Professional Documents

Culture Documents

Shoe WO9001276A1

Uploaded by

Gek CagatanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Shoe WO9001276A1

Uploaded by

Gek CagatanCopyright:

Available Formats

per

WORLD INTELLECTUAL PROPERTY ORGANIZATION

International Bureau

INTERNATIONAL APPLICATION PUBLISHED UNDER THE PATENT COOPERATION TREATY (PCT)

(51) International Patent Classification 4 ;

(11) International Publication Number:

Al (43) International Publication Date:

A43B 5/00,13/42, 21/32

(21) International Application Number:

(22) International Filing Date:

(30) Priority data:

226,058

PCT/US89/03259

28 July 1989 (28.07.89)

WO 90/01276

22 Febraary 1990 (22.02.90)

(74)Agents: GOLDSTEIN, Jorge, A. et al.; Saidman, Sterne,

Kessler & Goldstein, 1225 Connecticut Avenue, N.W.,

Suite 300, Washington, DC 20036 (US).

(81) Designated State: JP.

29 July 1988 (29.07.88)

US

(71)Applicant: AVTA GROUP INTERNATIONAL, INC.

[US/US]; 16160 S.W. Upper Boones Feny Road, Portland, OR 97223 (US).

Published

With international search report.

(72)Inventors: TONG, James, Kai ; 5080 S.W. 160th Street,

Beaverton, OR 97007 (US). SELBIGER, Lawrence ; 931

N.W. 20th, ,21, Portland, OR 97209 (US). STUBBLEFIELD, Jerry, D. ; 11725 N.W. Damascus Road, Portland, OR 97229 (US). CURLEY, Jack ; 51 Pleasant

Street, Dunstable, MA 01827 (US).

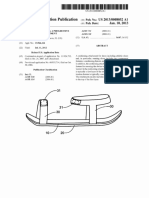

(54)Title: ATHLETIC SHOE HAVING AN INSERT MEMBER

(57) Abstract

An insert (56) for an athletic shoe (20) is described. The insert (56) is generally used in conjunction with other shoe components (28) to provide additional stability to a shoe sole (24). The insert member (56) includes a central body (58) and a plurality of

insert extensions (60-72) which extend outwardly from the central body (58). The extensions (60-72) may cooperate with lugs

(32-46) of an outsole (26).

FOR THE PURPOSES OF INFORMATION ONLY

Codes used to identify States party to the PCT on the front pages of pamphlets publishing international

applications under the PCT.

AT

All

BS

BE

BF

BG

BJ

BR

CA

CF

Aiatta

AuttnJti

BuiadM

Bclpiiii

BuitiuFiao

Bulgua

Benin

BozS

Cuuda

Central Afrkan Republic

E5

FI

FR

GA

GB

HU

IT

JP

KP

CG

CH

CM

DE

DK

Congo

SwszerljDd

Cunetoon

Genniny. Federal Republic of

Dennurt.

KR

U

U

UU

MC

Spain

Finknd

France

Gabon

United Kmtiom

Hiuifaty

Italy

Xapan

Democratic People's Republic

of Korea

Republic of Korea

Uechteratein

SriUnka

Luxembouri

Monaco

MG

ML

MR

MW

NL

NO

RO

SD

SE

SS

SU

TO

TG

US

Madagascar

Mali

Mauritania

Malawi

Netherlands

Norway

Romania

Sudan

Sweden

Senegal

Soviet Union

Chad

Togo

United States of America

WO 90/01276

PCT/US89/03259

-1-

ATHLETIC SHOE HAVING AN INSERT MEMBER

BACKGROUND OF THE INVENTION

1.

Field of the Invention

This invention relates generally to athletic shoes, and

more particularly to an apparatus and method for providing

increased durability, stability and rebound in athletic shoes.

2.

Description of Related Art

A recent surge to provide footwear which is both comfortable and anatomically beneficial has resulted in a plethora of

ideas having varying degrees of effectiveness. Most of these

ideas are merely variations of ideas which have been around

for years. Historically, there have been a number of attempts

to increase the cushioning and control of an athletic shoe by

making modifications to the midsole, which is that material

which generally lies above the outsole. The development of

the midsole has led to shoes which take into account the

physiology of the foot.

The numerous attempts to provide

superior cushioning in athletic shoes have led to three broad

categories of developments, two of which involve the midsole

directly.

WO 90/01276

PCT/US89/03259

-2The first broad category utilizes different materials and

configurations of the midsole to improve cushioning as well as

provide effective foot control.

For example, materials of

different hardnesses may be used to provide cushioning and

foot control, or a variety of devices may be encapsulated in a

midsole to increase cushioning. This type of show has the

disadvantage of a short life due to breakdown of the materials

used to form the midsole.

Since many shoes use only ethyl

vinyl acetate EVA or polyurethane (PU) for cushioning, the

cells of these foams have a tendency to break down and thus

diminish the usefulness of the shoe.

The second category of device utilizes pneumatic devices

within the midsole.

An example of this is taught in U.S.

Patent No. 545,705, issued to McDonald. The McDonald device

is an elastic air filled cushioning device which is incorporated into the heel of a shoe to provide cushioning.

A

similar device is taught in U.S. Patent No. 1,498,838 to

Harrison Jr. which uses a number of tubes which lie within the

midsole. These tubes are inflated by a valve to maintain a

pressure above ambient. The tubes in the Harrison Jr. device

are made of a flexible inelastic material.

The disadvantages of encapsulating gas within the midsole

of a shoe are numerous.

It is exceedingly difficult and

costly to encapsulate gas in a material. It is much easier,

for example, to cut a piece of conventional midsole material

such as ethyl vinyl acetate (EVA) to a desired specification

than to make a container which retains pressurized air or

other gas. The problem of diffusion of gas from a container

can be somewhat decreased by using large molecule gases as the

encapsulated gas. Using such a gas is expensive and as such

increases the expense of manufacturing such a shoe.

Material puncture is also a problem with pressurized gas

midsoles.

Again, while this problem might be somewhat

WO 90/01276

PCT/US89/03259

diminished by careful material selection, the problem of

puncture nevertheless exists and the solution to such a

problem can add additional manufacturing expense. Yet another

serious drawback with this type of shoe is that the pressure

of the gas within the encapsulating container is temperature

dependent. As such, the stiffness of the shoe varies as the

shoe warms up. Similarly, the shoe may respond differently in

cold and warm temperatures.

Along these same lines, the

midsoles are altitude dependent, which means that the shoe

will have different support characteristics depending on what

altitude it is used at.

Rear foot control and stability is another problem with

shoes which encapsulate gas within the midsole.

In simple

terms, encapsulated gas midsoles are oftentimes too mushy to

give proper support.

In light of the multitude of problems associated with

gas-encapsulated midsoles, it is of great importance to find

alternatives which provide both adequate cushioning, stability

and support.

Such alternatives must be economical and must

eliminate the problems of encapsulated tube technology without

sacrificing cushioning.

The third broad category of devices which are intended to

increase the cushioning of a shoe include devices which modify

an outsole. An outsole is typically made of material such as

rubber, polyurethane (PU), thermoplastic rubber (e.g.,

EVA)

and the like. These materials are chosen for outsoles because

they are wear resistant.

Typically, these materials have

fairly good memory characteristics. That is, if the outsole

material is deformed either by compression or bending forces,

it tends to return to its original shape. The best example of

a shoe which falls into this third broad category is U.S.

Patent No. 4,372,058 to Stubblefield, which teaches an outsole

in which the periphery of the heel of the outsole maintains

WO 90/01276

PCT/US89/03259

-4the remaining portion of the heel of the outsole in a spaced

apart relationship to the ground. This configuration is known

as a cantilever outsole. The cantilever configuration helps

to redirect vertical forces while increasing energy return to

a runner.

In the Stubblefield patent referred to above, an outsole

is provided which has a plurality of lugs or levers which

extend from the periphery of the bottom of the outsole. These

lugs are designed to redirect vertical forces on the outsole

so that the forces have at least a horizontal component

thereby reducing the stresses on a runner. The Stubblefield

patent provides a shoe which provides both cushioning and

stability.

One object of the present invention is to improve the

design of the Stubblefield shoe by providing even better

stability and rebound characteristics and to provide a shoe

which utilizes a minimum amount of the heavy outsole material

found in conventional outsoles.

SUMMARY OF THE INVENTION

To achieve the foregoing and other objects, and in

accordance with the purposes of the present invention, as

embodied and broadly described herein, the athletic shoe of

the present invention includes the use of a conventional upper

and a sole attached to the upper.

The sole includes an

outsole having a central heel portion and a plurality of

periphery lugs.

These lugs are effective to contact the

ground and to maintain the central heel portion in a spaced

apart relationship to the ground. The athletic shoe of the

present invention may also include a midsole and an insert

member. This insert member is made of a material which may

WO 90/01276

PCr/US89/03259

have a hardness greater than the midsole and positioned to

cooperate with the outsole by coacting with the outsole.

In one aspect of the invention, the central heel portion

of the outsole defines an opening which may expose the insert

member. Another aspect of the invention is for the periphery

lugs to extend downwardly and outwardly from the central heel

portion and for insert extensions to also extend downwardly

and outwardly.

In yet another aspect of the invention, the insert has a

substantially planar body portion and has insert extensions

which extend downward from the body portion.

The insert

member may be made of a number of materials such as a polymeric material such as Hytrel, Delrin, or Rynite, all products

made by E.I. Dupont de Nemours & Co., Inc. The insert member

may also be made of a combination of these materials, for

example, a combination of Rynite and Hytrel. Similarly, the

polymeric material may be glass-reinforced and may have a

number of openings for reducing the weight of the insert or

built up portions for increasing the rigidity and strength of

the insert member. In addition, other high memory, resilient

material may be used to practice the invention.

Yet another aspect of the invention is a method for

fabricating

a sole.

This method

preloading an insert member

member in a midsole material

retains the insert member in a

this method, the insert member

includes

the

steps

of

and encapsulating the insert

whereby the midsole material

preloaded condition. In using

may have a body portion and a

plurality of extension members which extend downwardly and

outwardly from said body portion.

To preload the insert

member, the insert extensions may be forced into a mold which

retains the insert member in a preloaded position. Midsole

material may then be blown into the mold and set to retain the

WO 90/01276

PCr/US89/03259

-6insert member in the loaded position.

midsole to store potential energy.

This method allows a

In one aspect of this method, the insert member has a

hardness which is greater than the hardness of the midsole

material. The insert in this method may be made of a polymeric material such as a polyester elastomer such as Hytrel.

In addition, the material may be a polyamide such as Zytel or

the like.

One advantage of the invention is that the insert member

provides improved energy return and improves the memory

characteristics of the sole.

Yet another advantage of the invention is that it

increases the life of a shoe because it will not break down

and slows fatigue. If a midsole is used in conjunction with

the insert, it can slow fatigue of the midsole material.

Yet another advantage of the invention is that it

provides a sole which has improved load characteristics and

strength.

Yet another advantage of the invention is that it allows

the midsole to be tuned during manufacture for optimum energy

return for its intended end use.

Yet another advantage of the invention is that it allows

a midsole to recover to a relaxed state between strides of a

user.

BRIEF DESCRIPTION OF THE DRAWINGS

The accompanying drawings, which are incorporated in and

form a part of the specification, illustrate the embodiments

of the present invention and, together with the description,

serve to explain the principles of the invention.

In the

drawings:

WO 90/01276

PCr/US89/03259

-7Figure 1 is an elevational view of the lateral side of a

shoe embodying the present invention;

Figure 2 is a bottom view of the shoe shown in Figure 1;

Figure 3 is a schematic representation

section cut along line 3-3 of Figure 2;

of a cross-

Figure 3A is a cross-section of another embodiment of the

invention;

Figure 3B is a cross-section of another embodiment of the

invention;

Figure 4 is a top plan view of one insert member of the

present invention;

Figure 5 is a side view of the insert member shown in

Figure 4;

Figure 6 is the bottom of a heel showing another embodiment of the invention;

Figure 7 is a cross-sectional view of Figure 6 cut along

lines 7-7;

Figure 8 is a cross-section of Figure 6 cut along lines

8-8;

Figure 9 is a top view of the insert used in the outsole

shown in Figure 6;

Figure 10 is a bottom view of the insert shown in Figure

9;

Figure 11 is a view of Figure 9 cut along line 11-11;

Figure 12 is a view of Figure 9 cut along lines 12-12;

Figure 13 is a view of Figure 11 cut along lines 13-13;

Figure 14 is a side view of Figure 9 looking in the

direction of arrow 14;

Figure 15 is a side of the insert shown in Figure 9;

Figure 16 is yet another embodiment of the insert of the

present invention;

Figure 17 is a side view schematic of the insert member

of Figure 20 in operation with other components;

WO 90/01276

PCr/US89/03259

-8Figure 18 is a bottom view of an outsole used for

practicing the present invention;

Figure 19 is a view of Figure 18 cut along line 19-19;

Figure 20 is a view of Figure 18 cut along line 20-20;

and

Figure 21 is a view of Figure 18 cut along line 21-21.

DETAILED DESCRTPTTQN OF THE PREFERRED ENBODIMFNTS

Referring first to Figures 1-3, there is shown an

athletic shoe which has improved energy return, memory

characteristics and increased durability. A shoe, designated

generally as 20, is made of a number of component parts which

include an upper 22 and a sole 24. In the present invention,

any conventional upper 22 may be used to practice the invention. Although an athletic shoe is shown in Figure 1, and the

specification is directed in particular to athletic shoes, it

is contemplated that the invention may be used on a number of

different categories of shoes or boots, for example, hiking

boots, casual shoes and the like. The upper 22 is attached to

a sole 24 in any conventional manner. The sole 24 is made up

of an outsole 26 made of a material which is wear resistant

and provides traction. As with conventional outsoles, it may

be made of any abrasive resistant material such as rubber or

the like. A midsole 28 is disposed generally between outsole

26 and upper 22. Midsole 28 may take on a number of forms and

modifications as an artisan in the field of shoes will readily

recognize. For example, midsole 28 may be made from a single

material or several different materials, each having different

characteristics such as density and rebound characteristics.

The main purpose of midsole 28 is for cushioning and it may be

made of a number of different materials, for example, ethyl

WO 90/01276

PCr/US89/03259

-9vinyl acetate, polyurethane, or a combination thereof.

addition, midsole 28 may include a heel wedge.

In

The heel region of the shoe, designated as 30, is that

portion of the shoe which underlies the heel of a wearer.

While heel region 30 of shoe 20 has no precise borders, it

generally may be considered as that half of the shoe away from

the toe of a wearer. Although the term "heel region" is used

throughout this specification, it should be noted that this

region may extend into what is traditionally known as the arch

area of the shoe and may in fact extend well beyond what might

traditionally be characterized as the heel.

In heel region 30 of outsole 26, there are a plurality of

lugs 32-46 (Fig. 2) which extend downwardly from a central

heel portion 47 (Fig. 3) of the heel region 30.

Lugs 32-46

are preferably arranged in a cantilever configuration and thus

maintain the central heel portion 47 at a spaced relationship

to the ground. This is best seen in Figure 3 which illustrates that the central heel portion 47 is prevented from

contacting the ground.

Sole 24 is shown in an unloaded

condition in this figure.

In a preferred embodiment of the

invention, lugs 32-46 are designed to flare outwardly to

change the direction of forces which are disposed substantially perpendicular to the heel. To highlight the importance of

redirecting forces, a runner may generate, upon foot strike,

forces which are up to three times the runner's body weight.

If these extreme forces are not dissipated, a runner may face

serious and debilitating injuries. Typically, forces generated during running or other activities are not precisely

perpendicular to the heel. During heel strike, for example,

the lateral side of a shoe makes contact with the ground first

and the shoe then rotates before toe-off. Different sports

generate varying forces at various angles to a shoe.

The

above-described cantilever outsole serves to redirect forces

WO 90/01276

PCr/US89/03259

-10irrespective of the precise angle of incidence upon a shoe.

This cantilever outsole concept is more fully disclosed in

U.S. Patent No. 4,372,058 to Stubblefield, the disclosure of

which is expressly incorporated herein by reference.

Each of the lugs 32-46 on outsole 26 have a land 48 for

contacting the ground. These lands 48 are configured to make

contact with the ground and preferably have a roughened

surface to provide traction. Lands 48 may consist of a flat

surface as shown in Figure 2 and 3 or may be a point or small

area. Each of the lugs 32-46 may have an angled area 50 which

leads from the central heel portion 47 to the lands 48. It is

preferred that this angled area 50 is a gradual angle as shown

in Figure 3, but it may also be vertical. In the embodiment

of the invention shown in Figure 2, wedge-shaped portions 28'

of midsole 28 extend between lugs 32-46.

The spacing 52

between adjacent lugs enables lugs 32-46 to act more independently of each other.

Although the lugs in the accompanying drawings are shown

to be separate and distinct members, it is contemplated that

the heel portion of the outsole may form a concavity, without

individual lugs.

In other words, instead of distinct,

individual lugs such as the eight lugs 32-46 shown in Figure

2, there may be a single "lug" which extends from the medial

side of the shoe, around the heel, to the lateral side of the

heel.

Outsole 26 may include a cut-out 54 in substantially the

central heel portion 47 of the outsole.

Cut-out 54 is

provided primarily to reduce the weight of outsole 24 by

eliminating material which is not necessary. Because central

heel portion 47 never makes contact with the ground, there is

no need for the abrasive resistant material of the outsole to

be present in that area. By having a cut-out 54, the overall

weight of the shoe is reduced without reducing stability.

In

WO 90/01276

PCT/US89/03259

-11addition, the outsole may extend up along the side of the

midsole for, e.g. basketball shoes and the like.

The present invention comprises a configuration of

components to improve the rebound characteristics of a sole

and to provide improved stability. To achieve this, an insert

member 56 is generally used in conjunction with the abovementioned shoe components to provide additional stability and

memory characteristics to the sole of the shoe. The insert

member 56 helps to increase the life of a shoe. The insert

member while having a long life itself also helps prevent a

midsole material from breakdown due to fatigue. A long life

and decreased break down due to fatigue is possible because it

is the insert which absorbs and transmits most of the generated forces. In addition, the insert member allows a midsole

to recover to a relaxed state between strides.

In running,

for example, a runner while jogging may take one hundred

strides per minute. While most midsoles cannot recover fully

between strides, the present invention will enable a midsole

to make such a recovery.

The insert member 56, which may be positioned in a number

of different locations as will be amplified below, enhances

the overall stability of sole 24 and works in conjunction with

the other component parts of sole 24.

Generally, insert

member 56 is positioned either sandwiched between the outsole

26 and the midsole 28, encapsulated within the midsole 28 or

encapsulated within outsole 26.

In Figure 3A, an alternative embodiment of the invention

is shown. This embodiment is a similar view as Figure 3, but

shows an alternative position of insert member 56.

In this

embodiment, the insert member 56 makes contact with both the

outsole 26 and a lasting board which is typically placed above

the midsole in a conventional athletic shoe. This configuration provides for an efficient use of the invention, since

WO 90/01276

PCr/US89/03259

12-

there is no midsole material, e.g., polyurethane, above the

insert member 56 along the longitudinal center!ine of the heel

region of the shoe.

In Figure 3B, yet another embodiment of the invention is

depicted.

In this cross-sectional view, it is seen that

outsole 26 extends up the side of midsole 28. The outsole may

extend upward onto the midsole around the entire heel of the

shoe, if desired.

In a preferred embodiment of the invention as illustrated

in Figures 4 and 5, insert member 56 has a central body

portion 58 and a plurality of insert extensions 60-72 which

extend outwardly and downwardly from central body portion 58.

In general, insert extensions 60-72 have a flat section 75 at

the distal ends thereof (seen best in Figures 3 and 5). It

should be noted that the insert member 56 illustrated in

Figure 4 utilizes ten insert extensions, while the insert

member of Figures 1-3 utilizes eight insert extensions. For

convenience, the additional two insert extensions of member 56

of Figure 4 have been designated 60a and 60b. In operation,

the number of insert extensions may be varied as needed to

most effectively operate in conjunction with the other

component parts of the sole.

The rebound characteristics of the insert member 56 can

be controlled by varying a number of different parameters.

For example, some or all of the insert extensions 60-72 may

define openings 78 or may be built up. Openings 78 increase

flexibility of an individual insert extension and decrease the

weight of the insert 56.

A number of different conventional materials are available for making insert member 56.

Examples of possible

materials include:

Zytel, a polyamide which may be glass

reinforced with, for example, 18% glass; Delrin; Rynite;

Hytrel; or a combination of the above materials such as a

WO 90/01276

PCT/US89/03259

13-

Hytrel/Rynite mixture.

Zytel, Delrin, Rynite and Hytrel are

all manufactured by DuPont. Hytrel is a semi crystal line and

fully polymerized, high molecular weight, chemically stable,

thermoplastic polyester elastomer composed of alternate

amorphous and crystalline chains.

The above materials are intended to be illustrative of

some of the possible materials for use in insert member 56.

This list is not exhaustive or comprehensive and it should be

understood that many different materials may be used to

practice the invention. In general, the common denominator of

the materials which may be utilized to embody the invention is

that the material must have good memory characteristics, that

is, the material must tend to return to its original shape

after deformation. In addition, the material must be durable

and must not be brittle; otherwise, it may not be able to

withstand the constant cycling of the material without

cracking or breaking. The material used for making the insert

member may be harder than the midsole material, but need' not

be harder. Since the hardness of the insert member as well as

its thickness may be modified to achieve a desired response,

there may be circumstances whereby a relatively soft insert

member 56 is utilized.

The invention can be modified and

tuned for the different requirements of different sports.

Insert member 56 is preferably disposed in a location which

will allow the insert member to cooperate with the other shoe

components. This location is not limited to being next to or

juxtaposed to the outsole. The insert member 56 may cooperate

with the outsole if it is encapsulated within the midsole,

sandwiched between the midsole and the outsole, or encapsulated within the outsole.

The insert member may also be

partially encapsulated within the midsole. In the embodiment

of the invention shown in Figures 1-3, insert member 56 lies

between outsole 26 and midsole 28. It may be attached to the

WO 90/01276

PCT/US89/03259

14outsole and midsole in any conventional manner. For example,

the insert member may be cemented to the outsole. If insert

member 56 is disposed directly above outsole 26, the central

portion of the insert member may be exposed through cut-out 54

in outsole 26 as shown in Figure 2. The insert extensions 6072 positionally correspond to lugs 32-46 in outsole 26 and

cooperate therewith to provide increased stability and rebound

characteristics for sole 24. The insert extensions 60-72 have

a flat section 75 which positionally correspond to lands 48 in

the outsole.

In operation, insert member 56 and insert

extensions 60-72 cooperate with lugs 32-46 and move outward as

forces impinge on the sole. In this specification, the term

"outward" is used to mean that direction which is away from

the central portion of the shoe in the plane defined generally

by the outsole.

This direction is locally the direction

perpendicular to a line which is tangent to the perimeter of

the outsole. In Figures 2 and 3, "outward" is the direction

shown by arrows 77.

Conversely, "inward" is the direction

toward the central portion of the shoe. Generally speaking, a

curved portion 76 connects the flat portion 75 of insert

extensions 60-72 to central body 58 of insert member 56.

Member 56 may be tailored to specific needs by adding additional openings 78 or by building up sections of the extensions as desired.

Additional apertures will increase the

flexibility of the insert extension having the apertures.

Conversely, building up an insert extension will make the

insert extension more rigid. In effect, the insert member may

be "tuned" by adding apertures to those extension members

where additional flexibility is desired and building up those

extension members where it is desirable for the extension

member to be more rigid. For example, it may be desirable to

have a specific area of the sole less compressible than the

remaining areas of the sole.

This can be accomplished by

WO 90/01276

PCr/US89/03259

-15building up those extension members in the area for which less

compression is desired or by adding apertures to the extension

members in the area for which more compression is desired or a

combination of these two approaches.

Figures 6-17 illustrate yet another embodiment of the

invention.

Figures 6-8 illustrate a part of a sole 80 which

has an outsole 82 and a midsole 84. As with the previously

described embodiment of the invention, outsole 82 has a

plurality of lugs 86 which are shaped to maintain the remaining, central portions of the sole 80 at a spaced relationship

to the ground. As with other embodiments of the invention,

there may be a cutout 88 in the outsole. This cutout reduces

the weight of the shoe by eliminating the outsole in an area

it is not necessary. Figures 7-8 illustrates an insert member

90 encapsulated within midsole 84. A portion 85 of midsole 84

lies below insert member 90. By encapsulating insert member

90 within midsole 84, it is possible to improve the rebound

characteristics of the sole

90 prior to encapsulation.

prestressing of the insert

practice the invention. To

80 by pre-stressing insert member

It should be noted, however, that

member is not a requirement to

do so, insert member 90 is first

placed in a mold, the perimeter of which is smaller at least

in part than the perimeter of the pre-stressed insert member

90. By doing so, insert member 90 exerts a force against the

mold and is biased in an outward direction.

In Figure 8,

outward is the direction depicted by arrows 104.

After insert member 90 has been pre-stressed and placed

in a mold, midsole material such as polyurethane (PU) is used

to encapsulate insert member 90. This may be done by injection molding, for example. By selecting the proper materials,

the midsole maintains the insert in a loaded or stressed

configuration, and thus the midsole has potential energy

stored within it.

WO 90/01276

PCr/US89/03259

16-

One embodiment of insert member 90 fier se is illustrated

in Figures 9-15. Figure 9 is a top view of insert member 90

and Figure 10 is a bottom view. Insert member 90 has insert

extensions 92 which extend outwardly from a central body

portion 94. These insert extensions 92 cooperate with lugs 86

of outsole 82 so that when a force impinges on the sole, both

lugs 86 and insert extensions 92 will move in an outward

direction and insert extension members 92, in cooperation with

the other components of the sole, will act as a spring to

return the sole to its original shape. A shortened recovery

time or shortened midsole cycle time is particularly important

in such activities as jogging and basketball. This serves to

return energy to the user without having the "mushy" feeling

associated with fluid filled shoes.

It can be seen from Figure 11 that insert extensions 92

may have a built up section 102 which extends along the

surface of insert extensions 92.

Built up section 102 may

take on a number of different forms but is used generally to

tailor the response of the midsole.

Built up section 102

gives the insert extensions more strength and less flexibility.

As with built up section 102, insert extensions 92 may

define holes or apertures 100 as shown in Figure 12. Holes

100 may be used as needed to tailor the insert 90 to provide a

desired response. Built up section 102 and apertures 100 may

be used as needed, either alone in an insert member or

together.

As shown in Figures 13-15, insert extensions 92 may have

a flat portion 96 which positionally corresponds generally to

that portion of the outsole 82 which contacts the ground. A

curved portion 98 connects flat portion 96 to central portion

94.

WO 90/01276

PCT/US89/03259

-17Referring now to Figures 16 and 17, yet another embodiment of the invention is shown.

Figure 16 shows an insert

member 120 having an extending portion 124, the distal end of

which extends into the forefoot region of a shoe when positioned within the sole of a shoe.

The outline of a shoe 123

is shown in Figure 18 to help illustrate one possible placement of insert member 120. The extending portion 124 may be

formed from a single piece of material such as those materials

previously described for making the insert member and the

insert member 120 and extending portion 124 are generally made

from a single monolithic piece of material. It is understood,

however, that it is possible to form the extending portion 124

from separate and distinct pieces of material.

The extending portion 124 may be formed by a plurality of

fingers 122 which extend generally from the remaining portion

of insert member 120 toward the toe region of shoe 123.

In a preferred embodiment, extending portion 124 is made

to have an undulating or sinusoidal shape in cross section

(Figure 17).

The undulations have peaks 128 which make

contact with outsole 118 and spaced by valleys 130.

The

spaces 132 between midsole 116 and insert member 120, and

between outsole 118 and insert member 120, are filled with air

at ambient pressure.

In operation, the extending portion 124 of insert member

120 acts as a spring to return energy to the user.

This

occurs because forces acting perpendicular to sole 118 deflect

the extending portion 124 and tend to decrease the size of the

peaks 128 and valleys 130 when the load is placed on the

extending portion 124.

Because the materials used to form

extending portion 124 have good memory characteristics, it

tends to return to its original, unloaded shape.

If the

distal end of extending portion 124 is not attached to either

the midsole or outsole, the extending portion 124 will

WO 90/01276

PCr/US89/03259

18increase in overall length upon loading. This occurs

the decreasing of the peaks 128 and valleys 130

undulations tend to force extending portion 124

direction away from the remaining portion of insert

120.

because

of the

in the

member

Extending portion 124 is a feature which increases

overall cushioning of the sole but does not otherwise affect

the operation of the remaining portion of insert member 120.

In other respects, insert member 120 shown in Figures 18 and

19 operates substantially the same as the insert member shown

in Figure 4.

In the embodiment of the invention depicted in Figures

18-21, an insert member is substantially encapsulated by

outsole material. These figures depict an outsole 140 which

has a plurality of lugs 146. The outsole 140 is attached to a

midsole 142 (shown in phantom).

These lugs 146 work in

substantially the same manner as those embodiments of the

invention previously described. The outsole 140 includes an

upper portion 148 and a lower portion 150. Between the upper

and lower portions 148 and 150, respectively, is an insert

member 144 (shown in phantom).

This insert member 144

operates in substantially the same manner in this embodiment

as it does in the embodiments of the invention previously

described.

As seen in Figure 20 and 21, outsole 140 may

define an opening 152. The upper and lower portions may be

interconnected to wrap around the insert as shown in Figure

19.

The foregoing description of the preferred embodiments of

the invention have been presented for purposes of illustration

and description.

It is not intended to be exhaustive or to

limit the invention to the precise form disclosed, and

obviously many modifications and variations are possible in

light of the above teaching. The embodiments were chosen and

WO 90/01276

PCr/US89/03259

-19described in order to best

invention and its practical

others skilled in the art to

various embodiments and with

explain the principles of the

application to thereby enable

best utilize the invention in

various modifications as are

suited to the particular use contemplated.

It is intended

that the scope of the invention be defined by the claims

appended hereto.

WO 90/01276

PCr/US89/03259

-20-

WE CLAIM:

1.

An athletic shoe, comprising:

a.

an upper;

b.

sole

attached

to

said

upper,

said

sole

including:

i.

a midsole,

surface and a bottom surface:

said

midsole

having

top

ii. an outsole, said outsole having a central

heel portion and a plurality of periphery lugs, said lugs

being effective to contact the ground and to maintain said

central heel portion in a spaced-apart relationship to the

ground; and

iii. an insert member, said insert member being

made of a material having a hardness greater than said midsole

and having insert

periphery lugs.

extensions

which

cooperate

with

said

2.

The athletic shoe of claim 1, wherein said insert

member is positioned between said outsole and said midsole.

3.

The athletic shoe of claim 1, wherein said insert

member is encapsulated in said midsole.

4.

The athletic shoe of claim 1, wherein said insert

member is partially encapsulated in said midsole.

5.

The athletic shoe of claim 1, wherein said central

heel portion defines an opening.

6.

The athletic shoe of claim 5, wherein the opening

defined by said outsole exposes said insert.

WO 90/01276

PCT/US89/03259

-217.

The athletic shoe of claim 1, wherein said periphery

lugs extend downwardly and outwardly from the central heel

portion.

8.

The athletic shoe of claim 7, wherein said insert

lugs extend downwardly and outwardly.

9.

The athletic shoe of claim 7, wherein said lower

surface of said midsole extends between said periphery lugs.

10. The athletic shoe of claim 1, wherein said insert

has a substantially planar body portion and wherein said

insert lugs extend downwardly from said body portion.

11. The athletic shoe of claim 1, wherein said insert

comprises a polymeric material.

12. The athletic shoe of claim 11, wherein said insert

comprises HYTREL.

13. The athletic shoe of claim 11, wherein said insert

comprises DELRIN.

14. The athletic shoe of claim 11, wherein said insert

comprises RYNITE.

15.

The athletic shoe of claim 11, wherein said insert

comprises a combination of RYNITE and HYTREL.

16. The athletic shoe of claim 11, wherein said polymeric material is glass reinforced.

WO 90/01276

PCr/US89/03259

22-

17. The athletic shoe of claim 16, wherein said polymeric material is glass-reinforced ZYTEL.

18. The athletic shoe of claim 11, wherein said insert

comprised approximately 18% glass-reinforced ZYTEL.

19. The athletic shoe of claim 10, wherein said insert

defines a plurality of openings for reducing the weight

thereof.

20.

A shoe sole construction, comprising:

a.

an outsole having a plurality of lugs, said

lugs extending downwardly from the periphery of said outsole;

b.

an insert member, said insert member having a

body portion and at least one insert extension extending from

said body portion, said at least one insert extension positioned above at least one of said lugs.

21. The shoe as defined by claim 20, further comprising

a midsole positioned above the body portion of said insert

member and extending between said plurality of lugs of said

outsole.

22. The shoe as defined by claim 20, wherein the distal

end of said lugs have lands with a ground-contacting surface,

said ground-contacting surface of said land defining a first

plane.

23.

An athletic shoe comprising:

a.

an upper;

b.

including:

sole

attached

to

said

upper,

said

sole

WO 90/01276

PCT/US89/03259

23-

i.

an outsole having a top surface, a bottom

surface, a forefoot region, and a heel region, the heel region

having a periphery region for contacting the ground, said

periphery region including a plurality of lugs which both

contact the ground and support the remaining area of said heel

region above the ground;

ii. an insert member, said insert member being

made of a material having a hardness greater than the hardness

of said outsole and being positioned above said top surface of

said outsole and a plurality of insert extensions which

cooperate with said lugs to redirect vertical forces which

impinge on said outsole.

24. The athletic shoe of claim 23 wherein said heel

region of said outsole defines an opening.

25.

A method of fabricating a sole, comprising the steps

of:

a.

preloading an insert member, said insert member

having a body portion and a plurality of extension members

extending downwardly and outwardly from said body portion,

said preloading being effective to bias said extension members

so that said extension members exert forces in a direction

away from said body portion; and

b.

encapsulating said insert member in a sole

material, said sole material retaining said insert member in a

preloaded condition.

26. The method of claim 25 wherein said step of preloading an insert member comprises the step of placing said insert

member into a mold, said mold having a width which is narrower

than the insert member when said insert member is in an

unloaded condition.

WO 90/01276

PCr/US89/03259

-24-

27. The method of claim 26 wherein said insert member

comprises a material having a hardness greater than the

hardness of said midsole material.

28. The method of claim 27 wherein said insert comprises

a polyester elastomer.

29. The method

elastomer is HYTREL.

of claim

28 wherein

said

polyester

30. The method of claim 27 wherein said insert comprises

a polyamide.

31.

Zytel.

The method of claim 30 wherein said polyamide is

32. The method of claim 25 further comprising the step

of attaching said midsole material with said insert member

encapsulated therein to an outsole.

33. The method of claim 32 wherein said outsole is

cantilevered.

"*-:..

PCr/US89/03259

WO 90/01276

1/11

N

SUBSTITUTE SHEET

PCr/US89/03259

WO 90/01276

2/11

CVJ

CD

G:

SUBSTITUTE SHEET

PCT/US89/03259

WO 90/01276

3/11

'0M

*':'/A'fa

Wfi'~r*

CO

ION

fci

^c

to

e>

'A

w\

^v^Sl

* *^/^"Y3\

c:

8- 0'v iv|vL

CO

k^ll

'"' ^Kvi

CVJ

SUBSTITUTE SHEET

WO 90/01276

PCT/US89/03259

4/11

SUBSTITUTE SHEET

PCT/US89/03259

WO 90/01276

5/11

k

Oi

o ^- o CO

00 CO ?> CO

i~

SUBSTITUTE SHEZ I

"to

PCT/US89/03259

WO 90/01276

6/11

o

o

Sx

8-

CD

S:

S2

SUBSTITUTE SHEET

PCr/US89/03259

WO 90/01276

7/77

FIG.

ro

^3-

SUBSTITUTE SHEET

PCr/US89/03259

WO 90/01276

6/11

SUBSTITUTE: SHEET

WO 90/01276

PCT/US89/03259

9/11

<o.

IUB3TITUTE SHEET

WO 90/01276

PCr/US89/03259

JO/7/

o

<r

o

o'

0/^

1 ' J c

C=) C

v^ (

( ) f

J

j

V '\

(

o \

=kM

e^a

^*

CO

CVll

1-4

L.

SUBSTITUTE SHEET

PCT/US89/03259

WO 90/01276

11/11

r

CVJ

CM

CD

Si

SQ

L.

eg

^"

r'St

CD

00-

SUBSTITUTE SHEET

INTERNATIONAL SEARCH REPORT

International ADDlication No. PCT/USS 9 / 0 3 2 5 9

I. CLASSIFICATION OF SUBJECT MATTER (il several classification symcois acoly. maicaie am 6

According to Iniernational Patent Classification (IPC) or lo ootn National Classification and IPC

INT CL4 A43B 5/00, 13/42,21/32

US CL 36/114, 30R,37 12/146B

II FIELDS SEARCHED

Minimum Documentation Searched

Classification System

Classification Symools

36/3 0R,30A,32R,37,38,59R,107,,108,114

12/142R, 142P, 142RS, 146B, 146BR, 146S

us

Documentation Searched other than Minimum Documentation

to the Eitent that such Documents are Included m the Fields Searched '

III. DOCUMENTS CONSIDERED TO BE RELEVANT

Citation ol Document, " with indication, where aporopnate, ol the relevant passages '*

Relevant to Claim No.)3

Category

Y,T

USrA, 1,923,365 GAINES 22 AUGUST 1933

An athletic shoe having an arch plate

with extensions cooperating with the

cleats.

US,A, 4,854,057 MISEVICH 08 AUGUST 1989

1-24

1-24,27,32

An athletic shoe having a midsole with

force disersing

plate.

A

GB,A, 1,081,988 NADAUD 06 SEPTEMBER 1967

A resilient support insert comprising

spring plate with a plurality of

1-33

flanges and projecting members.

3,4,11,16,

GB,A, 2,114,869 CORRAO 01 SEPTEMBER 19 8 3

A stiffening formation 37 encapsulated 27,32

or partially encapsulated in the

midsole.

5,6,9,24

US,A, 4,335,530 STUBBLEFIELD 22 JUNE 1982

An outsole having an opening in the

heel region to expose the insert

US,A, 4,372,058 STUBBLEFIELD 08 FEBRUARY 198$ 7,8,9,33

The flexible lugs are disposed downwardly and outwardly to cushion the

fon-h arping-h imparl- Inari (cantileverefsole)

* Soacial categories of cited documents: ,0

"A" document defining the general state of the art which is not

considered to be ol particular relevance

"E" earlier document but published on or alter the international

filing date

"L" document which may throw doubts on prtority elaim(s) or

which is cited to establish the publication date of another

citation or other special reason (as specified)

"0" document referring to an oral disclosure, use. exhibition or

other means

"P" document published prior to the international filing date but

later than the priority date claimed

"T" later document published after the international filing date

or priority date and not in conflict with the application but

cited to understand the principle or theory underlying the

invention

"X" document ol particular relevance: the claimed invention

cannot be considered novel or cannot be considered to

involve an inventive step

"Y" document of particular relevance; the claimed invention

cannot beconsidered to involve an inventive step when the

document is comomed with one or more other such documents, such comomation being obvious to a person skilled

m the art.

"&" document member of the same patent family

IV. CERTIFICATION

Date of the Actual Completion of the International Search

Date

o M il

' ' gflljj|jjT98&1rch Report

07 NOVEMBER 1989

International Searching Authority

ISA/US

fomPOMSA/JloteeccndsneeClftev.ll-ST)

Sigpenre ol Authorized Officer

/^d antes "ee Chi

>-.

International Apnlication No.

PCT/US89/03259

III. DOCUMEHTS CONSIDERED TO BE RELEVANT

Category |

C.lal.on ol Document,

JP,A,

(CONTINUED FROM THE SECOND SHEET)

wth md.ca.ion, where appropnate, of the relevant passages

55-55817 FUKUJOKA 24 APRIL 1980

iSwiethod of fabricating a sole by

encapsulating an insert in the sole

material.

US,A, 4,614,046 DASSLER 30 SEPTEMBER 1986

Insert member located between an

outsole and an insole.

FR,A5,

481,026 MARTEAU 24

OCT. 1916

An insert with a plurality of

extensions.

US,A, 3,204,347 SNOW 07 SEPTEMBER 1965

A sole plate

GB,A, 1,404,456 BRITISH BATA 28 AUGUST 197 5

A foa/m plastic sole with a skeletal

insert.

US,A, 4,506,460 RUDY 26 MARCH 1985

A moderator 16 with extensions.

US,A, 4,624,061 WEZEL 25 NOVEMBER 1986

An insert 21 with lobes.

US,A, 3,577,503 INNOCENTI 04 MAY 1971

A^process of making an athletic sole

with injection molded sole having a

plate.

A

A

US,A, 3,852,895 FUNCK 10 DECEMBER 1974

A method of making a footwear with a

plate in the midsole.

Form PCT/BAfflio (tnaihMl) (RWMI-BT)

| Relevant to Cla.m No

25-33

international Application No.

PCT/US89/03259

FURTHER INFORMATION CONTINUED FROM THE SECOND SHEET

Y,P

US,A, 4,815,221 DIAZ 28 MARCH 1989

HYTREL

12,15,29

GB,A, 1,378,461 BROOKER 27 DECEMBER 1974

DELRIN

13

US,A, 2,918,733 ANDERSON 29 DECEMBER 1959

Nylon plate

14,15,30

US,A, 3,101,763 McGEHEE 27 AUGUST 1963

ZYTEL

17,18,31

US,A, 4,481,726 PHILLIPS 13 NOVEMBER 1984

Insert comprising polyester resin.

28

V.Q OBSERVATIONS WHERE CERTAIN CLAIMS WERE FOUND UNSEARCHABLE1

Tins international search report has not been established in respect ot certain claims under Article 17(2) (a) for the lollowmj reasons:

1.|_J Claim numbers

. because they relate to subject matter'- not required to be searched by this Authority, namely:

2.Q Claim numbers

because they relate to parts of the international application that do not comply with the prescribed requirements to such an extent that no meaningful international search can bt carried out13, specifically:

s.Q Claim numbers

PCTRule6.(a).

, tweauM toy art dapandant daira not drafted in accordance with the second and third sentences of

VI. 0 OBSERVATIONS WHERE UNITY OF INVENTION IS LACKING'

This International Searching Authority fou/cj multiple inventions in this international application at follows:

Group I, Claims 1-24 drawn to an athletic shoe with an

insert member.

Group II, Claims 25-33 drawn to a method of fabricating

a sole

1.0

all required additional search lees were timely paid by the applicant, this international search report covers all searchable claims

of the international application.

2.[j As only some of the required additional search fees were timely paid by the applicant, this international search report covers only

those claims of the international application for which fees were paid, specifically claims:

3.Q No required additional search fees were timely paid by the applicant. Consequently, this international search report is restricted to

the invention first mentioned in the claims: it is covered by claim numbers:

4.Q As all searchable claims could be searched without effort justifymg an additional fee, the International Searching Authority aid not

invite payment of any additional fee.

Remark on Protest

l| The additional search fees were accompanied by aoolicant's orotest.

[j No protest accompanied the payment of additional search fees.

Form PCT/1SM210 lawMmecul sheet 0 (Rev. 11-87)

You might also like

- U.S. Patent No. 8,371,044Document20 pagesU.S. Patent No. 8,371,044Sarah BursteinNo ratings yet

- 04 Foot WearDocument9 pages04 Foot WearNiyati RathodNo ratings yet

- Explosively Formed Penetrator Having Fins - US Patent 5365852Document8 pagesExplosively Formed Penetrator Having Fins - US Patent 5365852warrior_2008No ratings yet

- ReviewoflitDocument16 pagesReviewoflitapi-328115572No ratings yet

- Us 7367619Document11 pagesUs 7367619P ANo ratings yet

- Shoe Sizing and Fitting - An Analysis of Practices and TrendsFrom EverandShoe Sizing and Fitting - An Analysis of Practices and TrendsNo ratings yet

- Knee ScooterDocument8 pagesKnee ScooterYona OuNo ratings yet

- Notes on the Purchase, Manufacture, and Inspection of United States Army Shoes and Shoe LastsFrom EverandNotes on the Purchase, Manufacture, and Inspection of United States Army Shoes and Shoe LastsNo ratings yet

- Third PatentDocument24 pagesThird Patentjoselito marcianoNo ratings yet

- Us20130008052a1 PDFDocument19 pagesUs20130008052a1 PDFYash ChoudharyNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0255107 A1Document22 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0255107 A1Dave ThompsonNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0373744 A1Document18 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0373744 A1kahj juliNo ratings yet

- Pants5 9Document14 pagesPants5 9Choo Wei shengNo ratings yet

- US6575294Document9 pagesUS6575294AdailsonNo ratings yet

- A Practical Guide to Piping and Valves for the Oil and Gas IndustryFrom EverandA Practical Guide to Piping and Valves for the Oil and Gas IndustryRating: 5 out of 5 stars5/5 (3)

- Ripple Sole Corporation v. American Biltrite Rubber Co., Inc., 302 F.2d 2, 1st Cir. (1962)Document4 pagesRipple Sole Corporation v. American Biltrite Rubber Co., Inc., 302 F.2d 2, 1st Cir. (1962)Scribd Government DocsNo ratings yet

- Us 20110283566Document7 pagesUs 20110283566mrdelNo ratings yet

- SEO-Optimized Title for Pasteurizer Conveyor Belt PatentDocument15 pagesSEO-Optimized Title for Pasteurizer Conveyor Belt PatentIon BumbuNo ratings yet

- Manufacturing Methodology For Personalised Symptom Specific Sports PDFDocument16 pagesManufacturing Methodology For Personalised Symptom Specific Sports PDFAaiesha MohammedNo ratings yet

- United States Patent (10) Patent No.: Us 6,210,769 B1: Dipede Et Al. (45) Date of Patent: Apr. 3, 2001Document16 pagesUnited States Patent (10) Patent No.: Us 6,210,769 B1: Dipede Et Al. (45) Date of Patent: Apr. 3, 2001Abd Alkarim MohamedNo ratings yet

- Cloth Tow Target Sleeve (1992)Document26 pagesCloth Tow Target Sleeve (1992)CAP History LibraryNo ratings yet

- EP3427602A1Document45 pagesEP3427602A1Maria pervaiz AwanNo ratings yet

- BACKPACK LUMBAR SUPPORT TITLEDocument11 pagesBACKPACK LUMBAR SUPPORT TITLEAnureet BhardwajNo ratings yet

- Handbook of Shoe Factory EngineeringFrom EverandHandbook of Shoe Factory EngineeringRating: 4.5 out of 5 stars4.5/5 (3)

- US7698836Document31 pagesUS7698836zoyaNo ratings yet

- Tire Tread with Improved Grip on Wet RoadsDocument11 pagesTire Tread with Improved Grip on Wet RoadsJajnadatta DashNo ratings yet

- CGNCGFNDocument7 pagesCGNCGFNfernando Ancaya AncayaNo ratings yet

- IPRDocument20 pagesIPRRhea SharmaNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2017/0197720 A1Document7 pagesPatent Application Publication (10) Pub. No.: US 2017/0197720 A1gorgiNo ratings yet

- Building A Better BootDocument5 pagesBuilding A Better Bootjwilbert2014nowNo ratings yet

- US20040016851A1Document10 pagesUS20040016851A1B.EKICINo ratings yet

- United States Patent: (12) (10) Patent No.: US 9,702,197 B2Document10 pagesUnited States Patent: (12) (10) Patent No.: US 9,702,197 B2moreliaNo ratings yet

- Patent for ambient air vaporizer with dissimilar materials couplingDocument12 pagesPatent for ambient air vaporizer with dissimilar materials couplingJaime Ocampo SalgadoNo ratings yet

- United States Patent: Gow (10) Patent N0.: (45) Date of PatentDocument5 pagesUnited States Patent: Gow (10) Patent N0.: (45) Date of PatentAdam SalehNo ratings yet

- United States Patent (10) Patent N0.2 US 8,146,767 B1Document9 pagesUnited States Patent (10) Patent N0.2 US 8,146,767 B1TannyVaneNo ratings yet

- United States Patent (191: Durand Et AlDocument8 pagesUnited States Patent (191: Durand Et AlCarter TatumNo ratings yet

- US20100059503 Pulse Electrothermal Deicing (PETD) of Complex Shapes Application (IceMakers)Document9 pagesUS20100059503 Pulse Electrothermal Deicing (PETD) of Complex Shapes Application (IceMakers)PolarStarNo ratings yet

- Final Self Cleaning Step - FinalDocument9 pagesFinal Self Cleaning Step - Finaler.jayeshmoreNo ratings yet

- BackgroundDocument6 pagesBackgroundFekade DejeneNo ratings yet

- Lasting Handout 1Document27 pagesLasting Handout 1Tes KingNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- Venting Apparatus for Tire Mold Improves Air DischargeDocument9 pagesVenting Apparatus for Tire Mold Improves Air DischargeDaikinllcNo ratings yet

- Thomson2022 HeyCoach AspetarjournalWC2022Document6 pagesThomson2022 HeyCoach AspetarjournalWC2022Lucas Quiles VillaNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 7,377,754 B2Document23 pagesUnited States Patent: (12) (10) Patent N0.: US 7,377,754 B2Selvaraji MuthuNo ratings yet

- Tubeless TyreDocument16 pagesTubeless Tyreaarasu007No ratings yet

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsNo ratings yet

- US5820225Document10 pagesUS5820225aungkyawzoreNo ratings yet

- US20030094838A1Document22 pagesUS20030094838A1Liam SkrooNo ratings yet

- United States Patent (10) Patent No.: US 7,134,558 B1: Mimlitch, III Et Al. (45) Date of Patent: Nov. 14, 2006Document22 pagesUnited States Patent (10) Patent No.: US 7,134,558 B1: Mimlitch, III Et Al. (45) Date of Patent: Nov. 14, 2006Erin GokNo ratings yet

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- United States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDocument3 pagesUnited States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDanister GladwinNo ratings yet

- Patente Americana - Us 8615970Document22 pagesPatente Americana - Us 8615970Maurício OliveiraNo ratings yet

- Apron FeederDocument12 pagesApron FeederMidDeL'OrmeNo ratings yet

- United States Patent (19) 11 Patent Number: 5,804,612Document4 pagesUnited States Patent (19) 11 Patent Number: 5,804,612Thuận LêNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- 2011 Us7998221Document44 pages2011 Us7998221Daffa Hafiz ZaidanNo ratings yet

- WO 2Ull/13Uo47 A L: WorldDocument21 pagesWO 2Ull/13Uo47 A L: WorldFarid BelkadiNo ratings yet

- LDR Sensor Module Users Manual V10Document5 pagesLDR Sensor Module Users Manual V10Gek CagatanNo ratings yet

- Nokia 5G Mmwave Revolution White Paper EN PDFDocument15 pagesNokia 5G Mmwave Revolution White Paper EN PDFGek CagatanNo ratings yet

- Predicting Surface RoughnessDocument12 pagesPredicting Surface RoughnessGek CagatanNo ratings yet

- Composition For Use As Coating Material and Adhesive, Method For Adhesive Bonding, and Laminated ProductsDocument96 pagesComposition For Use As Coating Material and Adhesive, Method For Adhesive Bonding, and Laminated ProductsGek CagatanNo ratings yet

- Pcti Us5287848Document8 pagesPcti Us5287848Gek CagatanNo ratings yet

- Annual Growth Rings - Tree Knowledge - Booklet - Forest Academy - DomtarDocument6 pagesAnnual Growth Rings - Tree Knowledge - Booklet - Forest Academy - DomtarGek CagatanNo ratings yet

- Us8535785 PDFDocument27 pagesUs8535785 PDFGek CagatanNo ratings yet

- Arduino Soil Moisture Sensor ProjectDocument5 pagesArduino Soil Moisture Sensor ProjectGek CagatanNo ratings yet

- EP2339092A1Document20 pagesEP2339092A1Gek CagatanNo ratings yet

- EP1576326B1 AutomatedTranslationDocument6 pagesEP1576326B1 AutomatedTranslationGek CagatanNo ratings yet

- Annual Growth Rings - Tree Knowledge - Booklet - Forest Academy - DomtarDocument6 pagesAnnual Growth Rings - Tree Knowledge - Booklet - Forest Academy - DomtarGek CagatanNo ratings yet

- United States Patent: (12) (10) Patent N0.: US 6,256,489 B1Document8 pagesUnited States Patent: (12) (10) Patent N0.: US 6,256,489 B1Gek CagatanNo ratings yet

- Us8535785 PDFDocument27 pagesUs8535785 PDFGek CagatanNo ratings yet

- Us 10188296Document64 pagesUs 10188296Gek CagatanNo ratings yet

- Us6421653 Ref 4Document63 pagesUs6421653 Ref 4Gek CagatanNo ratings yet

- Patent Application Publication: (19) United StatesDocument82 pagesPatent Application Publication: (19) United StatesGek CagatanNo ratings yet

- Us6387185 PPS20Document38 pagesUs6387185 PPS20Gek CagatanNo ratings yet

- St. Benedict PrayerDocument1 pageSt. Benedict PrayerGek CagatanNo ratings yet

- Programmable Mobile Networks Middleware Enables Adaptive ServicesDocument22 pagesProgrammable Mobile Networks Middleware Enables Adaptive ServicesGek CagatanNo ratings yet

- United States Patent: (10) Patent No.: (45) Date of PatentDocument27 pagesUnited States Patent: (10) Patent No.: (45) Date of PatentGek CagatanNo ratings yet

- w006 Travel PDFDocument1 pagew006 Travel PDFGek CagatanNo ratings yet

- w006 Travel PDFDocument1 pagew006 Travel PDFGek CagatanNo ratings yet

- Potter Pangrams: Harry Potter Inspired Sentences Using Every LetterDocument1 pagePotter Pangrams: Harry Potter Inspired Sentences Using Every LetterGek CagatanNo ratings yet

- Us5761513 ADocument15 pagesUs5761513 AGek CagatanNo ratings yet

- Show Original: FulltextDocument9 pagesShow Original: FulltextGek CagatanNo ratings yet

- US6572025Document33 pagesUS6572025Gek CagatanNo ratings yet

- JP4473685 - 11321Document6 pagesJP4473685 - 11321Gek CagatanNo ratings yet

- Show Original: FulltextDocument9 pagesShow Original: FulltextGek CagatanNo ratings yet

- JP2007098063ADocument64 pagesJP2007098063AGek CagatanNo ratings yet

- Method and Apparatus for Radiographic Imaging with Antidiffusion Grid MotionDocument12 pagesMethod and Apparatus for Radiographic Imaging with Antidiffusion Grid MotionGek CagatanNo ratings yet

- Test Certificate: Ferro Steel SolutionDocument1 pageTest Certificate: Ferro Steel SolutionNeeraj Singh100% (4)

- Biopharm Tubing: For Every Part of Your ProcessDocument24 pagesBiopharm Tubing: For Every Part of Your ProcessFer PabNo ratings yet

- Econ 2Document16 pagesEcon 2ediabcNo ratings yet

- KENDRIYA VIDYALAYA SANGATHAN SAMPLE PAPER FOR PERIODIC TEST II EXAMDocument4 pagesKENDRIYA VIDYALAYA SANGATHAN SAMPLE PAPER FOR PERIODIC TEST II EXAMhweta173No ratings yet

- Sport Stroller Instructions Philandteds 20150820 8209-01Document44 pagesSport Stroller Instructions Philandteds 20150820 8209-01Herczku AnnamáriaNo ratings yet

- E 155 - 00 - Rte1nq - PDFDocument4 pagesE 155 - 00 - Rte1nq - PDFLeón SuárezNo ratings yet

- Chapter 3 Bio461 (Revised)Document61 pagesChapter 3 Bio461 (Revised)Muhammad Arief AimanNo ratings yet

- Cooling Tower AnalysisDocument6 pagesCooling Tower AnalysisACNo ratings yet

- BLENDEX 587msdsDocument6 pagesBLENDEX 587msdsAnonymous eq5zSUNo ratings yet

- MC Electricity and MagnetismDocument7 pagesMC Electricity and MagnetismMelvin Garcia QuirosNo ratings yet

- Importance of Analytical Instrumentation. Concepts To RememberDocument4 pagesImportance of Analytical Instrumentation. Concepts To RememberPrimer AsaltoNo ratings yet

- Fruit Enzymes LabDocument10 pagesFruit Enzymes Labapi-340117487No ratings yet

- A Review On Pharmacological and Phytochemical Activities of Lilium Polyphyllum (Liliaceae) Himalaya LilyDocument5 pagesA Review On Pharmacological and Phytochemical Activities of Lilium Polyphyllum (Liliaceae) Himalaya LilyInternational Journal of Innovative Science and Research Technology100% (1)

- Urestone Binder 10-05-11Document17 pagesUrestone Binder 10-05-11Serkan EkingenNo ratings yet

- Selectividad Ingles 2011-2012Document2 pagesSelectividad Ingles 2011-2012sergiosanroNo ratings yet

- Research Article: Synthesis of New Benzofuran-2-Carboxylic Acid DerivativesDocument8 pagesResearch Article: Synthesis of New Benzofuran-2-Carboxylic Acid Derivativesfatriani smakNo ratings yet

- Polymers: Chitosan: An Overview of Its Properties and ApplicationsDocument27 pagesPolymers: Chitosan: An Overview of Its Properties and Applicationsjuan esteban MonroyNo ratings yet

- VTF Filtro BolsilloDocument7 pagesVTF Filtro BolsilloArmandoMiquilenaNo ratings yet

- Introduction About Steel FiberDocument25 pagesIntroduction About Steel FiberVirupakshappa C Koti100% (4)

- WTP 3PS Mce0 TP002Document15 pagesWTP 3PS Mce0 TP002Marian PascuNo ratings yet

- Treating Sullage Water Using Natural and Chemical CoagulantsDocument5 pagesTreating Sullage Water Using Natural and Chemical CoagulantsMuhammad Ramadhan SaputraNo ratings yet

- Extraction of Fennel (Foeniculum Vulgare) Seeds: Process Optimization and Antioxidant Capacity of The ExtractsDocument9 pagesExtraction of Fennel (Foeniculum Vulgare) Seeds: Process Optimization and Antioxidant Capacity of The ExtractsruriNo ratings yet

- India refinery configurations-Meeting future demand & regulationsDocument9 pagesIndia refinery configurations-Meeting future demand & regulationsphantanthanhNo ratings yet

- Pretreatment in Reverse Osmosis Seawater DesalinatDocument9 pagesPretreatment in Reverse Osmosis Seawater DesalinataquaNo ratings yet

- Crystal Appearance/Characteristics Clinical SignificanceDocument4 pagesCrystal Appearance/Characteristics Clinical SignificanceAngela LaglivaNo ratings yet

- Sieve Analysis and Density Test For AggregatesDocument11 pagesSieve Analysis and Density Test For AggregatesgeorgeantoniosNo ratings yet

- p1 Coverage Animal Nutrition - Chapter 1Document13 pagesp1 Coverage Animal Nutrition - Chapter 1jayr ludoviceNo ratings yet

- Abrasion & Impact TestDocument10 pagesAbrasion & Impact TestMuhammad Hafizuddin100% (1)

- Topic: Aseptic Techniques in Plant Tissue Culture LabDocument8 pagesTopic: Aseptic Techniques in Plant Tissue Culture LabMaryam BilalNo ratings yet

- IADC/SPE 100824 Swell Packers: Enabling Openhole Intelligent and Multilateral Well Completions For Enhanced Oil RecoveryDocument8 pagesIADC/SPE 100824 Swell Packers: Enabling Openhole Intelligent and Multilateral Well Completions For Enhanced Oil RecoveryHadi KoraniNo ratings yet