Professional Documents

Culture Documents

Boletin de Servicio Mantenimiento de Baterias 17-2964

Uploaded by

gustavofx21Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Boletin de Servicio Mantenimiento de Baterias 17-2964

Uploaded by

gustavofx21Copyright:

Available Formats

SERVICE BULLETIN

TOPIC:

IDENT NO:

SUPERSEDES:

DATE:

SUBJECT:

Electronic Controls

17-2964

New

September 15, 2006

Battery Maintenance

MODELS AFFECTED:

All Engines

Always keep the engine batteries in good operating

condition and at full charge. Failure to do so may effect

the performance of the ESM and other electronic controls.

Sulfation of batteries starts when specific gravity falls

below 1.225 or voltage measures less than 12.4 (see

Table 1). Sulfation hardens the battery plates reducing

and eventually destroying the ability of the battery to

generate power or to dampen voltage ripples (noise)

caused by battery charging or loads with switching

power supplies. Failure of the battery to adequately

dampen voltage ripples may lead to malfunction of

battery powered devices.

WARNING

Comply with the battery manufacturer's

recommendations for procedures concerning

proper battery use and maintenance. Improper

maintenance or misuse can cause severe personal

injury or death.

WARNING

Batteries contain sulfuric acid and generate

explosive mixtures of hydrogen and oxygen

gases. Keep any device that may cause sparks or

flames away from the battery to prevent explosion.

Batteries can explode causing severe personal

injury or death.

WARNING

Always wear protective glasses or goggles and

protective clothing when working with batteries.

You must follow the battery manufacturers

i n s t r u c t i o n s o n s a f e t y, m a i n t e n a n c e a n d

installation procedures. Failure to follow the

battery manufacturers instructions can cause

severe personal injury or death.

WAUKESHA ENGINE

DRESSER, INC.

WAUKESHA, WI 53188-4999

BATTERY INDICATED STATE OF CHARGE

NOTE: The battery must be fully charged for several

hours before testing. If batteries have been receiving a

charge current within the previous few hours, the

open-circuit voltage may read misleadingly high. The

surface charge must be removed before testing. To

remove surface charge, the battery must experience a

load of 20 amps for three or more minutes.

1. Use a temperature compensated hydrometer to

measure the electrolyte specific gravity readings in

each cell. Record the readings.

2. Measure the open circuit voltage across the

terminals. Record the reading.

3. Using the recorded values determine the state of

charge (see Table 1).

4. See Table 3 troubleshooting chart.

NOTE: The state of charge listed is approximate. The

relationship between state of charge and voltage

varies by CCA rating and size. Voltage below 11.90 V

may mean that the battery has a shorted cell or that

the plates are sulfated and can not accept a charge.

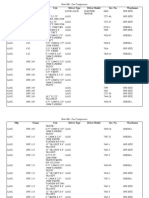

Table 1. Determining State of Charge

STATE OF

CHARGE

SPECIFIC

GRAVITY

12.70 & Above

100 %

.280

12.50

75 %

.240

12.30

50 %

.200

12.10

25 %

.170

Discharged

.140

VOLTAGE

11.90 & Below

Table 2. Cranking Amps - Commercial Batteries

CCA @ 0F (-18 C)

CA @ 32F (0 C)

RC minutes @ 25 A

4D

8D

1000A

1300A

1200A

1560A

320 min.

435 min.

CCA = Cold Cranking Amps

CA = Cranking Amps

RC = Reserve Capacity

Page 1 of 2

Service Bulletin No. 17-2964

Table 3. Battery Troubleshooting

IF

Has cracks or holes in the container or

cover.

Battery

Appearance

Has black deposits on underside of vent

plugs.

Is low.

Is adjusted frequently.

Is 75% or greater.

Is between 25% and 75%.

State Of Charge

Battery has been overcharged (see NOTE 4)

Verify battery charger is operating correctly and settings are correct.

Fill electrolyte to correct level using distilled or deionized water.

Battery is receiving too much charging current.

Verify battery charger is operating correctly and settings are correct.

Verify battery is good with a high rate load test (see NOTE 3).

Recharge battery (see NOTE 2).

Is less than 25%.

Measured open circuit voltage is lower

than value given in the Table 2.

Specific Gravity

Of Cells

Replace battery.

Has corroded terminals posts.

Has black tide-marks on inside walls

about one inch below the cover.

Electrolyte Level

THEN

Differential between cells exceeds .05.

Is uniformly low.

Replace battery.

Replace battery (internally short-circuited).

Verify battery charger is operating correctly and settings

are correct, recharge battery (see NOTE 1).

NOTE 1:Batteries which have low but uniform specific gravities in each cell and which clearly require an extended

recharge may have become deeply discharged. This may be nothing more than a battery charger problem,

but the system should be checked out before the battery is returned to service.

NOTE 2:Recharging Batteries which are at less than 75% state of charge need recharging before proceeding with

any further tests. Observe that the battery does accept a charging current, even though it may be small in

amperes, when the charger is switched on. The battery must be fully charged for several hours before testing.

If batteries have been receiving a charge current within the previous few hours, the open-circuit voltage may

read misleadingly high. The surface charge must be removed before testing. To remove surface charge, the

battery must experience a load of 20 amps for 3 plus minutes.

NOTE 3:High-Rate Load TestIf the state-of-charge is 75% or higher, the battery should be given a high-rate load

test. Typically, the high-rate load tester will discharge a battery through an adjustable carbon-pile resistance

and indicate the terminal voltage as the discharge proceeds. After 15 seconds the battery voltage will not

drop below a specified value (typically 9.6 V) if the battery is in good condition and if the current is set at

about 50% of the Cold Cranking Amps (CCA) (see Table 2). The minimum acceptable voltage reading will

vary as battery temperature decreases. Read and follow the manufacturers instructions for the tester.

NOTE 4:OverchargingBatteries which have suffered as a result of considerable overcharging may show extremely

low electrolyte levels, black deposits on the underside of the vent plugs or black tide-marks on the inside

walls of the container from about one inch below the cover. If these signs are present, the battery charger

setting must be checked and reset according to the manufacturer's instructions before a battery is returned

to service, batteries in which electrolyte levels have to be adjusted frequently are clearly receiving too much

charging current.

Page 2 of 2

WAUKESHA ENGINE

DRESSER, INC.

WAUKESHA, WI 53188-4999

You might also like

- Resources Newsletterfive1982-2Document1 pageResources Newsletterfive1982-2gustavofx21No ratings yet

- Rino KK - Gas CompressorsDocument20 pagesRino KK - Gas Compressorsgustavofx21No ratings yet

- Woodward Mechanical TG Governor PDFDocument52 pagesWoodward Mechanical TG Governor PDFgustavofx21No ratings yet

- Ariel Er 111.2Document1 pageAriel Er 111.2gustavofx21No ratings yet

- CATERPILLAR 3516 TA Parts 1 PrelubricadoraDocument2 pagesCATERPILLAR 3516 TA Parts 1 Prelubricadoragustavofx21No ratings yet

- Force Feed Lubricator Pump: PrimingDocument2 pagesForce Feed Lubricator Pump: Priminggustavofx21No ratings yet

- Ariel Er 105.7 PDFDocument1 pageAriel Er 105.7 PDFgustavofx21No ratings yet

- Ariel-Er-105 1 1Document9 pagesAriel-Er-105 1 1gustavofx21No ratings yet

- Ariel Er 93 PDFDocument2 pagesAriel Er 93 PDFgustavofx21No ratings yet

- Recommended Maintenance Intervals For Continuous Duty Reciprocating CompressorsDocument7 pagesRecommended Maintenance Intervals For Continuous Duty Reciprocating Compressorsgustavofx21No ratings yet

- Proflo Jr. No-Flow SwitchDocument3 pagesProflo Jr. No-Flow Switchgustavofx21No ratings yet

- LoggerDocument2 pagesLoggergustavofx21No ratings yet

- B 170Document50 pagesB 170gustavofx21100% (1)

- Psu 2 PDFDocument2 pagesPsu 2 PDFgustavofx21No ratings yet

- GE COMPRESSORS 00-001 Frame Oil PressureDocument1 pageGE COMPRESSORS 00-001 Frame Oil Pressuregustavofx21No ratings yet

- A 1582Document4 pagesA 1582gustavofx21No ratings yet

- Inner Outer Measurement Data File AnalysisDocument20 pagesInner Outer Measurement Data File Analysisgustavofx21No ratings yet

- Demo 24x3ringDocument20 pagesDemo 24x3ringgustavofx21No ratings yet

- K 178Document2 pagesK 178gustavofx21No ratings yet

- U 062Document2 pagesU 062gustavofx21No ratings yet

- P 172Document2 pagesP 172gustavofx21No ratings yet

- W 155Document18 pagesW 155gustavofx21No ratings yet

- U 134Document2 pagesU 134gustavofx21No ratings yet

- H 276Document46 pagesH 276gustavofx21No ratings yet

- A 1658Document10 pagesA 1658gustavofx21No ratings yet

- Trouble Shooting ChartDocument2 pagesTrouble Shooting Chartgustavofx21No ratings yet

- P 172Document2 pagesP 172gustavofx21No ratings yet

- York Centrifugal M PamphletDocument8 pagesYork Centrifugal M Pamphletgustavofx21No ratings yet

- Process Reciprocating CompressorsDocument1 pageProcess Reciprocating Compressorsgustavofx21No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Copper Applications Technology RoadmapDocument34 pagesCopper Applications Technology RoadmapPaco RotenNo ratings yet

- HS80G ServiceMaDocument54 pagesHS80G ServiceMaRICHIHOTS2No ratings yet

- Solar Powered Automatic Shrimp Feeding SDocument8 pagesSolar Powered Automatic Shrimp Feeding SSalomón Martínez VásquezNo ratings yet

- HTX 202 Owners ManualDocument44 pagesHTX 202 Owners Manualbellscb100% (2)

- Marathonnorco Aerospace IncDocument48 pagesMarathonnorco Aerospace IncNIXON BENITEZNo ratings yet

- Orion 910Document21 pagesOrion 910David DangNo ratings yet

- 2 Hybrid High Voltage BatteriesDocument55 pages2 Hybrid High Voltage Batteriessamuel GyimahNo ratings yet

- Gilian HFS513 - Fpro2105 - CDocument32 pagesGilian HFS513 - Fpro2105 - CEDERSON GUIMARÃES SILVANo ratings yet

- Toshiba Smart Grids To Realize Advanced Energy ManagementDocument4 pagesToshiba Smart Grids To Realize Advanced Energy ManagementAsian Development BankNo ratings yet

- Recoil Offgrid JuneJuly 2017 VK Com StopthepressDocument101 pagesRecoil Offgrid JuneJuly 2017 VK Com Stopthepressshenlong27100% (1)

- WSN Chapter 3Document75 pagesWSN Chapter 3sanyukta246No ratings yet

- OPTALIGN Smart Catalog enDocument11 pagesOPTALIGN Smart Catalog enEdward KuantanNo ratings yet

- Automatic Battery Charger Cargador de Baterías Automático Chargeur de Batterie AutomatiqueDocument28 pagesAutomatic Battery Charger Cargador de Baterías Automático Chargeur de Batterie AutomatiqueBryan CarballoNo ratings yet

- Consumer Perception of Electric Vehicles Project ReportDocument58 pagesConsumer Perception of Electric Vehicles Project ReportGaurang Velaskar33% (3)

- APC Symmetra LX Technical Specifications for 12-16 kVA Rack-mount and Tower UPS ModelsDocument6 pagesAPC Symmetra LX Technical Specifications for 12-16 kVA Rack-mount and Tower UPS ModelsBazingaNo ratings yet

- Geomative Catalog & Rusume - 20190315Document19 pagesGeomative Catalog & Rusume - 20190315Shahzad KhanNo ratings yet

- en HR RoDocument86 pagesen HR RoGabriel SetnicNo ratings yet

- Unique 1Pc RC Model Battery Charger Cable 4.8V 250ma USB Balance Fast Charging Amazon - in ElectronicsDocument1 pageUnique 1Pc RC Model Battery Charger Cable 4.8V 250ma USB Balance Fast Charging Amazon - in ElectronicsSmitha ShekarNo ratings yet

- Manual - PV1800-3KW-120VAC-T1.0Document16 pagesManual - PV1800-3KW-120VAC-T1.0Ferney CastroNo ratings yet

- 2009 Battery RGDocument40 pages2009 Battery RGDonyen LiuNo ratings yet

- Tesla Battery Module Controller Guide for Home Solar InstallationsDocument56 pagesTesla Battery Module Controller Guide for Home Solar InstallationsYora Erlangga100% (1)

- JBL Flip 6Document30 pagesJBL Flip 6maibac3300No ratings yet

- ZLL SG908 KUN User ManualDocument24 pagesZLL SG908 KUN User ManualDm Duplicatas ControleNo ratings yet

- Manual Yamaha DGX-505 - enDocument112 pagesManual Yamaha DGX-505 - endyu_1976No ratings yet

- Battery Types Used For Auxiliary Power Supply in Substations and Power PlantsDocument13 pagesBattery Types Used For Auxiliary Power Supply in Substations and Power PlantsJyot ParikhNo ratings yet

- The BURN Meter Rechargeable Arduino UV Index MeterDocument29 pagesThe BURN Meter Rechargeable Arduino UV Index MeterJunior ElimeelogodavejuniorNo ratings yet

- Celina Mikolajczak, Michael Kahn, Kevin White, Richard Thomas Long - Lithium-Ion Batteries Hazard and Use AssessmentDocument126 pagesCelina Mikolajczak, Michael Kahn, Kevin White, Richard Thomas Long - Lithium-Ion Batteries Hazard and Use AssessmentJuan Manuel Rodríguez GonzálezNo ratings yet

- ULTRA LONG LIFE FAST CHARGE SAFEST Graphene Supercapacitor BatteryDocument19 pagesULTRA LONG LIFE FAST CHARGE SAFEST Graphene Supercapacitor BatteryRamon CuevasNo ratings yet

- Ancel BA101Document17 pagesAncel BA101Raúl Gil TomeyNo ratings yet

- Direct Methanol Fuel Cell Systems For Portable Applications (Samsung)Document21 pagesDirect Methanol Fuel Cell Systems For Portable Applications (Samsung)Dimitrios TsiplakidesNo ratings yet