Professional Documents

Culture Documents

LR97 TL4760M

Uploaded by

vuong49vtuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

LR97 TL4760M

Uploaded by

vuong49vtuCopyright:

Available Formats

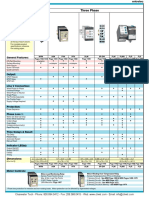

TeSys protection components

Presentation,

description

Electronic over current relays

Presentation

109487

LR97 D and LT47 electronic over current relays have been developed to satisfy machine

protection requirements.

These relays have definite time characteristics: current threshold and time based function.

They are particularly recommended for providing mechanical protection on machines with high

resistive torque, high inertia and with strong probability of jamming under steady state conditions.

They can be used for motor protection in the case of long starting times or frequent starting.

The LR97 D relay also incorporates two fixed time protection functions, one of 0.5 seconds

against locked rotor and one of 3 seconds against phase failure.

LR97 D and LT47 can be used to provide mechanical shock protection. In this case, setting the

O-Time knob to minimum will ensure tripping in 0.3 seconds.

Applications

LR97 D and LT47 relays are particularly suitable for the following machines:

b Monitoring function for excessively long starting time on machines with a risk of difficult

starting:

v Machines with high resistive torque, high inertia machines.

b Monitoring of machines during steady state operation: overtorque detection function

v Machines with strong risk of jamming, machines with torque build-up over time,

v Mechanical failure monitoring,

v Faster detection of malfunctioning on machines where the motor is oversized in relation to its

thermal protection It.

b Motor protection for specific applications:

v Machines with long starting times,

v Machines with high on-load factor: more than 30 to 50 starts/hour,

v Machine with fluctuating load from a steady state, where the thermal image of a thermal

overload relay (thermal memory) is unsuitable in relation to actual overheating of the motor.

Examples of machines:

v Conveyors, crushers and mixers,

v Fans, pumps and compressors,

v Centrifuges and spin-dryers,

v Presses, shearing machines, saws, broaching machines, sanders and lifting hoists.

109502

LR97 Dppppp

Operation

Because of their two separate time settings, LR97 D and LT47 relays can be combined with the

motor-starter function:

D-Time: starting time, O-Time: trip time during steady state.

The D-Time function is only available during the motor starting phase. During this phase the

overload detection function is inhibited in order to allow starting. Under steady state conditions,

when the motor current is greater than the setting current due to an overload or single-phasing,

the red LED lights up and the internal relay switches its contact after a time preset by the O-Time

knob.

The red LED stays on, indicating that the relay has tripped.

LT47 60ppp

The relays are simple to set, in 5 easy steps:

- Adjust the 3 knobs to maximum (Load, D-Time and O-Time),

- Adjust the D-Time knob to the value corresponding to the motor starting time.

- When the motor reaches steady state, adjust the Load knob (turn the knob counter-clockwise

until the red LED starts to flicker).

- Slowly turn the Load knob clockwise until the LED goes out.

- Set the required tripping time, using the O-Time knob.

Description

Description

Status signalling

LT47 ppppp

LR97 Dppppp

RESET

3

4

9

1

8

2

3

4

2

TEST

TEST/STOP

RESET

A1

A2

2T1

98

4T2

95

LED signal

Status

Green LED

Voltage

On

Red LED

Voltage

Off

LED signal

Condition

Green LED

Red LED

On

Off

Steady

state

On

Off

Overload

On

Starting

Starting

96

Steady

state

6T3

5 6 7

1

2

3

4

5

6

LR97 Dppppp

LT47 ppppp

To assist fast diagnostics, two LEDs (one green and one red) allow signalling of the operating

status:

RESET knob

TEST/STOP knob

Ready/Run Indicator

Relay tripped indicator

Current setting

Adjustment of starting

time

10

7 Adjustment of tripping

time

8 Manual/Auto adjustment

9 Single-phase/3-phase

adjustment

10 Retractable fixing lugs

On

Overload

On

OverTrip current

Rotor

locked

Pha

se

failure

Off

Off

On

Trip

Off

Off

L1 Off

L2

Off

L3 Off

Curves :

pages 24517/3 and 24517/4

24517-EN_Ver5.1.fm/2

Characteristics :

pages 24517/4 and 24517/5

References :

page 24517/6

Dimensions, mounting :

page 24517/7

Schemes :

page 24517/7

On

TeSys protection components

Curves

Electronic over current relays

LR97D

Overload protection

Protection against locked rotor and mechanical jamming under steady state conditions

U power supply A1-A2

Starting

Locked rotor

on starting

Mechanical jamming

during steady state

operation

Overload

Brief

overload

3 x I setting

Setting current

Normal steady state operation

Current

D-Time

O-Time

0,5 s

O-Time

Reset: Manual (1)

or electric (3)

Tripping due to locked rotor or

mechanical jamming during 95

steady state operation

96

98

96

Tripping on overload 95

98

Reset: Manual (1)

automatic (2)

or electric (3)

Overload protection

Protection against phase failure during starting and during steady state operation

U power supply A1-A2

Starting

Phase

failure

Overload

Missing

phase

Brief

overload

Setting current

Normal steady state operation

Current

D-Time

<3s

O-Time

O-Time

Reset: Manual (1)

or electric (3)

<3s

Tripping due to 95

phase failure

96

98

96

Tripping on overload 95

98

Reset: Manual (1)

automatic (2)

or electric (3)

Mechanical shock protection

U power supply A1-A2

Starting

Overload

Setting current

Normal steady state operation

Current

D-Time

O-Time set to

minimum (02-03 s)

Tripping to due mechanical shock 95

Reset: Manual (1)

automatic (2)

or electric (3)

96

98

(1) By Reset button.

(2) Fixed time of 120 s. Selectable by dip switch. Function not available in the event of tripping due to locked rotor/mechanical jamming (I> 3 x I setting) or phase failure.

(3) By brief interruption of power supply, minimum 0.1 s.

Presentation, description :

page 24517/2

Characteristics :

pages 24517/4 and 24517/5

References :

page 24517/6

Dimensions, mounting :

page 24517/7

Schemes :

page 24517/7

24517-EN_Ver5.1.fm/3

TeSys protection components

Curves (continued),

characteristics

Electronic over current relays

Curves

LT47

Overload protection

U power supply A1-A2

Starting

Overload

Brief

overload

Setting current

Normal steady state operation

Current

D-Time

Trip

on overload

95

97

O-Time

O-Time

Reset: Manual (1)

automatic (2)

or electric (3)

96

98

Mechanical shock protection

U power supply A1-A2

Starting

Overload

Setting current

Normal steady state operation

Current

D-Time

O-Time set to

Reset: Manual (1)

automatic (2)

or electric (3)

minimum (02-03 s)

Tripping due to 95

mechanical shock 97

96

98

(1) By Reset button.

(2) Only available on version with automatic reset (LT47 ppppA). Time adjustable from 1 to 120 s with the R-Time knob.

(3) By brief interruption of power supply, minimum 0.1 s.

Characteristics

Environment

Relay type

Conforming to standards

Product certifications

Degree of protection

Protective treatment

Ambient air temperature

around the device

Conforming to IEC 60529

and VDE 0106

Conforming to IEC 60068

Storage

Normal operation without derating

(IEC 60947-4-1)

Maximum operating altitude

Operating positions

In relation to normal

without derating

vertical mounting plane

Shock resistance

Permissible acceleration

conforming to IEC 60068-2-7

Vibration resistance

Permissible acceleration

conforming to IEC 60068-2-6

Dielectric strength at 50 Hz Conforming to IEC 60255-5

Surge withstand

Conforming to IEC 61000-4-5

Resistance to

In open air

electrostatic discharge

In direct mode

Immunity to radiated radio-frequency disturbance

Immunity to fast transient currents

Conducted emissions

Conforming to EN 55011

Conducted HF disturbance Conforming to EN 61000-4-6

Presentation, description :

page 24517/2

24517-EN_Ver5.1.fm/4

References :

page 24517/6

C

C

m

kV

kV

kV

kV

V/m

kV

V

LR97 Dppppp

IEC 60255-6, IEC 60947

UL, CSA (pending)

IP 20 (front face)

LT47 ppppp

IEC 60255-6, IEC 60947

UL, CSA (pending)

IP 20 (front face)

TH

- 30+ 80

- 25+ 60

TH

- 30+ 80

- 25+ 60

2000

Any position

2000

Any position

15 gn - 11 ms

15 gn - 11 ms

4 gn

4 gn

2

6

8 (level 3)

6 (level 3)

10 (level 3)

2

Class A

10

2

6

8 (level 3)

6 (level 3)

10 (level 3)

2

Class A

10

Dimensions, mounting :

page 24517/7

Schemes :

page 24517/7

TeSys protection components

Characteristics (continued)

Electronic over current relays

Characteristics

Auxiliary contact characteristics

Relay type

Contact type

Conventional thermal current

Maximum hold consumption

of controlled contactor coils

(occasional operating cycles

of contact 95-96)

Conforming to IEC 947

Short-circuit protection

By gG, BS fuses. Maximum

rating or GB2 circuit-breaker

Connection by cable or lug-clamps

Flexible cable

1 or 2 conductors

Min.

without cable end

Max.

Flexible cable

1 or 2 conductors

Min.

with cable end

Max.

External of lugs

of screw

Tightening torque

A

V

VA

V

W

A

LR97 Dppppp

1 NO/NC

3

a 24

a 48

70

140

c 24

c 48

55

55

3

mm 2

mm 2

mm 2

mm 2

mm

mm

N.m

1 x 0.75

2 x 2.5

1 x 0.34

1 x 1.5 + 1 x 2.5

7

M3

0.61.2

a 110

360

c 110

28

a 220

360

c 220

28

LT47 ppppp

1 N/O + 1N/C

3

a 24

a 48

70

140

c 24

c 48

55

55

3

a 110

360

c 110

28

a 220

360

c 220

28

1x1

2 x 2.5

1x1

2 x 2.5

7

M3.5

0.8...1.7

Electrical characteristics of power circuit

Relay type

Setting range

Tripping class

Rated insulation voltage (Ui)

Depending on model

Conforming to IEC 60947-4-1

Conforming to UL, CSA

V

V

kV

Hz

5060

mm 2

mm

mm

N.m

1.5

10

1

4

10

M4

2

A

s

LR97 Dppppp

"Load" knob

0.530

LT47 ppppS

"Load" knob

0.530

LT47 ppppA

"Load" knob

0.2/0.310

0.2/0.310

0.2/0.330

1120

Reset button

120 s fixed

By interruption of power

supply (minimum 0.1 s)

On starting Steady

state

Inhibited

After O-time

during

D-time

After D-time < 0.5 s

Reset button

R-time knob: 1-120 s

By interruption of power

supply (minimum 0.1 s)

2 LEDs

Reset button

By interruption of power

supply (minimum 0.1 s)

On starting Steady

state

Inhibited

After O-time

during

D-time

Inhibited

After O-time

during

D-time

Inhibited

After O-time

during

D-time

2 LEDs

No load

Under load

Yes

No load

Under load

Yes

No load

Under load

Yes

Dimensions, mounting :

page 24517/7

Schemes :

page 24517/7

Rated impulse

withstand voltage (Uimp)

Frequency limits

Of the operating current

Connection by cable or lug-clamps

Flexible cable

1 conductor

Min.

without cable end

Max.

Flexible cable

1 conductor

Min.

with cable end

Max.

External of lugs

of screw

Tightening torque

mm 2

LR97 D38pp

LT47 ppppp

LR97 D015pp to

LR97 D25pp

0.538

Adjustable

690

600

6

0.360

Adjustable

690

600

6

5060

2.5

10

1

6

12

M4

2

Operating characteristics

Relay type

Adjustment

Reset

Current

Time

D-time

knob

O-time

knob

R-time

knob

Manual

Automatic

Electrical

Protection functions

Overload Imax > Isetting

Tripping

Locked rotor, mechanical

jamming I > 3 x I setting

Tripping

Sensitivity to phase failure Tripping

Status and fault signalling

(see table page 24517/2)

TEST/STOP function

Test

Stop

Sealing

Presentation, description :

page 24517/2

Curves :

pages 24517/3 and 24517/4

<3s

References :

page 24517/6

<3s

After O-time

After O-time

After O-time

2 LEDs

24517-EN_Ver5.1.fm/5

TeSys protection components

References

109487

Electronic over current relays

LR97 D electronic over current relays

LR97 Dppppp

Relay

setting

range

A

0.31.5

Usable

range

(1)

A

0.31.3

For use

with contactor

(2)

Relay

supply

voltage

Reference

LC1 D09D38

1.27

1.26

LC1 D09D38

525

521

LC1 D09D38

2038

2034

LC1 D25D38

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

LR97

D015M7

D015F7

D015B

D015E

D07M7

D07F7

D07B

D07E

D25M7

D25F7

D25B

D25E

D38M7

D38F7

D38B

D38E

Weight

kg

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

0.172

109502

LT47 electronic over current relays

Relay

setting

range

A

Usable

range

(1)

A

Relay

supply

voltage

Reference

(3)

Weight

kg

LT47 relay with manual/electric reset

0.56

0.55

330

325

560

550

LT47 60ppp

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

06M7S

06F7S

06BS

06ES

30M7S

30F7S

30BS

30ES

60M7S

60F7S

60BS

60ES

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

LT47

06M7A

06F7A

06BA

06EA

30M7A

30F7A

30BA

30EA

60M7A

60F7A

60BA

60EA

0,192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

0.192

LT47 relay with automatic reset

0.56

0.55

330

325

560

550

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

a 220 V

a 110 V

c/a 24 V

c/a 48 V

Accessories (to be ordered separately)

Description

For

use with

Sold in

lots of

Unit

reference

Weight

kg

Pre-wiring kits allowing

LC1 D09D18

10

LAD 7C1

0.002

connection of the LR97 D

LC1 D25D38

10

LAD 7C2

0.003

relay N/C contact directly to

the contactor

Terminal block for clip-on LR97 D

1

LAD 7B106

0.100

mounting on 35 mm rail

(AM1 DP200)

(1) To allow adjustment of the tripping sensitivity, see adjustment method (page 24517/2).

(2) Please see our "Motor starter solutions" catalogue.

(3) If a pre-wiring kit is used, it is no longer possible to electrically wire signalling of tripped status.

Presentation, description :

page 24517/2

24517-EN_Ver5.1.fm/6

Curves :

pages 24517/3 and 24517/4

Characteristics :

pages 24517/4 and 24517/5

Dimensions, mounting :

page 24517/7

Schemes :

page 24517/7

TeSys protection components

Dimensions,

mounting,

schemes

Electronic over current relays

Dimensions

LT47 pppp

LR97 Dpppp

62,2

51

70,3

20,4

67,5

50,8

51,5

19,5

13

12

63

10

45

77,2

56

71

Mounting

LT47 pppp

LR97 Dpppp

Direct mounting beneath the contactor

c

45

67,5

LC1b

c

Note: Can be mounted on 5 rail.

D09D18

D25D38

123

137

See pages 24531/2 and 24531/3

Schemes

MCBB

L3

L1

L3

L2

L1

L2

LT47 pppp

LR97 Dpppp

MCBB

Stop

Stop

A1

A2

KM1

a

M3

Curves :

pages 24517/3 and 24517/4

LT47

Characteristics :

pages 24517/4 and 24517/5

A1 A2 97 98 95 96

A1

A2

A1 A2 98 95 96

KM1

M3

Presentation, description :

page 24517/2

14

Test/Stop

Reset

14

T3

T2

T1

A1 A2 98 95 96

Start

KM1

Test/Stop

Reset

LR 97D

Start

KM1

L3

L2

L1

13

13

KM1

References :

page 24517/6

24517-EN_Ver5.1.fm/7

You might also like

- Ramde Motor Protection RelayDocument8 pagesRamde Motor Protection RelayishhumzpNo ratings yet

- Ramde RelayDocument8 pagesRamde RelayculwavesNo ratings yet

- MCDocument300 pagesMCdiegobenitezNo ratings yet

- Siemens - Tyco V23084 C2001 A303Document5 pagesSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- CD Application NotesDocument48 pagesCD Application NotesJuan Carlos PiotrovskiNo ratings yet

- Electronic RelaysDocument21 pagesElectronic Relayslopablito24No ratings yet

- D - 481 - Relay NT10 Brochure - Revised 5VDocument8 pagesD - 481 - Relay NT10 Brochure - Revised 5Vhariprasath1986No ratings yet

- 3VT4 Molded Case PDFDocument17 pages3VT4 Molded Case PDFAnonymous clMeE4g70No ratings yet

- Atm 72Document8 pagesAtm 72muhammad arifNo ratings yet

- Micom P225 Motor Protection RelayDocument12 pagesMicom P225 Motor Protection RelayJatinder SainiNo ratings yet

- Type TA Class 10: Thermal Overload RelaysDocument18 pagesType TA Class 10: Thermal Overload RelaysAli ArslanNo ratings yet

- Rem 610Document16 pagesRem 610Padmo PadmundonoNo ratings yet

- LT6 CatalogueDocument24 pagesLT6 CatalogueMohamed Elsayed HasanNo ratings yet

- RE7ML11BU TelemecaniqueDocument22 pagesRE7ML11BU TelemecaniqueHugo FermartiNo ratings yet

- ALTSTART-46Document13 pagesALTSTART-46steve_osullivanNo ratings yet

- MPR300Document4 pagesMPR300KUNALJAY100% (1)

- Alstom Relay CDG 21Document4 pagesAlstom Relay CDG 21Jeffrey ChavezNo ratings yet

- Sicop Bimetal OL Relay Type 3UA5-6 3UC5-6Document14 pagesSicop Bimetal OL Relay Type 3UA5-6 3UC5-6erkamlakar2234No ratings yet

- Measurements: CDG 11 CDG 16Document4 pagesMeasurements: CDG 11 CDG 16girish1950% (2)

- L&T SWITCHGEAR: SAFE & SUREDocument27 pagesL&T SWITCHGEAR: SAFE & SUREKarthikeyanNo ratings yet

- 3RP15 DatasheetDocument4 pages3RP15 Datasheetquocphong10No ratings yet

- EOCR EnglishDocument38 pagesEOCR Englishjb10No ratings yet

- Overload and Short Circuit Relay: Eocr-3Dis-AuDocument2 pagesOverload and Short Circuit Relay: Eocr-3Dis-AuAngelo Michael ClementeNo ratings yet

- METALMECDocument20 pagesMETALMECClayton PedroNo ratings yet

- 25 A 20Document9 pages25 A 20s_barriosNo ratings yet

- Air Circuit Breakers - AH TypeDocument12 pagesAir Circuit Breakers - AH TypeSanjay JoshiNo ratings yet

- 10 KvaDocument4 pages10 KvaLeonardusHSijabatNo ratings yet

- Ucc3580 4Document20 pagesUcc3580 4vanhuong87No ratings yet

- ICM21Document8 pagesICM21pldalpianNo ratings yet

- Schneider LR-D Overload RelaysDocument17 pagesSchneider LR-D Overload RelaysVasu Iyer100% (1)

- SIemens TimerDocument4 pagesSIemens Timervaithy1990No ratings yet

- Siemens Timer CatalogDocument4 pagesSiemens Timer Catalogshamim93146No ratings yet

- Esab Rt3 To Rt35Document2 pagesEsab Rt3 To Rt35Okan KöksalNo ratings yet

- Reverse Power RelayDocument2 pagesReverse Power RelaykirananneNo ratings yet

- Rental: XQ2000 Sound Attenuated Power ModuleDocument8 pagesRental: XQ2000 Sound Attenuated Power ModuleAngel Javier NuñezNo ratings yet

- Transformer ProectionDocument27 pagesTransformer ProectionRitesh JaiswalNo ratings yet

- 001b Schneider Reclosers Introduction & Product Range 1.6Document83 pages001b Schneider Reclosers Introduction & Product Range 1.6Thức VõNo ratings yet

- Entrelec Voltage Phase Monitors PDFDocument26 pagesEntrelec Voltage Phase Monitors PDFnew2trackNo ratings yet

- RMP-112D Data Sheet 4921240110 UKDocument8 pagesRMP-112D Data Sheet 4921240110 UKd13g0bcNo ratings yet

- Hcf4541bey ApplicationDocument10 pagesHcf4541bey ApplicationAlecsandru NitaNo ratings yet

- Type TA Class 10: Thermal Overload RelaysDocument18 pagesType TA Class 10: Thermal Overload RelayssantoshkumarNo ratings yet

- VA TECH Transmission and Distribution Overcurrent and Earth Fault RelaysDocument7 pagesVA TECH Transmission and Distribution Overcurrent and Earth Fault RelaysBasudev Patra100% (1)

- Air Circuit Breakers-AHA TypeDocument8 pagesAir Circuit Breakers-AHA TypeanbarasubalayahoocomNo ratings yet

- AREVA Motor Protectionn MiCOM P220 225 TechnicalDatasheet enDocument37 pagesAREVA Motor Protectionn MiCOM P220 225 TechnicalDatasheet enNesarkiran Bagade67% (3)

- Diesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PDocument4 pagesDiesel Generator Set: Continuous Model:YM9-1P Standby Model:YM10S-1PYashveer TakooryNo ratings yet

- Timers, Time, Switches, Hour Meters & Supply MonitorsDocument24 pagesTimers, Time, Switches, Hour Meters & Supply MonitorsnogeshwarNo ratings yet

- ABB Overload RelayDocument36 pagesABB Overload Relayleedsutd100% (1)

- Schneider Releu NivelDocument8 pagesSchneider Releu NivelDan MircescuNo ratings yet

- Power System Protection: Dr. Ibrahim El-AminDocument53 pagesPower System Protection: Dr. Ibrahim El-AminLegalli AmcaNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- 110 Waveform Generator Projects for the Home ConstructorFrom Everand110 Waveform Generator Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlFrom EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlRating: 5 out of 5 stars5/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- Influence of System Parameters Using Fuse Protection of Regenerative DC DrivesFrom EverandInfluence of System Parameters Using Fuse Protection of Regenerative DC DrivesNo ratings yet

- RC Circuit DelayDocument6 pagesRC Circuit DelaybdmbudimanNo ratings yet

- B0505S D 1WDocument3 pagesB0505S D 1Wvuong49vtuNo ratings yet

- Wcs1800 - CB Do Dong DCDocument5 pagesWcs1800 - CB Do Dong DCvuong49vtuNo ratings yet

- 74HC4040 74HCT4040: 1. General DescriptionDocument24 pages74HC4040 74HCT4040: 1. General Descriptionvuong49vtuNo ratings yet

- S7-1200manual Modbus RTUDocument1 pageS7-1200manual Modbus RTUvuong49vtuNo ratings yet

- E2a M12-KS04Document18 pagesE2a M12-KS04vuong49vtuNo ratings yet

- SCH ConnectDocument2 pagesSCH Connectvuong49vtuNo ratings yet

- References: Engineering, Allyn and Bacon Inc., MassachusetsDocument2 pagesReferences: Engineering, Allyn and Bacon Inc., MassachusetssafiraginaNo ratings yet

- Design and Construction of Breakaway Walls for Coastal Flood AreasDocument17 pagesDesign and Construction of Breakaway Walls for Coastal Flood Areasrk_vijay81No ratings yet

- Lafarge Surma Cement LTD PDFDocument2 pagesLafarge Surma Cement LTD PDFAzad KhanNo ratings yet

- Math156 Ie Feb 2019Document7 pagesMath156 Ie Feb 2019Josef CatiggayNo ratings yet

- Liebherr Splitter BoxesDocument20 pagesLiebherr Splitter BoxesLuckas OuedraogoNo ratings yet

- Life Cycle Models (Lecture 2) Prof. R. Mall Dept. of CSE, IIT, KharagpurDocument63 pagesLife Cycle Models (Lecture 2) Prof. R. Mall Dept. of CSE, IIT, KharagpurAnuj NagpalNo ratings yet

- M5100 Bochure W-New WordsDocument4 pagesM5100 Bochure W-New WordsOSCAR TRUJILLONo ratings yet

- Training - Power System Protection - AREVADocument461 pagesTraining - Power System Protection - AREVAMallikarjun Reddy100% (47)

- Stress Analysis of Reactor Nozzle to Head JunctionDocument5 pagesStress Analysis of Reactor Nozzle to Head JunctionMohamed Rafeek0% (1)

- JOHN ZINK Combustion HandbookDocument801 pagesJOHN ZINK Combustion HandbookBaher Elsheikh100% (4)

- Question Design of Concrete VSem CivilDocument25 pagesQuestion Design of Concrete VSem CivilVaibhav SharmaNo ratings yet

- DNV-GL - Certification and Shop Approval For Repair Work On Rotor Blades PDFDocument19 pagesDNV-GL - Certification and Shop Approval For Repair Work On Rotor Blades PDFdavidlokitoNo ratings yet

- Construction Techniques of Steel and Concrete Composite StructuresDocument8 pagesConstruction Techniques of Steel and Concrete Composite StructuresAvinash KommireddiNo ratings yet

- Tekla Quick RefrenceDocument2 pagesTekla Quick RefrenceAtul Kumar Engineer100% (1)

- S3300ap-Brochure Ascensor PDFDocument20 pagesS3300ap-Brochure Ascensor PDFStephanie García100% (1)

- MEP ChecklistDocument8 pagesMEP ChecklistvirtechNo ratings yet

- Vel Murugan 2020Document5 pagesVel Murugan 2020Yhony Narvaez TtitoNo ratings yet

- IEEE Recommended Practice For Routine Impulse Test For Distribution TransformersDocument56 pagesIEEE Recommended Practice For Routine Impulse Test For Distribution TransformersIngTec2016 IngTec2016No ratings yet

- Producing Corrugated Pipes 200-800mmDocument24 pagesProducing Corrugated Pipes 200-800mmdirect2aakashNo ratings yet

- BS Civil Engineering Curriculum 2021-2022Document3 pagesBS Civil Engineering Curriculum 2021-2022Sweetie CagangNo ratings yet

- 890 - Slrtce - Mechanical 4 (CBC) C Scheme - FH 2021Document22 pages890 - Slrtce - Mechanical 4 (CBC) C Scheme - FH 2021Shreyas BhosaleNo ratings yet

- Plastic Processing OperatorDocument51 pagesPlastic Processing OperatorRam Avtar DhariwalNo ratings yet

- Slope Design Option For Seri Kembangan LinkDocument14 pagesSlope Design Option For Seri Kembangan LinkRuzani Hj IsmailNo ratings yet

- The Relationship Between National Culture and Organizational CultureDocument104 pagesThe Relationship Between National Culture and Organizational CulturepecescdNo ratings yet

- Various Precast Components and ConnectionsDocument44 pagesVarious Precast Components and ConnectionsZiya Ahmed100% (1)

- Georgia Peach StandardsDocument48 pagesGeorgia Peach StandardsGustavo ChavesNo ratings yet

- Final BQDocument60 pagesFinal BQSee Wei ChuanNo ratings yet

- Delhi MetroDocument8 pagesDelhi MetroPriyanka Sharma100% (1)

- Hydronic system types and piping arrangementsDocument36 pagesHydronic system types and piping arrangementsSharon LambertNo ratings yet

- IEE On-Site GuideDocument179 pagesIEE On-Site GuideMahmud Sied100% (5)