year fabric life is common under Air

standard conditions. Plenum

Fuller-Kinyon TM

Pump Line Charger

Pump inlet • Continuously injects bulk materials

3-piece screw into a pressurized convey pipeline

for ease of maintenance • Variable pitch screw continuously

compresses bulk product as it

enters the windbox (material/air

mixing chamber). Compressed

product forms a “material seal”

against the convey line pressure.

• Extremely simple operation and

maintenance

• Direct dive, electric motor

• Over 30 pumps installed for fly ash

Pump discharge

conveyance within coal-fired

Windbox

power plants in the last six years.

Literally thousands of pumps

installed worldwide since pump

was introduced in 1920’s.

Additional Power Industry Information

Fly Ash Management

Fly ash intercept systems

TM

Process conveying with Fuller-Kinyon pumps

Dome storage and reclaim

Silo aeration and loadout

Fly ash blending

Modu-Flo MT Dense Phase TM

Ash Handling Systems

Simple, but heavy-duty components for long life and reliability

Simplified controls result in reduced system and installation costs

Only one valve in contact with the conveyed material

Low velocity conveying for greater efficiency and cost effectiveness

Minimal headroom required

Reagent Handling Systems for

the Power Industry

Transport and unloading

In-plant transfer

Flue duct injection

Boiler injection

Duct injection

Conventional Fly Ash Handling Systems

Silo storage, fluidizing, loadout

Vacuum systems

Pressure systems

Vacuum / Pressure systems

Our brochure makes no offers, representations or warranties (express or implied), and information and data contained in this brochure are for general

reference only and may change at any time. Please contact us for specific information or data that may relate to your interests.

DENMARK USA INDIA

FLSmidth A/S FLSmidth Inc. FLSmidth Ltd.

Vigerslev Allé 77 2040 Avenue C Capital Towers

www.fls-pt.com DK-2500 Valby Bethlehem, PA 18017-2188 180, Kodambakkam High Road

03-2006 A2P

Copenhagen Tel:+1 610-264-6011 Nungambakkam

Tel:+45 36 18 10 00 Tel:+1 800-523-9482 Chennai 600 034

Up-to-date addresses of worldwide Fax:+45 36 30 18 20 Fax:+1 610-264-6170 Tel:+91 – 44-52 191234

subsidiaries and sales offices are Email: info@flsmidth.com E-mail: info-us@flsmidth.com Fax:+91 – 44-2827 9393

available from our website E-mail: indiainfo@flsmidth.com

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- How To Time An Event of Dinesh Mathur SABook Review Section BWDocument11 pagesHow To Time An Event of Dinesh Mathur SABook Review Section BWleohimak100% (3)

- All You Wanted To Know About The PlanetsDocument106 pagesAll You Wanted To Know About The Planetschalimac100% (7)

- Pneumatic Ship and Barge UnloadersDocument6 pagesPneumatic Ship and Barge Unloadersomni_partsNo ratings yet

- Navamsa and Pushkar Navamsa - InterpretationDocument9 pagesNavamsa and Pushkar Navamsa - InterpretationANTHONY WRITER100% (2)

- O&M Manual - Solyvent Flakt Bag Filter Fans For Humboltd-NCC YemenDocument62 pagesO&M Manual - Solyvent Flakt Bag Filter Fans For Humboltd-NCC YemenanasNo ratings yet

- Ammann Asphalt Mixing-Plant Brochure enDocument72 pagesAmmann Asphalt Mixing-Plant Brochure enMuzammil Khalil100% (1)

- Ash Handling SystemsDocument32 pagesAsh Handling Systemsamit14326367% (9)

- Training Hot-Mix Plant OperatorDocument9 pagesTraining Hot-Mix Plant OperatorAnonymous ciKyr0t100% (2)

- 327 - IBAU Silo-Das Original PDFDocument28 pages327 - IBAU Silo-Das Original PDFtaghdirimNo ratings yet

- Filter media selection for cement production processesDocument4 pagesFilter media selection for cement production processesm_verma21No ratings yet

- Comparing Premix Crusher Offers from TKF, Hazemag, and SinomaDocument6 pagesComparing Premix Crusher Offers from TKF, Hazemag, and Sinomafauzan tarmiziNo ratings yet

- VDZ Cement Manufacturing Course FlyerDocument4 pagesVDZ Cement Manufacturing Course FlyerfaheemqcNo ratings yet

- MBE EWB LTD - Ash Handling TechnologiesDocument23 pagesMBE EWB LTD - Ash Handling TechnologieshbookNo ratings yet

- Astrology - Impact of Transit Conjunctions On Natal PointsDocument11 pagesAstrology - Impact of Transit Conjunctions On Natal PointsjeydownloadNo ratings yet

- Services For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhaseDocument29 pagesServices For Bulk Material Handling Projects: Project Formulation Phase Project Engineering PhasesrichmechNo ratings yet

- Mecawber DenseveyorDocument4 pagesMecawber DenseveyorkanthmekalaNo ratings yet

- Fly Ash Unloading and Storage SystemDocument12 pagesFly Ash Unloading and Storage Systemmynz_24No ratings yet

- Case Study - Maintenance ManagementDocument27 pagesCase Study - Maintenance ManagementDuke Maher SalemNo ratings yet

- Chemical Engineering April 2017Document84 pagesChemical Engineering April 2017Jessicalba LouNo ratings yet

- Design of Silos 2010Document21 pagesDesign of Silos 2010Topaca Paec100% (3)

- Pneumatic Cement Conveying SystemsDocument8 pagesPneumatic Cement Conveying SystemsKendra TerryNo ratings yet

- Cfi SiloDocument4 pagesCfi SiloSyed KhalilNo ratings yet

- Polytrack Clinker Cooler.: PolysiusDocument3 pagesPolytrack Clinker Cooler.: PolysiushathamphanNo ratings yet

- BV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Document20 pagesBV-P2103GB Pneumatic Conveying For The Cement and Gypsum Industries Sept 12Kenny RuizNo ratings yet

- Storage and Aeration System in SiloDocument2 pagesStorage and Aeration System in Siloibnuwibowo1990No ratings yet

- Applications & Advantages of Pipe ConveyorsDocument4 pagesApplications & Advantages of Pipe Conveyorsayaskant751001No ratings yet

- Pneumatic Conveying: Technology You Can TrustDocument16 pagesPneumatic Conveying: Technology You Can TrustSyed Rameez MohiuddinNo ratings yet

- Ash Handling SystemDocument4 pagesAsh Handling Systemrmm99rmm99No ratings yet

- Bag Filter ComponentsDocument6 pagesBag Filter ComponentsAhmad Dagamseh100% (2)

- Excel List of BooksDocument6 pagesExcel List of BooksVikas SuryavanshiNo ratings yet

- Pneumatic TechnikDocument16 pagesPneumatic TechnikFarid AhmedNo ratings yet

- Fan Selection & PerformanceDocument63 pagesFan Selection & PerformanceVishva Deepak MishraNo ratings yet

- Imperial Sugar Refinery Combustible Dust Explosion InvestigationDocument16 pagesImperial Sugar Refinery Combustible Dust Explosion InvestigationNataraj Naik Banavath ch20m025No ratings yet

- Bucket ElevatorsDocument11 pagesBucket ElevatorsMehmet CNo ratings yet

- Material Handling System in Cement IndustryDocument9 pagesMaterial Handling System in Cement IndustryUmairIsmailNo ratings yet

- Bag Filters For Cement IndustryDocument9 pagesBag Filters For Cement Industrymahreza189No ratings yet

- Field Operator Certification: Air SlidesDocument27 pagesField Operator Certification: Air SlidesSatya Makhija100% (1)

- Feedmill of The FutureDocument14 pagesFeedmill of The FutureMilling and Grain magazineNo ratings yet

- ASH Handling 4Document42 pagesASH Handling 4Tamíris da Costa100% (2)

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- FLSPfister IB05000 I GBTRWSD0216 MailDocument26 pagesFLSPfister IB05000 I GBTRWSD0216 MailLuis Angel BusturiaNo ratings yet

- Importance of Dedusting Pipe LayoutDocument4 pagesImportance of Dedusting Pipe LayoutManoj ThakurNo ratings yet

- FLS-pneumatic Transfer From Storage (Tse)Document22 pagesFLS-pneumatic Transfer From Storage (Tse)Dilnesa EjiguNo ratings yet

- Ash HandlingDocument3 pagesAsh HandlingYhaneNo ratings yet

- Logic of Ash HandlingDocument8 pagesLogic of Ash HandlingPratama Trendy LeoNo ratings yet

- CFI Controlled Flow Inverted Cone SiloDocument4 pagesCFI Controlled Flow Inverted Cone SiloTùng CCIDNo ratings yet

- Long Filter BagDocument1 pageLong Filter BagAlbar BudimanNo ratings yet

- The Cement Grinding Office: Home About Us Services Mining AreaDocument3 pagesThe Cement Grinding Office: Home About Us Services Mining AreaVisnu SankarNo ratings yet

- WWW - Nol Tec - Com Documents Pdfs Answers To Eight Common QuestionsDocument6 pagesWWW - Nol Tec - Com Documents Pdfs Answers To Eight Common QuestionsIaponaira de Abreu100% (1)

- Ketapang Coal Fired Power Plant Ash Handling Operation ManualDocument24 pagesKetapang Coal Fired Power Plant Ash Handling Operation ManualKulata IrminaNo ratings yet

- Fly Ash Handling Challenges and SolutionsDocument10 pagesFly Ash Handling Challenges and SolutionsalvarikokexNo ratings yet

- 09.30 Cemengal Tanger BK6 FDDocument18 pages09.30 Cemengal Tanger BK6 FDMohd AliNo ratings yet

- Improving efficiency of industrial fansDocument19 pagesImproving efficiency of industrial fansmkpqNo ratings yet

- Benson Beltings LTD.: Product InformationDocument2 pagesBenson Beltings LTD.: Product InformationSen VanNo ratings yet

- Afr Mix Ratio Geo/Ims/Lab/Fmt/06/V1.1Document34 pagesAfr Mix Ratio Geo/Ims/Lab/Fmt/06/V1.1Santanu PachhalNo ratings yet

- 3 SOP For Cleaning of Clinker Cooler DischargeDocument3 pages3 SOP For Cleaning of Clinker Cooler DischargekakaNo ratings yet

- Hexa-Cover (R) Floating Cover Brochure AgricultureDocument5 pagesHexa-Cover (R) Floating Cover Brochure AgriculturehexacoverNo ratings yet

- Insert Able Jet Pulse FilterDocument4 pagesInsert Able Jet Pulse FilterM.IBRAHEEMNo ratings yet

- 0.1 Outline of Operation & Maintenance Training For Cement PlantDocument7 pages0.1 Outline of Operation & Maintenance Training For Cement PlantReubenNo ratings yet

- Locomotive Safety DevicesDocument5 pagesLocomotive Safety DevicesmajjisatNo ratings yet

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Document2 pagesCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalNo ratings yet

- 2012 - Design, Fabrication and Commissioning of RDF PDFDocument72 pages2012 - Design, Fabrication and Commissioning of RDF PDFHilmi Gazali TvkNo ratings yet

- Gravity Conveyor With Air FluidizeDocument3 pagesGravity Conveyor With Air Fluidizechem_taNo ratings yet

- Flow Assessment of Powders in Pneumatic Conveying - A Bench Top A PDFDocument385 pagesFlow Assessment of Powders in Pneumatic Conveying - A Bench Top A PDFwijaya adidarmaNo ratings yet

- V P P P: Alid Ractice Roduction RocessDocument7 pagesV P P P: Alid Ractice Roduction RocessMin MCLNo ratings yet

- Leaflet Diverter Valve WZKDocument2 pagesLeaflet Diverter Valve WZKLorenzo Antonio Vera GonzalezNo ratings yet

- Cement FactoryDocument20 pagesCement FactorySabbir KhanNo ratings yet

- FLS Minerals Brochure PDFDocument8 pagesFLS Minerals Brochure PDFmonam ellghorbeliNo ratings yet

- Fuller Kinyon PumpDocument6 pagesFuller Kinyon Pumpdj.aylwinNo ratings yet

- Dry Bottom Ash Handling System Improving Maintainability and Economic EfficiencyDocument4 pagesDry Bottom Ash Handling System Improving Maintainability and Economic EfficiencyDidit LinggaNo ratings yet

- Fuller Kin Yon Pump 2010Document6 pagesFuller Kin Yon Pump 2010BalajiNo ratings yet

- 09 Mathematics Quadrilateral Test 04Document2 pages09 Mathematics Quadrilateral Test 04Vikas SuryavanshiNo ratings yet

- 09 Mathematics Quadrilateral Test 05 PDFDocument2 pages09 Mathematics Quadrilateral Test 05 PDFVikas SuryavanshiNo ratings yet

- Ncert Sol 09 Science Ch03 Atoms and Molecules p32 ADocument1 pageNcert Sol 09 Science Ch03 Atoms and Molecules p32 AVikas SuryavanshiNo ratings yet

- 2017 09 Science SP Sa2 02 Ans Aya98Document6 pages2017 09 Science SP Sa2 02 Ans Aya98Vikas SuryavanshiNo ratings yet

- 2017 09 Science SP Sa2 02 QuesDocument4 pages2017 09 Science SP Sa2 02 QuesVikas SuryavanshiNo ratings yet

- 09 Science Notes Ch03 Atom and MoleculesDocument12 pages09 Science Notes Ch03 Atom and MoleculesVikas SuryavanshiNo ratings yet

- CBSE Sample Paper - 01 Summative Assessment - Ii SCIENCE (Theory) Class - IX SolutionDocument7 pagesCBSE Sample Paper - 01 Summative Assessment - Ii SCIENCE (Theory) Class - IX SolutionVikas SuryavanshiNo ratings yet

- 09 Mathematics Quadrilaterals Test 01Document2 pages09 Mathematics Quadrilaterals Test 01Vikas SuryavanshiNo ratings yet

- 2017 09 Science SP Sa2 01 QuesDocument4 pages2017 09 Science SP Sa2 01 QuesVikas SuryavanshiNo ratings yet

- Class - IX Atoms and Molecules (Page No. 39) AnswersDocument1 pageClass - IX Atoms and Molecules (Page No. 39) AnswersVikas SuryavanshiNo ratings yet

- 09 Mathematics Ncert Ch04 Linear Equations in Two Variables Ex 4.1 Ans KweDocument2 pages09 Mathematics Ncert Ch04 Linear Equations in Two Variables Ex 4.1 Ans KweVikas SuryavanshiNo ratings yet

- 09 Mathematics Quadrilateral Test 03 Answer 3ene PDFDocument3 pages09 Mathematics Quadrilateral Test 03 Answer 3ene PDFVikas SuryavanshiNo ratings yet

- 09 Mathematics Surface Areas and Volume Test 05Document1 page09 Mathematics Surface Areas and Volume Test 05Vikas SuryavanshiNo ratings yet

- 09 Mathematics Quadrilateral Test 03 Answer 3ene PDFDocument3 pages09 Mathematics Quadrilateral Test 03 Answer 3ene PDFVikas SuryavanshiNo ratings yet

- Geometry and AstrologyDocument6 pagesGeometry and AstrologyVikas SuryavanshiNo ratings yet

- 09 Mathematics Linear Equation in Two Variable 02Document2 pages09 Mathematics Linear Equation in Two Variable 02Vikas SuryavanshiNo ratings yet

- 09 Mathematics Surface Areas and Volume Test 03Document1 page09 Mathematics Surface Areas and Volume Test 03Vikas SuryavanshiNo ratings yet

- CBSE Class 9 Math Test on Surface Area and VolumeDocument2 pagesCBSE Class 9 Math Test on Surface Area and VolumeVikas SuryavanshiNo ratings yet

- 09 Mathematics Surface Areas and Volume Test 04Document1 page09 Mathematics Surface Areas and Volume Test 04Vikas SuryavanshiNo ratings yet

- Social Science Syllabus (2015 16) ClassXthDocument8 pagesSocial Science Syllabus (2015 16) ClassXthVikas SuryavanshiNo ratings yet

- 2016 Syllabus 09 Science PDFDocument6 pages2016 Syllabus 09 Science PDFAnonymous 9lzgafNo ratings yet

- 2014 09 Lyp Mathematics 17Document3 pages2014 09 Lyp Mathematics 17Vikas SuryavanshiNo ratings yet

- 2012 SP 09 Term 2 Mathematics 01Document3 pages2012 SP 09 Term 2 Mathematics 01Vikas SuryavanshiNo ratings yet

- 2015 09 Mathematics Sa1 05Document4 pages2015 09 Mathematics Sa1 05Vikas SuryavanshiNo ratings yet

- SA-II - IX - Final MathsDocument19 pagesSA-II - IX - Final MathsSaurav KumarNo ratings yet

- Cereal Storage PDFDocument5 pagesCereal Storage PDFMiguel Jurado García PosadaNo ratings yet

- Con - Evator ManualDocument30 pagesCon - Evator ManualsitirNo ratings yet

- Brook SilosDocument8 pagesBrook Silosusman sharifNo ratings yet

- Price List 2017-2018Document50 pagesPrice List 2017-2018Aprilie MihaelaNo ratings yet

- Feeders and Storage Silos Technical ReportDocument16 pagesFeeders and Storage Silos Technical ReportVince Dominich MadroneroNo ratings yet

- Millingmixing EnglishDocument14 pagesMillingmixing Englishhicham boutoucheNo ratings yet

- Pelletron Dedusting BrochureDocument16 pagesPelletron Dedusting BrochureSatyam MadameNo ratings yet

- Cement Feeding SystemDocument2 pagesCement Feeding SystemSUPERMIX EquipmentsNo ratings yet

- Silo Weights and MeasuresDocument2 pagesSilo Weights and MeasuresMihailo RadivojevicNo ratings yet

- Manuale D'uso SilosDocument28 pagesManuale D'uso SilosRoyer CcosiNo ratings yet

- Irc - 109-1997 Wet Mix MacadamDocument20 pagesIrc - 109-1997 Wet Mix MacadamNeeraj Dubey100% (2)

- 65 Tons Horizontal Cement Silo Quotation 20210210Document4 pages65 Tons Horizontal Cement Silo Quotation 20210210Robert R. TiinNo ratings yet

- PRDocument12 pagesPRRitche Lim BragaisNo ratings yet

- Fowler Westrup-BrochureDocument20 pagesFowler Westrup-BrochureDevelopment [Agrosaw]No ratings yet

- Calcium CarbonateDocument2 pagesCalcium CarbonatemohammadazraiNo ratings yet

- Environmental Guidelines For Concrete Batching Plants 2016Document11 pagesEnvironmental Guidelines For Concrete Batching Plants 2016Zainal AbidhynNo ratings yet

- Conveying and Cooling in The Iron and Steel IndustryDocument16 pagesConveying and Cooling in The Iron and Steel IndustryMohammad KhazaieNo ratings yet

- 1.5-2wood Pellet Production LineDocument6 pages1.5-2wood Pellet Production LineddtyuriNo ratings yet

- P.O.Box:1832, P.C:112, Ruwi, Sultanate of OmanDocument38 pagesP.O.Box:1832, P.C:112, Ruwi, Sultanate of OmanKumarNo ratings yet

- Malaina Fed With Cassava PeelDocument23 pagesMalaina Fed With Cassava PeelIfeoluwa Segun IyandaNo ratings yet

- Rehabilitation of Batching Plant With SignDocument3 pagesRehabilitation of Batching Plant With SignRafael ObusanNo ratings yet

- Silotop Zero en 0217 EditDocument4 pagesSilotop Zero en 0217 EditJulio Vega AngelesNo ratings yet

- Akij Food and Beverage LimitedDocument32 pagesAkij Food and Beverage LimitedRajib ChowdhuryNo ratings yet