Professional Documents

Culture Documents

What Is SMED

Uploaded by

Arun BiswalOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

What Is SMED

Uploaded by

Arun BiswalCopyright:

Available Formats

SMED in SMS Mode

SMED, stands for Single-Minute Exchange of Die, is a theory and techniques for

performing setup operations in under ten minutes, i.e., in a number of minutes expressed

in a single digit. The SMED method was revolutionized by Mr. Shingo since 1950 in

Japan. The concepts and techniques became available to other countries started around

1974 in West Germany and Switzerland and in 1976 in Europe and United States.

However, not until 1980s, the SMED technique getting acceptace to companies outside

Japan.

Components of Lead Time

In manufacturing, lead time was consided starting from design until deliver the products

or services to the customers. Thus, the lead time consists of the following time elements:

Product Development (Design) Lead Time.

Sourcing (Purchasing) Lead Time.

Manufacturing (Production) Lead Time.

Order Processing Lead Time.

Distribution Lead Time.

Other (e.g. decision making, coordination) Lead Time.

Clearly, Production lead time is only a small portion of the whole lead time, but it is the

only component which is controllable by production function.

The production lead time can be further divided into:

Queue Time Before Processing.

Setup Time.

Run (Processing) Time.

Waiting Time after Processing.

Move Time.

Among these time elements, run time is the only portion that adds values to the products.

Others can be considered as a waste.

Effects of Setup Reduction

Setup reduction may bring the following impacts to the shop floor:

Lot-size can be reduced.

Help to reduce inventory.

Reduce the cost of setup labor.

Increase the capacity on bottleneck equipment.

Help to eliminate the setup scrap.

Reduce the potentail Quality problems and obsolescence

Alternatives for Setup Reduction

SMED is not the only approach for reducing setup time. Some other alternatives are:

Production Planning - reduce the number of setups.

Group Technology / cell foramtion - reduce the number of setups

Design Standardization - reduce the number of setups.

Use Standard Module - reduce the number of setups.

Work Simplification.

Mechanization or automation - an expensive option.

Procedures for Setup Reduction

SMED can be conducted according to the following steps:

1.

2.

3.

4.

5.

6.

7.

8.

Form the setup reduction team.

Conduct training and education.

Study the setup process (e.g., use video tape).

Classify setup operations into waste, internal setups (IED), and external setups

(OED).

o Waste - Operation which do not add values to the setup.

o Internal Setups - Operations that can only be performed while the machine

is shut down.

o External Setups - Operations that can be performed without shutting down

the machine.

Eliminate the waste.

Convert as many internal setups as possilbe to external setups.

o Use standard insert module.

Improve internal setups (include adjustment).

o Use specially designed cart to organize tools.

o Use quick-release fasteners instead of bolts and nuts.

o Use stoppers to quickly position the jigs.

o Use rolling bolsters instead of cranes.

o Use overhang mechanisms to handle heavy jigs.

o Use locating pins and holes (socket) to eliminate the adjustment.

o Use standardized die height.

Improve external setups.

Apply visual control principles.

Use checklist to avoid omission.

Use specially designed cart to help organize tools.

Organize workplace (5S) to reduce search.

9. Develop the standard operating procedure (SOP).

10. Evaluate the performance of setup reduction.

11. Prepare for the next setup reduction project.

o

o

o

o

Toolkits for Setup Reduction

Many toolkits can be applied to help setup reductions. For instance:

Visual Control.

Checklist.

Specially designed setup cart.

Workplace organization (5S).

Railed cart.

Standardized baseplate and socket.

Attachment plate.

Overhang tools.

Quick fasteners -- clamping cam, crank, clamping (lock) lever.

Standardized die height.

Locating pins.

Stopper.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- JAYCO CARAVANS - 2016 Silverline and Starcraft PDFDocument12 pagesJAYCO CARAVANS - 2016 Silverline and Starcraft PDFBrisbane CamperlandNo ratings yet

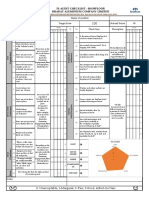

- 5S Audit Checklist-NewDocument1 page5S Audit Checklist-NewArun BiswalNo ratings yet

- BSBPMG410+Apply+project+time+management+techniques V170225Document35 pagesBSBPMG410+Apply+project+time+management+techniques V170225Sabrina Gao100% (1)

- Fobasv 6Document3 pagesFobasv 6Satyabrat Gaan100% (3)

- District OfficesDocument2 pagesDistrict OfficesArun BiswalNo ratings yet

- Collaboration To ChanceDocument1 pageCollaboration To ChanceArun BiswalNo ratings yet

- Scamper For Solution BraiSCAMPER FOR SOLUTION BRAINSTORMING - DocxnstormingDocument1 pageScamper For Solution BraiSCAMPER FOR SOLUTION BRAINSTORMING - DocxnstormingArun BiswalNo ratings yet

- How Effective Are Your MeetingsDocument3 pagesHow Effective Are Your MeetingsArun BiswalNo ratings yet

- Expect More Out of MeetingsDocument4 pagesExpect More Out of MeetingsArun BiswalNo ratings yet

- Identifying Causes of Production IssuesDocument2 pagesIdentifying Causes of Production IssuesArun BiswalNo ratings yet

- Ten Tips For Conducting PowerDocument5 pagesTen Tips For Conducting PowerArun BiswalNo ratings yet

- How Effective Are Your MeetingsDocument3 pagesHow Effective Are Your MeetingsArun BiswalNo ratings yet

- Be Creative: 10 Easy Steps To Increase Your Confidence, Creativity and Cash in The Attention EconomyDocument2 pagesBe Creative: 10 Easy Steps To Increase Your Confidence, Creativity and Cash in The Attention EconomyArun BiswalNo ratings yet

- Root CuaseDocument1 pageRoot CuaseArun BiswalNo ratings yet

- Cause & Effect DiagramDocument3 pagesCause & Effect DiagramArun BiswalNo ratings yet

- Difference Between Validation and VerificationDocument1 pageDifference Between Validation and VerificationArun BiswalNo ratings yet

- Effective CommunicationsDocument90 pagesEffective CommunicationsArun BiswalNo ratings yet

- Be Creative: 10 Easy Steps To Increase Your Confidence, Creativity and Cash in The Attention EconomyDocument2 pagesBe Creative: 10 Easy Steps To Increase Your Confidence, Creativity and Cash in The Attention EconomyArun BiswalNo ratings yet

- 1S2S Audit ChecklisDocument6 pages1S2S Audit ChecklisArun Biswal100% (1)

- Vision MissionDocument6 pagesVision MissionArun BiswalNo ratings yet

- Value Stream Map Examples: High Level Flow Chart ExampleDocument2 pagesValue Stream Map Examples: High Level Flow Chart ExampleArun BiswalNo ratings yet

- Idea Mela at Balco May 14-16Document1 pageIdea Mela at Balco May 14-16Arun BiswalNo ratings yet

- Physiotherapy ExercisesDocument587 pagesPhysiotherapy ExercisesHaish126100% (4)

- Cause & Effect TypesDocument5 pagesCause & Effect TypesArun BiswalNo ratings yet

- How To Construct A Histogram: Qcfi DCDocument2 pagesHow To Construct A Histogram: Qcfi DCArun BiswalNo ratings yet

- SWOT AnalysisDocument1 pageSWOT AnalysisArun BiswalNo ratings yet

- PM IS - 12818 June2021Document10 pagesPM IS - 12818 June2021Mahendra AhirwarNo ratings yet

- f094 PDFDocument4 pagesf094 PDFAnshuman SinghNo ratings yet

- 319918Document4 pages319918Daniel BilickiNo ratings yet

- Dunlop Cement Based Adhesives - SDS10024Document4 pagesDunlop Cement Based Adhesives - SDS10024Dominic LeeNo ratings yet

- Python Question Paper Mumbai UnivercityDocument5 pagesPython Question Paper Mumbai UnivercityRahul PawarNo ratings yet

- Wall Climbing Surveillance Robot ReportDocument79 pagesWall Climbing Surveillance Robot Reportneha gupta100% (3)

- Environmental Tech.Document31 pagesEnvironmental Tech.csyena28225No ratings yet

- Tacloban Master Training Schedule (January-June 2012) For Web New FormatDocument5 pagesTacloban Master Training Schedule (January-June 2012) For Web New FormatFariq AdlawanNo ratings yet

- NPS-1 Piano Stand Lnstallation Guide: List of PartsDocument2 pagesNPS-1 Piano Stand Lnstallation Guide: List of PartsFian PanekenanNo ratings yet

- Engineering Drawing Solution All Year First Part Ioe NotesDocument31 pagesEngineering Drawing Solution All Year First Part Ioe Notesई. सन्तोष शर्माNo ratings yet

- Curriculum Vitae: Vivek PatilDocument3 pagesCurriculum Vitae: Vivek PatilVivek PatilNo ratings yet

- Grade CalculatorDocument1 pageGrade CalculatorKHENN ALDIANONo ratings yet

- R12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Document3 pagesR12 Period-End Procedures For Oracle Financials E-Business Suite Document 961285Ravi BirhmanNo ratings yet

- Soil CompactionDocument13 pagesSoil Compactionbishry ahamedNo ratings yet

- LAB 2 Free N Force VibrationDocument8 pagesLAB 2 Free N Force Vibrationmohdanis53yahoocomNo ratings yet

- Arahan Penggunaan Lahan Dan Perencanaan Konservasi Tanah Dan Air Di Das Yeh Empas, Tabanan, BaliDocument9 pagesArahan Penggunaan Lahan Dan Perencanaan Konservasi Tanah Dan Air Di Das Yeh Empas, Tabanan, BalialyciaNo ratings yet

- Detailed Lesson Plan in Science IVDocument12 pagesDetailed Lesson Plan in Science IVAgnes DumlaoNo ratings yet

- Well Control - Fundamental - W2 - Well Control PrincipleDocument17 pagesWell Control - Fundamental - W2 - Well Control PrincipleGilbert SunaryoNo ratings yet

- EE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Document5 pagesEE105 - Fall 2015 Microelectronic Devices and Circuits: Prof. Ming C. Wu Wu@eecs - Berkeley.edu 511 Sutardja Dai Hall (SDH)Kulanthaivelu RamaswamyNo ratings yet

- Cava v6 1x Install enDocument29 pagesCava v6 1x Install enWael SalahNo ratings yet

- 7 Inch Liner Cementing ProgramDocument44 pages7 Inch Liner Cementing ProgramMarvin OmañaNo ratings yet

- Irc - 24-2010 PDFDocument128 pagesIrc - 24-2010 PDFkiranNo ratings yet

- Technical Information HANSA-FLEX Hose ConnectionsDocument75 pagesTechnical Information HANSA-FLEX Hose ConnectionshorsanicuNo ratings yet

- Demo-C Tfin52 67Document5 pagesDemo-C Tfin52 67namank005No ratings yet

- Final Page Size: A5 (148mm X 210mm)Document20 pagesFinal Page Size: A5 (148mm X 210mm)RJ BevyNo ratings yet

- Joker User Guide 3dlabgang Rev2019 12Document14 pagesJoker User Guide 3dlabgang Rev2019 12HD's RC ChannelNo ratings yet

- Carbon Dioxide in RespirationDocument1 pageCarbon Dioxide in Respirationlolay01No ratings yet